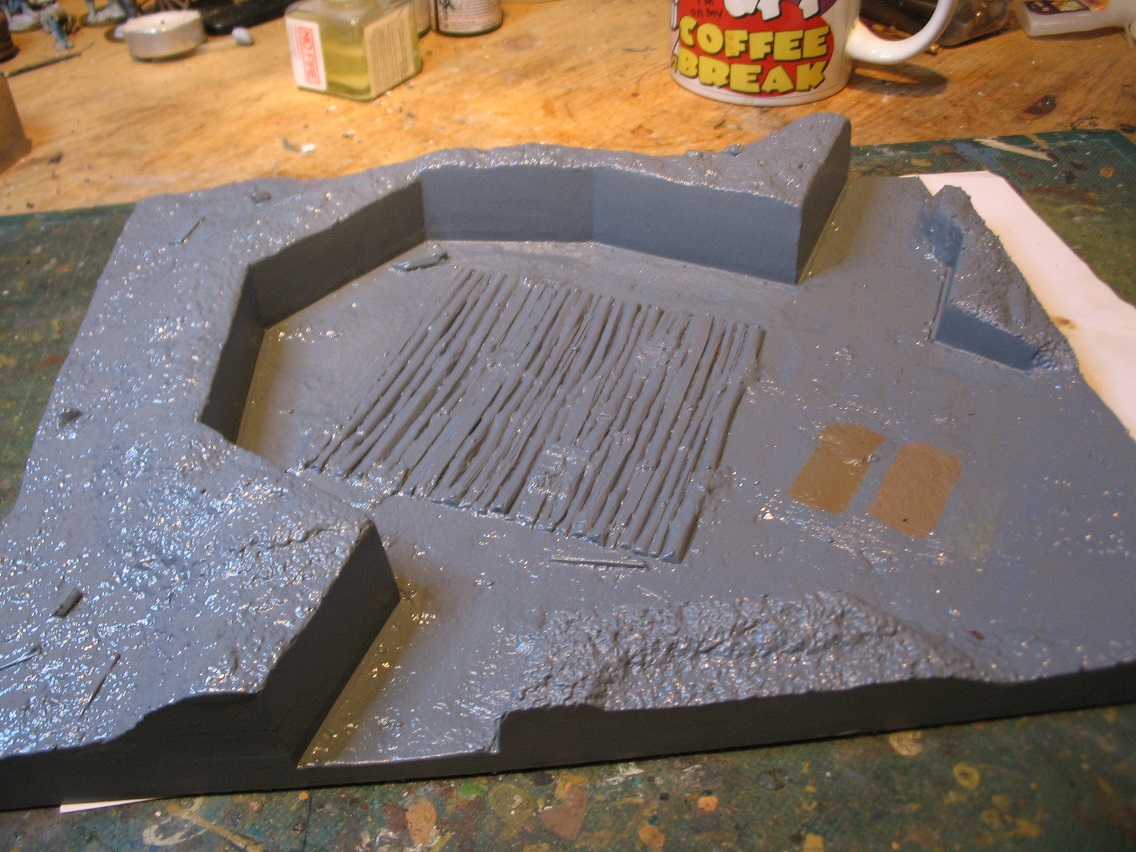

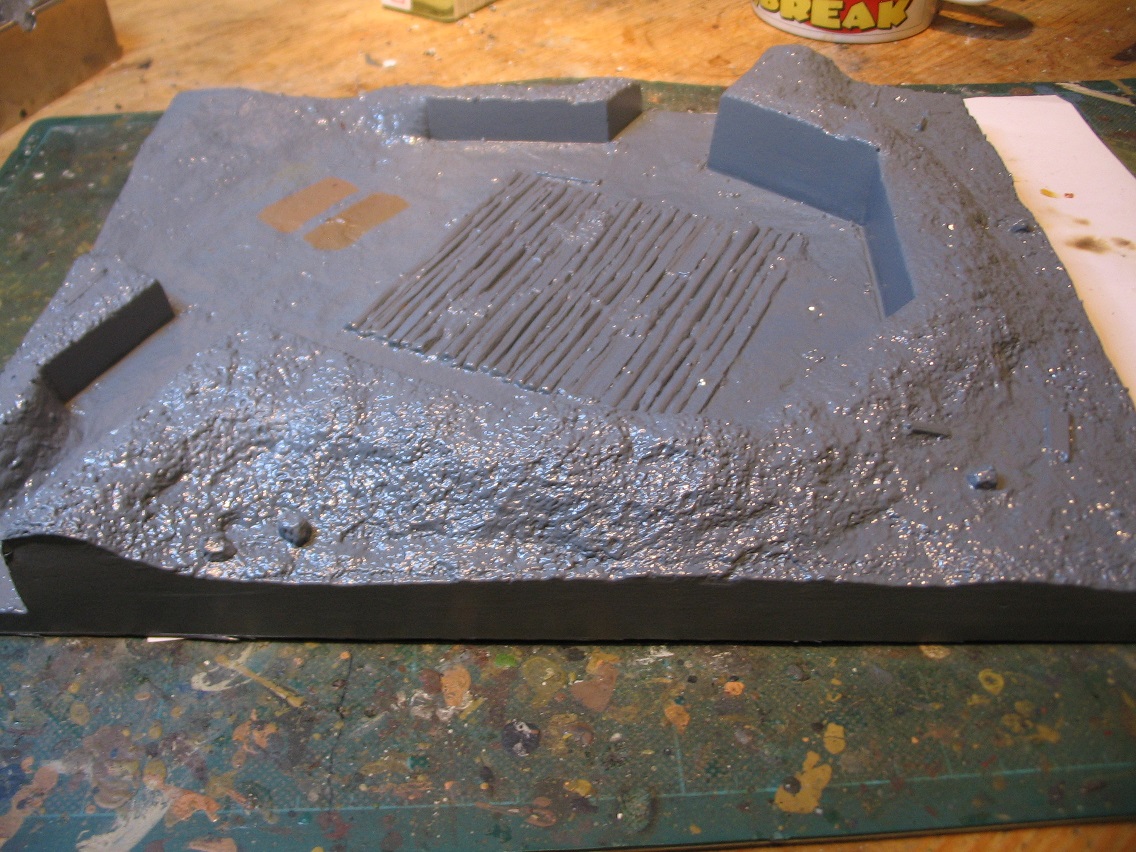

Inside you've got the base for the diorama which is part of a trench system. The Russians were masters of in depth anti-tank positions as was found to Germany's cost at Kursk in 1943. They lured German armour into a network of pre-prepared camouflaged anti-tank guns which turned the area into a killing zone with interlocking fields of fire. I imagine that is what the kit represents. There is seperate wooden panels to reinforce the sides of the position and a carpet of logs has been laid for the Zis 3 to sit on thus giving it a flat and solid surface even in heavy rain where heavy things tend to sink.

As you can see there is a definite spoil where they've dug it out which lends a nice effect as a recently dug pit. There are tyre marks but unfortunately you can't see them due to my dodgy photographic skills.

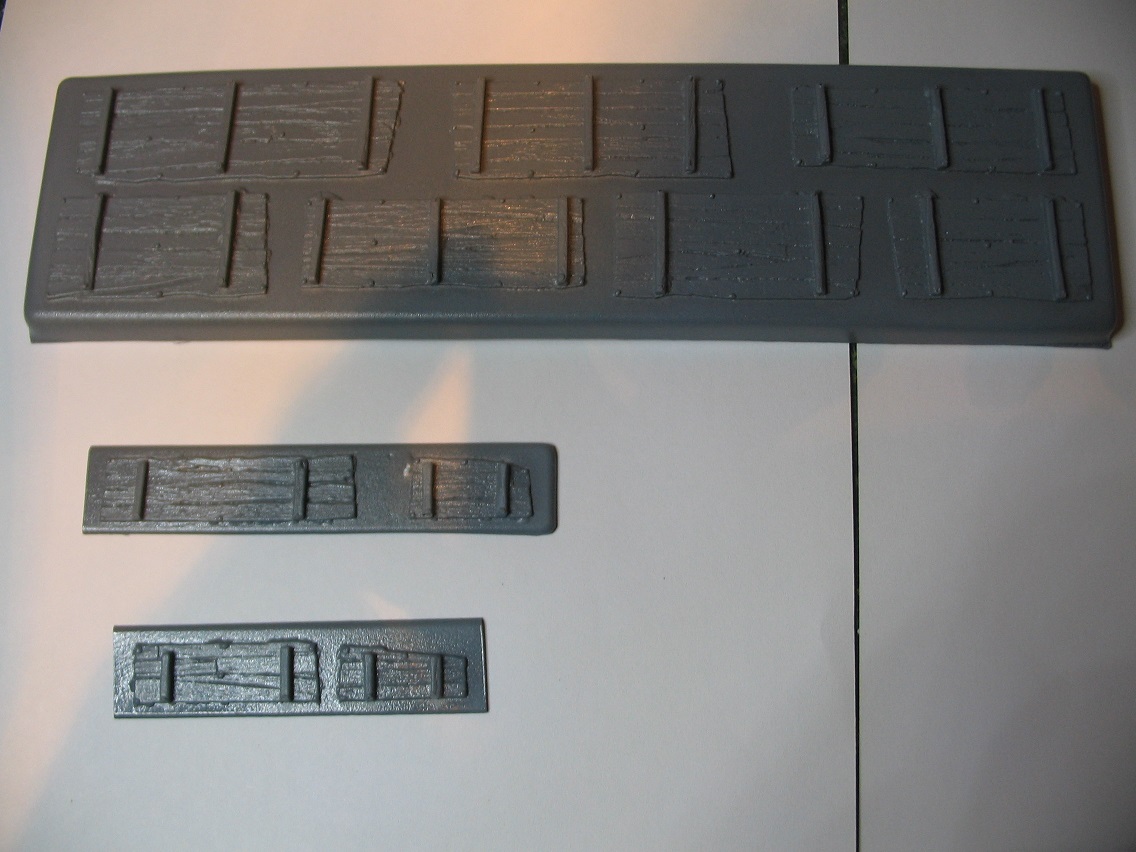

As you can see the wood panelling is rather rough in appearance (no neatly sawn planks) with crevices in between them which I think looks very effective. Should look good with some careful painting. Scrap wood just jammed behind a buttress post. One thing you can see here is Miniart pimples. These parts are vac form which I don't really see the point of here because they'll be flat when trimmed out. I don't know what it is but with their vac form buildings they're covered in these little pimples so these will need trimming off. Easily done anyway, just a minor annoyance.

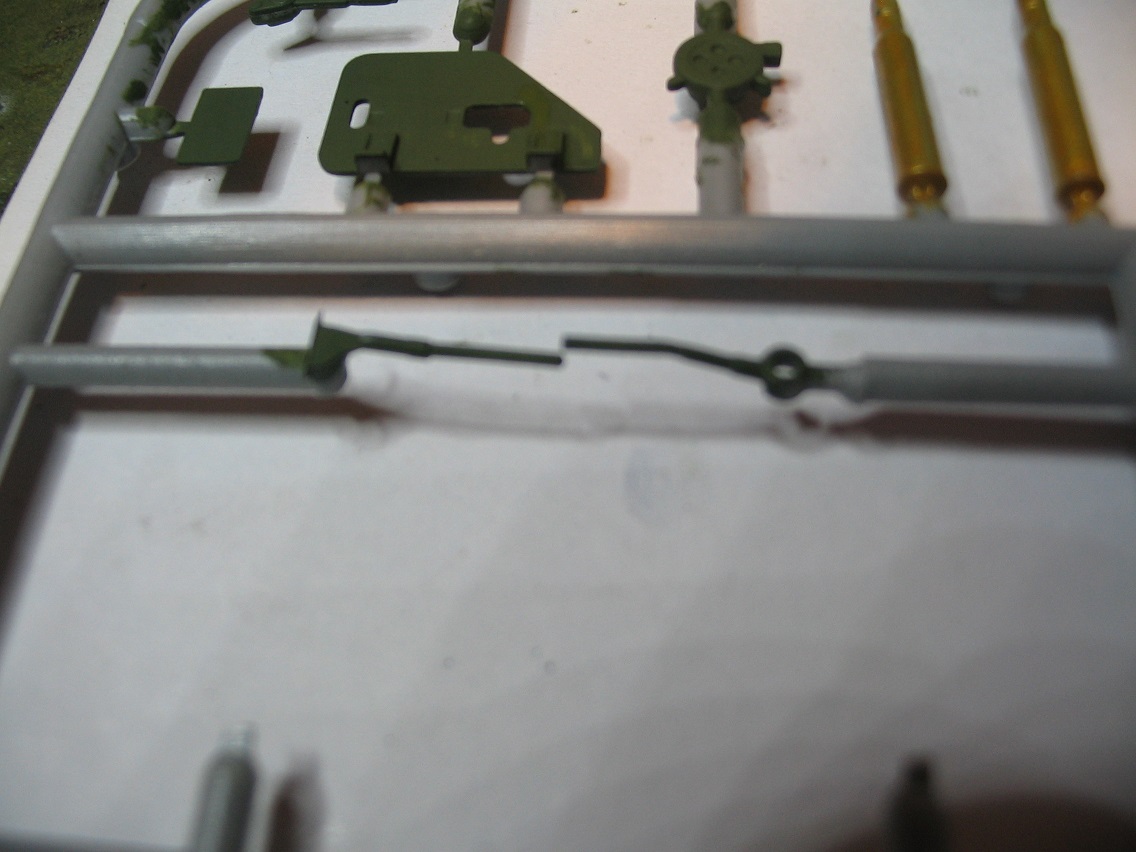

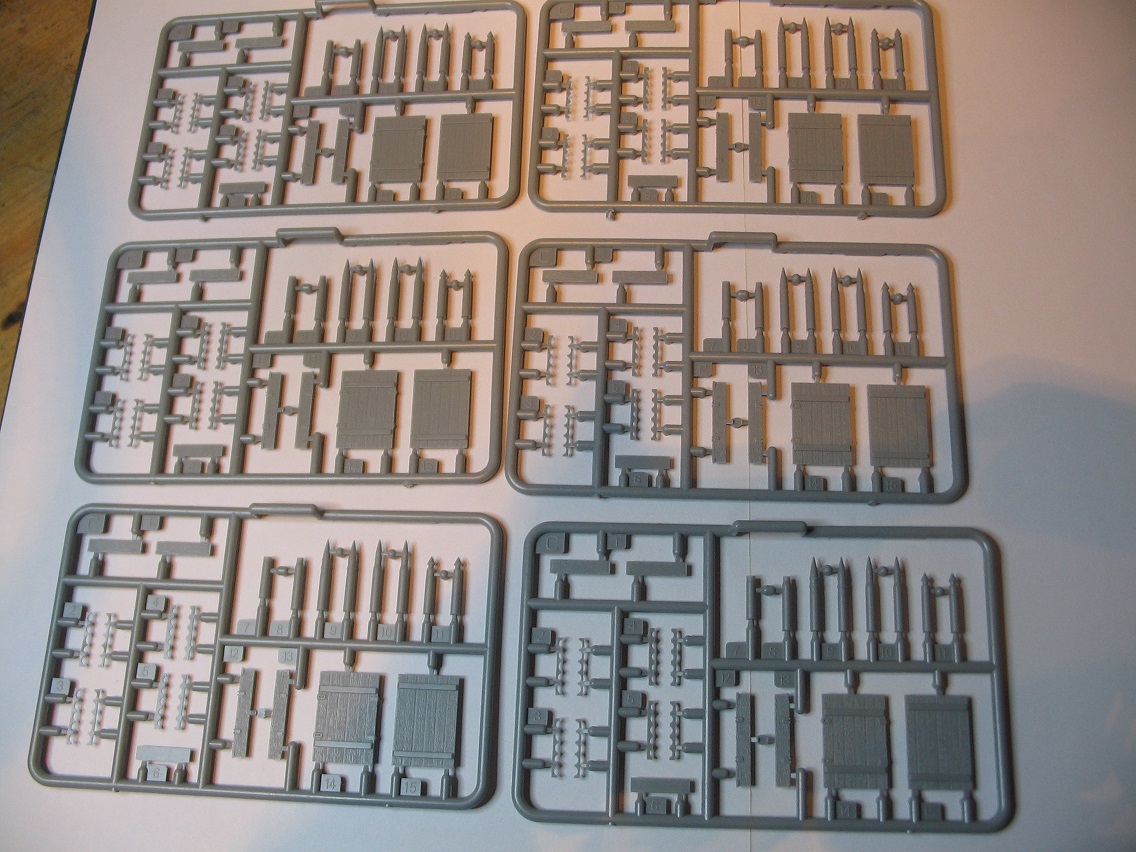

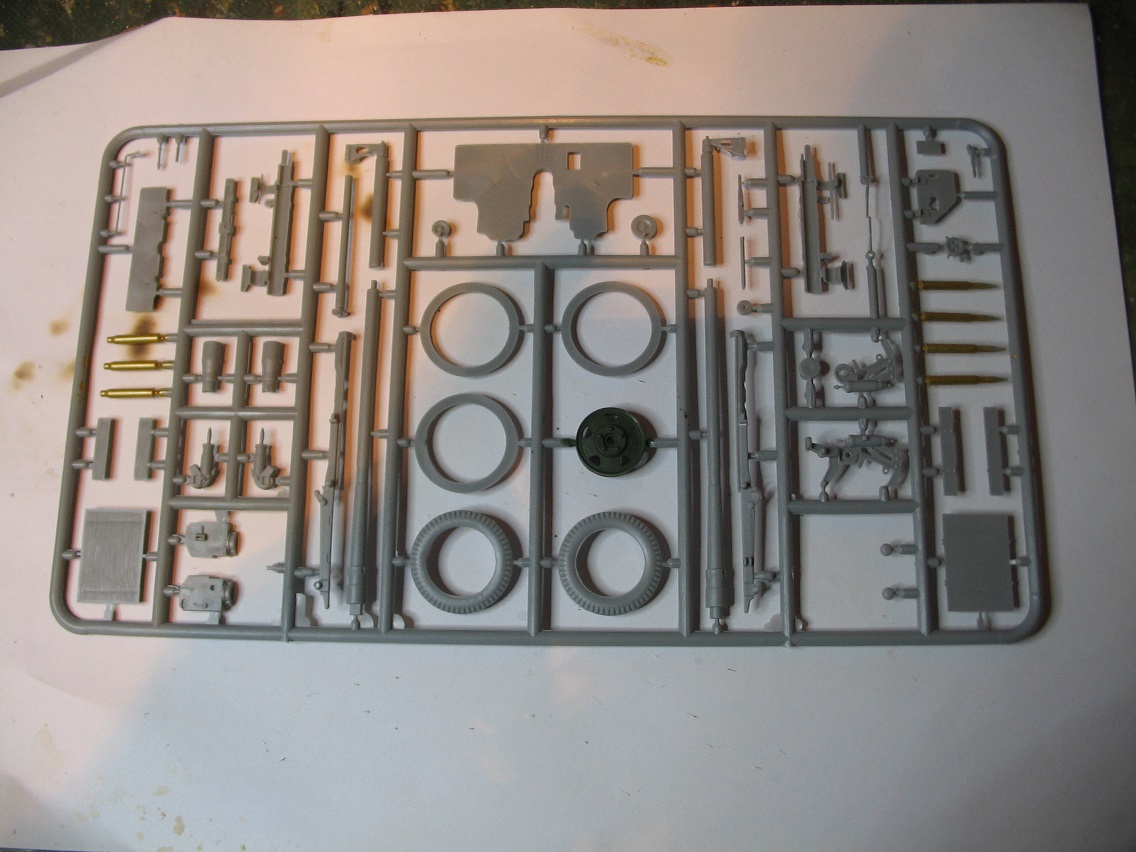

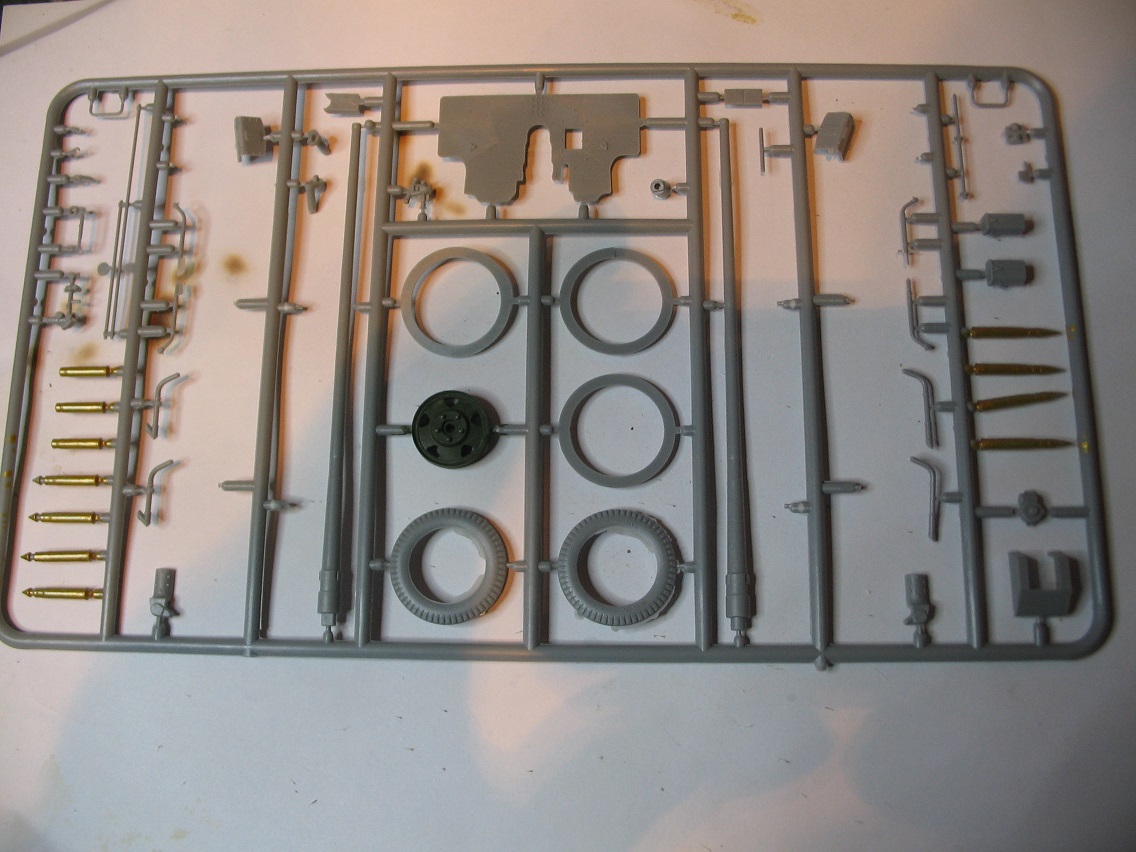

You get 6 sprues of ammunition and ammo boxes which I would imagine is the seperate ammo set that Miniart do. There's a nice selection of HE, AP and spent cases to litter the pit with. The Zis 3 was originally designed as a divisional artillery piece for line of sight suppressive fire. After some usage they found it to be a very capable anti-tank gun and produced anti-tank shells for it. It's the anti-tank capabilities that the gun is best known for.

The boxes have nice wood detailing and contain the vertical shell spacers so boxes can be left open ready for firing.

The figures are what we've comne to expect from Miniart in that the moulding is crisp, folds fall naturally and they're dynamic. They are posed loading the gun while a comrade brings up more ammunition and an officer is off to one side watching the fall of the shot. While these are specifically a crew to this gun I would imagine they'd be fine for any other Soviet or even captured German gun. They could even be kitbashed into normal Soviet infantry. Sorry, I always look at figures and think what else they can do lol. They look to be very good figures and I look forward to building them.

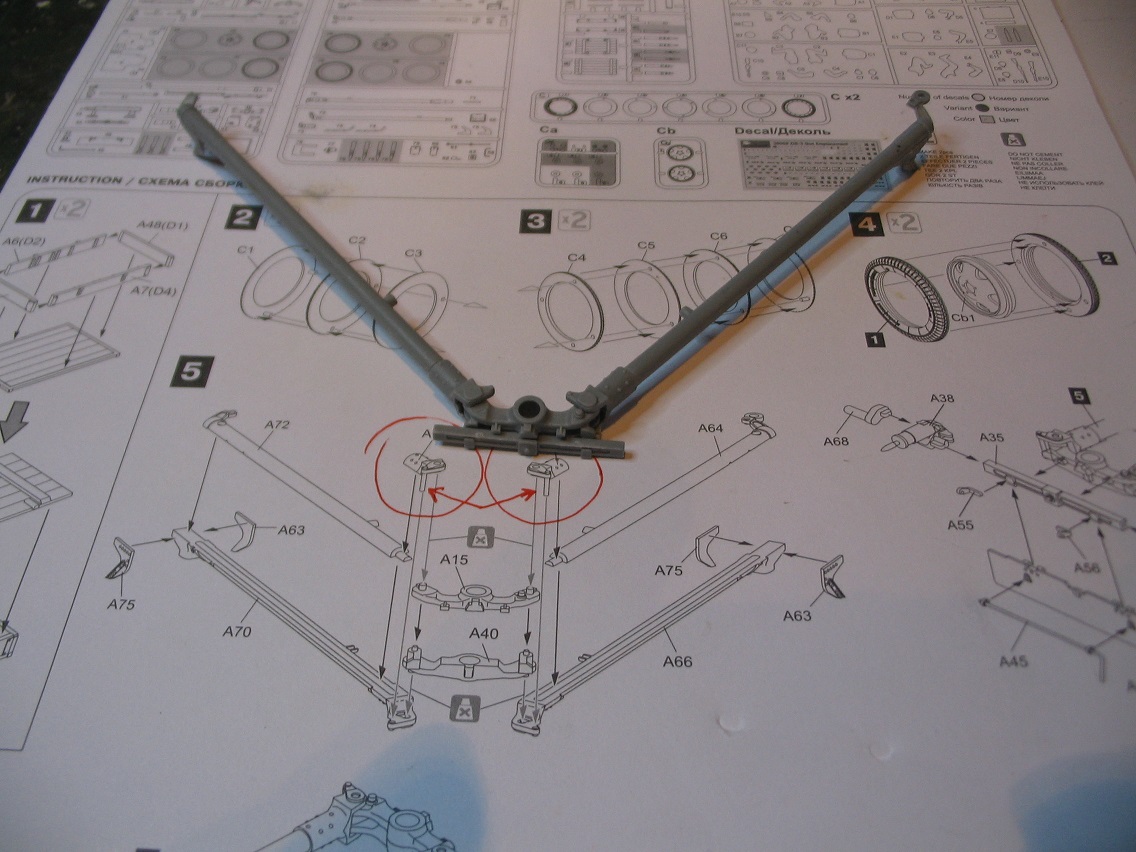

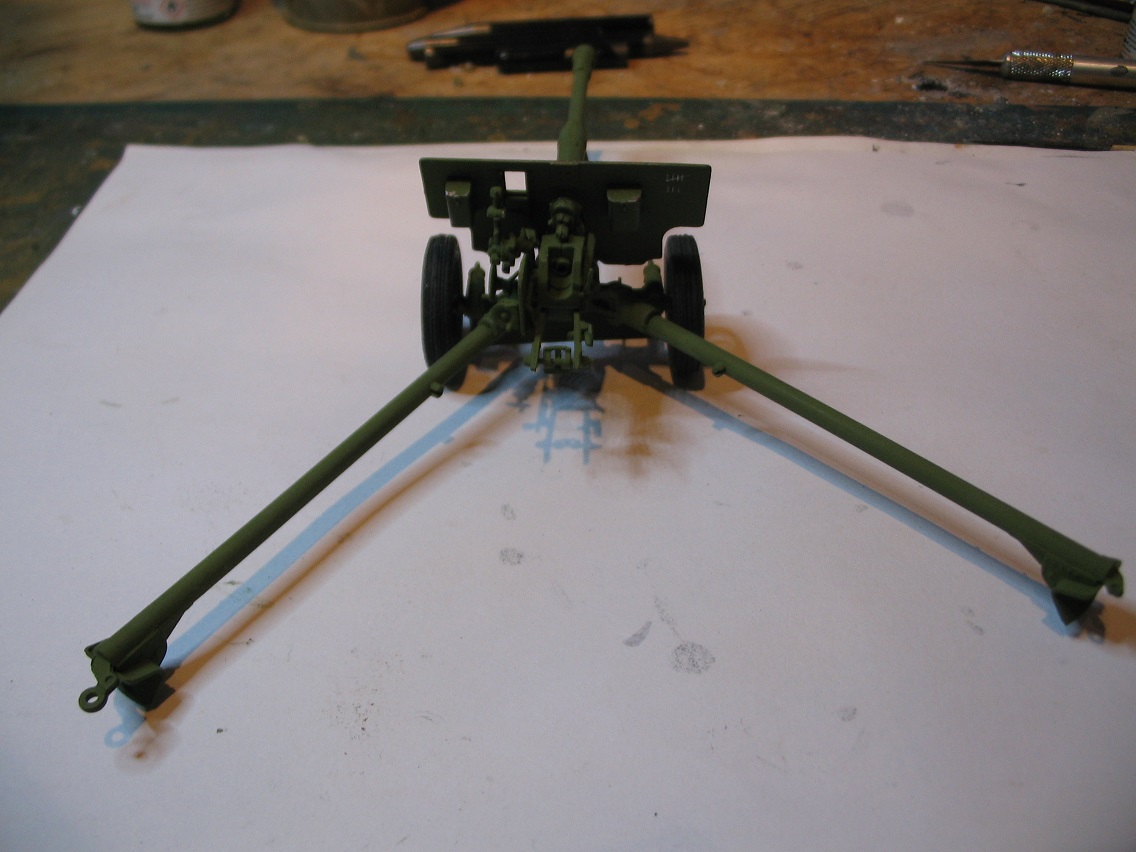

Then finally onto the gun. Not a weapon I'm particularly familiar with so I spent a couple of hours saving photos from walkarounds and photos of it in use so that I've got something to refer to for fit of parts if I have problems. I also find that looking at hundreds of photos gives some inspiration as well. These days whenever I build anything I always put together a file of photos on the PC, not only as reference to help me with the build but to give me dio ideas for later.

Sorry that one sprue is half empty. It was only after I'd put the wheels together that I realised I'd not taken photos of the sprues. Doh!

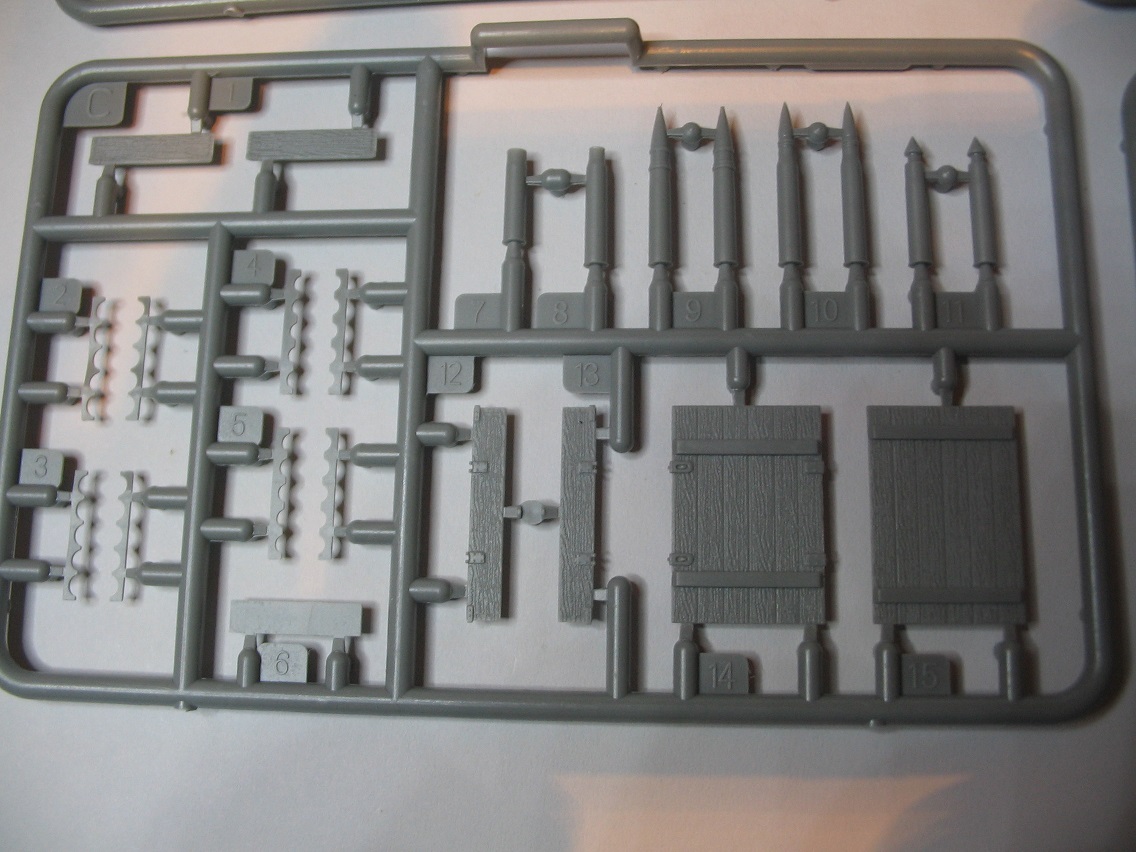

One thing that I have noticed and I don't like at all is that the parts are not numbered on the sprues.

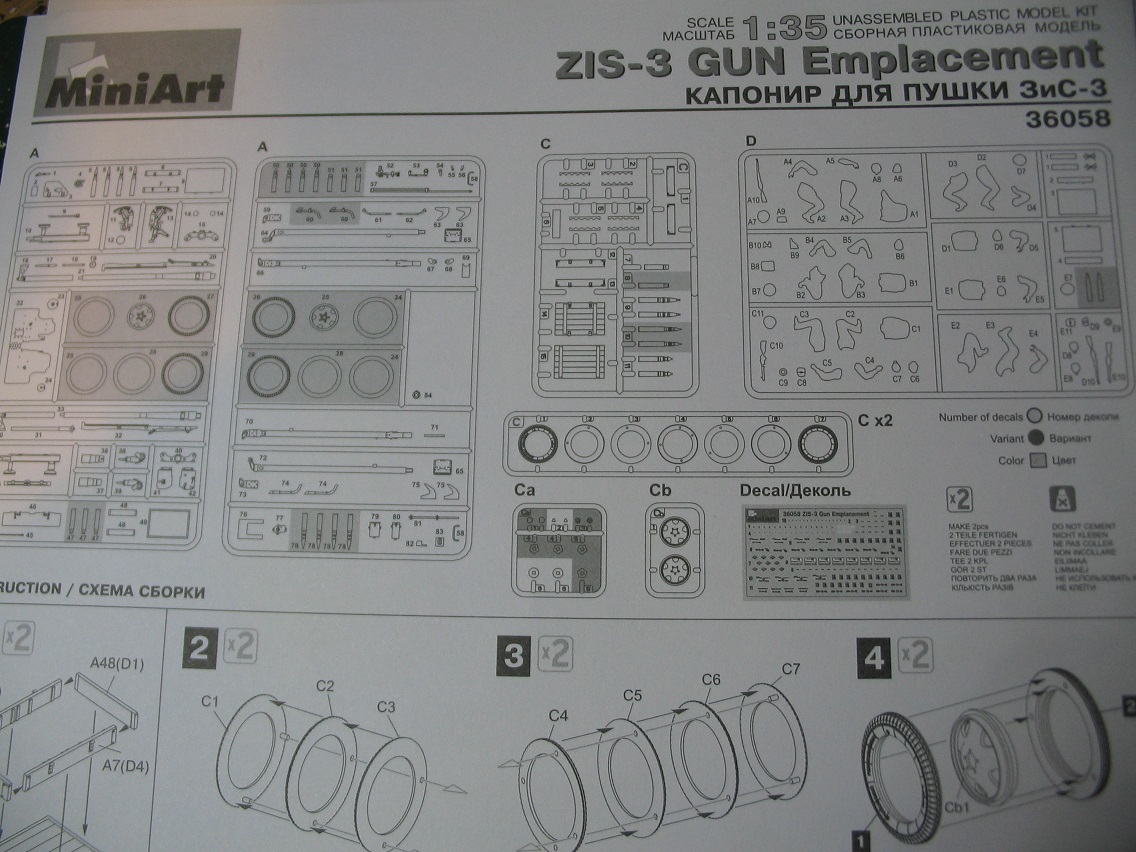

Okay there's a diagram in the instructions of all sprues with the appropriate part numbers on so how difficult would it have been to put the numbers on the sprues? While not a problem as such it is a bit annoying having to keep referring to the instructions to search out the part that I need. Rather than look at the build part then take the bits of the sprues,it's build part, instructions to find out which sprue the part is on then, search through then double check it is the right part. Just time consuming.

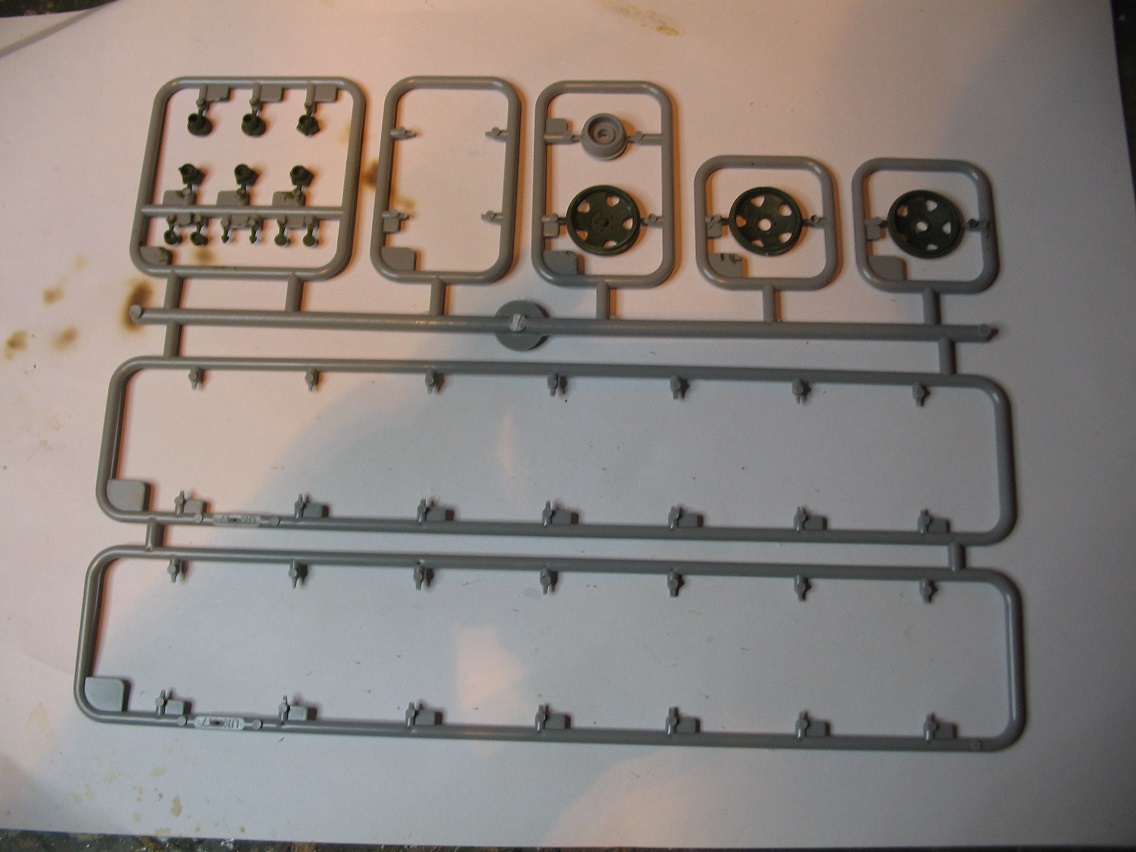

As you can see the tryes are made up of slices which does look good once it's all together as it gives quite a delcate pattern. One thing to bear in mind, and I didn't think of it till I'd done one tyre, is that each slice has a slightly different camber on the edge. If you take more than one part off at a time there's the possibility they may get jumbled up or be placed the wrong way round. What I did there was paint a stripe on each one so I knew which side faced the outer tyre. Simple but it worked.

/>

/>I built two tyres up before I went to bed last night and gave them a quick paint as I wanted to see what the tread looked like after using seven slices to make a tyre..

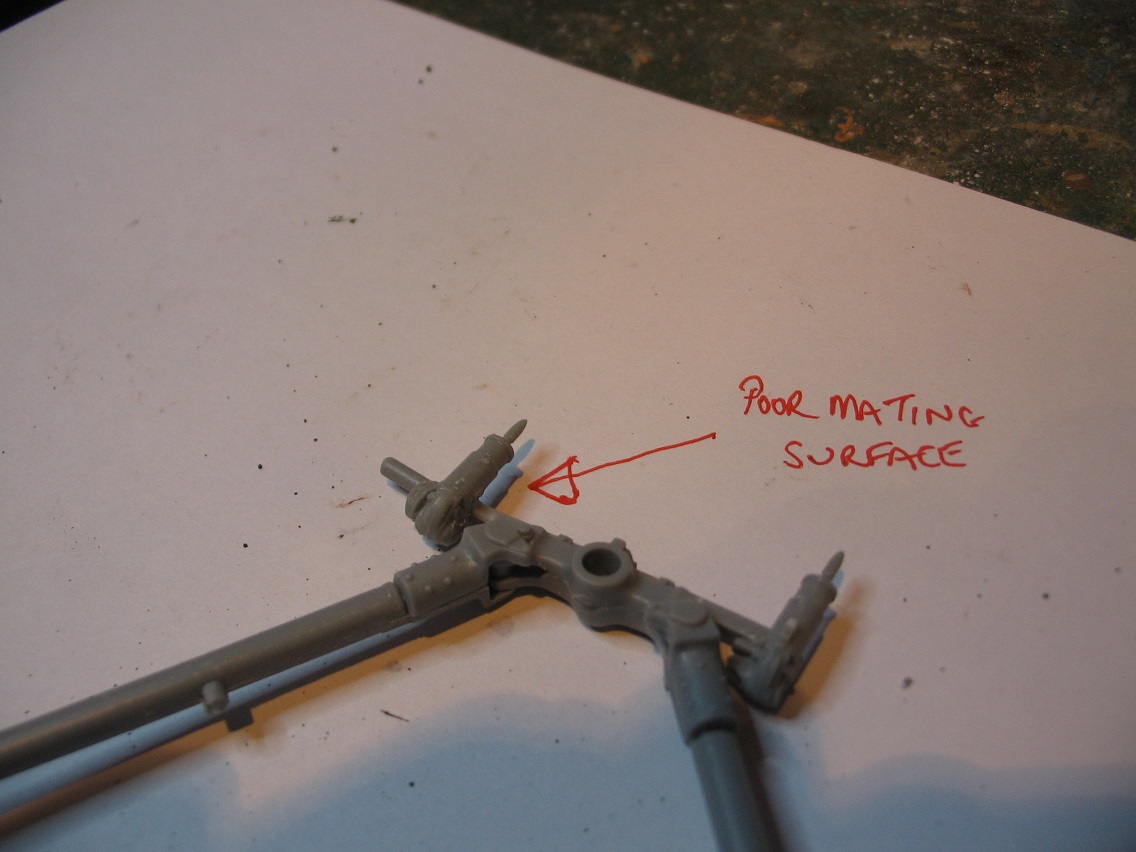

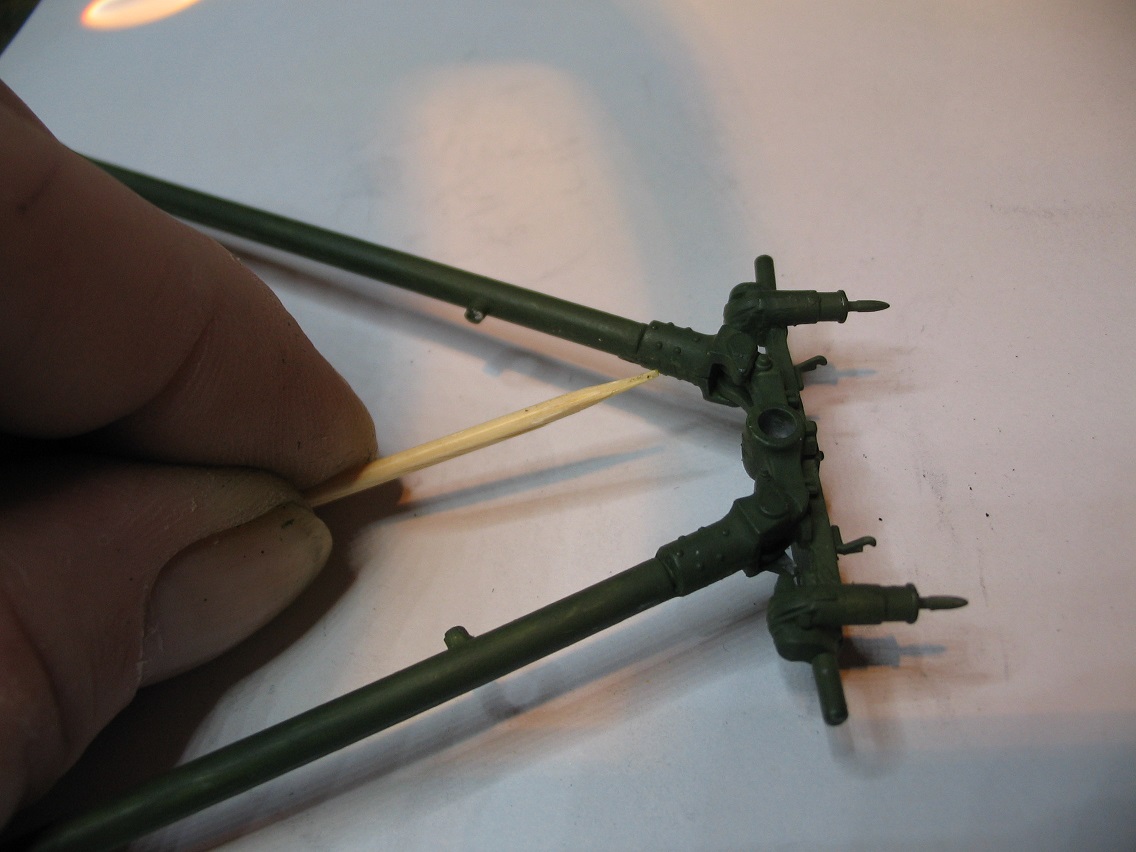

Not a great photo of it end on but you can see that the tyre pattern is quite effective when done. When I went to take the trail parts off the sprues I did notice quite a bit of flash. Easy enough to take off with a sharp No11 but I wonder if it's all going to be like this?

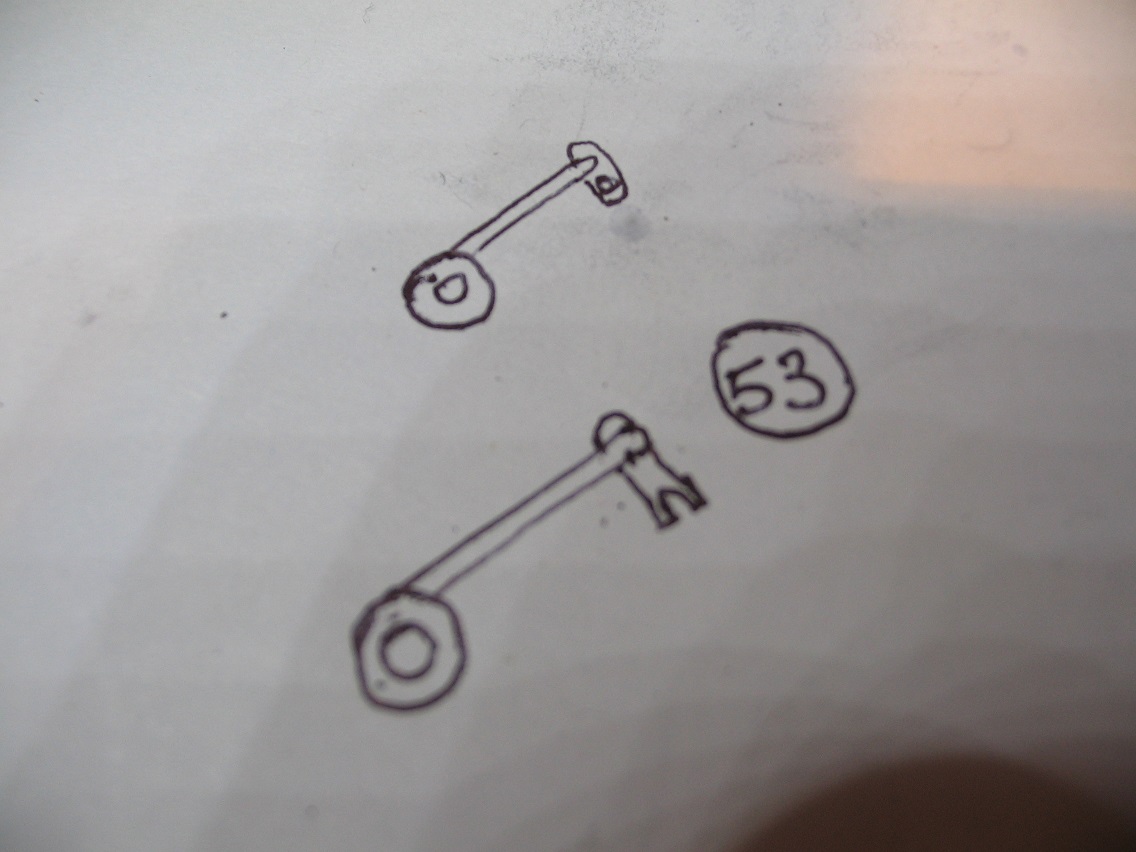

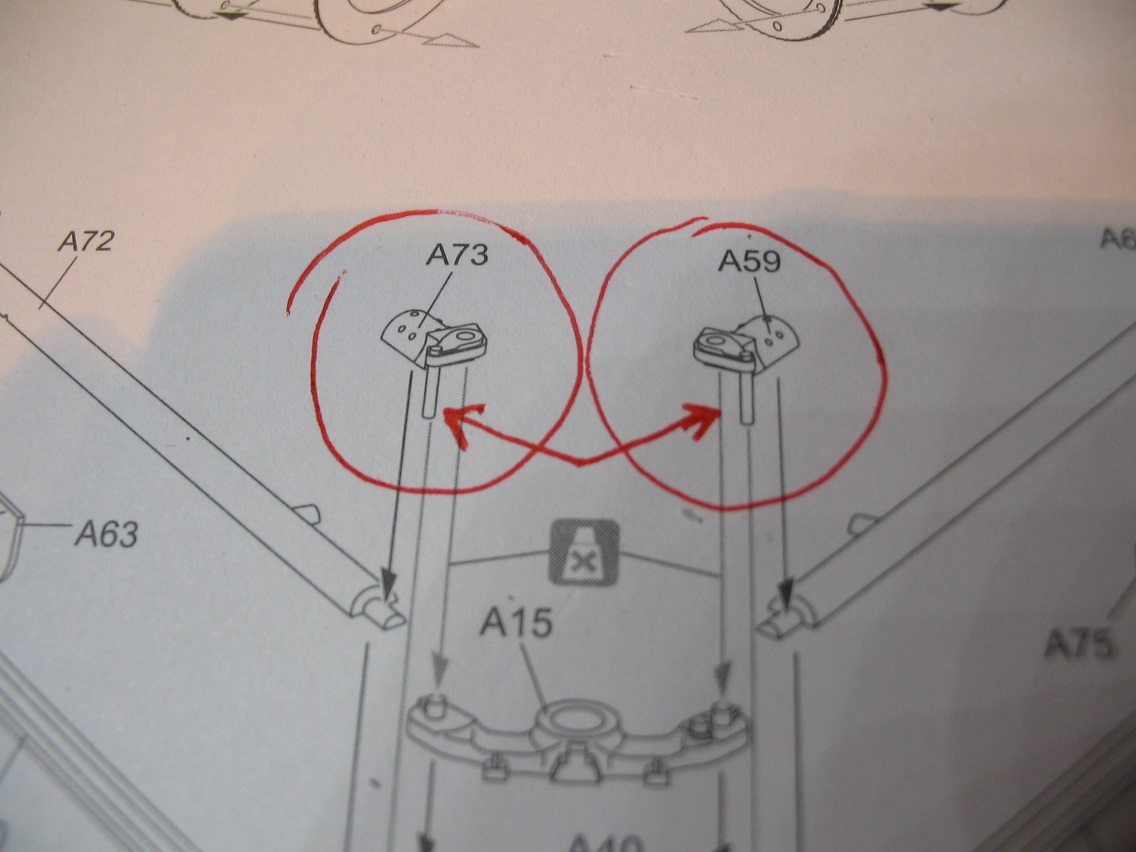

One thing I noticed when comparing parts with the instructions were these two parts.

As you can see there are two locating pins on the trail ends to mount it to the carriage. Not on mine there's not. They've both snapped off at some point. I'd heard people mention that Miniarts plastic is brittle and that backs that up I suppose. We'll see as the kit progresses. They've obviously bumped against other parts on it's journey from the factory and wherever else it's been before it got to me and consequently broken off. I can work around it but they shouldn't have broken off that easily

As you can see the instructions are very clear and detailed so no ambiguity unlike some manufacturers where you may as well not bother with the instructions as they just confuse matters.

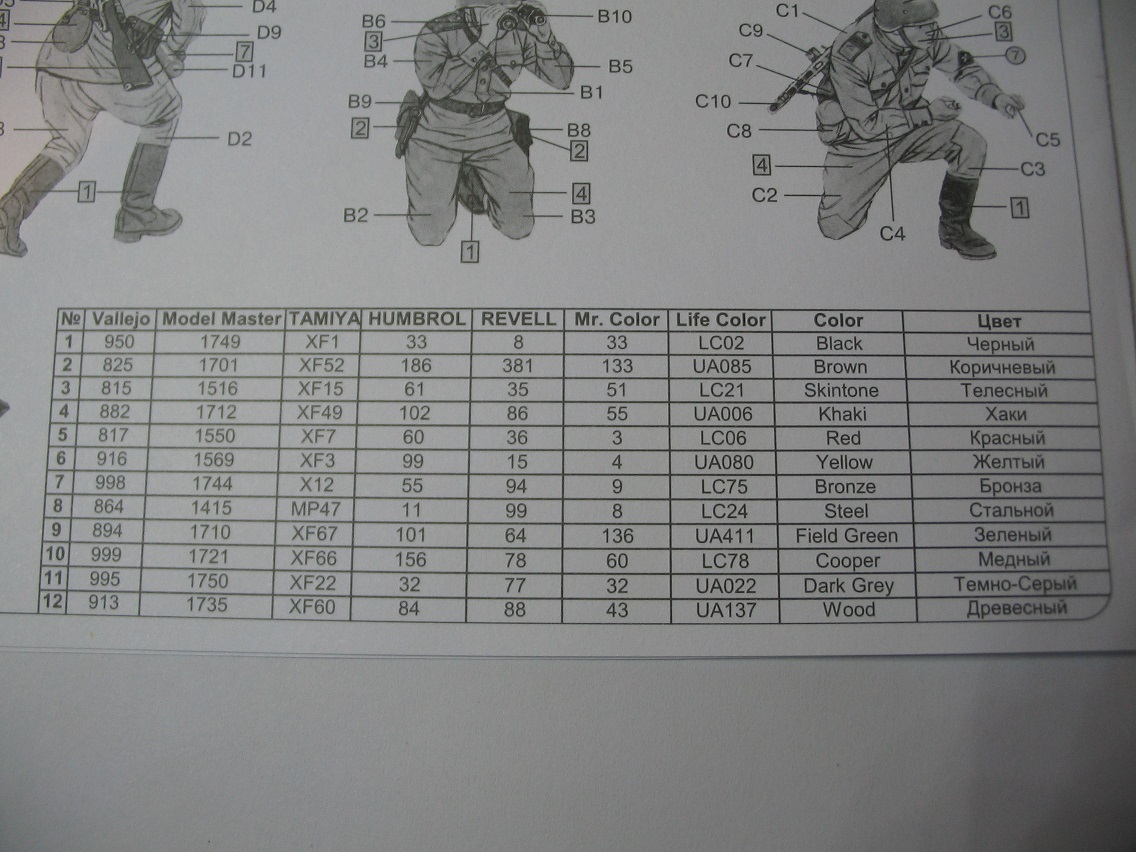

Another thing I noticed on the instructions was the paints guide.

They've listed the colours by all the main players in the paint world which is a massive aid so if you can't get one type at your LHS you can always get another or alternatively if you're not overly keen on say Tamiyas XF67 shade for green you've got a choice of another six manufacturers whose shades will inevitably vary.

Now that I've introduced you to the kit properly I can get on with the fun and interesting bit. The build! MOre later...