First produced in 1927, the Scammell was designed as a 6◊4 off-road vehicle for use in timber and oil industries in Britain's colonies where good hard surface roads were scarce. Although it lacked all-wheel drive its combination of a suspension with great travel movement and excellent traction along with its low-revving engine gave it impressive pulling power over rough ground at low speeds. In 1932 the Pioneer was offered to the British Army, who initially showed little interest apart from the 20t Tank Transporter version TRMU20. Near the end of 1936 the British Army ordered production of the R100 Artillery Tractors, and during 1937-1939 performed development of the SV/2S recovery vehicle.

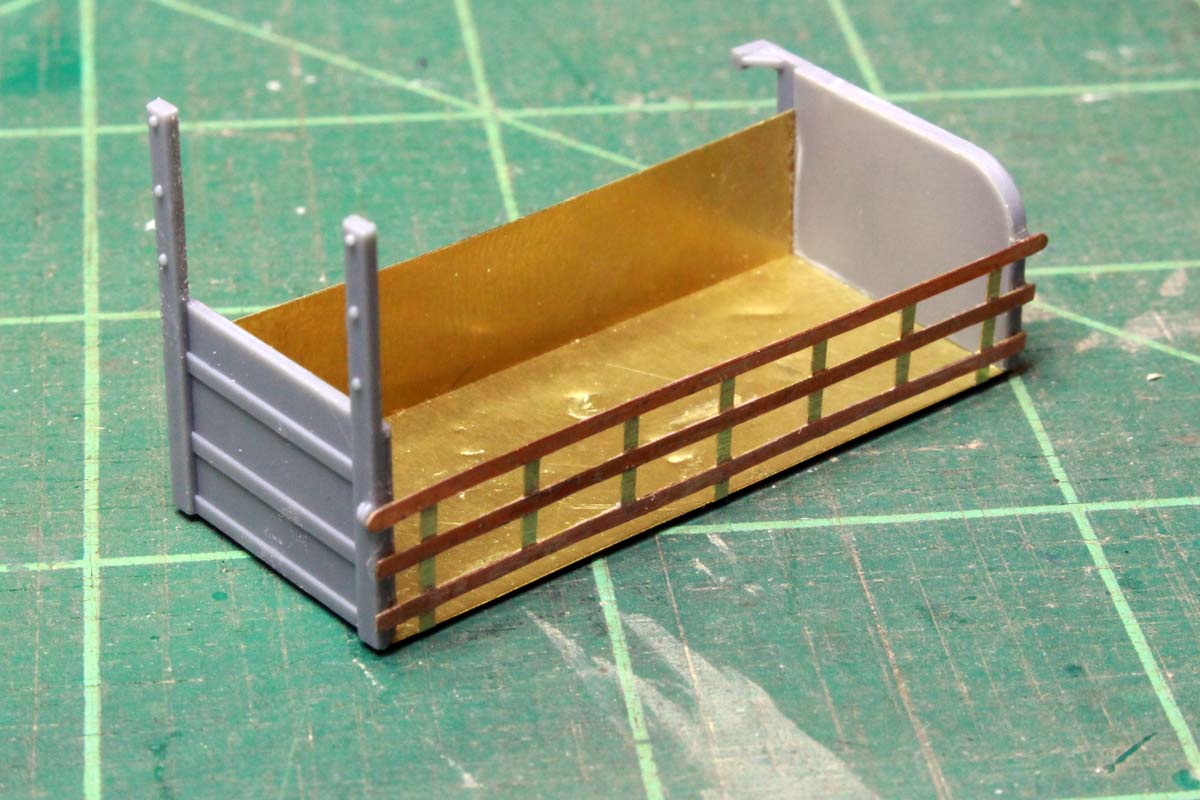

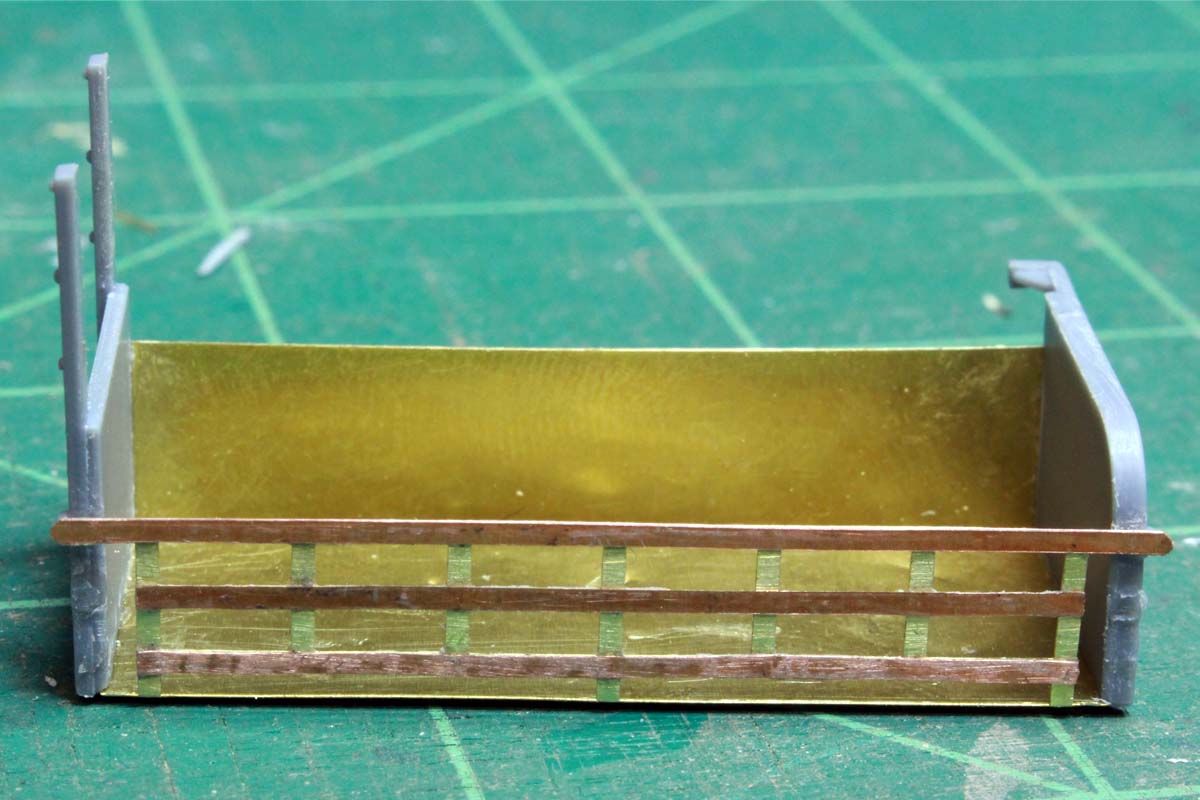

The R100 was a fully modernized version of the of the 1927 model and was significantly different than that original model. The truck bed was customized for artillery units with space for 9 crew members and ammunition. The crew seating was arranged with two sets of forward facing double seats directly behind the cab and another 4 seats on the sides. A small door and a foldable ladder where provided on each side of the bed behind the cab with a trap covering the window above the door. The rear of the cab was formed by a half bulkhead that separated the drivers compartment from the bed. The center of the bed housed a manual hoist for handling the heavy ammunition.

A total of 786 R100 vehicles were produced and used throughout the war and continues to soldier on until 1950 when they were replaced with the Leyland Martian vehicle.

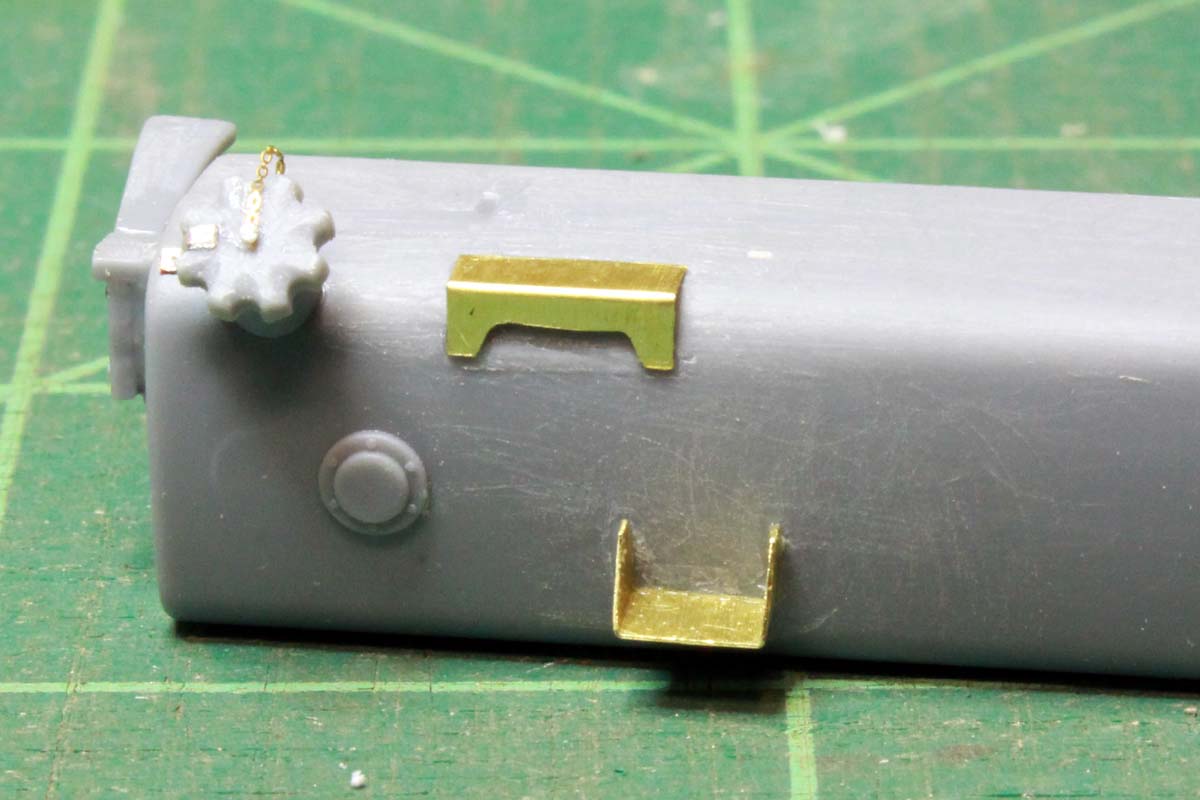

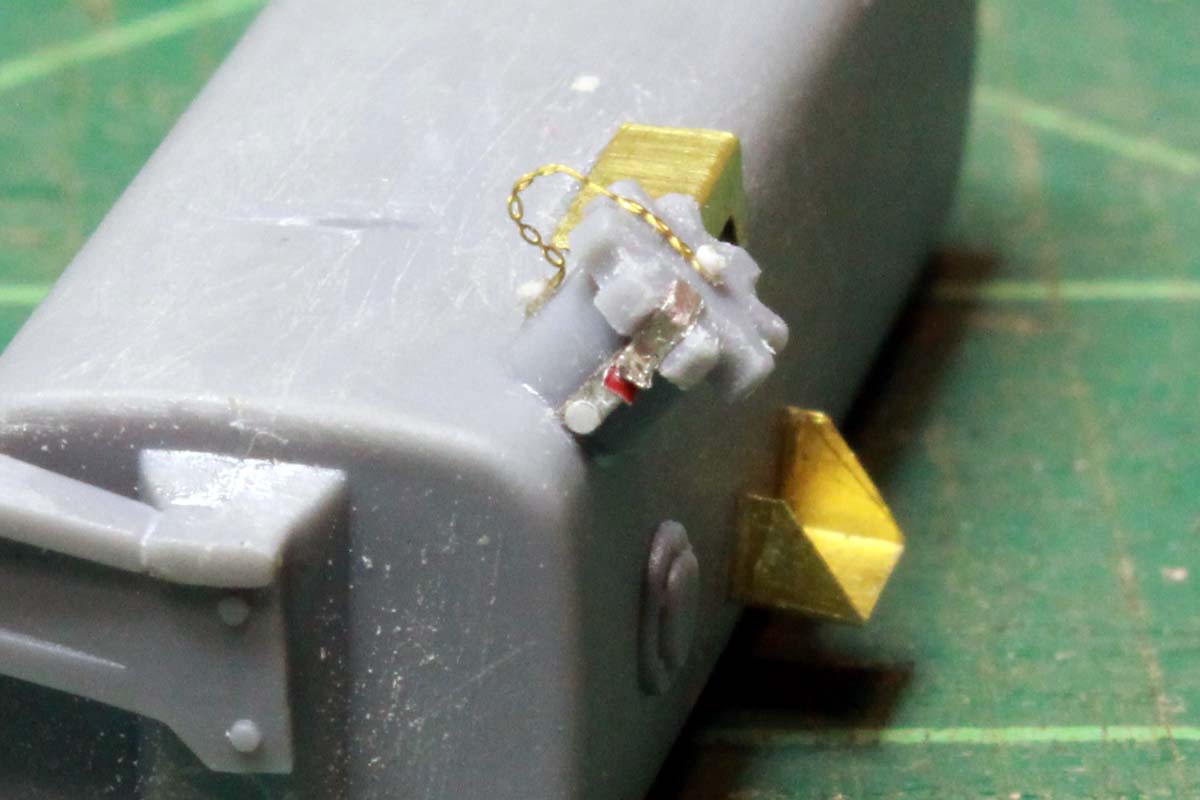

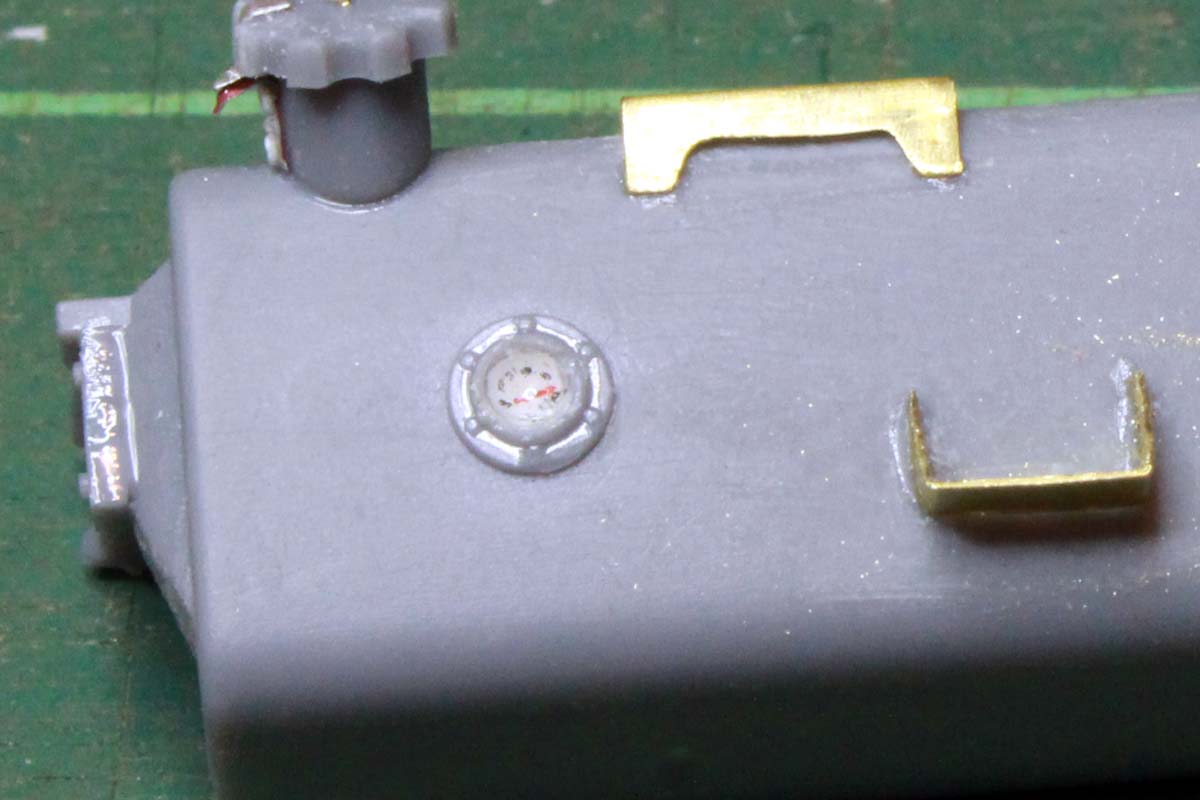

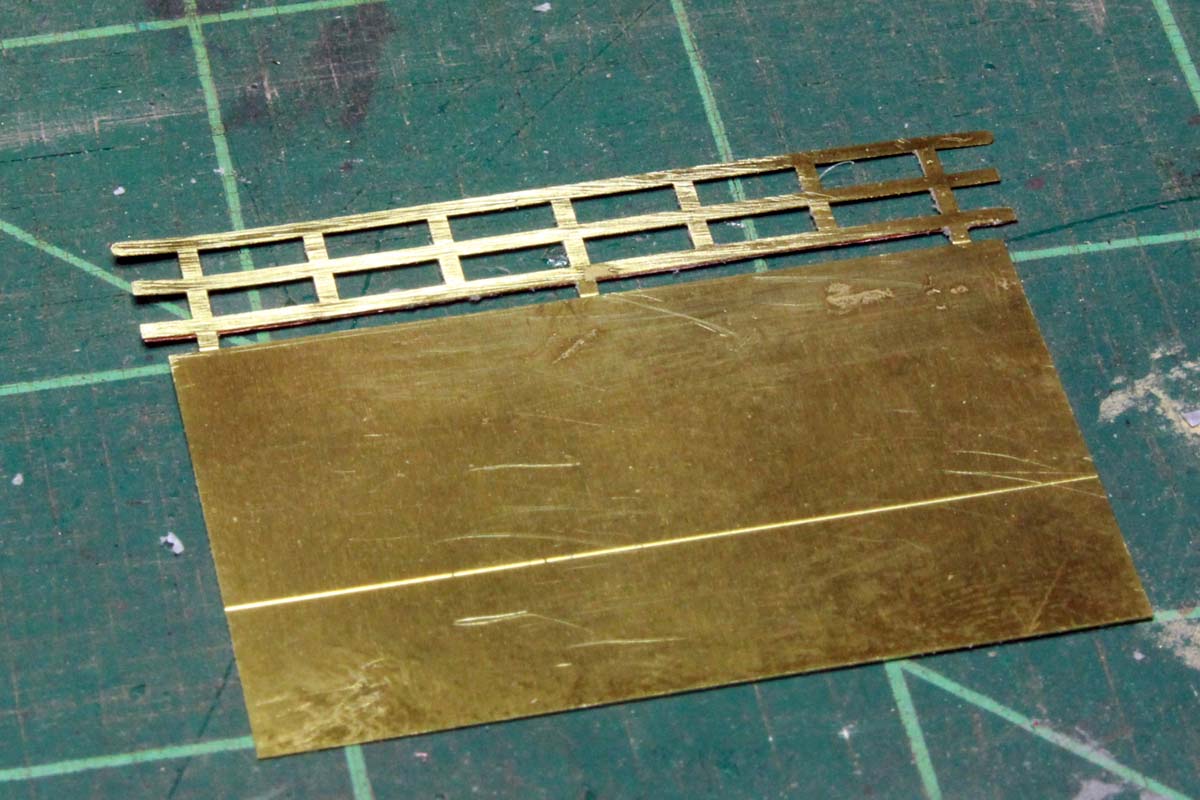

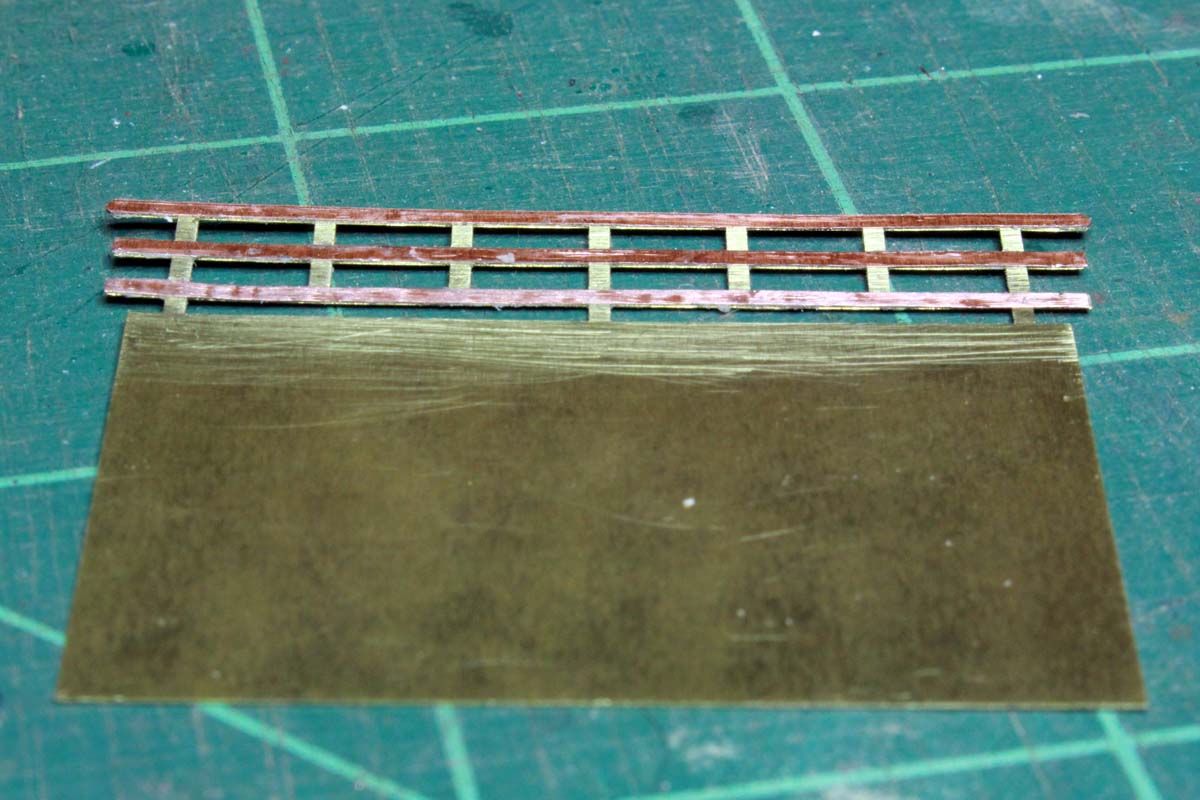

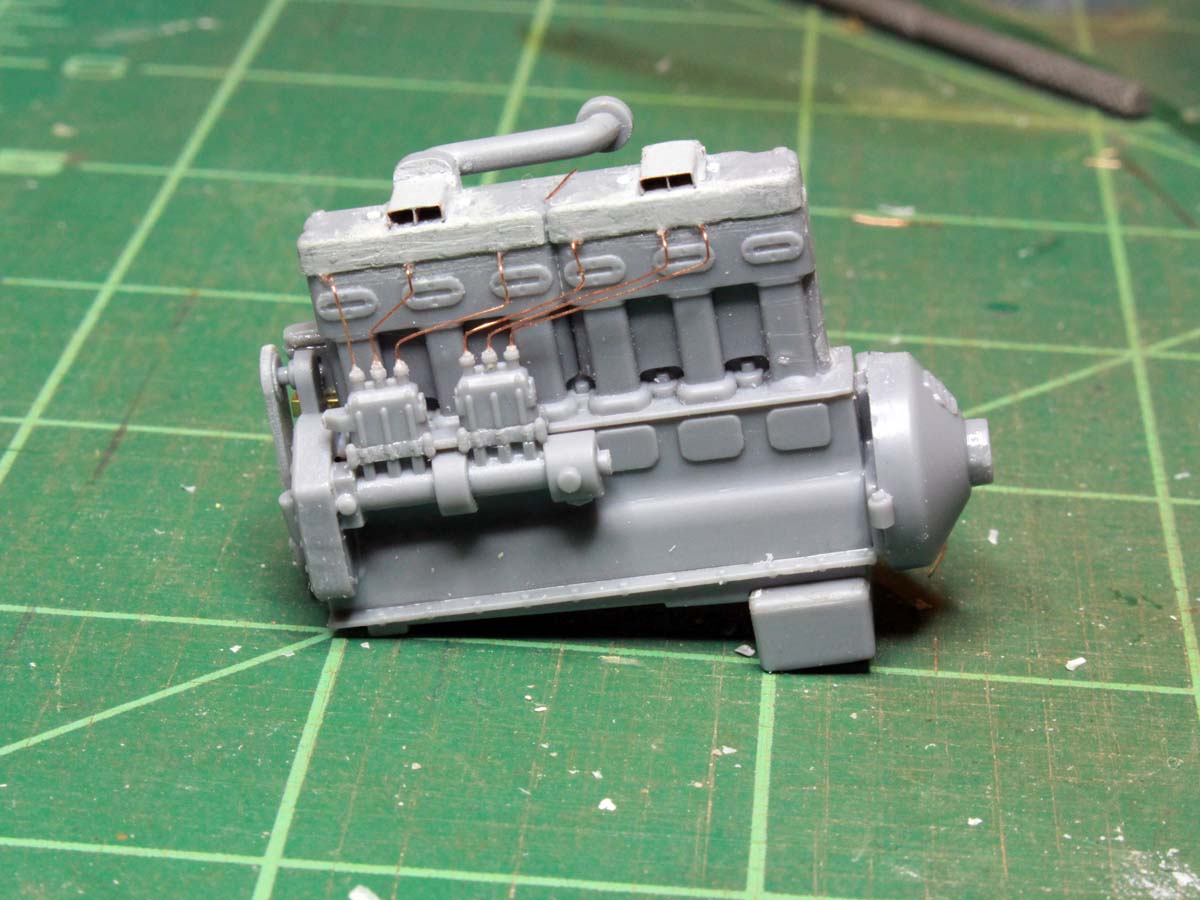

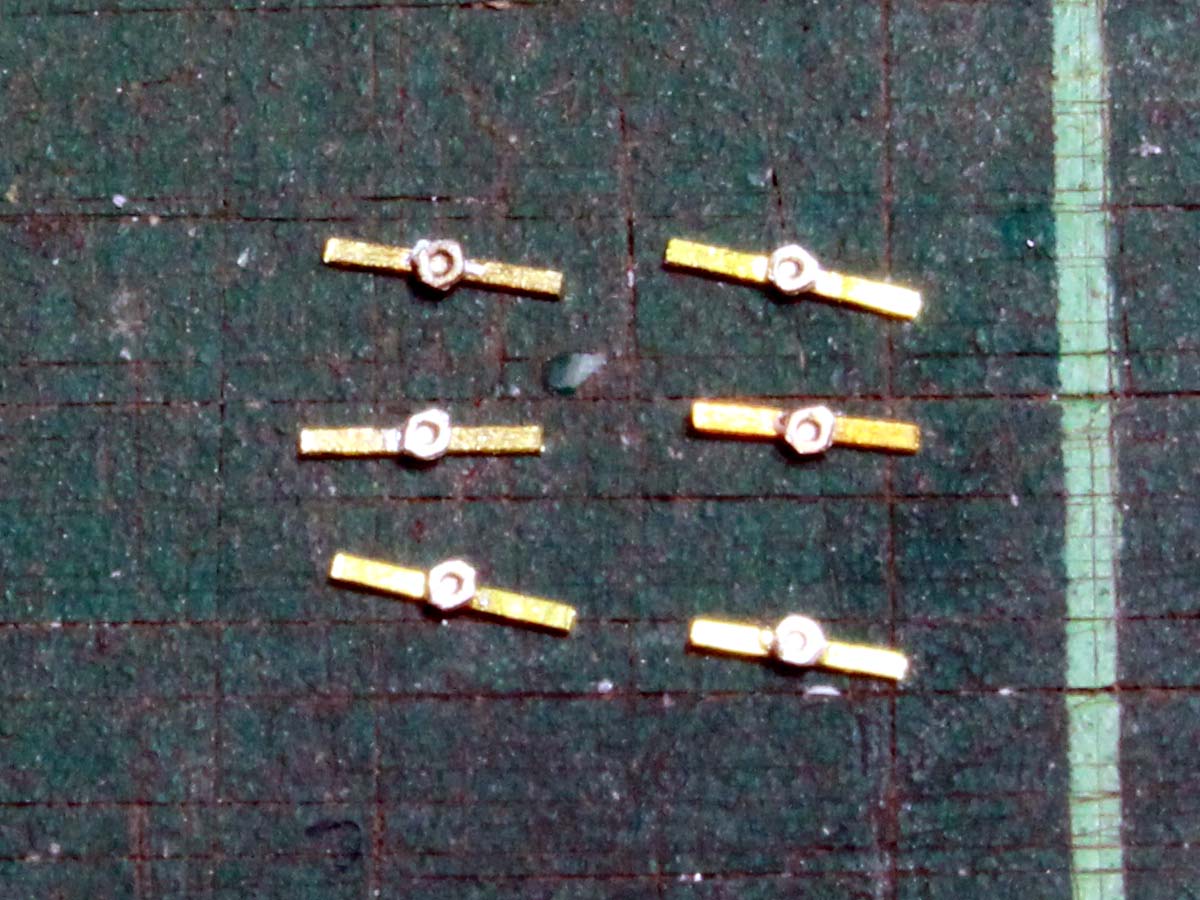

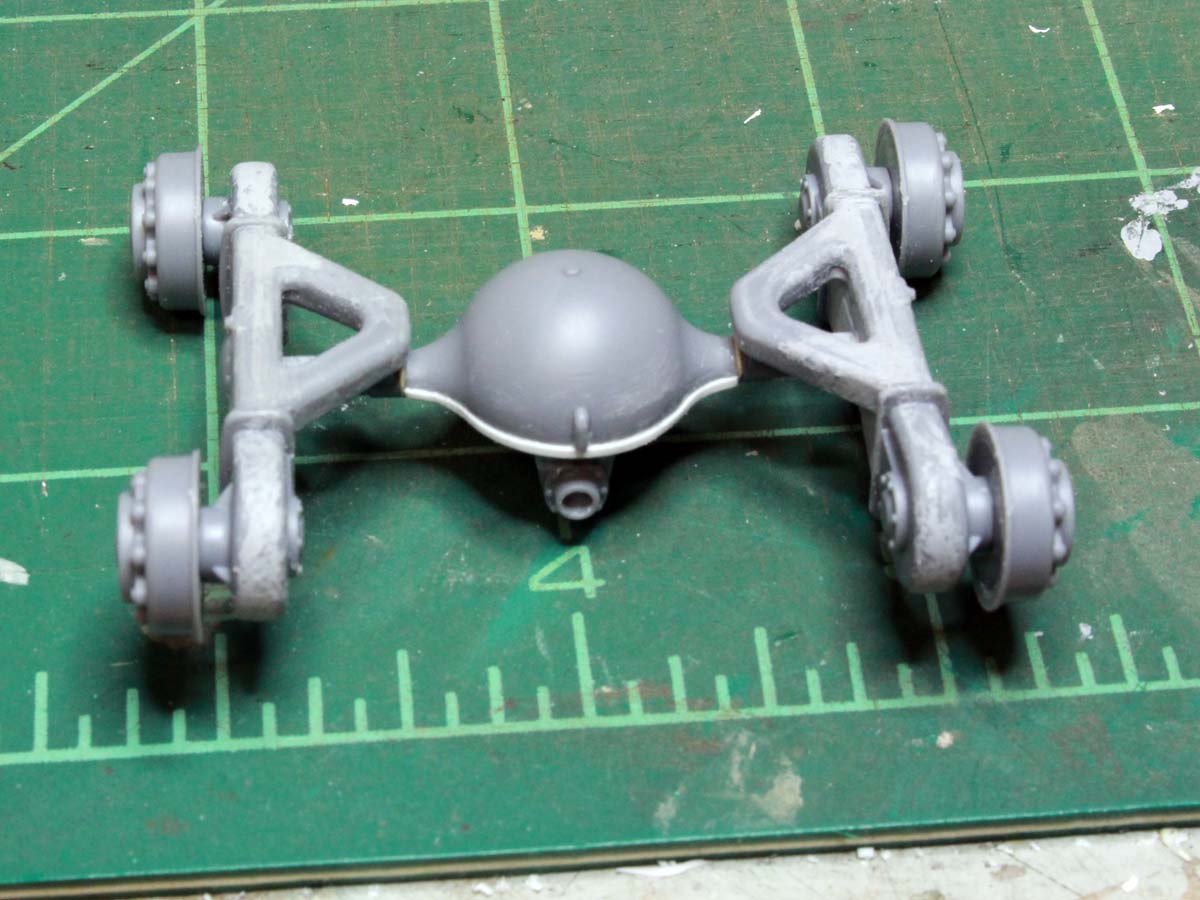

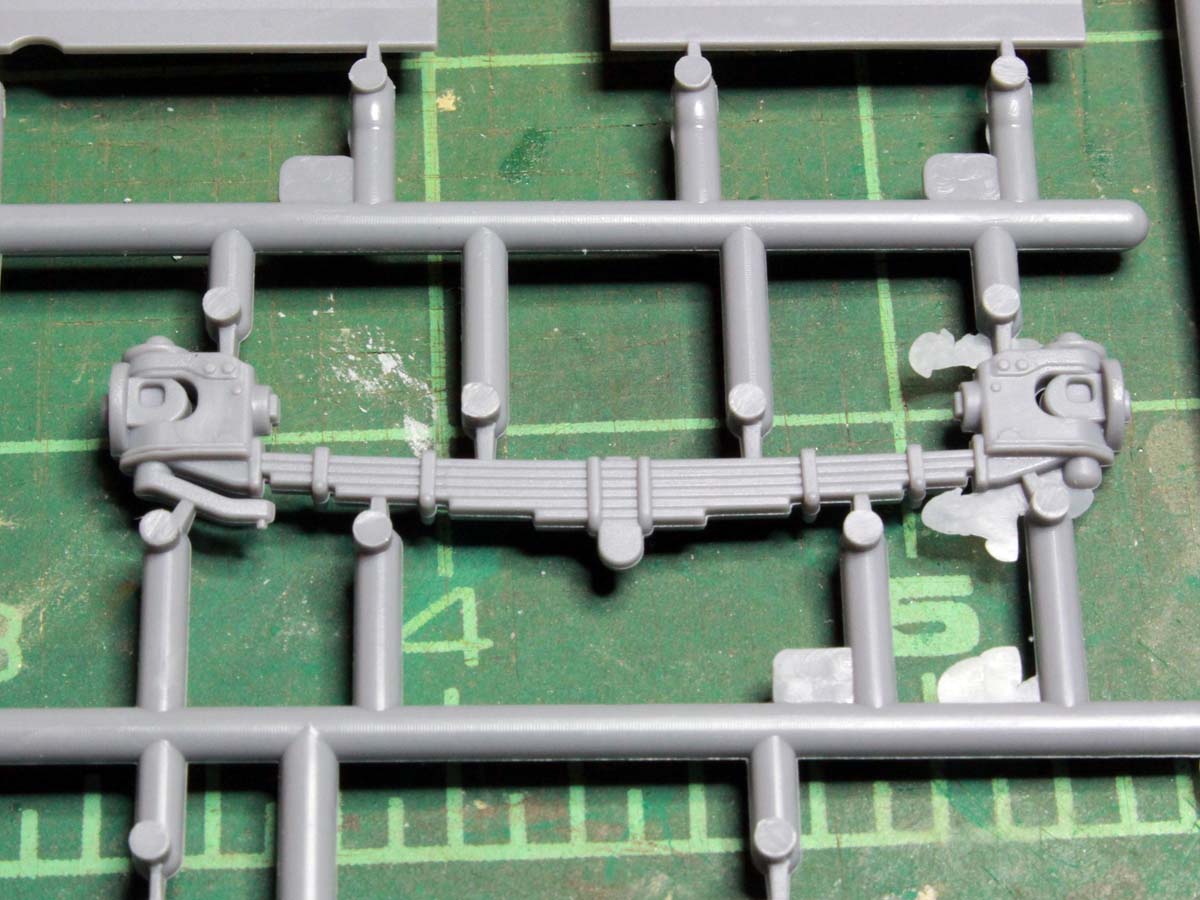

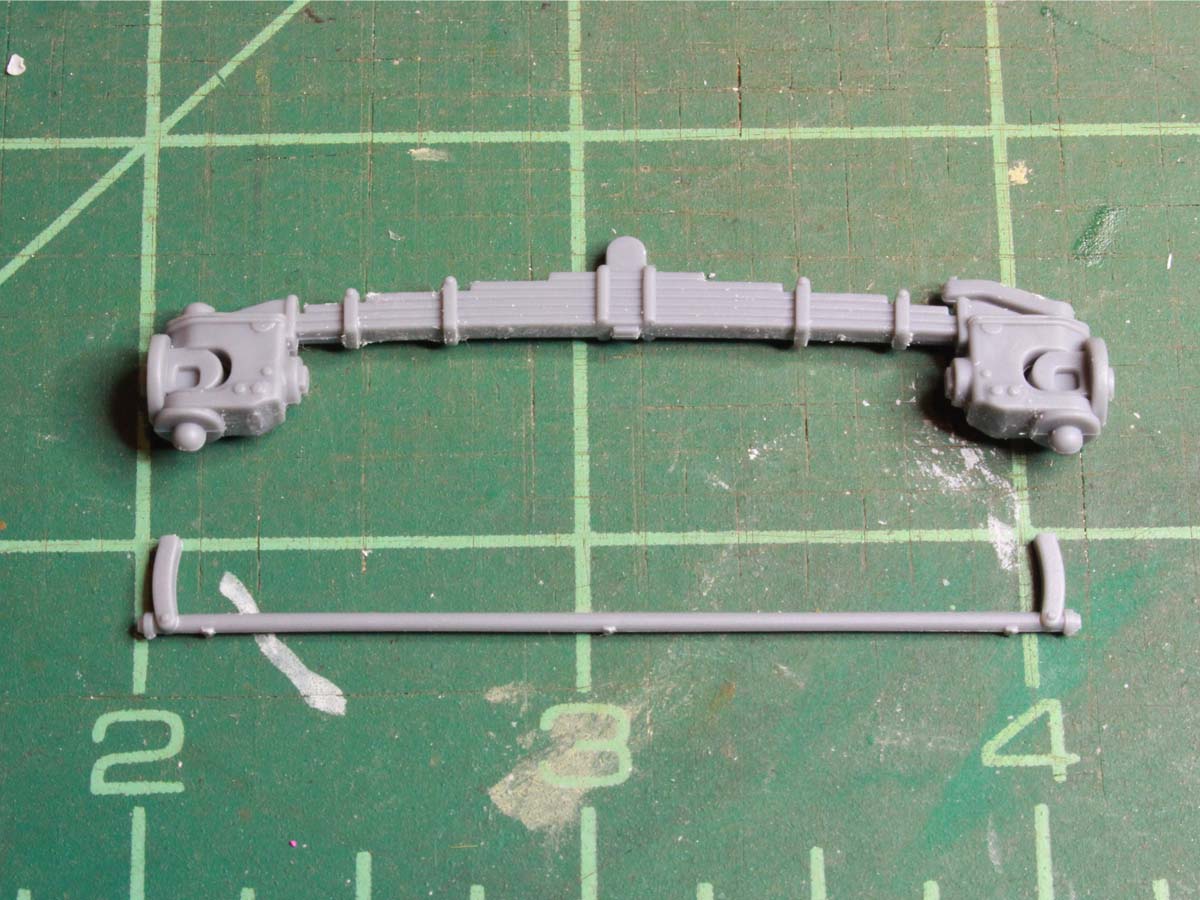

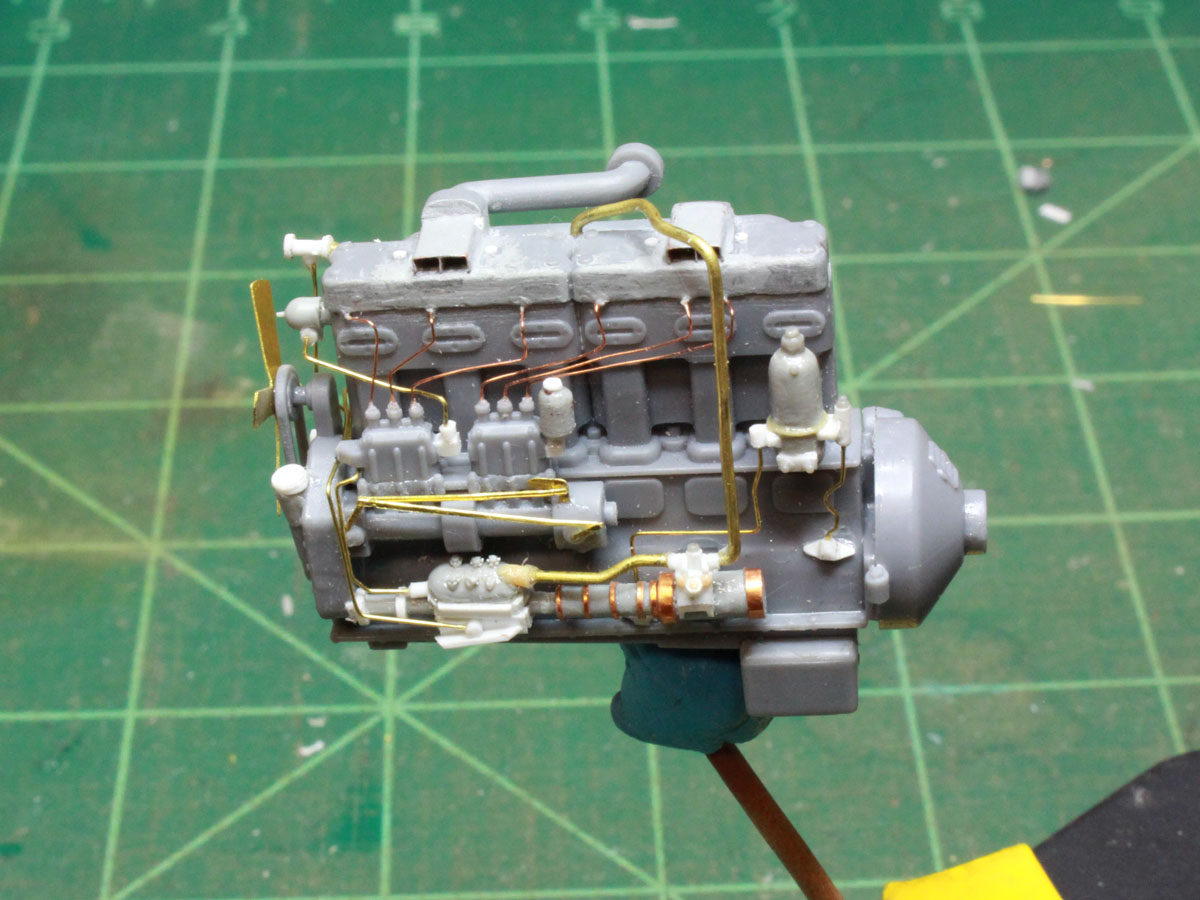

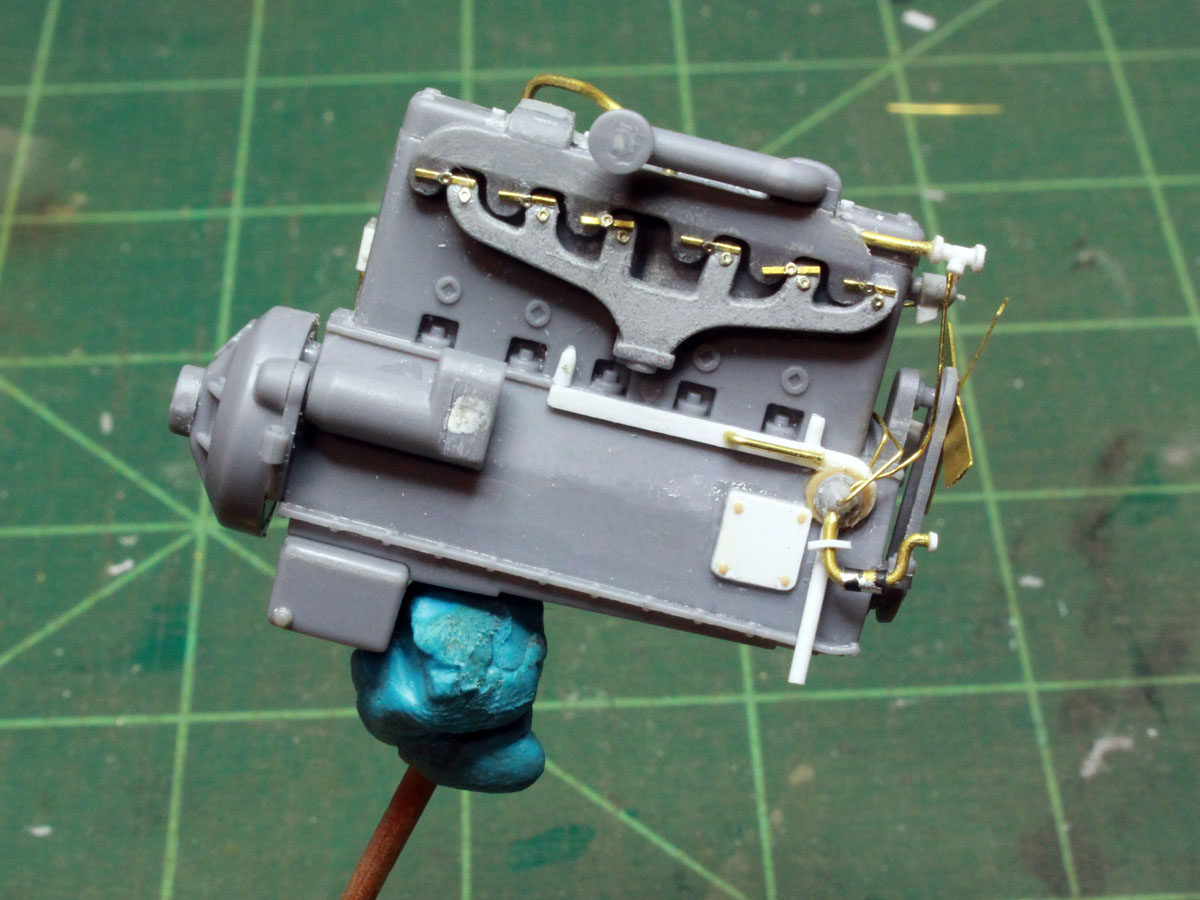

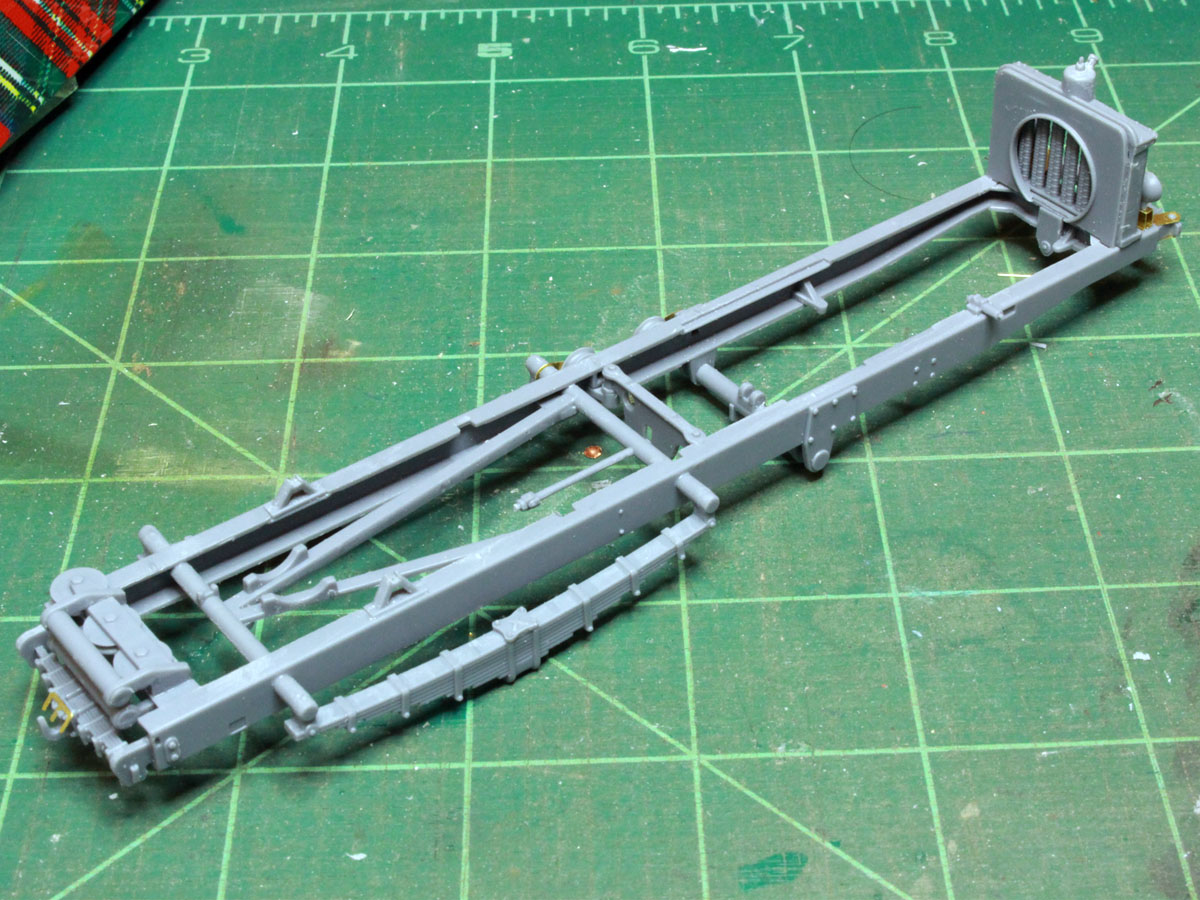

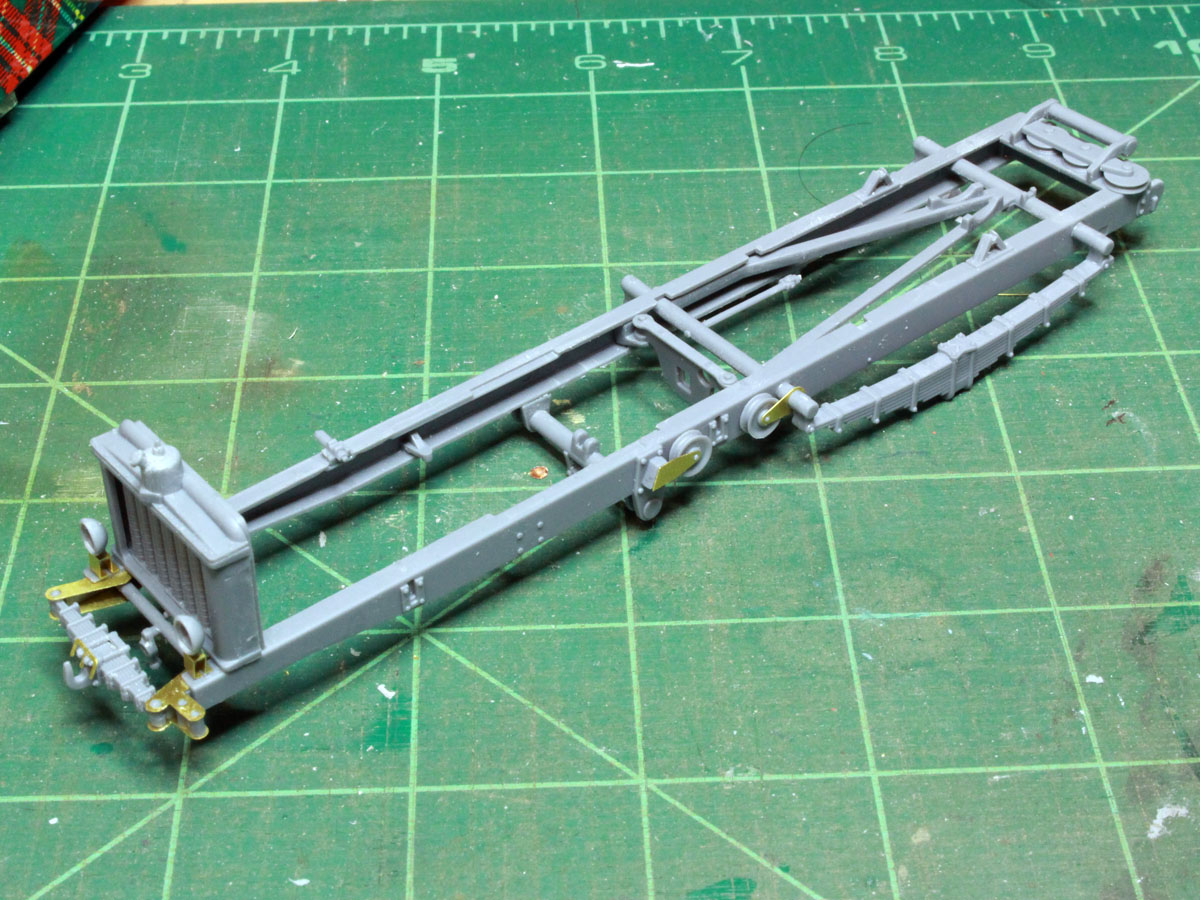

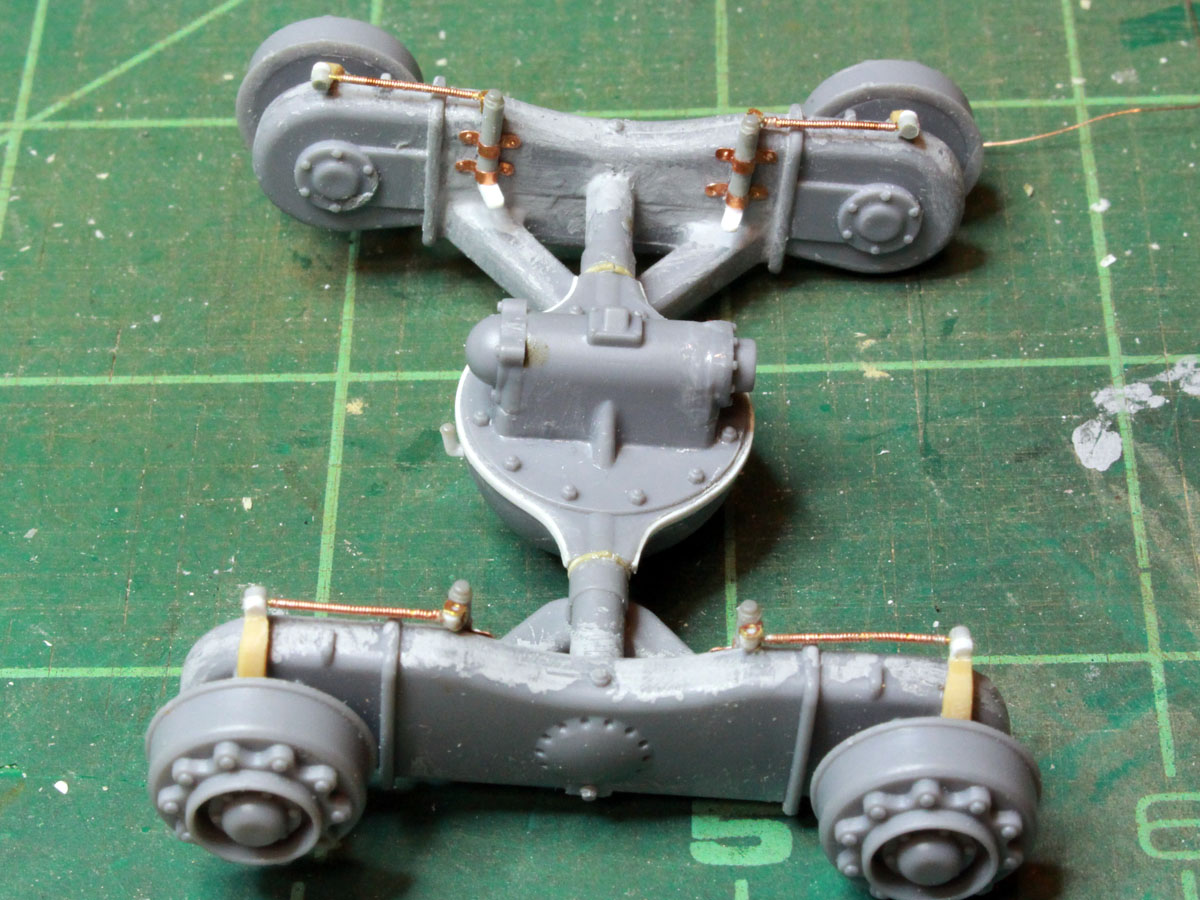

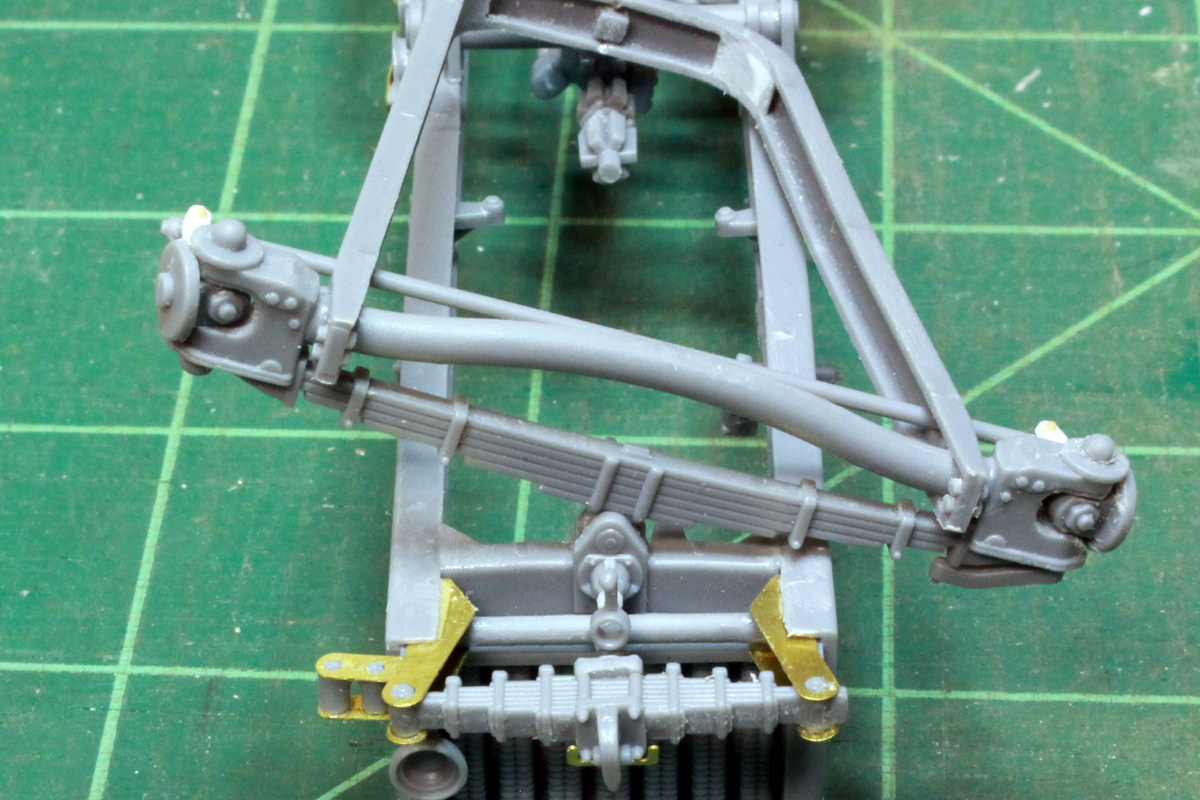

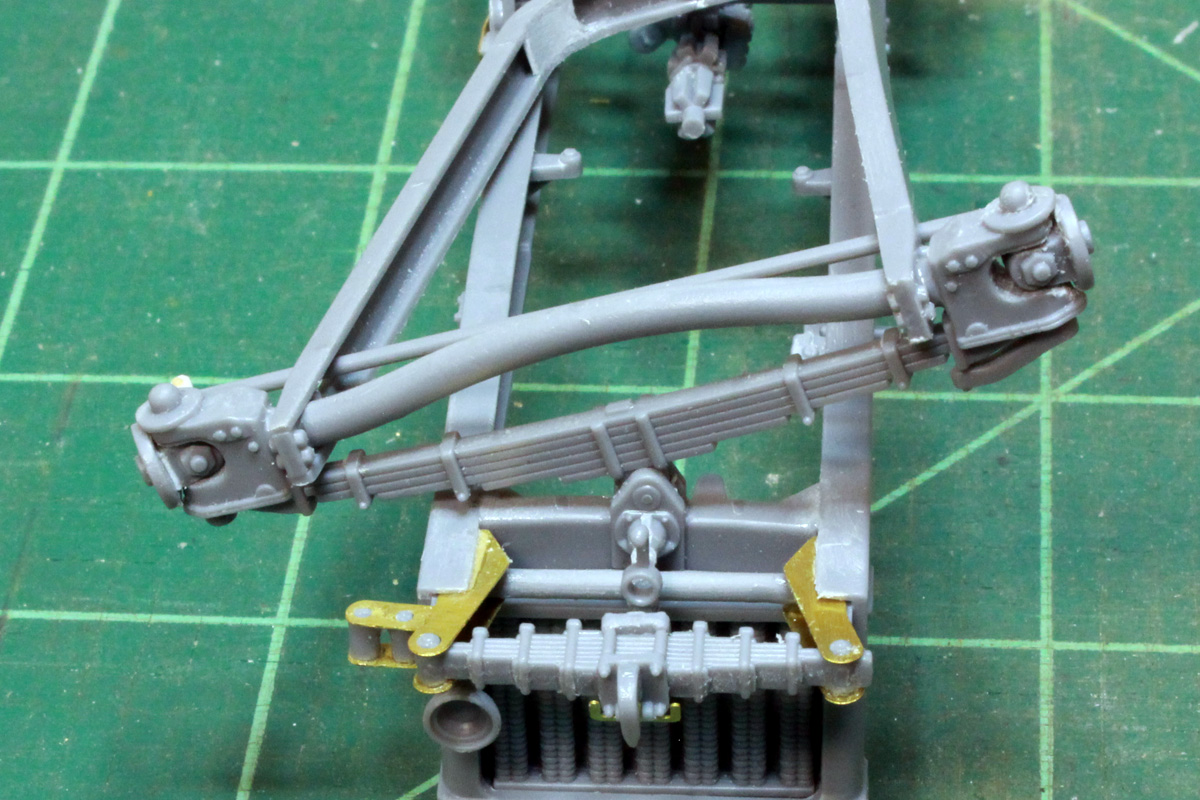

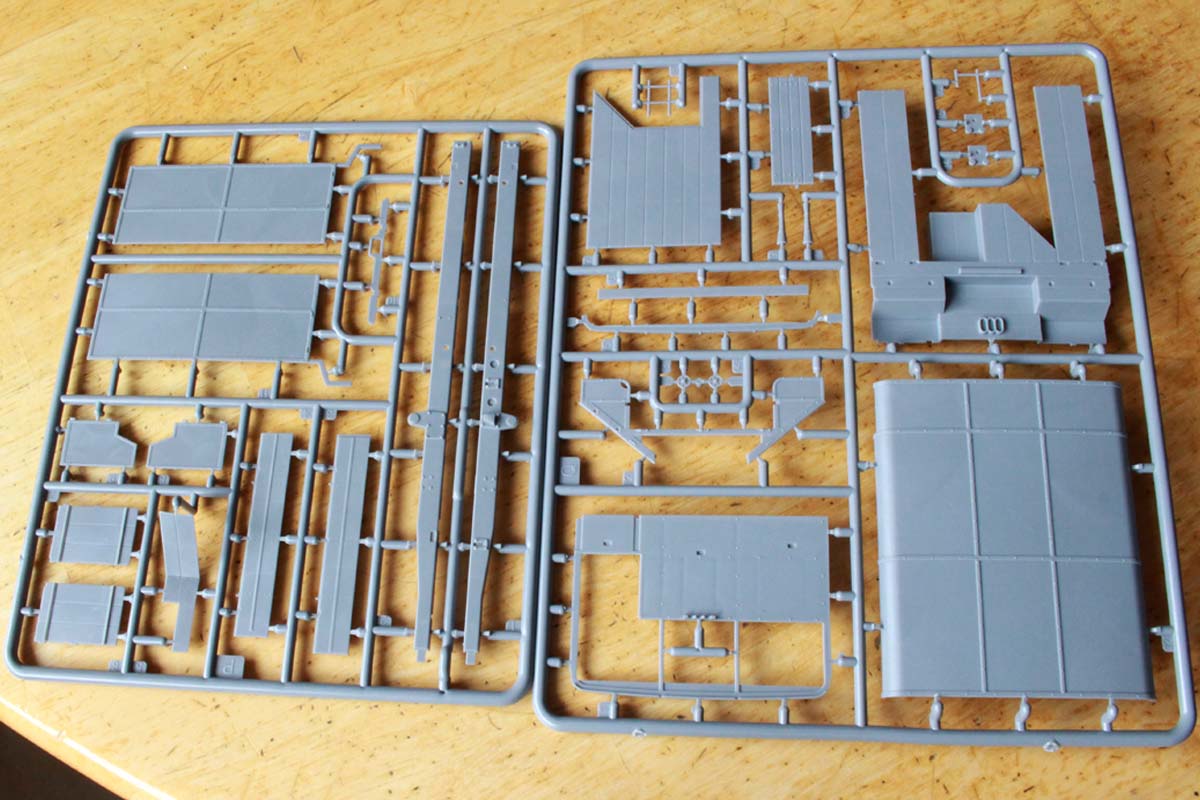

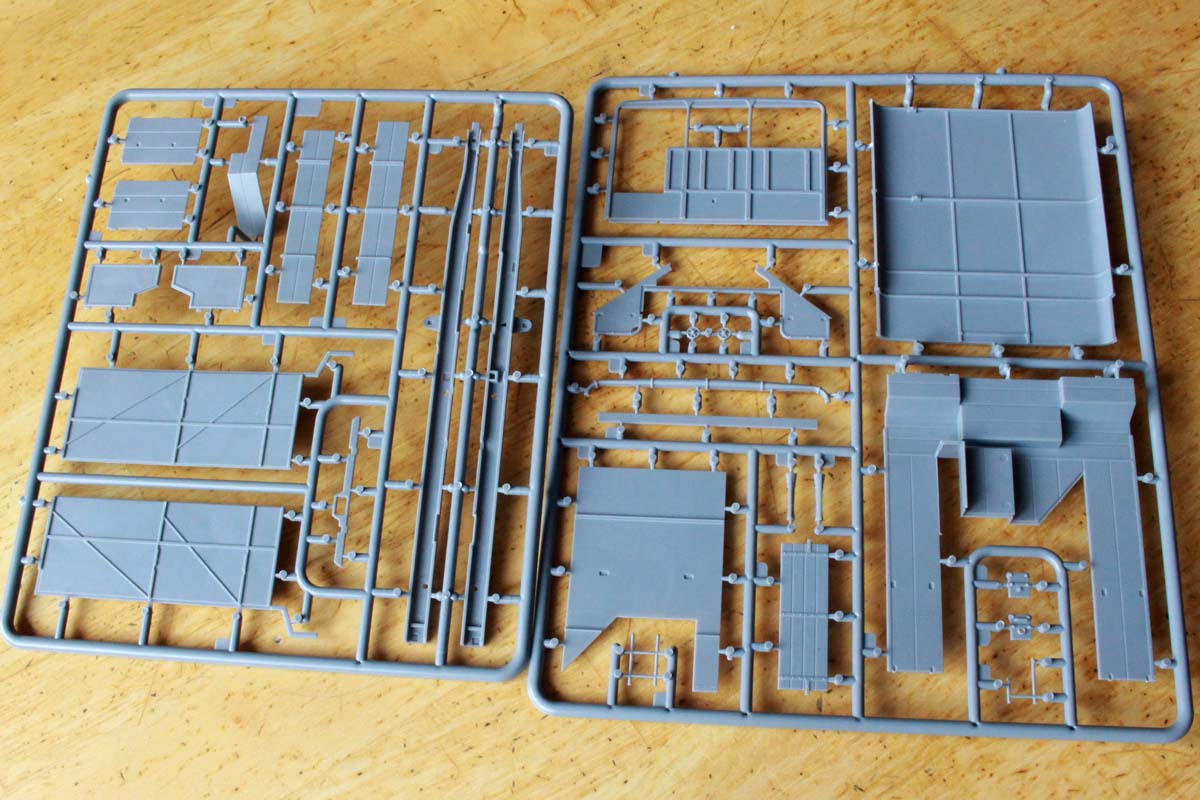

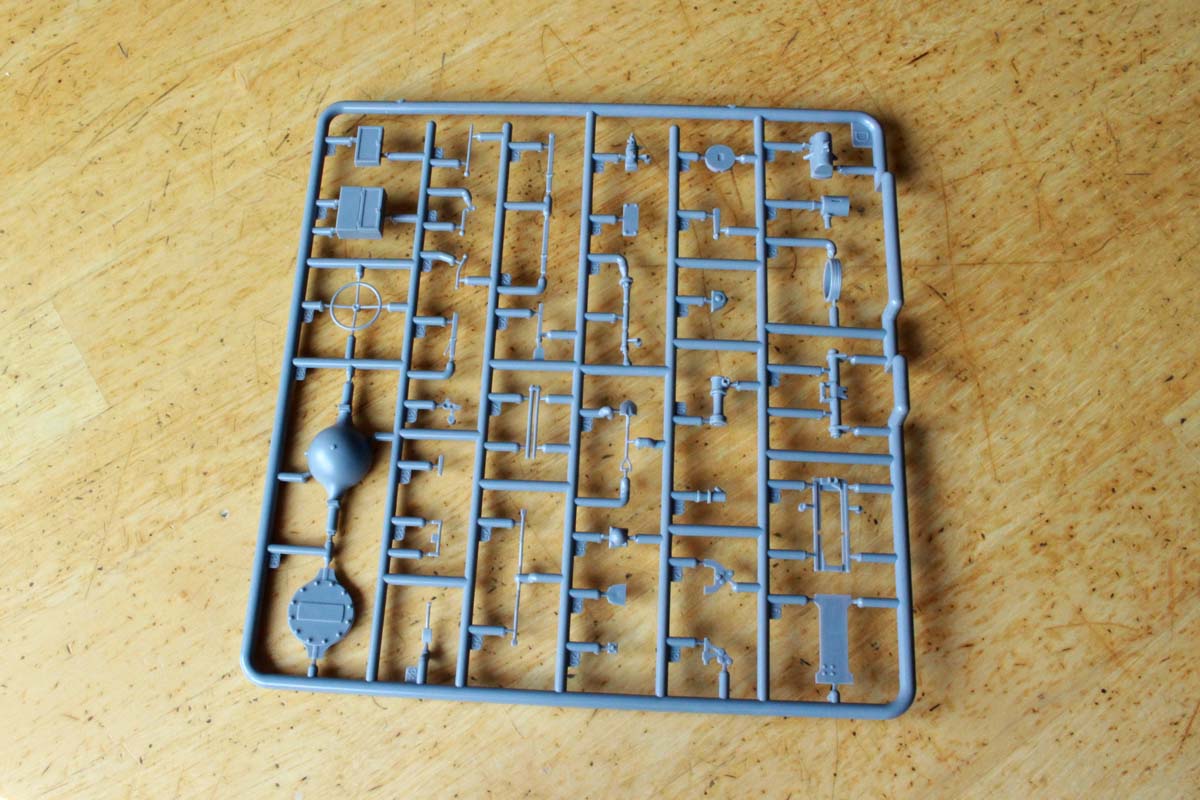

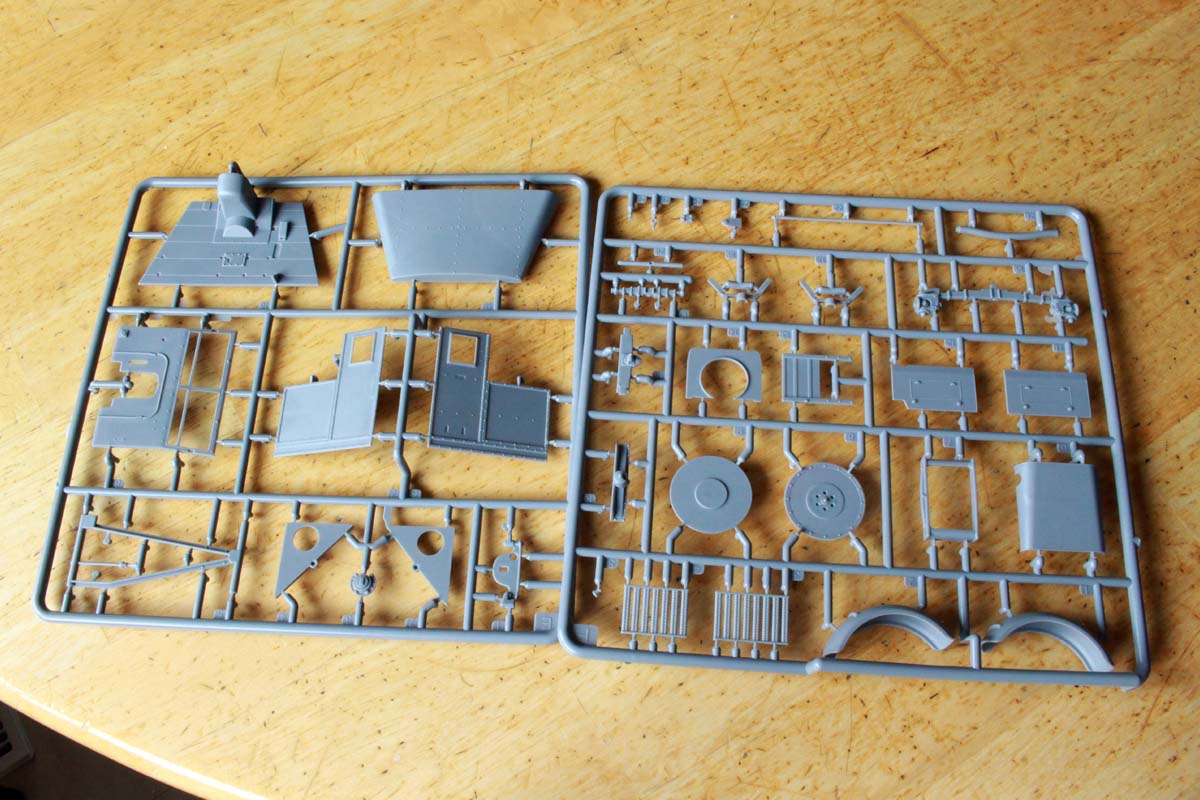

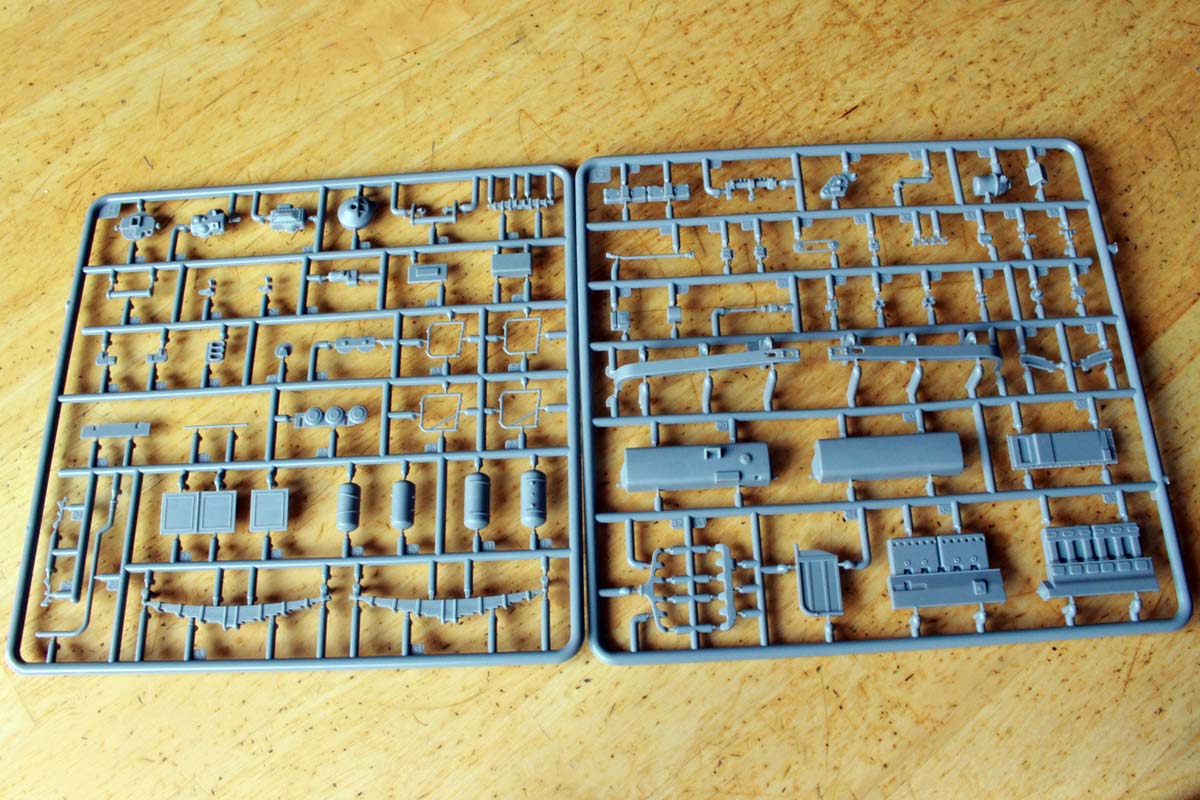

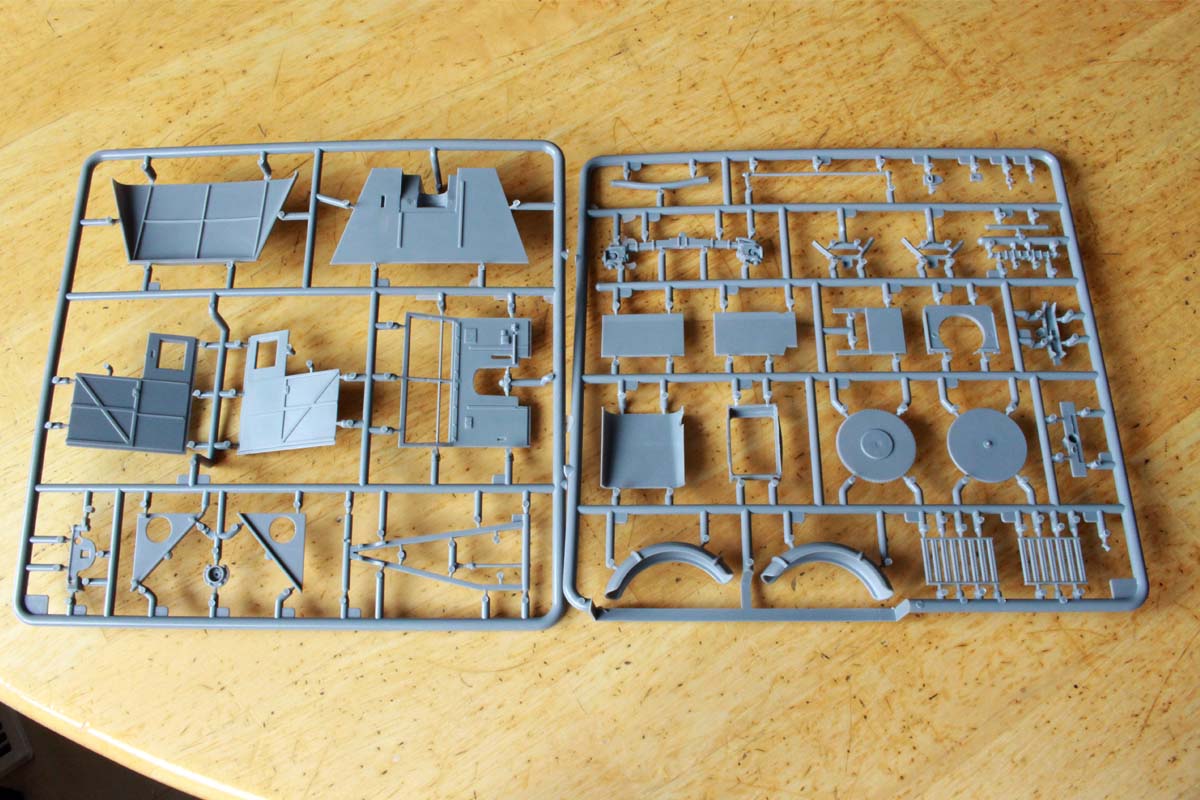

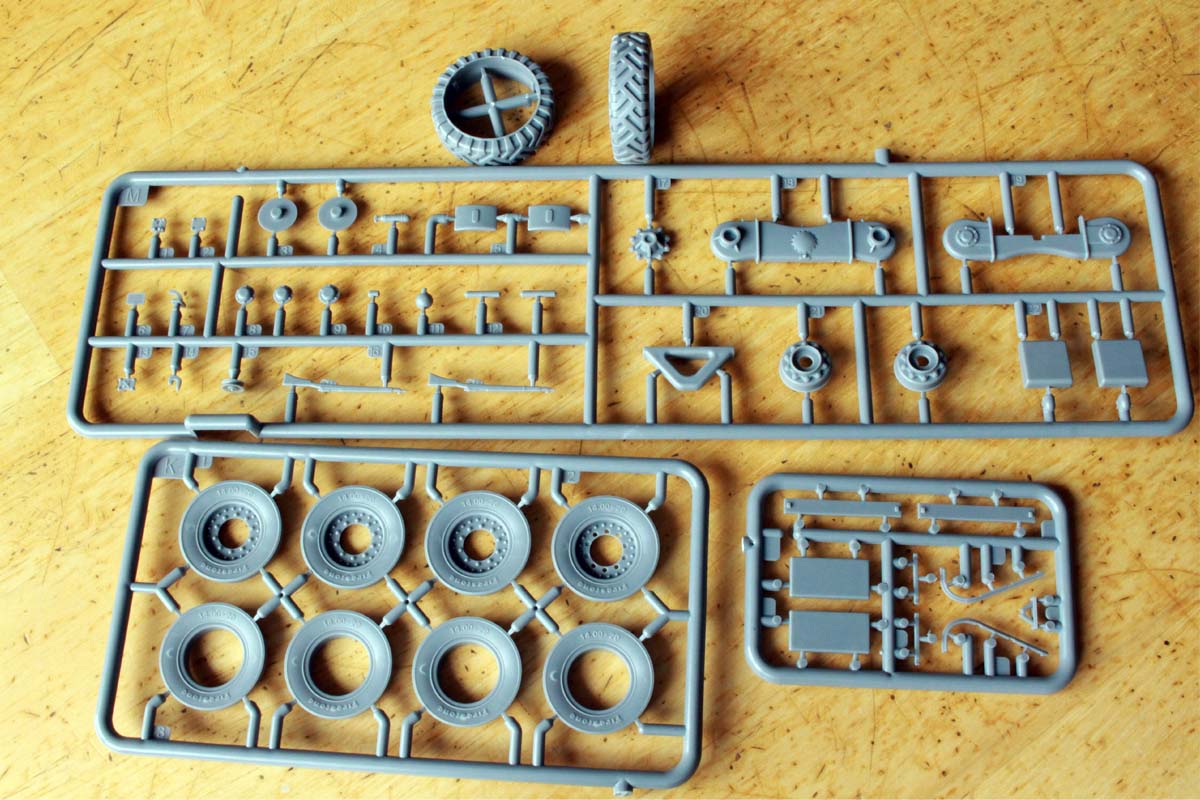

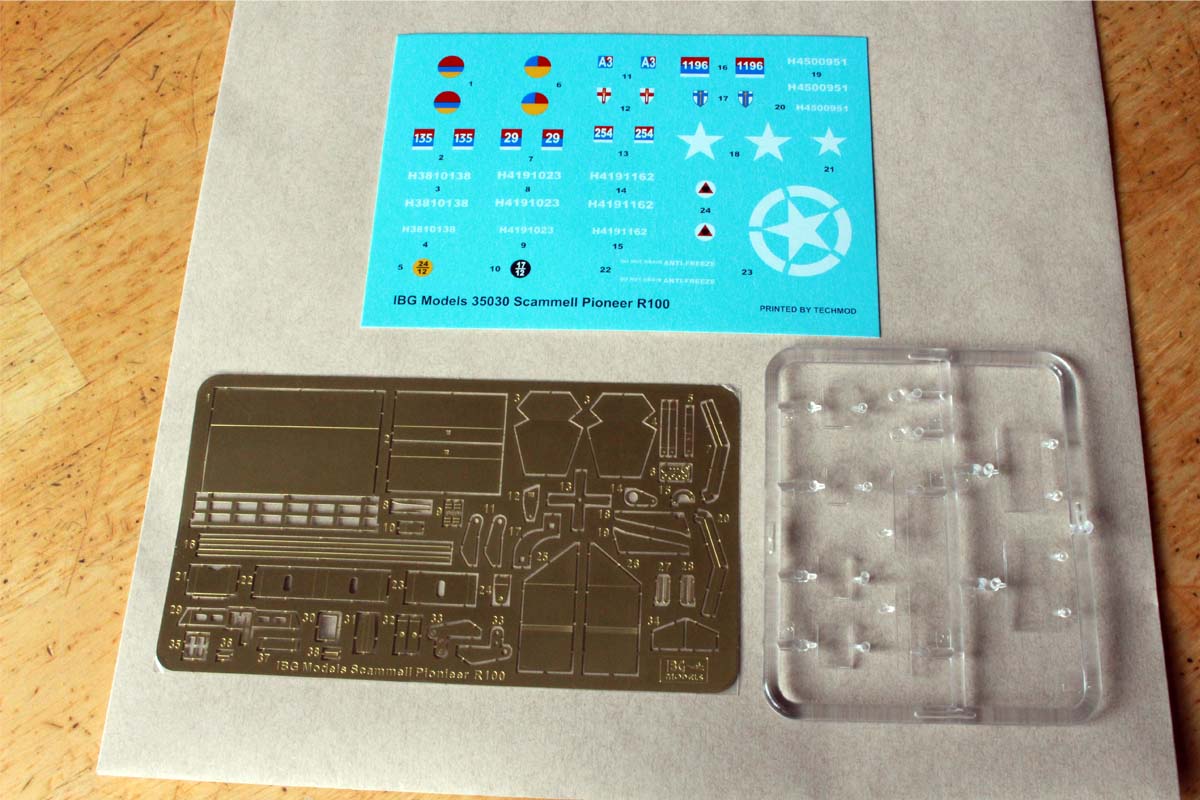

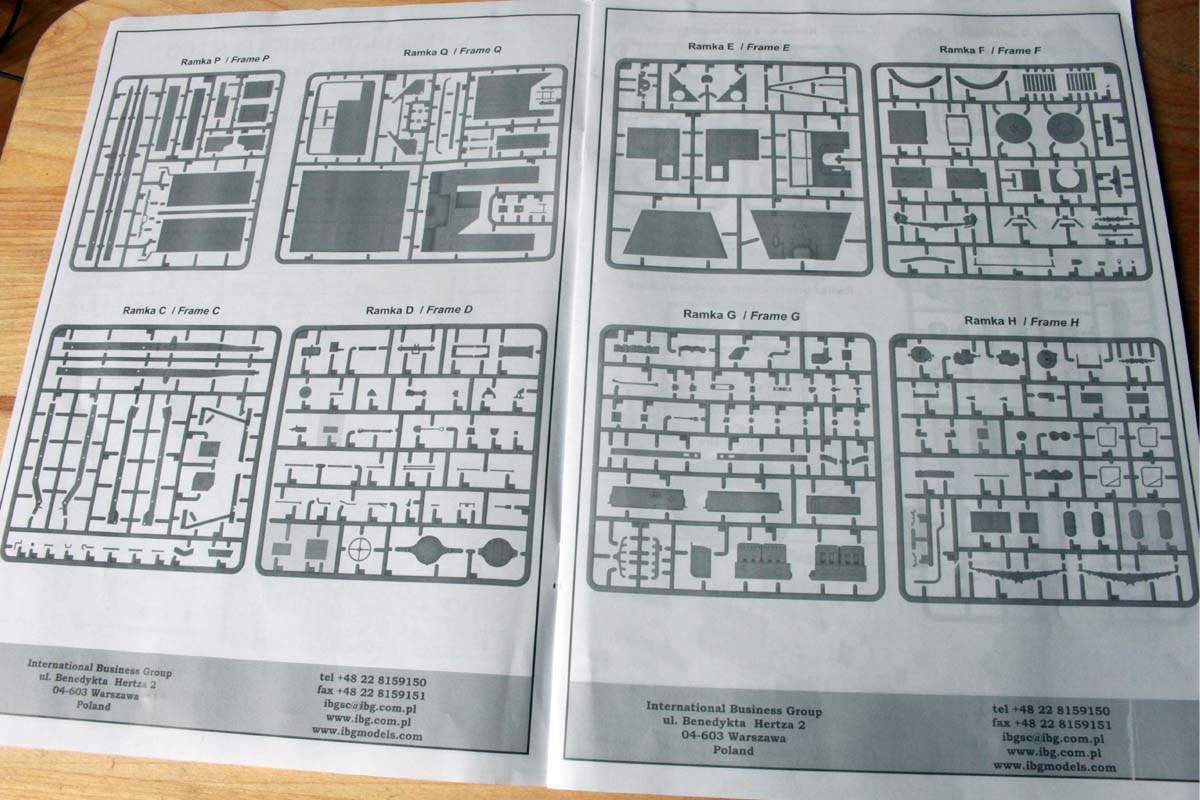

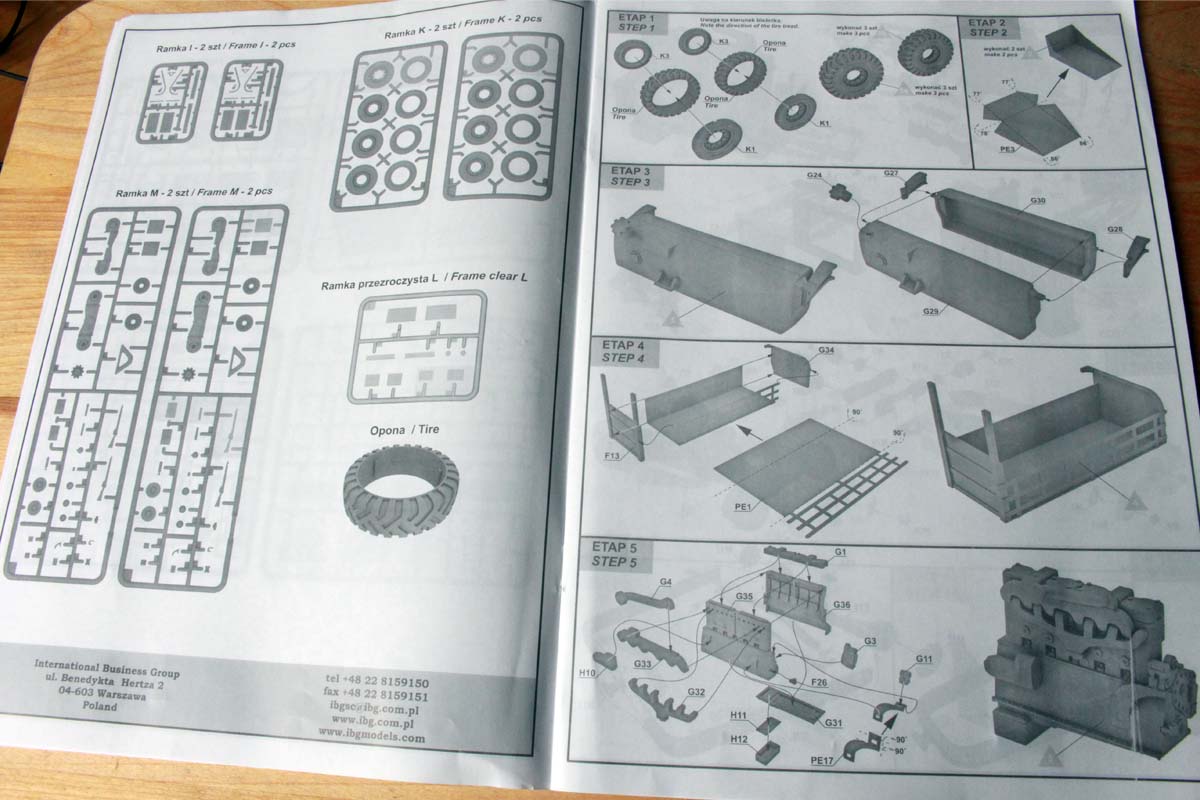

This all new 1/35 kit from IBG Models share sprues with IBG's other Scammell variants and comes in a sizable size box with the excellent box art we have come to associate with kits from IBG. Inside the box you are fourteen sprues moulded in a light grey plastic (including three doubled up sprues), one clear sprue and six tires moulded in the same light grey plastic. There is a total of 299 parts plus a brass photo-etched fret with another 51 parts.

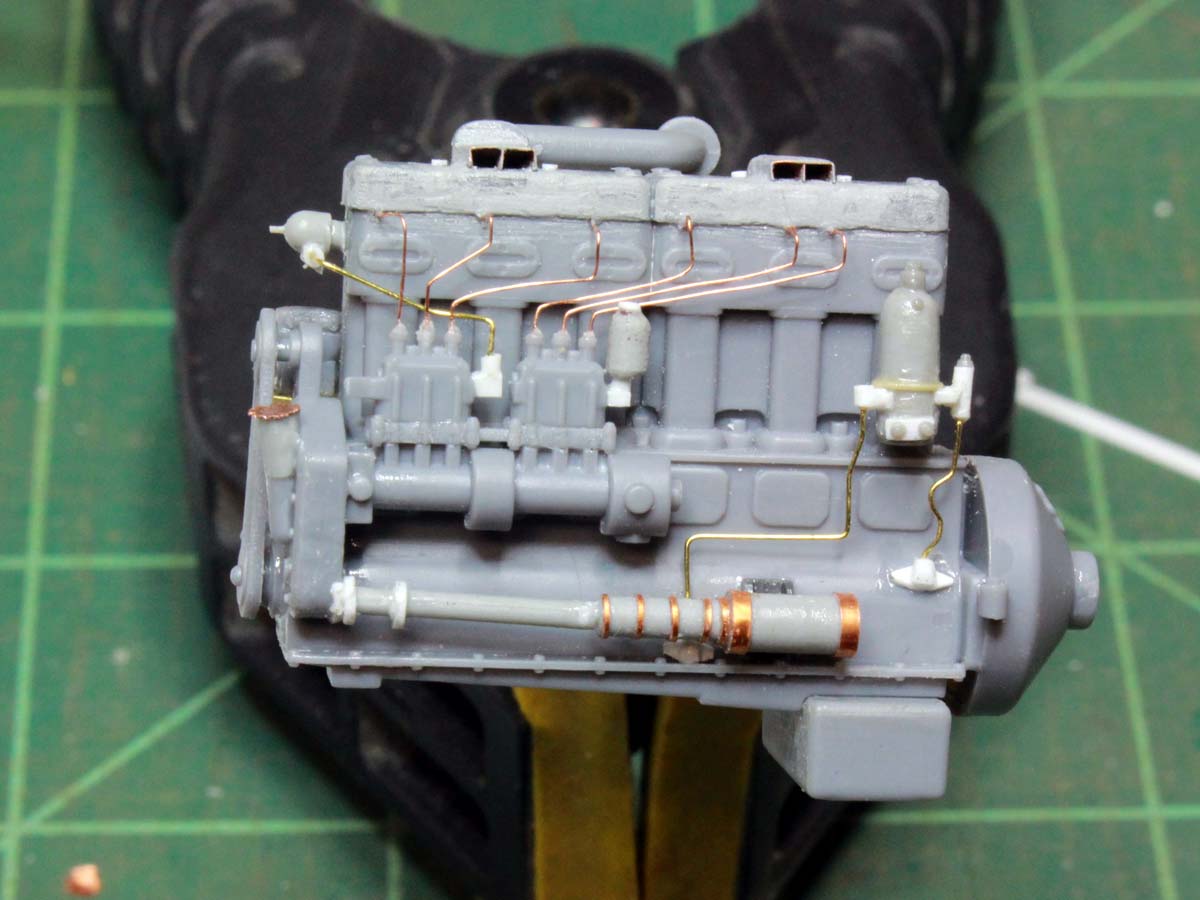

Overall casting quality looks excellent with some nice details, with very little in the way of flash or ejector pin marks. There are some tide marks in the plastic but these should not show through the paint.

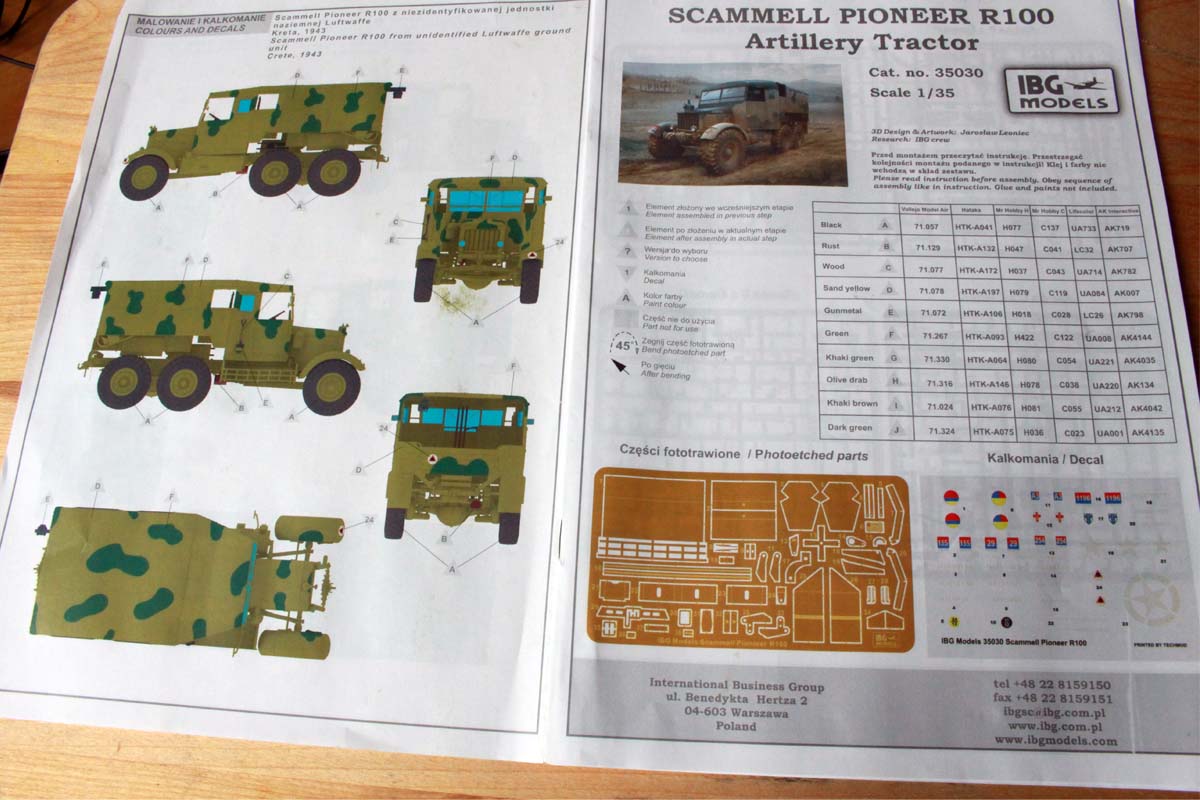

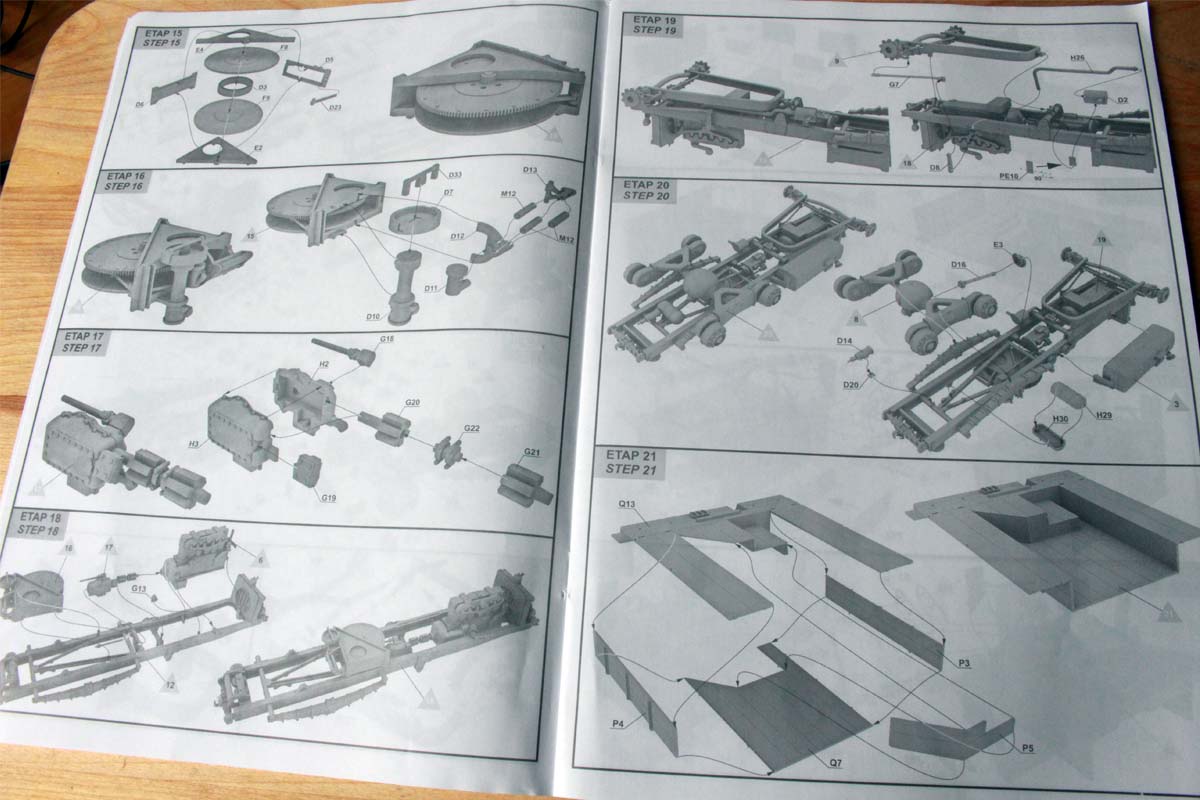

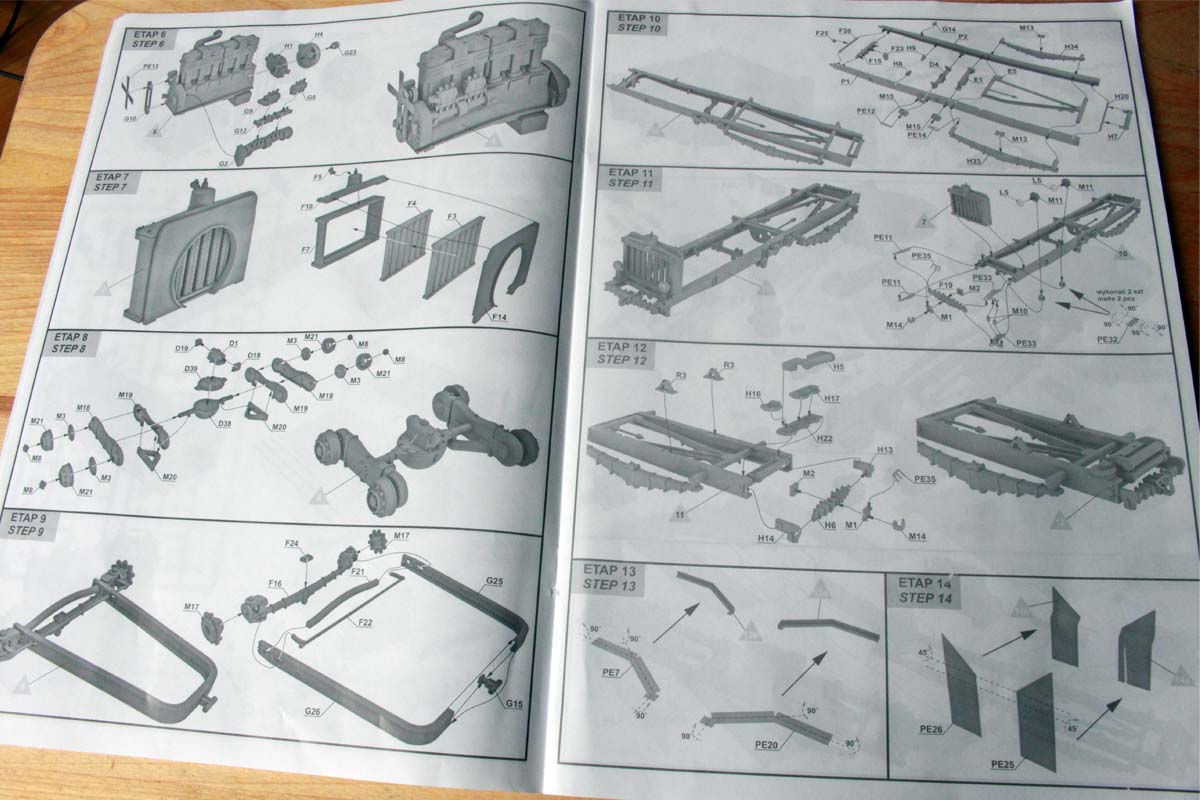

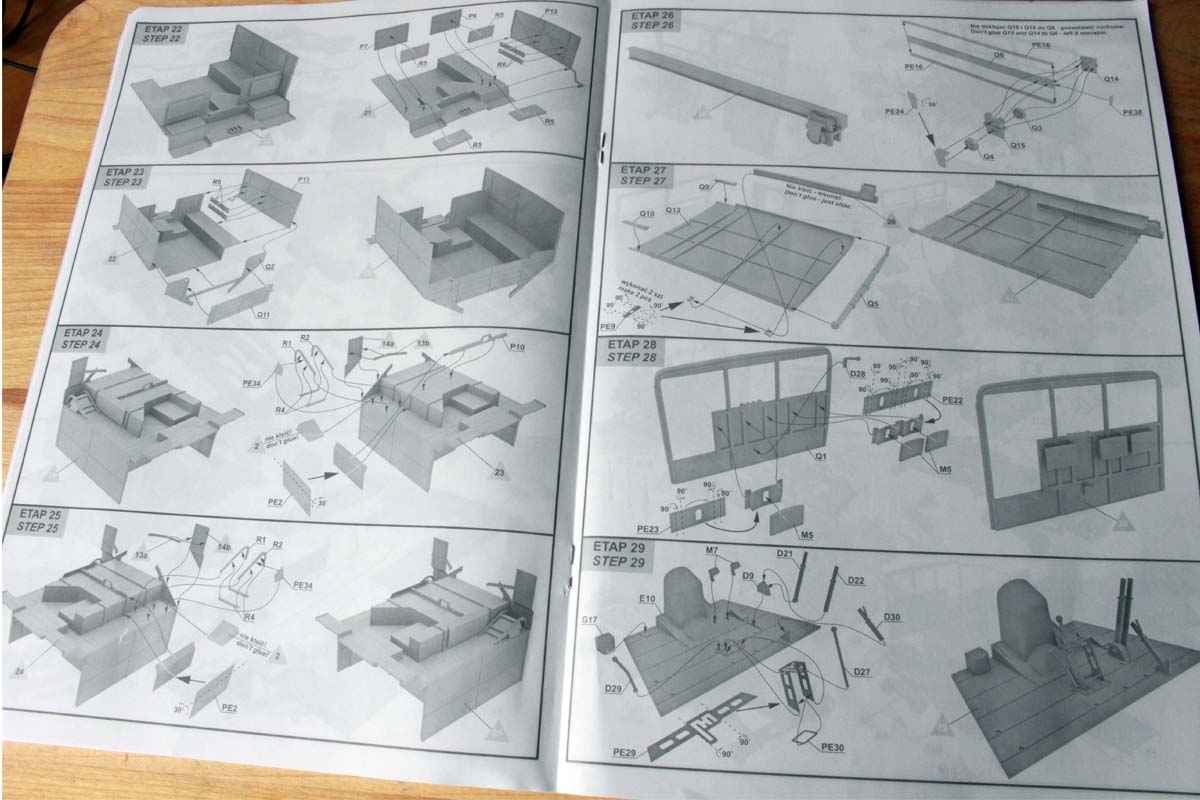

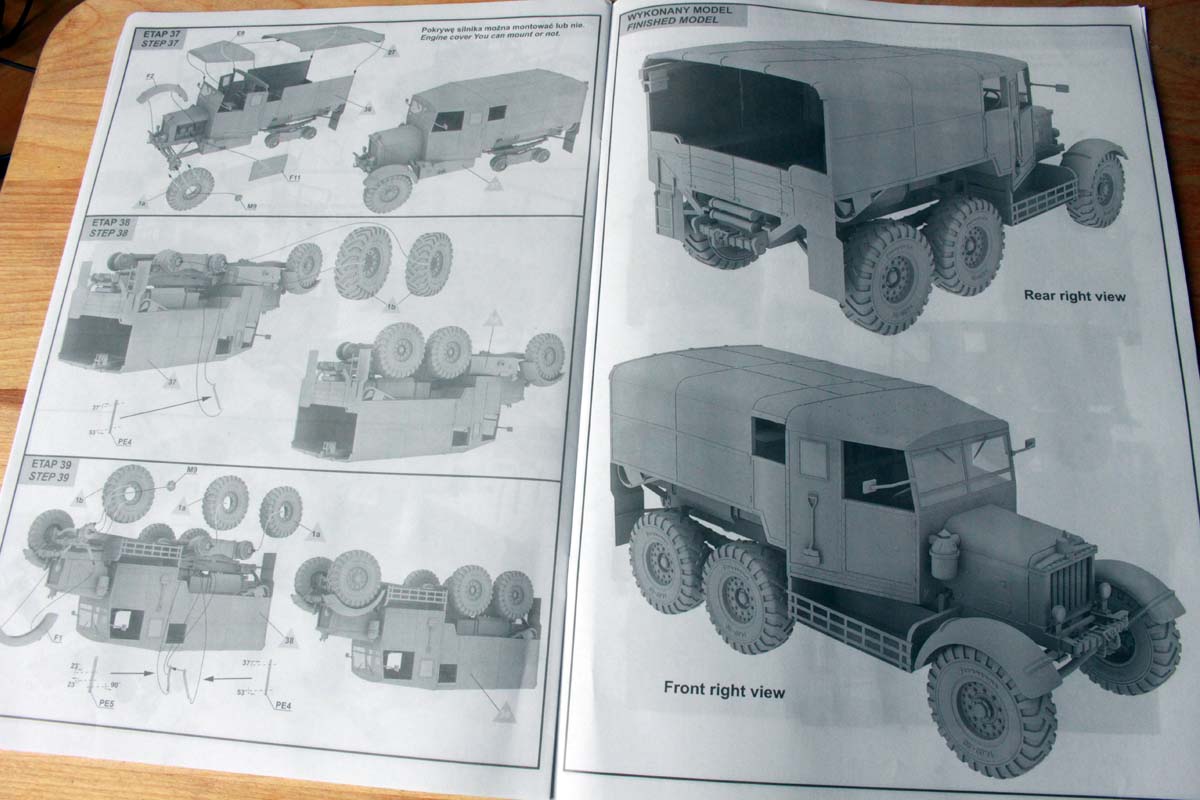

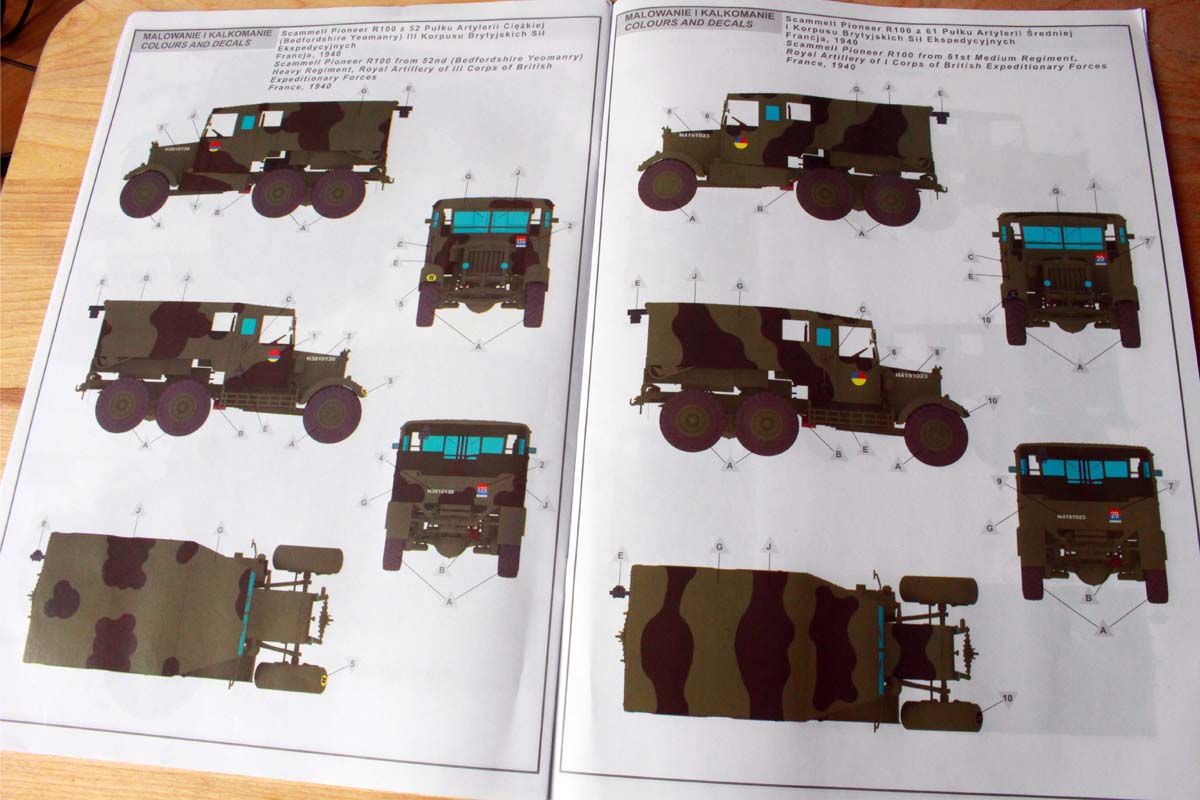

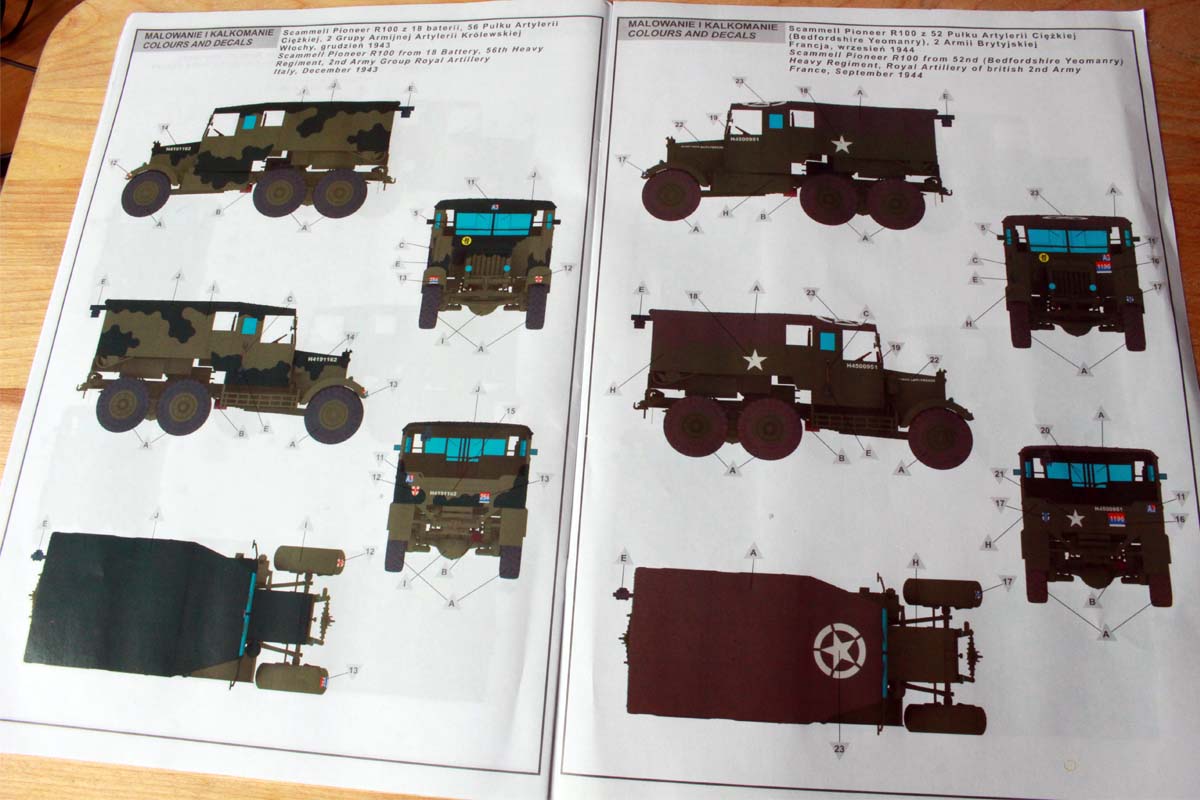

The instructions come in the form of an A4 glossy booklet with the construction broken down into 39 steps. At the rear of the instruction booklet are five paint schemes to choose from, and as a bonus, I had two complete decal sheets in my box.

1. Scammell Pioneer R100 from 52nd (Bedfordshire Yoemanry) Heavy Regiment, Royal Artillery of III Corps of British Expeditionary Forces, France, 1940.

2. Scammell Pioneer R100 from 61st Medium Regiment, Royal Artillery of I Corps of British Expeditionary Forces, France, 1940.

3. Scammell Pioneer R100 from 18 Battery, 56th Heavy Regiment, 2nd Army Group of Royal Artillery Italy, December 1943.

4. Scammell Pioneer R100 from 52nd (Bedfordshire Yoemanry) Heavy Regiment, Royal Artillery of British 2nd Army, France, September 1944.

5. Scammell Pioneer R100 from an unidentified Luftwaffe ground unit, Crete, 1943.

Paint references are supplied for Vallejo Model Air, Hataka, Mr Hobby (H & C), Lifecolor, and AK Interactive.

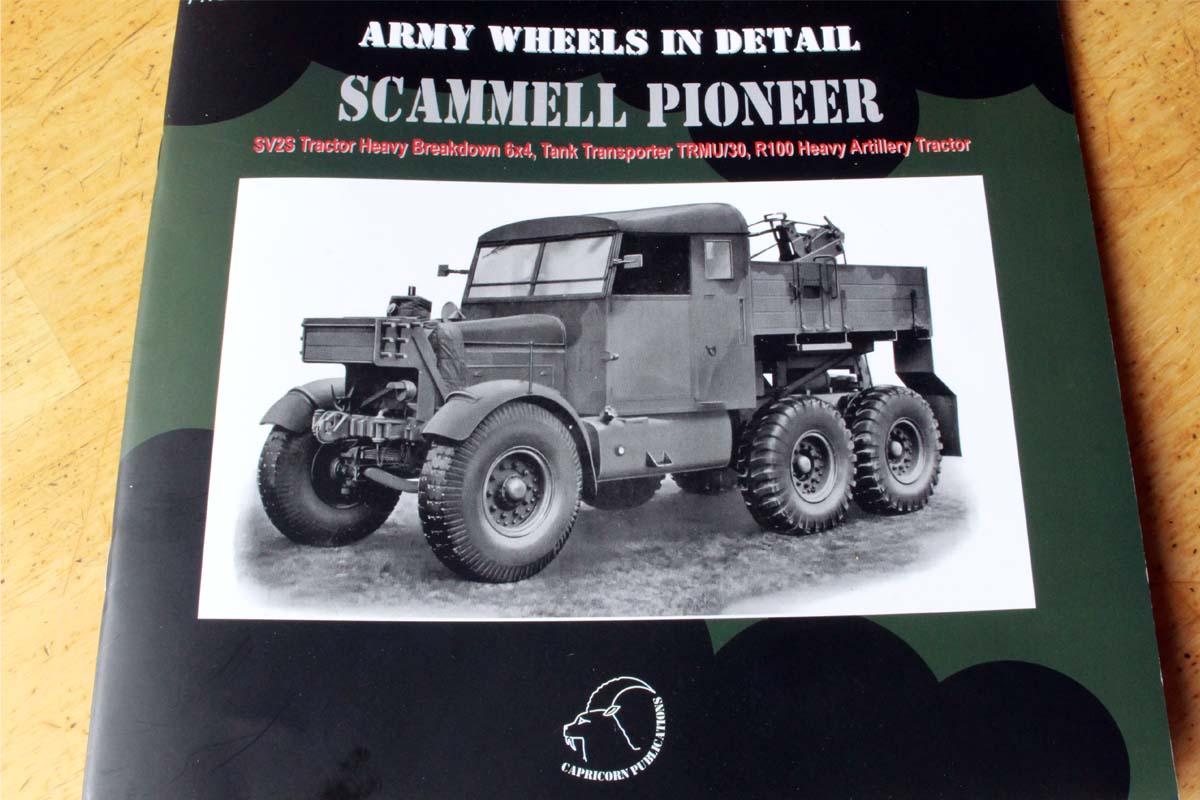

I also have this little gem to assist me:

Hopefully as I go through this I will be able to point out any accuracy or assembly issues. Stay tuned!