News

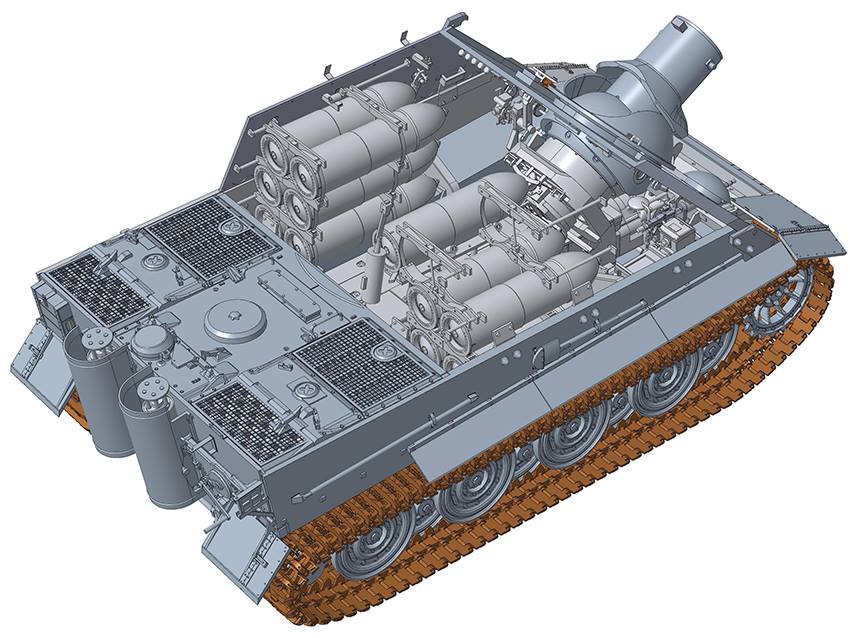

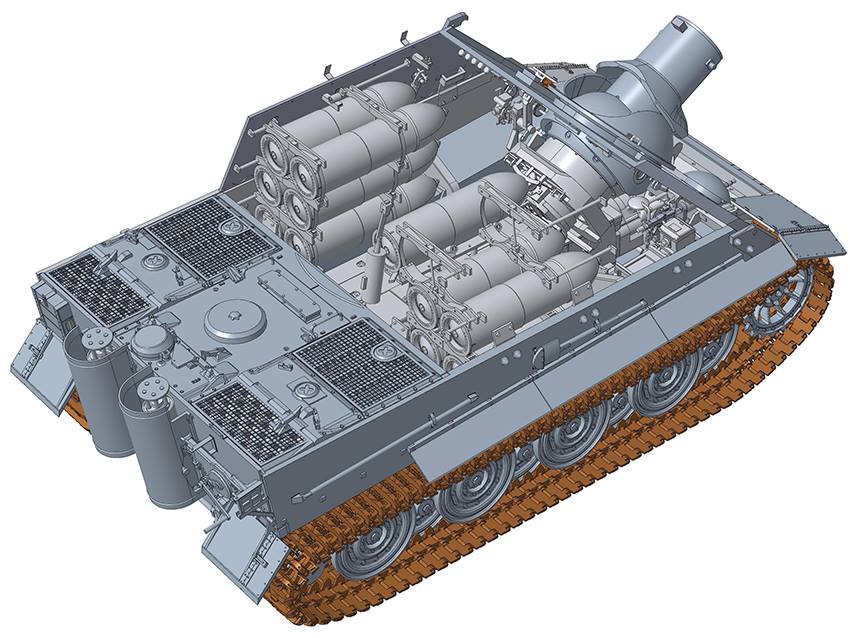

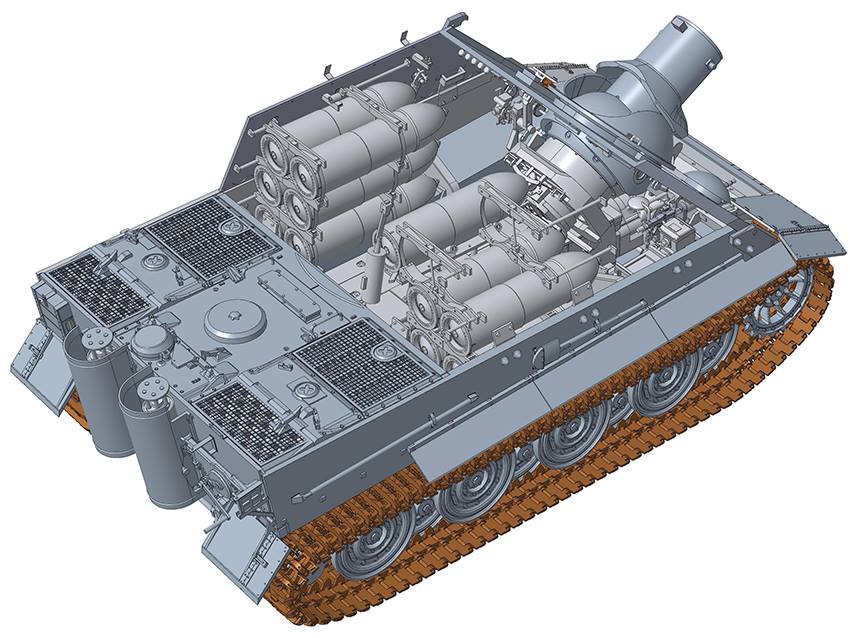

RyeField: Sturmtiger with Interior

varanusk

Managing Editor

Managing EditorSanta Cruz de Tenerife, Spain / Espaņa

Joined: July 04, 2013

KitMaker: 1,288 posts

Armorama: 942 posts

Posted: Tuesday, June 27, 2017 - 11:33 AM UTC

Rye Field Model adds a new member to their Tiger family, the Sturmtiger.

Read the Full News StoryIf you have comments or questions please post them here.

Thanks!

Washington, United States

Joined: March 15, 2009

KitMaker: 3,670 posts

Armorama: 2,052 posts

Posted: Tuesday, June 27, 2017 - 06:53 PM UTC

Probably to soon to ask, but the biggest drawback of the current 1/35 scale models on the market is the absence of the rifling on the inside of the barrel. Anyone know if Ryefield has addressed that? There's an aftermarket PE set out there, but it requires precise rolling to get it to fit. It would be nice to see a slide molded barrel with the rifling included.

VR, Russ

bill_c

Campaigns Administrator

Campaigns AdministratorNew Jersey, United States

Joined: January 09, 2008

KitMaker: 10,553 posts

Armorama: 8,109 posts

Posted: Tuesday, June 27, 2017 - 08:31 PM UTC

CAD seems to show the rifling.

Minnesota, United States

Joined: July 20, 2004

KitMaker: 1,513 posts

Armorama: 1,449 posts

Posted: Wednesday, June 28, 2017 - 03:23 AM UTC

AFV Club's kit has rifling via a piece of PE.

Looking to meet other MN Armor modellers. I live in Buffalo.

Washington, United States

Joined: March 15, 2009

KitMaker: 3,670 posts

Armorama: 2,052 posts

Posted: Wednesday, June 28, 2017 - 04:07 AM UTC

Quoted Text

CAD seems to show the rifling.

Yes, I see that-- I'm just wondering how it's done. I have the Eduard PE set and the Tamiya Sturmtiger, and I've seen the AFV club kit-- but getting the rifling in the tube is a big problem, and no matter what you do there will be a seam or gap-- I'm wondering if Ryefield has taken care of this with a slide mold-- which would be ideal.

VR, Russ

Oklahoma, United States

Joined: March 01, 2002

KitMaker: 6,043 posts

Armorama: 4,347 posts

Posted: Wednesday, June 28, 2017 - 04:29 AM UTC

I have a Takom kit of a Mortar that has rifling in it, should not be hard to do.

Manitoba, Canada

Joined: January 03, 2016

KitMaker: 3,791 posts

Armorama: 3,778 posts

Posted: Wednesday, June 28, 2017 - 05:00 AM UTC

That's what I thought too! How hard can it be when slide molding lets you do precise detailing on both sides of a complex part? About time. Hope other manufacturers are taking note!

Minnesota, United States

Joined: July 20, 2004

KitMaker: 1,513 posts

Armorama: 1,449 posts

Posted: Wednesday, June 28, 2017 - 07:42 AM UTC

I don't think slide molding can make the twist that is needed for correct rifling.

Looking to meet other MN Armor modellers. I live in Buffalo.

Minnesota, United States

Joined: July 20, 2004

KitMaker: 1,513 posts

Armorama: 1,449 posts

Posted: Wednesday, June 28, 2017 - 07:44 AM UTC

Looking to meet other MN Armor modellers. I live in Buffalo.

Colorado, United States

Joined: February 10, 2008

KitMaker: 730 posts

Armorama: 616 posts

Posted: Wednesday, June 28, 2017 - 08:46 AM UTC

I used Hussar barrel with my AFV Club Sturmtiger

Wien, Austria

Joined: July 12, 2005

KitMaker: 2,233 posts

Armorama: 2,221 posts

Posted: Wednesday, June 28, 2017 - 12:40 PM UTC

Quoted Text

That's what I thought too! How hard can it be when slide molding lets you do precise detailing on both sides of a complex part?

Ordinary molds let you do precise detailing on both sides of a complex part.

If you want to know how hard it can be, try designing the slide mold.

David

Minnesota, United States

Joined: July 20, 2004

KitMaker: 1,513 posts

Armorama: 1,449 posts

Posted: Thursday, June 29, 2017 - 03:02 AM UTC

Will the kit have Zimm?

Dan

Looking to meet other MN Armor modellers. I live in Buffalo.

barkingdigger

Associate Editor

Associate Editor

#013

England - East Anglia, United Kingdom

Joined: June 20, 2008

KitMaker: 3,981 posts

Armorama: 3,403 posts

Posted: Thursday, June 29, 2017 - 07:23 AM UTC

Quoted Text

I don't think slide molding can make the twist that is needed for correct rifling.

Very true! At best they can add the front edge of the grooves as seen at the tip of the barrel, but the groves go straight back without a twist. To add a twist you need the sliding plug to "corkscrew" as the mould is pulled open, and I suspect that would easily double the cost of making the tool for that sprue...

"Glue, or Glue Not - there is no Dry-Fit" - Yoda (original script from Return of the Jedi...)

Wien, Austria

Joined: July 12, 2005

KitMaker: 2,233 posts

Armorama: 2,221 posts

Posted: Thursday, June 29, 2017 - 12:38 PM UTC

I think that a PE inner sleeve for the gun is the cheapest and most practical way to make the rifling. But it could be difficult to bend it, because of course it will want to fold on the rifling lines instead of making a curve. I would provide a plastic guide to push it into.

David

Aichi-ken, Japan / 日本

Joined: June 04, 2016

KitMaker: 87 posts

Armorama: 76 posts

Posted: Thursday, June 29, 2017 - 01:39 PM UTC

I used Aber`s PE upgrade set for the Tamiya Sturmtiger.

I remember thinking to my self "well, this is impossible to fit inside", but somehow it worked carefully bending it to shape.

However, as someone else said in this post, gap between plastic and the PE seemed to be inevitable. Not to mention that adding a sheet of PE inside the barrel will screw up the barrel diameter.

Wien, Austria

Joined: July 12, 2005

KitMaker: 2,233 posts

Armorama: 2,221 posts

Posted: Thursday, June 29, 2017 - 04:22 PM UTC

The kit could be designed so that its own PE brings the barrel to the correct diameter.

Aftermarket PE won't do that.

David

New York, United States

Joined: May 27, 2013

KitMaker: 2,210 posts

Armorama: 1,712 posts

Posted: Friday, June 30, 2017 - 05:30 AM UTC

Does anyone have any info as to how the barrel attaches to the trunions in this kit? This area specifically:

I do some 3D design work. Message me for more info on what I'm doing or have done. Inquire about a product catalog.

Connecticut, United States

Joined: April 02, 2005

KitMaker: 3,608 posts

Armorama: 3,092 posts

Posted: Friday, June 30, 2017 - 06:15 AM UTC

This kit looks really impressive. I may just have to sell off my ancient Tamiya kit with the doodads I collected for it.

Best,

Matt

SSG, INF, USA (Ret.)

"I am waiting for the tanks, and the Americans."

General Philippe Petain, September 1917

Florida, United States

Joined: September 18, 2011

KitMaker: 73 posts

Armorama: 35 posts

Posted: Friday, June 30, 2017 - 07:32 PM UTC

Or you could mold it two halfs with the rifling following the mold lines,

Quebec, Canada

Joined: January 01, 2004

KitMaker: 7,600 posts

Armorama: 6,110 posts

Posted: Saturday, July 01, 2017 - 07:38 PM UTC

Quoted Text

Or you could mold it two halfs with the rifling following the mold lines,

Then you'll have people complaining about the several generations ago molding technique used, and the accompanying joint seam to fill!