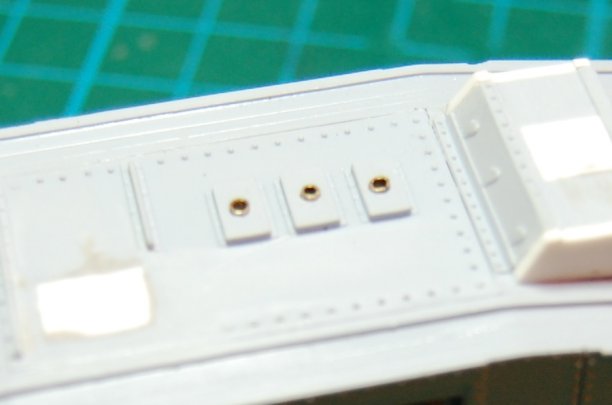

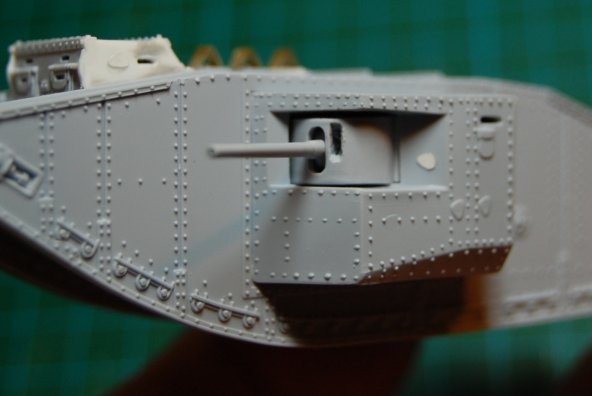

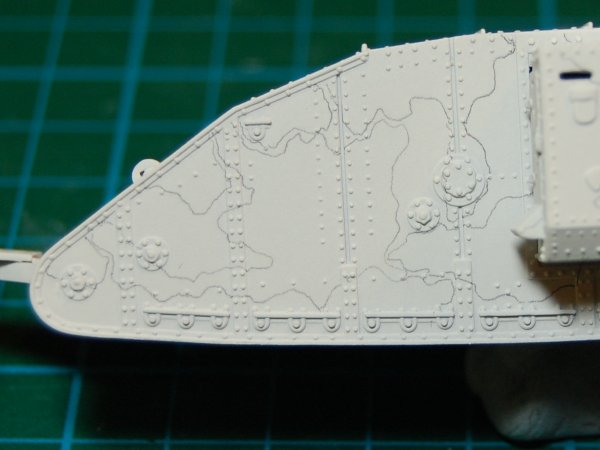

Rivetting isn't it? Except, this time it is. If you follow the link to the Landships site I put in the first post, there is an article on the rivets on this kit, saying basically there are too many of them on the sides. Like most modellers of this kit I will completely ignore that problem. There are however places where there are rivets missing on the original kit, also some were damaged or removed during my work on the roof, and the changes made require some more to be added.

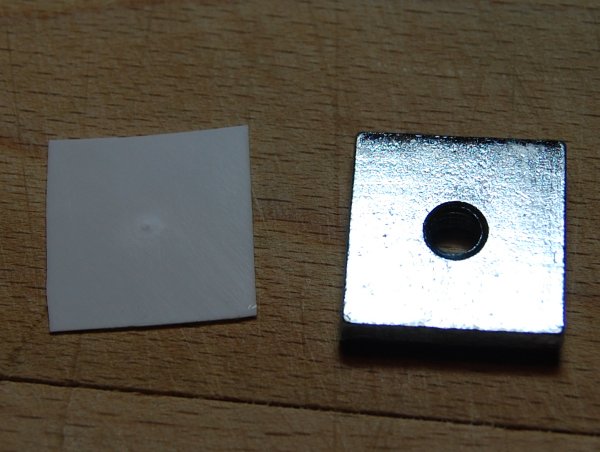

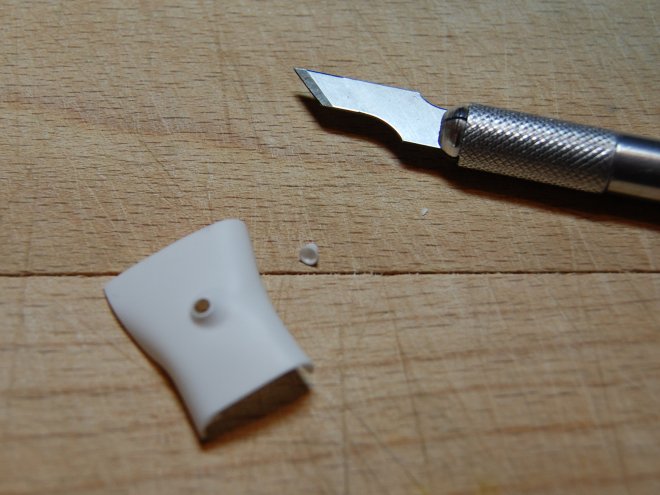

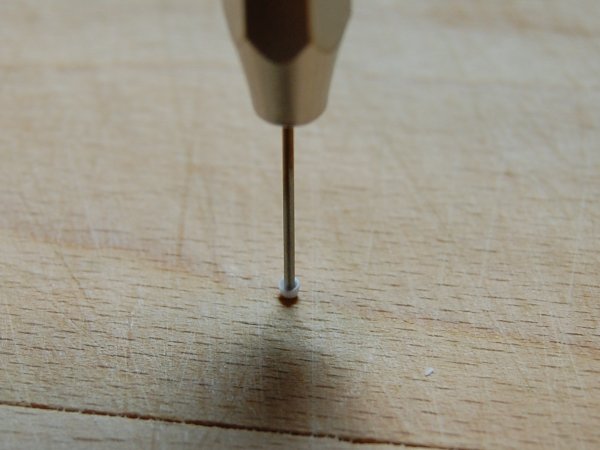

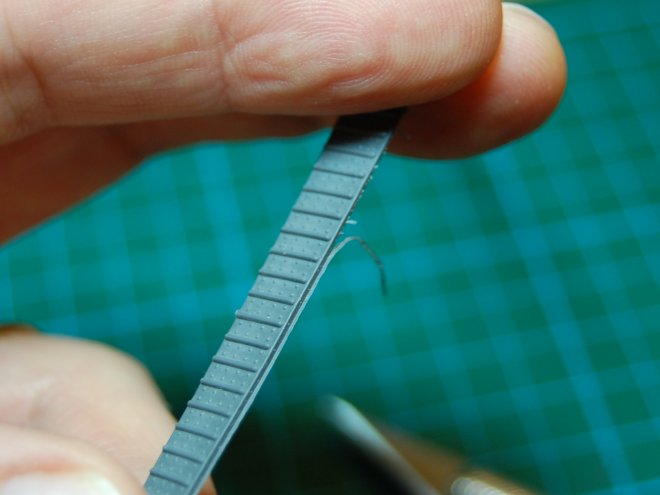

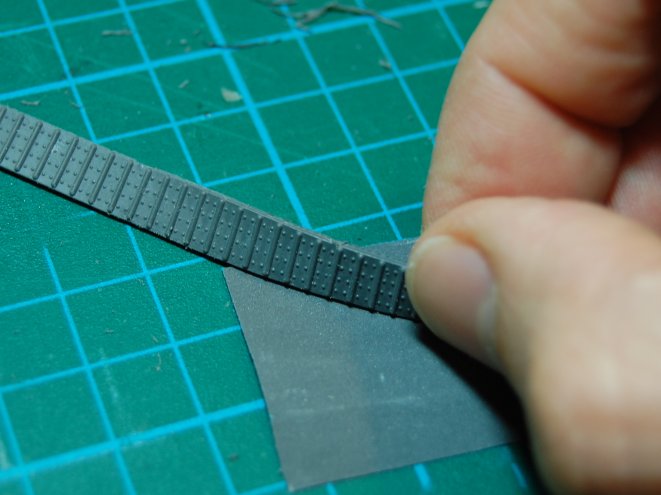

The rivets moulded on the kit (by the way, I never realised until this evening that Americans spell it "molded"...) are tiny. There are various ways of attempting to replicate rivets, but I just went for 0.5mm rod. They are bigger than the originals, but at least I can get them in the right place, and they have a regular look to them - I am hoping . . . I am fully prepared to realised once I paint it that it is a disaster.

I made tiny slices of rod with a brand new blade, and glued them on with liquid cement, applying them with the point of the blade. Forget tweezers. You need enough glue to keep them on but not so much that they melt. Getting the slices of regular size isn't that important, as providing they are fixed on properly, they can be sanded down to a regular profile later - preferably several hours later.

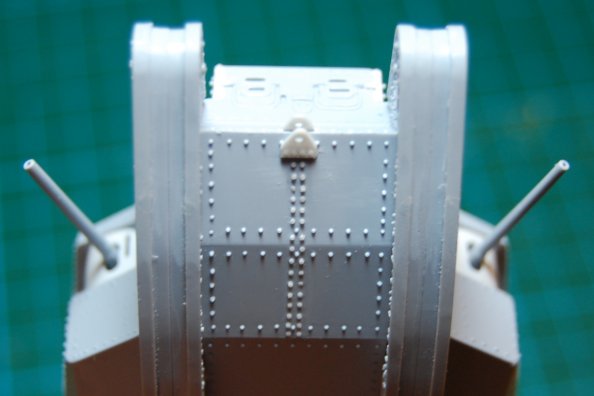

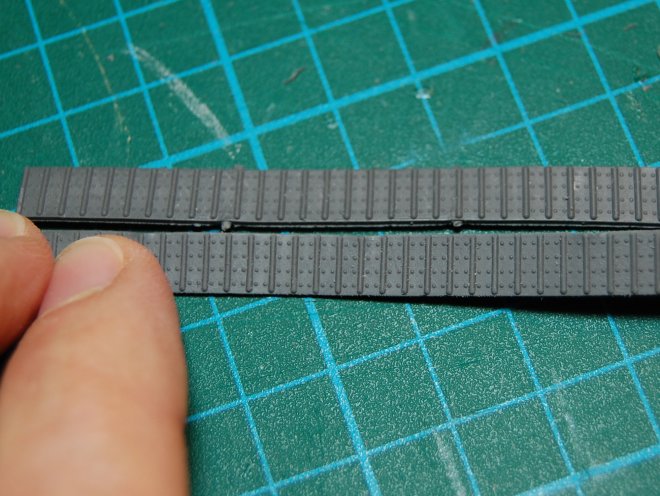

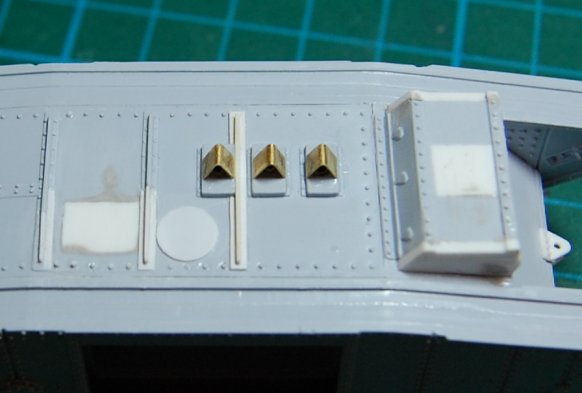

This is the line of rivets added to the top front of the cab roof, missing from the kit:

The different heights are apparent, but they were sanded down.

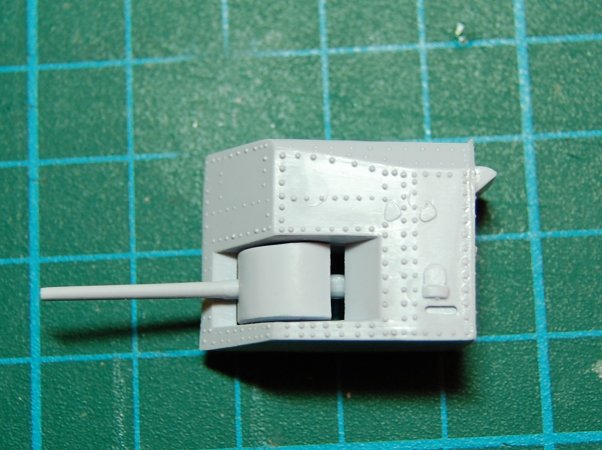

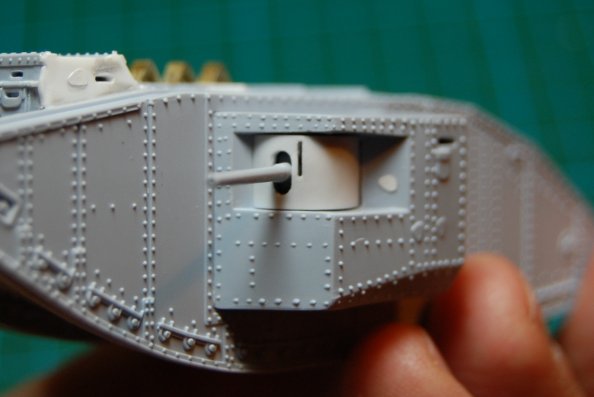

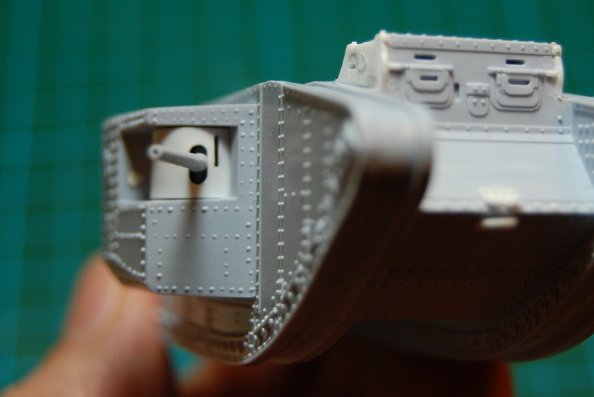

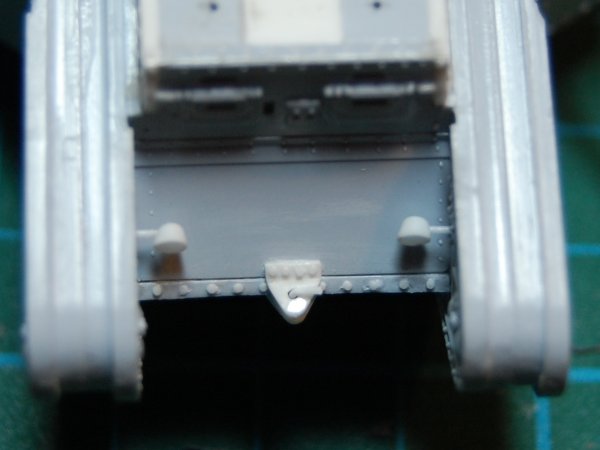

Four rivets added to each tow bracket :

As I said, I'm not too sure that, when this is painted, my 0.5mm rivets might look very oversize compared to the moulded on ones, but in this photo, they don't look that out of size. I was thinking, 0.5mm x 76 = 38mm, which is definitely too big, but it isn't that wild - to me anway. I think it is the texture and look of the rivets that is the important thing, and it is probably better to have big rivets than no rivets.

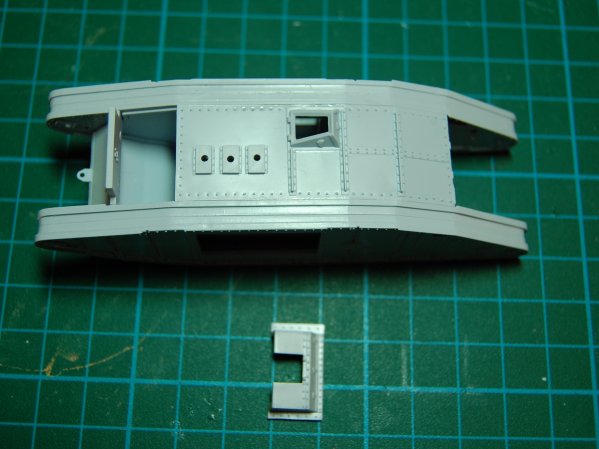

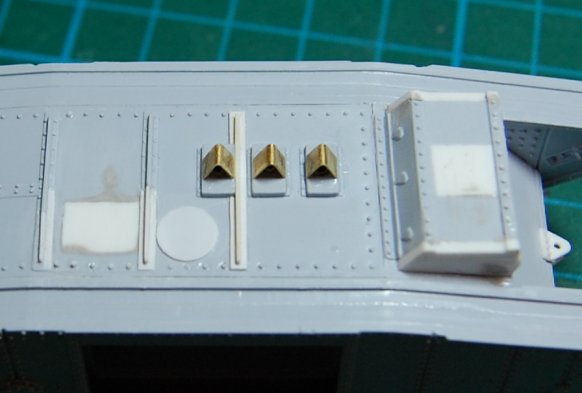

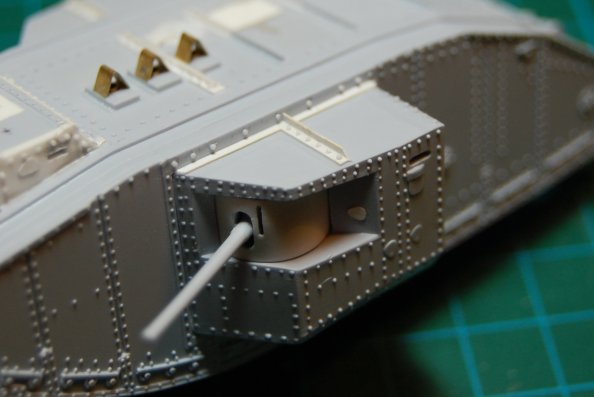

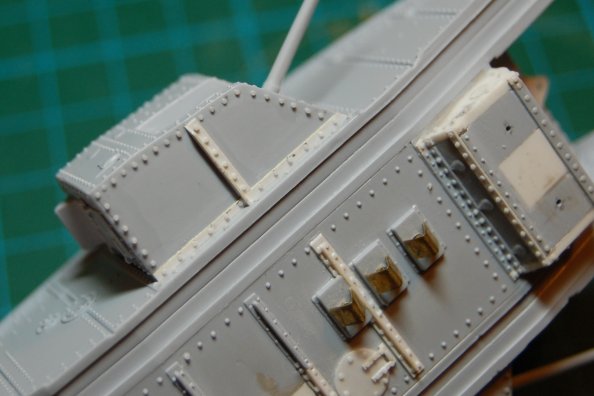

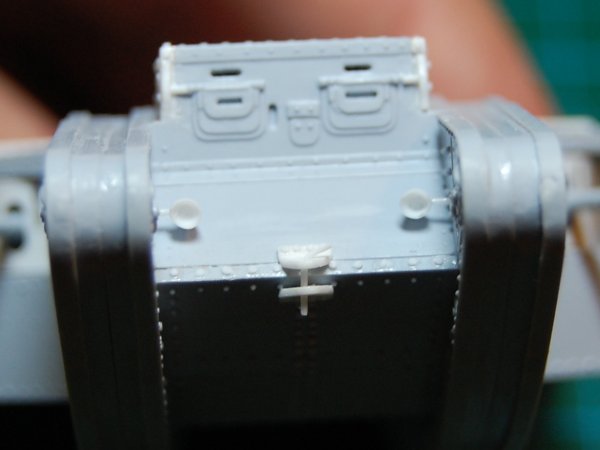

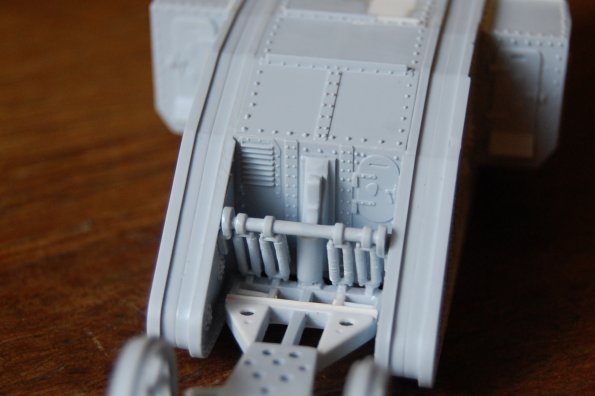

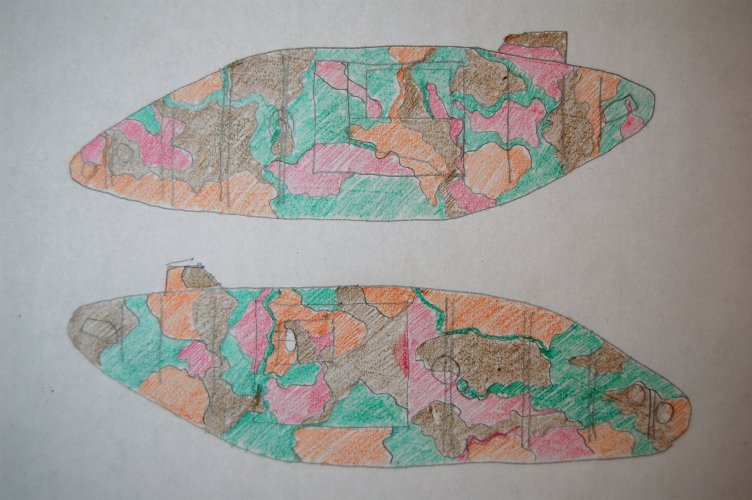

The extra details to be added to the roof. With the raised hatch removed and blanked out, there are some rivetted plate joints to be added in that area. I made them from microstrip. The one to the left of the deleted hatch needed repairing, the one to the right was extended to be the full width, and match the others, and an entirely new one added in between the rear and middle exhaust outlet.

Also in the above photo is the start of the circular hatch.

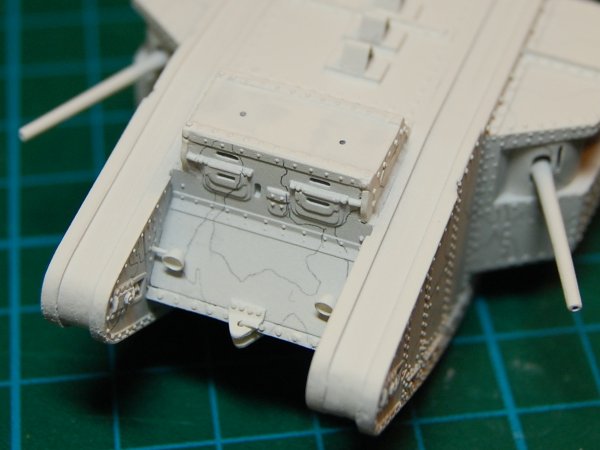

In the next one I have added the rivets both to the new joints and to the hatch, and the hatch also has a hinge.

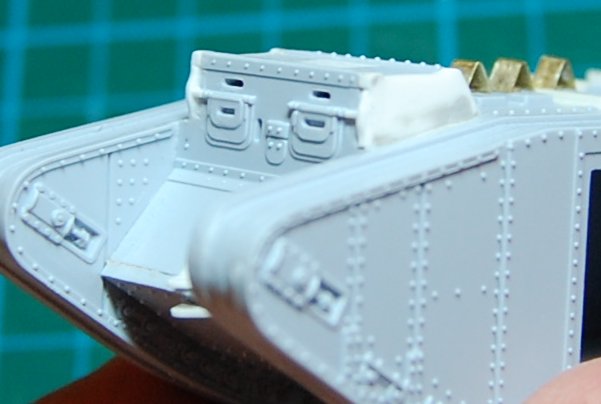

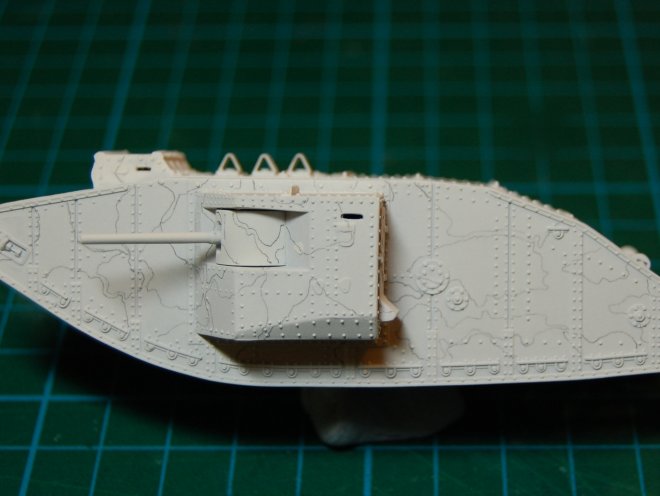

In fact this is a couple of days work later... notice that another strip has been added to the upper rear of the cab. Basically all the angled joints were covered over with extra plate rivetted on, and some of these are omitted on the kit. Looking at the front of the cab roof you should be able to see that the rivets have now been equalised and look a bit more subtle.

The sides of the cab have had some detail added. There is a vision port, which I located incorrectly on the first attempt hence the grey filler smudge at the top. This was drilled out with a series of 0.4mm holes which were then joined together. It OBVIOUSLY would have been better to have made these first before attaching the plates to the side of the cab - but... I always think I'm just going to build it quickly and not bother with all the detail. But then I go back and elaborate. Also on the side of the cab and on the sponson is the covers for the pistol port or whatever they are.

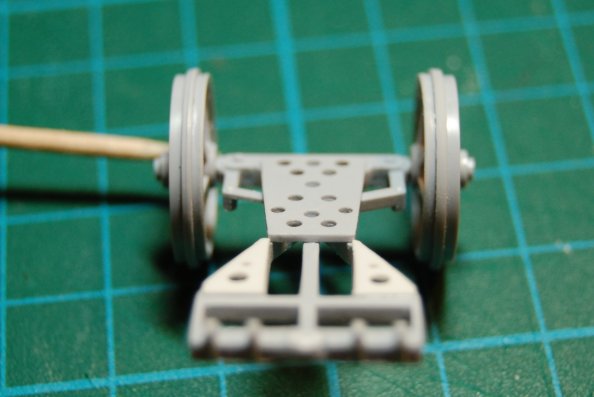

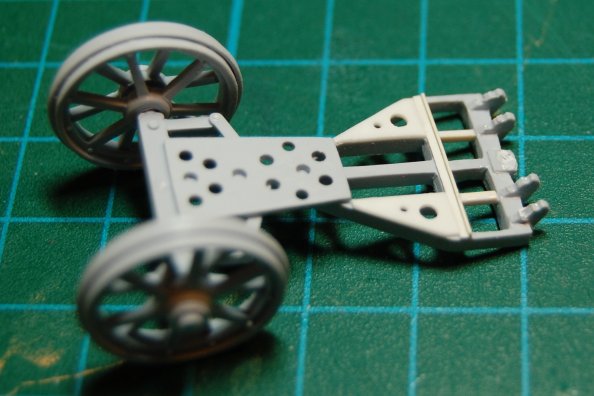

To come is the mystery that is the steering limber, and more of my backward detailing efforts.