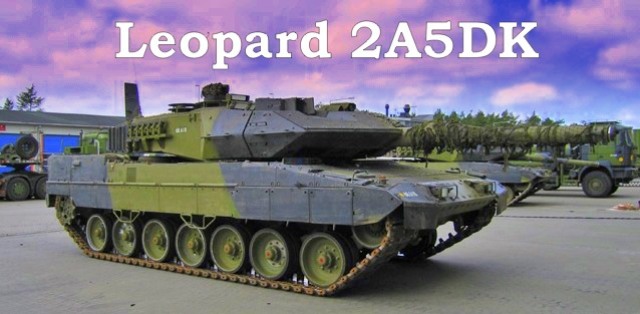

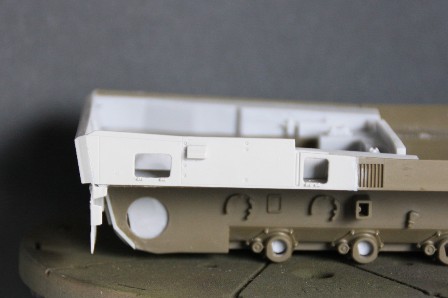

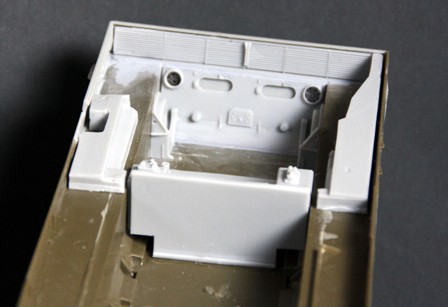

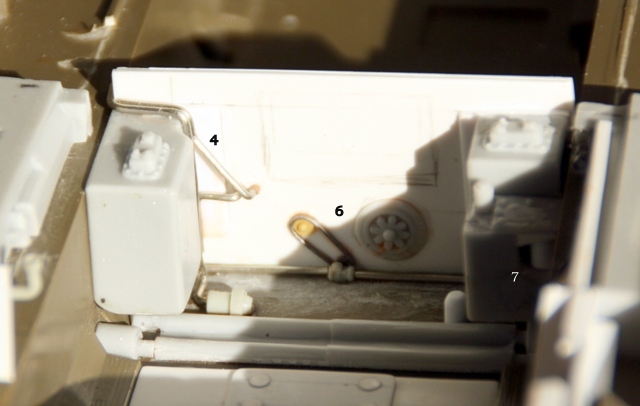

This build log will end – hopefully – with a Leopard 2A5DK. It’ll be based upon the Tamiya Leopard 2A6 (35271) with parts from Hobby Boss’ Danish Leopard 2A5DK (82405). It’ll be portrayed with the engine deck removed and the power pack placed on a trolley with a test panel. The kit for this will be Perfect Scale Modellbau Leopard 2 engine and engine room (35001).

At the moment I still haven’t decided which set of track I’ll use; I have a set of Elite Minitatures’, however after I made a set for a Challenger 2 from Bronco I think I’ll give it a go on these once more. Though very expensive I’ll use Voyager Models etch set for the Leopard 2A5 (35011), but it awaits better financial times.

Those who want to follow this project have to show patience as I tend to build in concentrated periods with pauses in-between. Please feel free to comment all you like as it progress. I have absolutely no experiences with tanks myself and even though I have around 1000 pics of the Danish Leopards there are always areas that are missing or even areas I’m not aware of.

:-H