Thanks to all, particularly Jomark who seems to know the technicalities of these devices. The pressure switch on mine doesn't have anything written on it (except a sticker that says '3'...) though the item you mention may well fit. When I web searched it, the same supplier in Malaysia came up, so perhaps that is their own model number. Couldn't see anyone in Europe selling these pressure switches on eBay, and 'Everything Airbrush' responded quickly to my question to say that they don't stock spares.

So anyway, I did what you do when you've got nothing to lose and disassembled the top end, and may have found the cause of the problem, which is corrosion. I now have a better understanding of why these compressors, although they work pretty well, are so cheap. The metal tube that runs vertically from the head of the cylinder down to the tank is steel and was quite rusty inside, to the point that I could knock lumps of rust out by poking through it. The cylinder head (with the fins on it) looks like some aluminium alloy and was corroded to the point that bits of fluffy alloy oxide was starting to creep into the aperture that the pressure switch screws into and into the end of the switch itself. Then when I took the plate between the head and the cylinder off, the piston sleeve had quite a bit of gunge hanging around on it.

I suppose all of that may restrict the airflow to the switch and / or be making the moving parts sticky. I cleaned it all up and gave it some WD40 and allowed that to dry before reassembling it.

A bit of an annoyance is that when I removed one of the allen bolts that holds the head on, a piece of what looked like swarf came out, but it was a piece of plastic coated wire that had been inserted in to the hole to make up for the fact that the thread had been drilled incorrectly or hadn't cut properly - in other words to repair a defect. Anyway, managed to get it back in with another piece of electrical wire. Probably not too critical, the pressure isn't that high, as witnessed by the piddly size of the allen bolts.

So all reassembled, I tried it out and it seemed OK - the motor kicked in and out sharply without any sign of a stutter and it didn't seem to be getting warm. Didn't use it for that long, but it was under the 300w halogen bulb on a pretty warm evening...

Some photos:

The front end off - did this to allow the pressure switch cable to turn while I was undoing it with a 14mm spanner, but not really necessary. To get the swich out it's probably better to take the head off and rotate that instead, while holding the switch body still with the spanner.

Under side of the cooling fins:

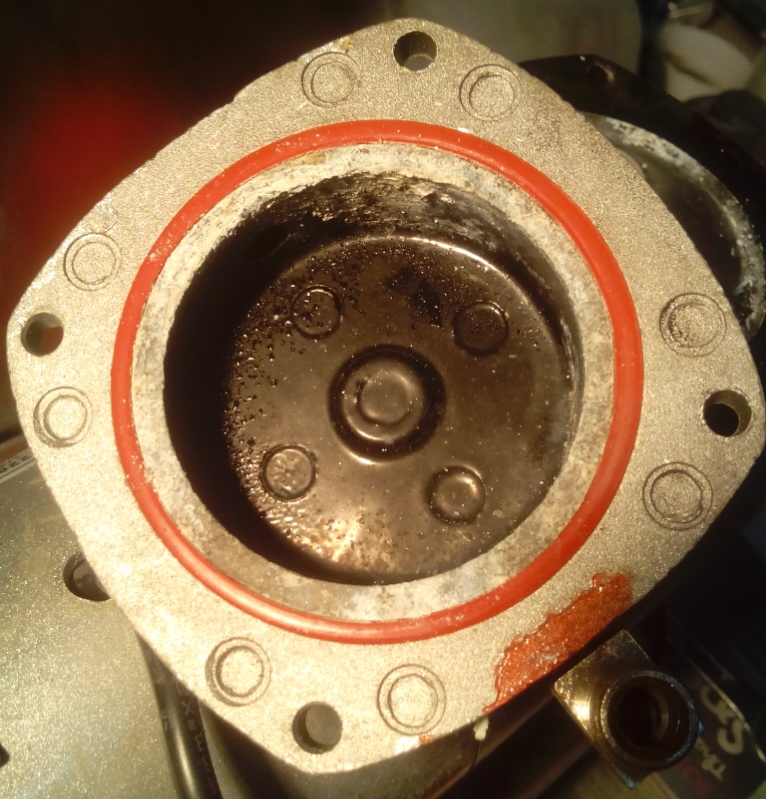

This is the top of the plate that sites over the cylinder sleeve and under the cooling finned head:

The white disk is a rubber valve that allows the air through - hence the marks around it. The white powder is corrosion dust from the head above it.

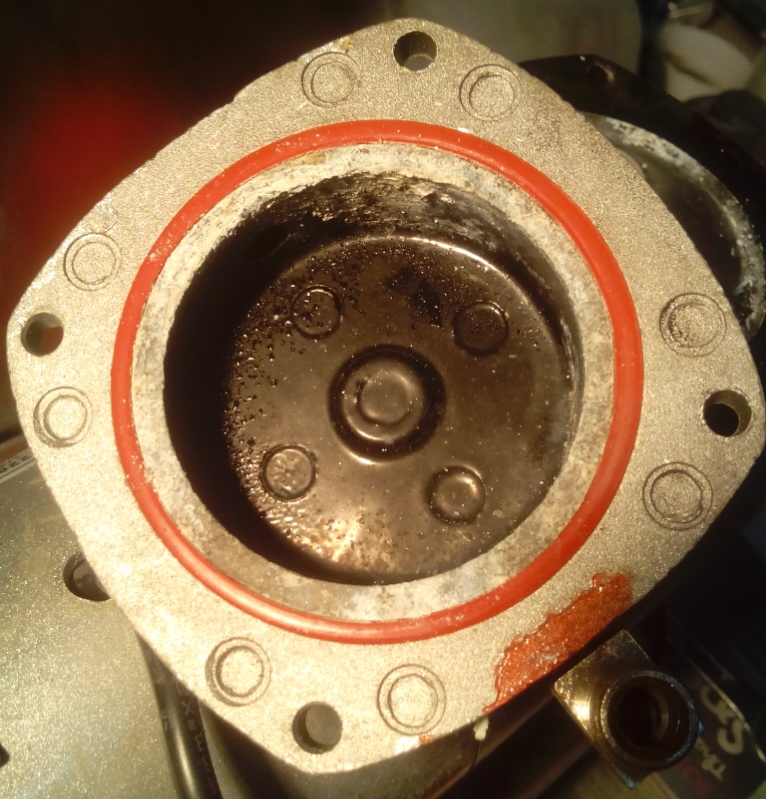

This is the top of the piston sitting inside the sleeve; note all the bits of corrosion dust and probably little bits of solidified lubricant.