I like working tracks and have recently built several sets of the Fruil metal tracks and been very pleased with the ease of construction and sturdiness of them. I have tried the plastic ones with the teeny plastic pins but find them too weak for my hamfisted fingers to work with easily. I ended up drilling out broken pins and pinning the links with extra Fruil wire on one recent set. This turned out pretty well in the places were it was needed.

There are some kits with no aftermarket working tracks that I know of including the Hobby Boss T-50 & the T-18 that I just picked up over the weekend. I know many are able to deal effectively with these glue together tracks but is it really necessary?

I'm just thinking how nice it would be to be able to convert these link to link glue type tracks into working tracks. All that is needed is a wire and holes in the tracks to hold the wire. The hard part is making that hole in the right place quickly so 200 to 300 links can be quickly drilled.

What would be helpful would be some sort of jig to hold the links together in the right position and at the right angle for a drill press to quickly drill the holes.

Any ideas on this?

Vintage Paul, HB T-18 kit calling my name . . .

Armor/AFV

For discussions on tanks, artillery, jeeps, etc.

For discussions on tanks, artillery, jeeps, etc.

Hosted by Darren Baker, Mario Matijasic

Jig for Drilling Track Links?

Posted: Wednesday, July 06, 2016 - 01:52 AM UTC

Posted: Wednesday, July 06, 2016 - 02:23 AM UTC

Paul,

Brilliant idea. I love Friuls, right up until I get to the cash register. Being able to create something just like them, but cheaper would be awesome.

I have a Dremel drill press which one might think would be ideal for what you describe, but I have found it to be so imprecise as to be virtually useless. Maybe Proxxon's offering might work better. Nor do I think a full-sized drill press could be used as the chucks on those normally can't hold bits that small.

I have a small hobbyist wood lathe that might work for such an application. The challenge seems like one would need to create a custom jig for each different type of track you wanted to modify. Also a lot of spare links to screw up until you got the positioning just right.

Brilliant idea. I love Friuls, right up until I get to the cash register. Being able to create something just like them, but cheaper would be awesome.

I have a Dremel drill press which one might think would be ideal for what you describe, but I have found it to be so imprecise as to be virtually useless. Maybe Proxxon's offering might work better. Nor do I think a full-sized drill press could be used as the chucks on those normally can't hold bits that small.

I have a small hobbyist wood lathe that might work for such an application. The challenge seems like one would need to create a custom jig for each different type of track you wanted to modify. Also a lot of spare links to screw up until you got the positioning just right.

Posted: Wednesday, July 06, 2016 - 03:30 AM UTC

Yes, an accurate drill press would be essential, something I hadn't thought about. I have been having a hard time visualizing the jig that would be needed.

Tracks are such an issue for so many of us that I think there might be opportunity for someone to make a jig that could be adjusted to hold most track links without damaging them. The wire is easily sourced.

I'm so hot to build this itty bitty T-18 that I may try gluing them together like the instructions say. Even if they do go together correctly and look good it is going to be tough to paint & finish them when they are rigidly glued in shapes that do not allow easy access.

Vintage Paul

Tracks are such an issue for so many of us that I think there might be opportunity for someone to make a jig that could be adjusted to hold most track links without damaging them. The wire is easily sourced.

I'm so hot to build this itty bitty T-18 that I may try gluing them together like the instructions say. Even if they do go together correctly and look good it is going to be tough to paint & finish them when they are rigidly glued in shapes that do not allow easy access.

Vintage Paul

KurtLaughlin

Joined: January 18, 2003

KitMaker: 2,402 posts

Armorama: 2,377 posts

Posted: Wednesday, July 06, 2016 - 04:21 AM UTC

Quoted Text

What would be helpful would be some sort of jig to hold the links together in the right position and at the right angle for a drill press to quickly drill the holes.

Any ideas on this?

You are probably going to have to invent one, but it shouldn't be difficult. I would use various pieces of Evergreen stock to locate the link and even guide the drill. Rather than guessing at the hole locations I would make one master link that fit the drill bit you wanted to use in the right place. I would then get a piece of stock with the same sized hole in it and slide it over the drill bit. When you are sure it is not binding the drill, fix it in place with super glue. Remove the drill, remove the link, and the jig should guide the drill properly into a blank link.

KL

m4sherman

Joined: January 18, 2006

KitMaker: 1,866 posts

Armorama: 1,808 posts

Posted: Wednesday, July 06, 2016 - 04:59 AM UTC

I made this little jig to drill out some AFV Club Churchill tracks. I was only doing about 20 links as add on armor for an M4A4. Once I had the side in the jig drilled I used the newly drilled holes to drill out the other side on the next link. I messed up a few, but salvaged them by drilling the hole a little larger. Once in the right position on the hull I glued them together.

It would be a challenge to do 300! Good luck.

It would be a challenge to do 300! Good luck.

Pave-Hawk

Joined: May 05, 2006

KitMaker: 900 posts

Armorama: 510 posts

Posted: Wednesday, July 06, 2016 - 06:13 AM UTC

For doing a lot of links I envisage something like the following diagram, please excuse the poor drawing skill

You could do this as a long jig that would let you line up a lot of links at once all clamped in place and aligned. If using a drill press arrangement just move the jig to the next link and drill until they are all done.

You could do this as a long jig that would let you line up a lot of links at once all clamped in place and aligned. If using a drill press arrangement just move the jig to the next link and drill until they are all done.

afvaficionado

Joined: February 16, 2010

KitMaker: 160 posts

Armorama: 159 posts

Posted: Wednesday, July 06, 2016 - 08:21 AM UTC

Would a bracelet sizing tool be a good place to start - http://www.mywatchmaker.net/watchmakertools.htm -

Mal

Mal

MassimoTessitori

Joined: March 14, 2013

KitMaker: 278 posts

Armorama: 278 posts

Posted: Wednesday, July 06, 2016 - 10:56 AM UTC

Be careful if you find a way to make the holes in quick sequence: plastic melts when in contact with an hot tool. You have to allow the tool to cool well between one hole and another.

Posted: Wednesday, July 06, 2016 - 05:04 PM UTC

Not much mass in those little bits to hold enough of the heat generated from drill something that soft to be an issue I would think. Considering the amount of time it's likely to take to remove one link and pop in another the I don't think heat is going to be a problem. Particularly when you consider how much care is going to be needed to ensure everything is lined up perfectly.

m4sherman

Joined: January 18, 2006

KitMaker: 1,866 posts

Armorama: 1,808 posts

Posted: Wednesday, July 06, 2016 - 05:46 PM UTC

Quoted Text

Not much mass in those little bits to hold enough of the heat generated from drill something that soft to be an issue I would think. Considering the amount of time it's likely to take to remove one link and pop in another the I don't think heat is going to be a problem. Particularly when you consider how much care is going to be needed to ensure everything is lined up perfectly.

True, if you keep the RPM's low. Rotational friction from the drill bit will be the issue.

Posted: Thursday, July 07, 2016 - 09:03 PM UTC

I like the drawing of the jig and some of the other ideas offered here. One of my pals thinks there may not be enough "meat" in the tracks to support a .4 mm hole like Fruil uses for their wire. I'll have to look into this over the weekend.

I was showing him the HobbyTrax tool that is used as a forming block for the individual link tracks on the early Panzer IIIs. He suggested that making a buck for other tanks might be easier than trying to convert the glue together links into working tracks.

His suggestion is to photograph the model side on with a measuring device to use for scale them and then make a paper pattern and from that make a wooden buck to use with the tracks.

Whadda ya think? Working tracks are tops for me, but a forming tool might be a good plan B.

Vintage Paul

I was showing him the HobbyTrax tool that is used as a forming block for the individual link tracks on the early Panzer IIIs. He suggested that making a buck for other tanks might be easier than trying to convert the glue together links into working tracks.

His suggestion is to photograph the model side on with a measuring device to use for scale them and then make a paper pattern and from that make a wooden buck to use with the tracks.

Whadda ya think? Working tracks are tops for me, but a forming tool might be a good plan B.

Vintage Paul

Posted: Thursday, July 07, 2016 - 09:07 PM UTC

Quoted Text

Quoted TextNot much mass in those little bits to hold enough of the heat generated from drill something that soft to be an issue I would think. Considering the amount of time it's likely to take to remove one link and pop in another the I don't think heat is going to be a problem. Particularly when you consider how much care is going to be needed to ensure everything is lined up perfectly.

True, if you keep the RPM's low. Rotational friction from the drill bit will be the issue.

When I've had to drill styrene parts with the lathe or drill press in the past I simply turn it by hand. RPMs stay REAL low that way.

Posted: Wednesday, July 13, 2016 - 04:24 AM UTC

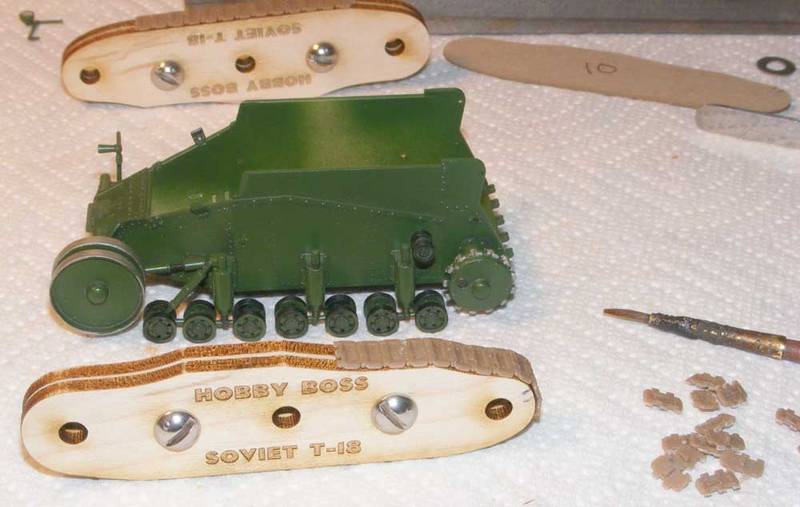

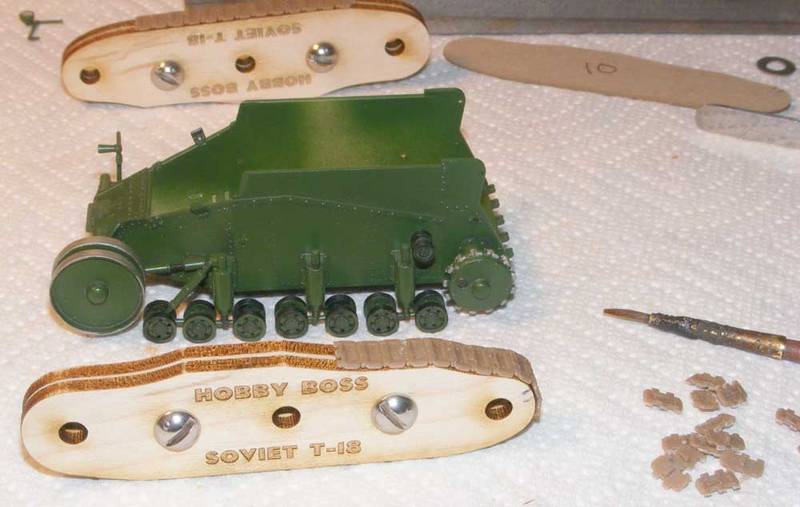

Given the tiny size of the tracks the drilling idea didn't seem too promising for this little tankette so I'm working on plan B, the HobbyTrax stye track forming buck.

The first part of making one was to define the shape and for this I brought a photo into Illustrator and laid out the points & curves. A cardboard pattern was cut with a laser and compared with the actual model for size. Small changes were made and the process repeated. On the tenth iteration, the pattern fit perfectly.

I have a plank of 1/8" maple ordered to make the actual tool out of. More later when there is any news.

The first part of making one was to define the shape and for this I brought a photo into Illustrator and laid out the points & curves. A cardboard pattern was cut with a laser and compared with the actual model for size. Small changes were made and the process repeated. On the tenth iteration, the pattern fit perfectly.

I have a plank of 1/8" maple ordered to make the actual tool out of. More later when there is any news.

andymacrae

Joined: September 01, 2005

KitMaker: 409 posts

Armorama: 402 posts

Posted: Wednesday, July 13, 2016 - 03:41 PM UTC

For the hobbyboss T-50 kit why not just get Masterclub tracks?

Andy

Andy

Posted: Wednesday, July 13, 2016 - 10:38 PM UTC

Quoted Text

For the hobbyboss T-50 kit why not just get Masterclub tracks?

Andy

Thanks for the heads up on these, they are new since I last checked. I now have a set on order.

I do worry that the resin pins might prove fragile. The Modelkasten tracks are very nice but the tiny plastic nibs proved very fragile. On the set that I built for a T-34/85 project I ended up pinning many of the links with spare Fruil wire.

Have you found the Masterclub resin pins to be reasonably sturdy?

andymacrae

Joined: September 01, 2005

KitMaker: 409 posts

Armorama: 402 posts

Posted: Thursday, July 14, 2016 - 01:05 PM UTC

Quoted Text

Quoted TextFor the hobbyboss T-50 kit why not just get Masterclub tracks?

Andy

Thanks for the heads up on these, they are new since I last checked. I now have a set on order.

I do worry that the resin pins might prove fragile. The Modelkasten tracks are very nice but the tiny plastic nibs proved very fragile. On the set that I built for a T-34/85 project I ended up pinning many of the links with spare Fruil wire.

Have you found the Masterclub resin pins to be reasonably sturdy?

I haven't had any problem with them and I'm not aware of any of my fellow club members having any any problems with them.

Regards,

Andy

Posted: Monday, July 18, 2016 - 09:45 PM UTC

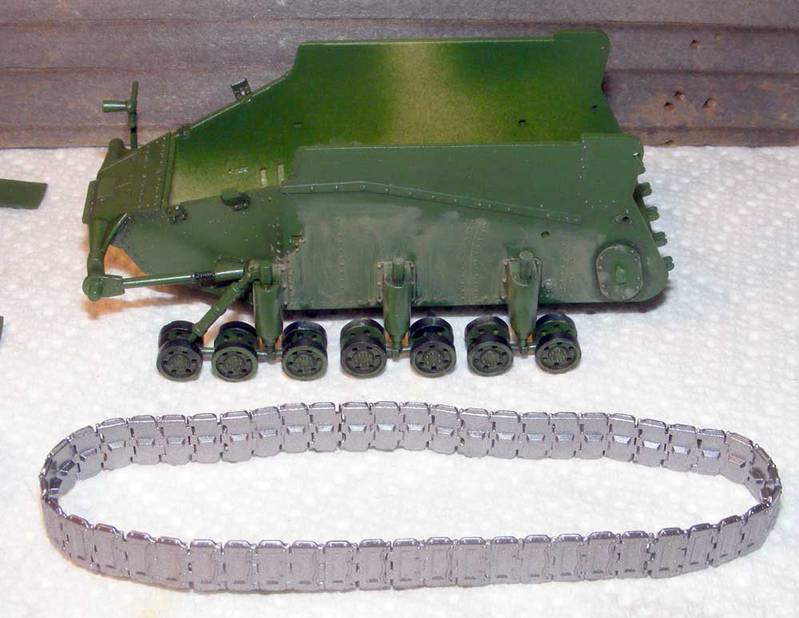

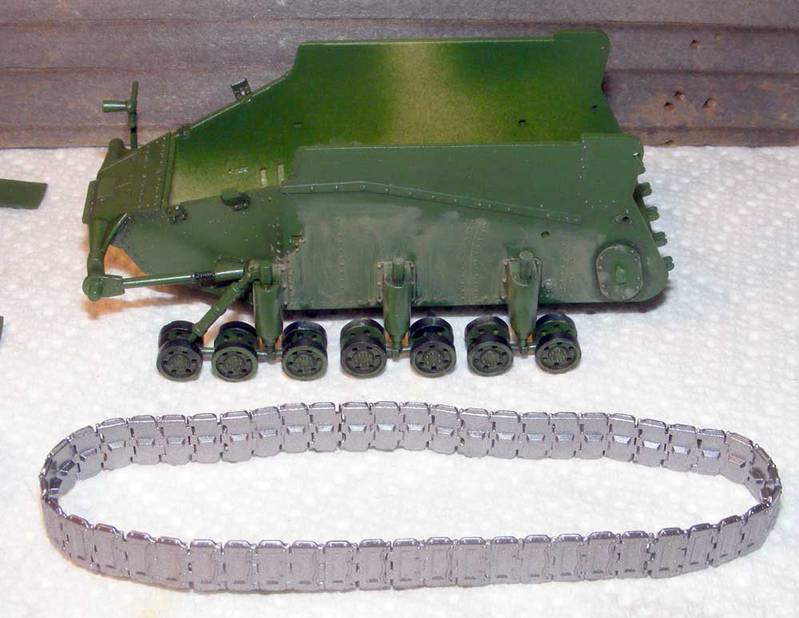

The 1/8" maple planks arrived and after a few additional tweaks, the laser cut out the buck halves. Because the sprockets on this tank are fixed and can not rotate, an index had to be added to hold the track teeth on the tool in the same position that they would assume on the model. This was made out of tiny bits of .040" sheet glued to one half of the tool.

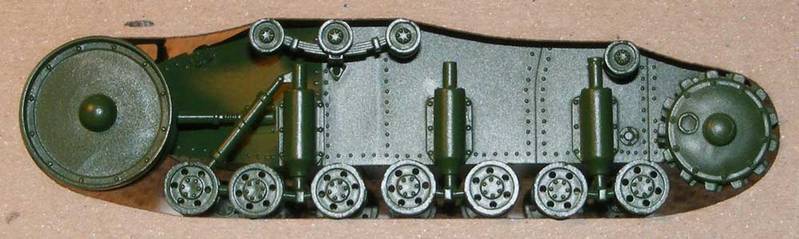

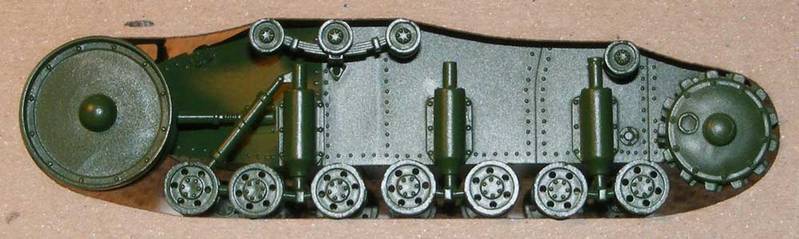

With that, construction of the first track built pretty rapidly. One link was not glued to allow the track to come off the tool and go on the model. Here are a few pics:

These aren't working tracks but the tool will get this build going again. I still like the idea of making a jig and drilling out the links to make working tracks out of the individual link kit tracks and will keep the idea in mind for the future.

With that, construction of the first track built pretty rapidly. One link was not glued to allow the track to come off the tool and go on the model. Here are a few pics:

These aren't working tracks but the tool will get this build going again. I still like the idea of making a jig and drilling out the links to make working tracks out of the individual link kit tracks and will keep the idea in mind for the future.

jon_a_its

Joined: April 29, 2004

KitMaker: 1,336 posts

Armorama: 1,137 posts

Posted: Tuesday, July 19, 2016 - 06:19 PM UTC

Nice Work Paul

MadModeler

Joined: July 26, 2012

KitMaker: 454 posts

Armorama: 281 posts

Posted: Tuesday, July 19, 2016 - 08:56 PM UTC

Looking good. Personally the metal tracks are a nice touch. Just not on the wallet. I did one with a T 80. It took forever. Still look sweet thou.

Cheers,

Tom D

Cheers,

Tom D

Posted: Wednesday, July 20, 2016 - 08:53 PM UTC

Thanks guys. I do not mind the cost of the metal tracks only because I actually build so few models, although this has changed in the last couple of years. In this case I know of no working tracks for this cute little T-18. Who knows what will be out in a year or two?

Posted: Friday, July 22, 2016 - 01:33 AM UTC

I have very little reference material on this tank so I used a small illustration found online for inspiration. It showed a T-18 in 1929 that participated in one of the big Red Square parades before Uncle Joe. I thought this sounded interesting and with no details, I made up my own "legend."

It seems reasonable to assume that no one in the Red Army from the highest general to the lowest boot would want to draw Uncle Joe's malevolent eye – so they gussied up the ole bus with a wash job, fresh paint and red star. The tracks would have been cleaned up but gathered dirt & mud from being in the staging area before running over the hard surfaces of the parade route.

I was darned curious to see how the tracks formed by my home made tool would fit on the model. I painted them using a new technique for me. I painted them with a Tamiya color, Light Gun Metal then dirtied them up with washes. My assembly job on the track links themselves was less than perfect and the tracks broke in a couple of places. No huge problem but it did cause extra fumbling trying to wrap them around the wheels & sprockets. I got them on after digging out some of Pop's old Marine Corp words that mother told me never to repeat . . .

So - here it is basically done. I forgot the three tow rings and will paint them and add them tomorrow. The total time from Hobby Shop to completion just under three weeks, light speed for me.

Working tracks are still the A option for me but when they are not available the individual links can be made to work even by a modeler with my modest skills.

It seems reasonable to assume that no one in the Red Army from the highest general to the lowest boot would want to draw Uncle Joe's malevolent eye – so they gussied up the ole bus with a wash job, fresh paint and red star. The tracks would have been cleaned up but gathered dirt & mud from being in the staging area before running over the hard surfaces of the parade route.

I was darned curious to see how the tracks formed by my home made tool would fit on the model. I painted them using a new technique for me. I painted them with a Tamiya color, Light Gun Metal then dirtied them up with washes. My assembly job on the track links themselves was less than perfect and the tracks broke in a couple of places. No huge problem but it did cause extra fumbling trying to wrap them around the wheels & sprockets. I got them on after digging out some of Pop's old Marine Corp words that mother told me never to repeat . . .

So - here it is basically done. I forgot the three tow rings and will paint them and add them tomorrow. The total time from Hobby Shop to completion just under three weeks, light speed for me.

Working tracks are still the A option for me but when they are not available the individual links can be made to work even by a modeler with my modest skills.

|