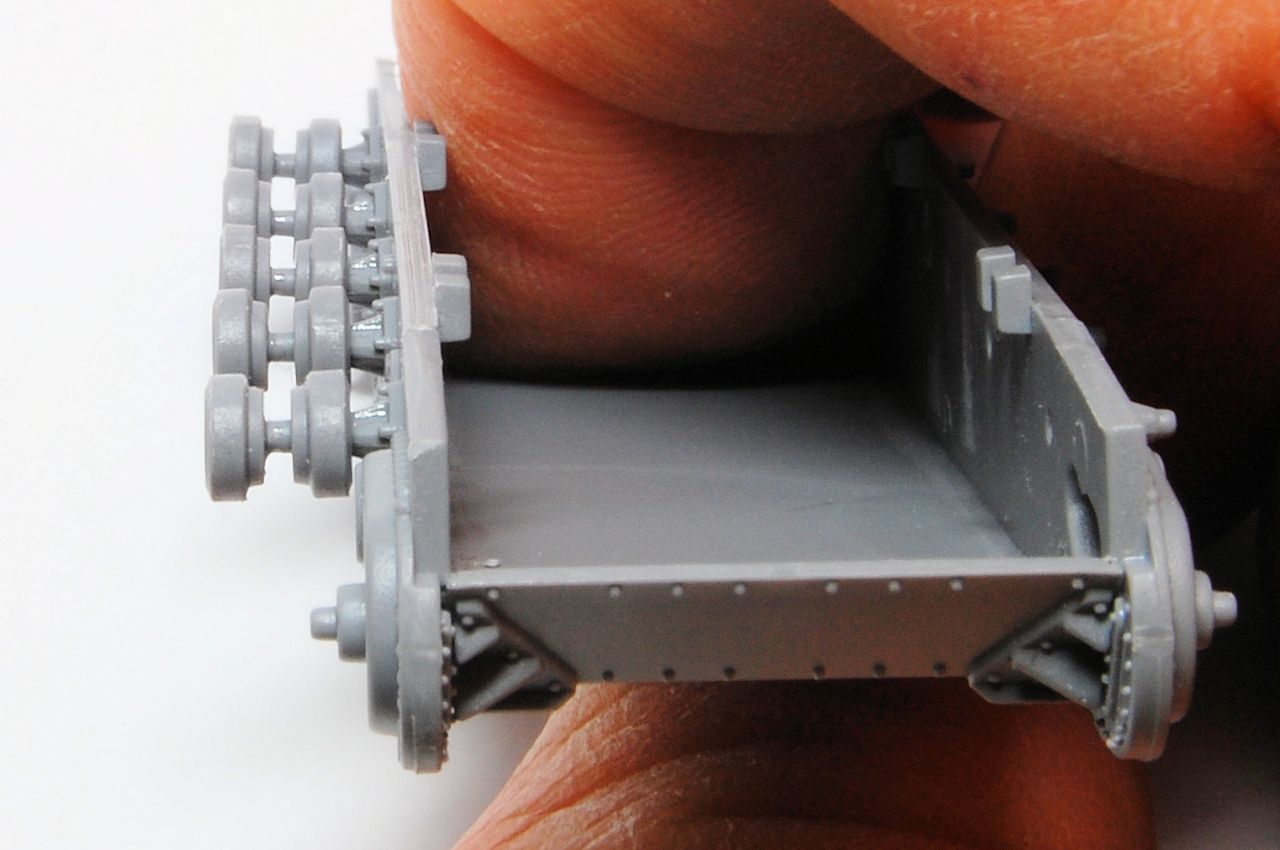

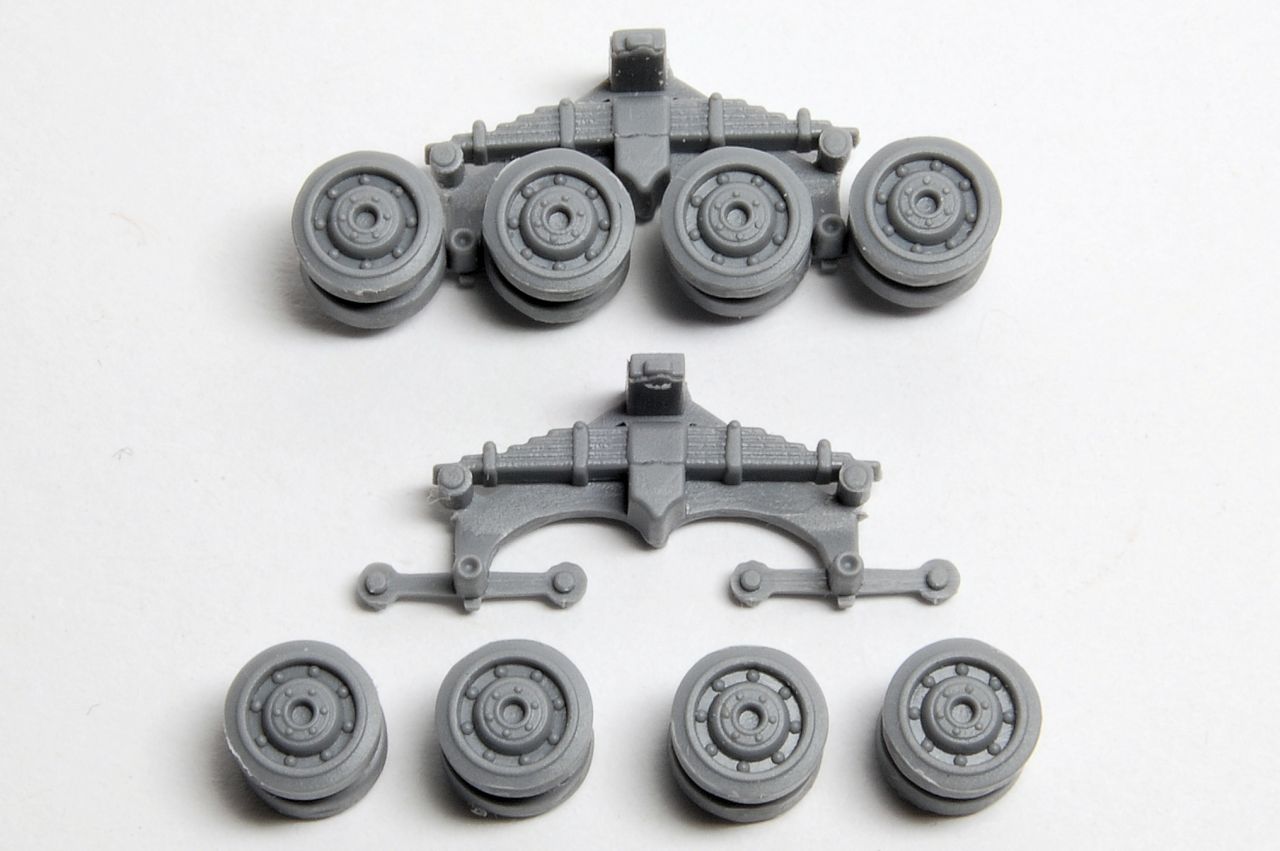

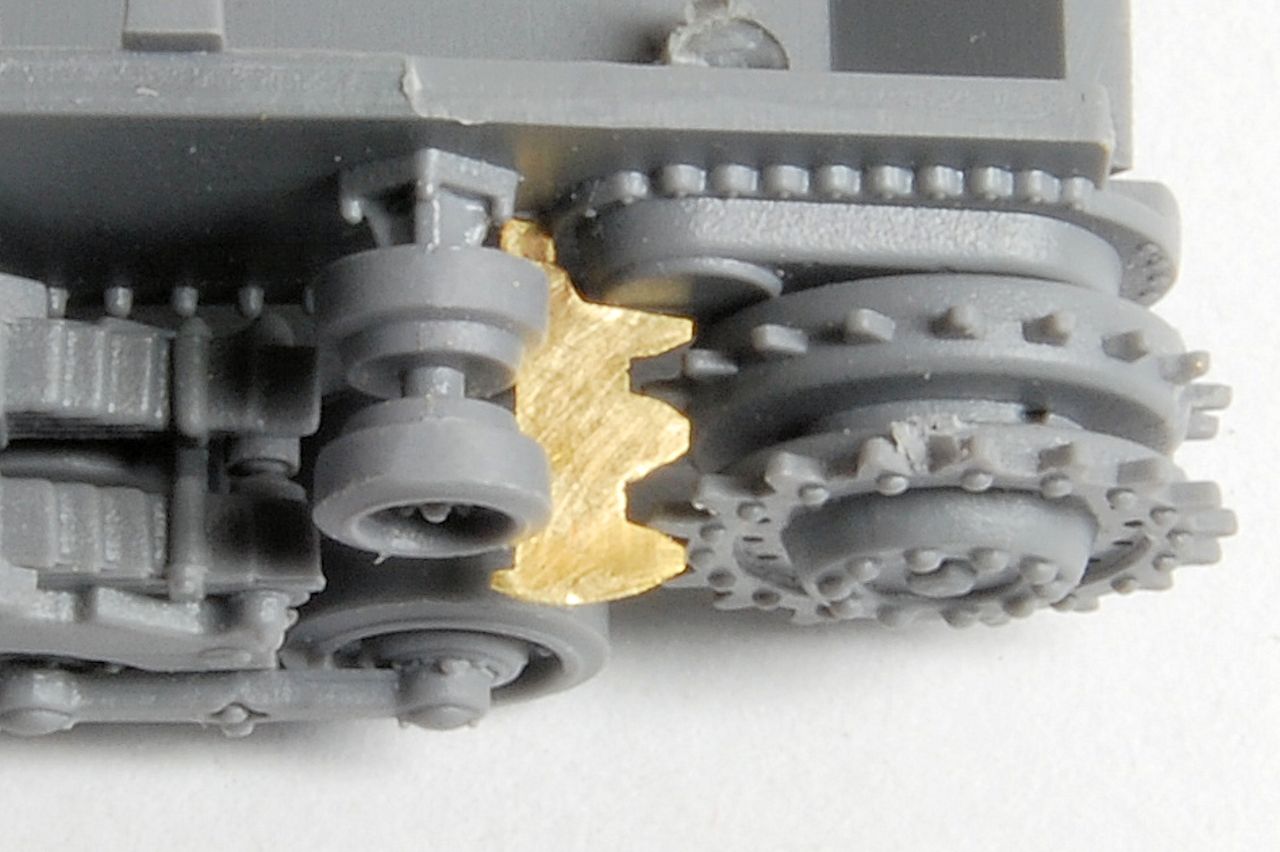

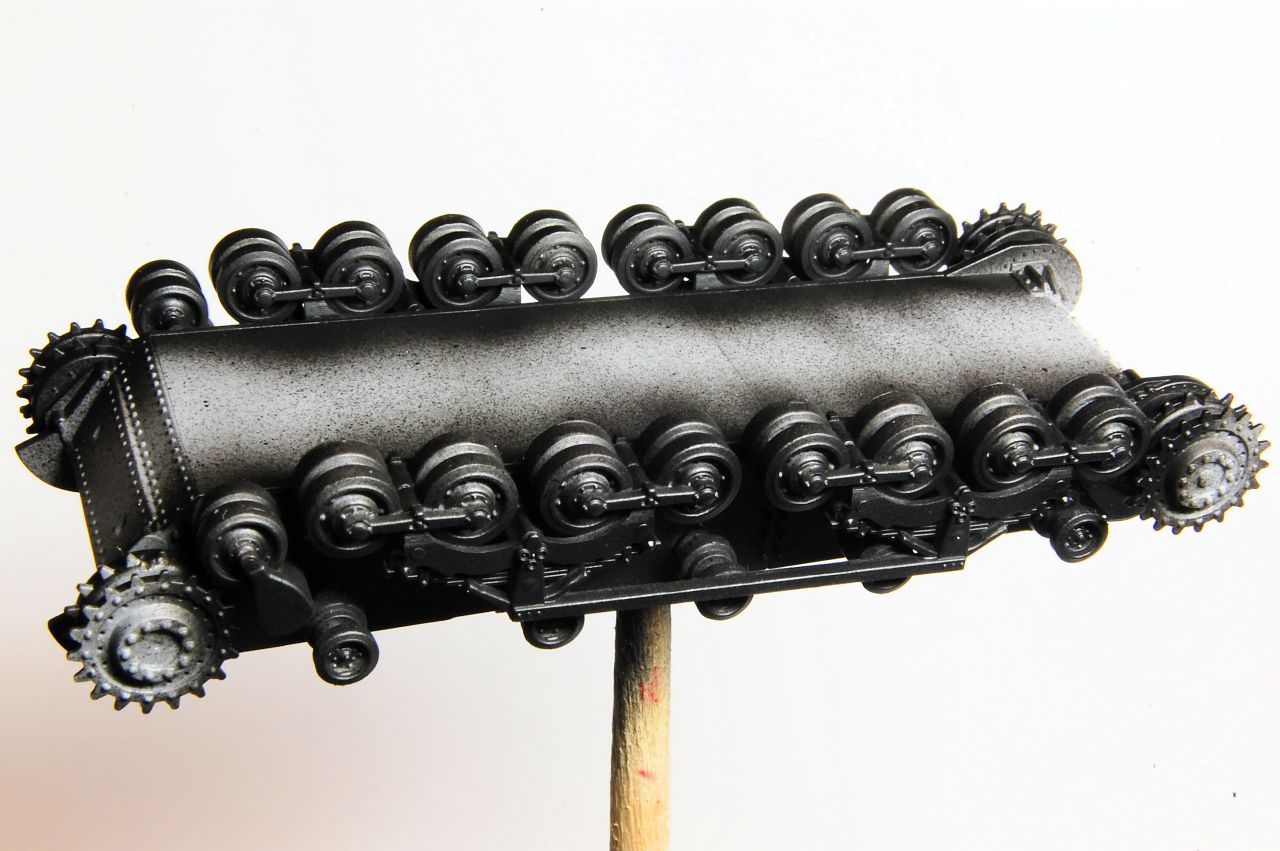

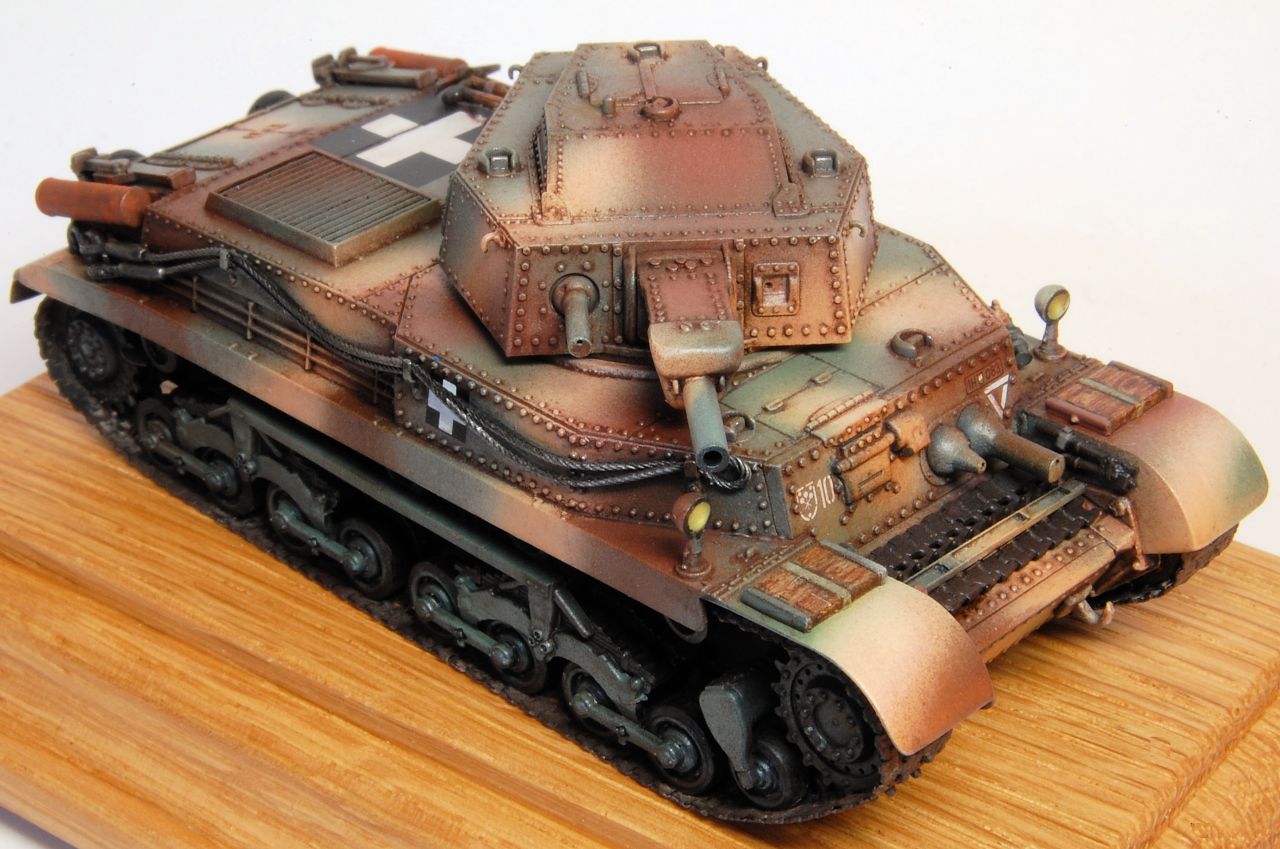

This is a review blog of IBG's 1/72 scale Hungarian Medium Tank 41.M Turan II, kit no. 72048, which was supplied to Armorama as a review sample. This tank is notable for having a quite complex suspension which I've built up twice already in small scale - IBG's 1/72 Turan I (reviewed here) and Zrinyi (reviewed here) - as well being most of the way through Bronco's 1/35 version (blogged here), so in for a penny, in for a pound (or should that be in for a filler, in for a forint??)...

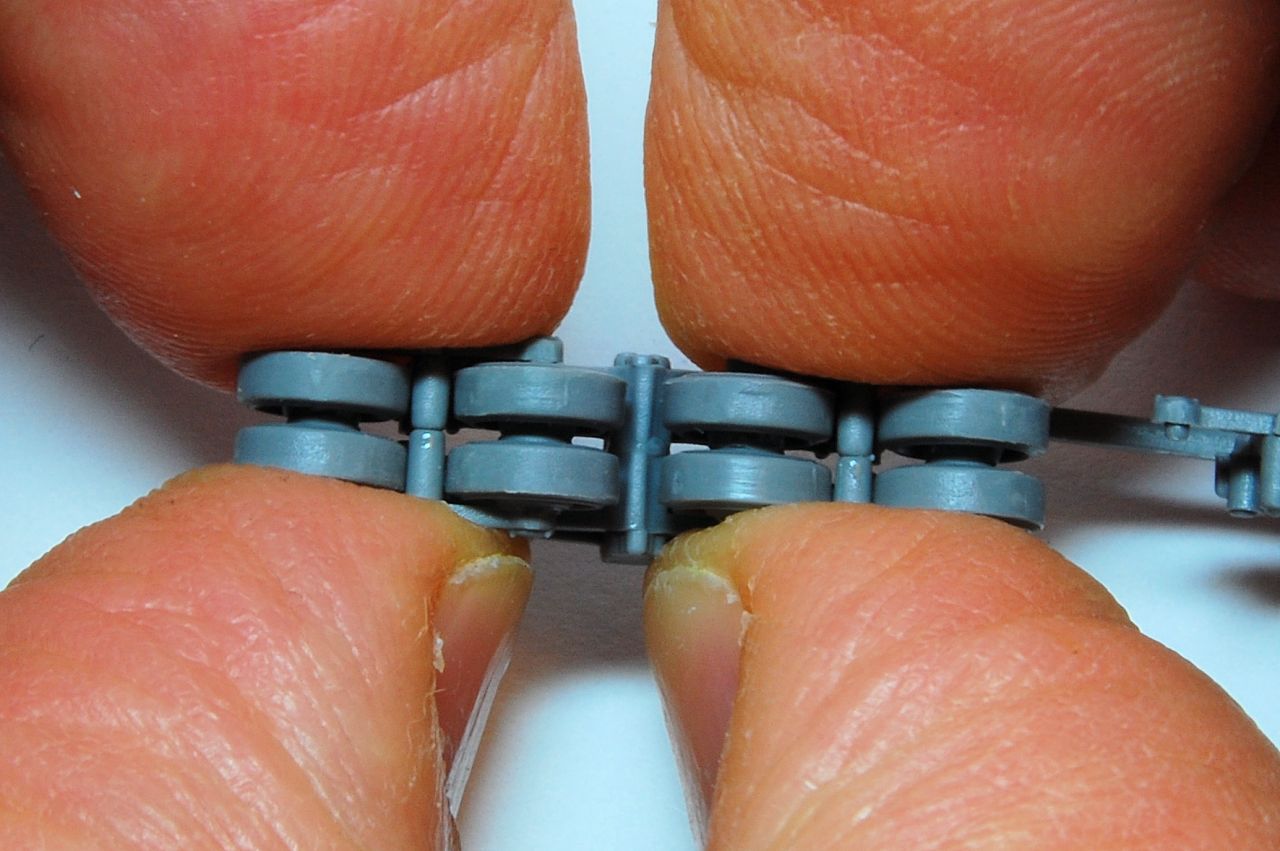

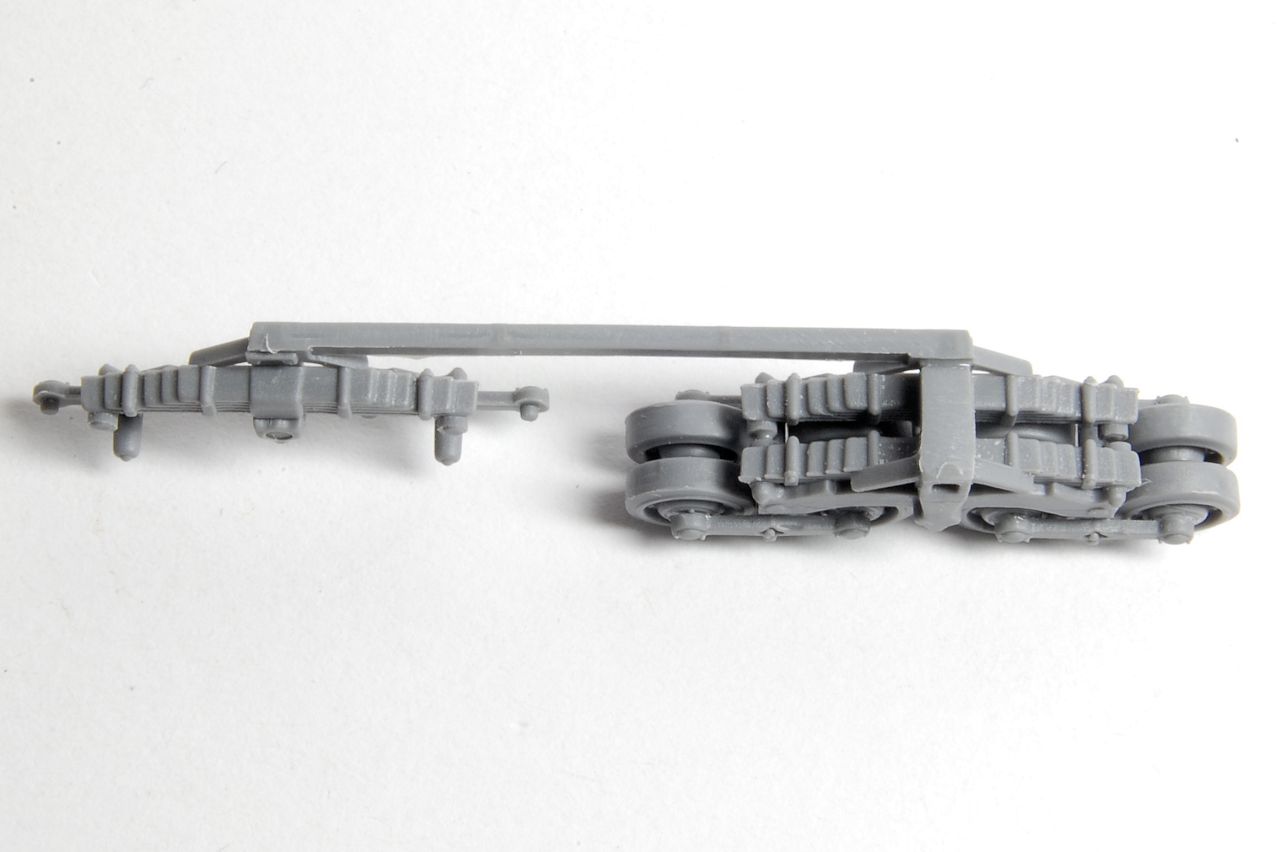

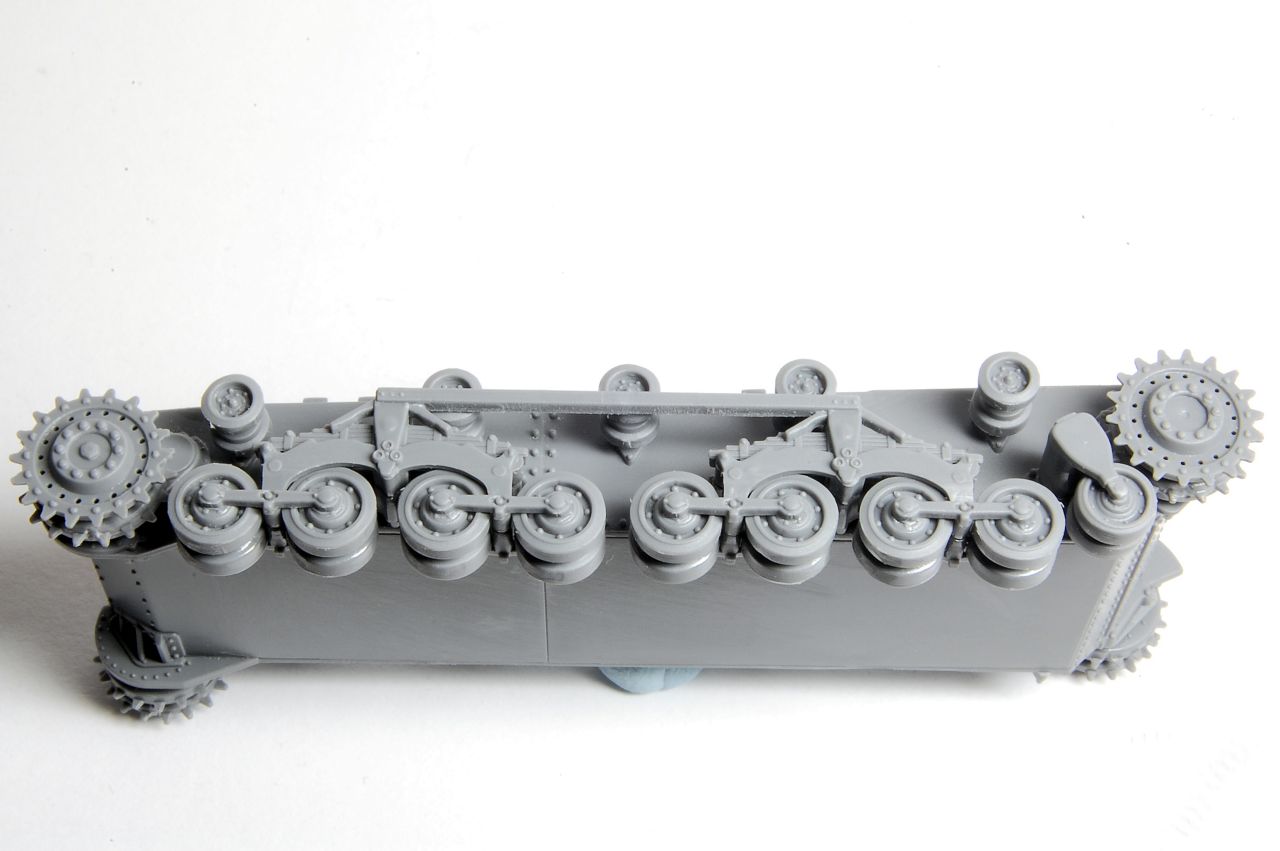

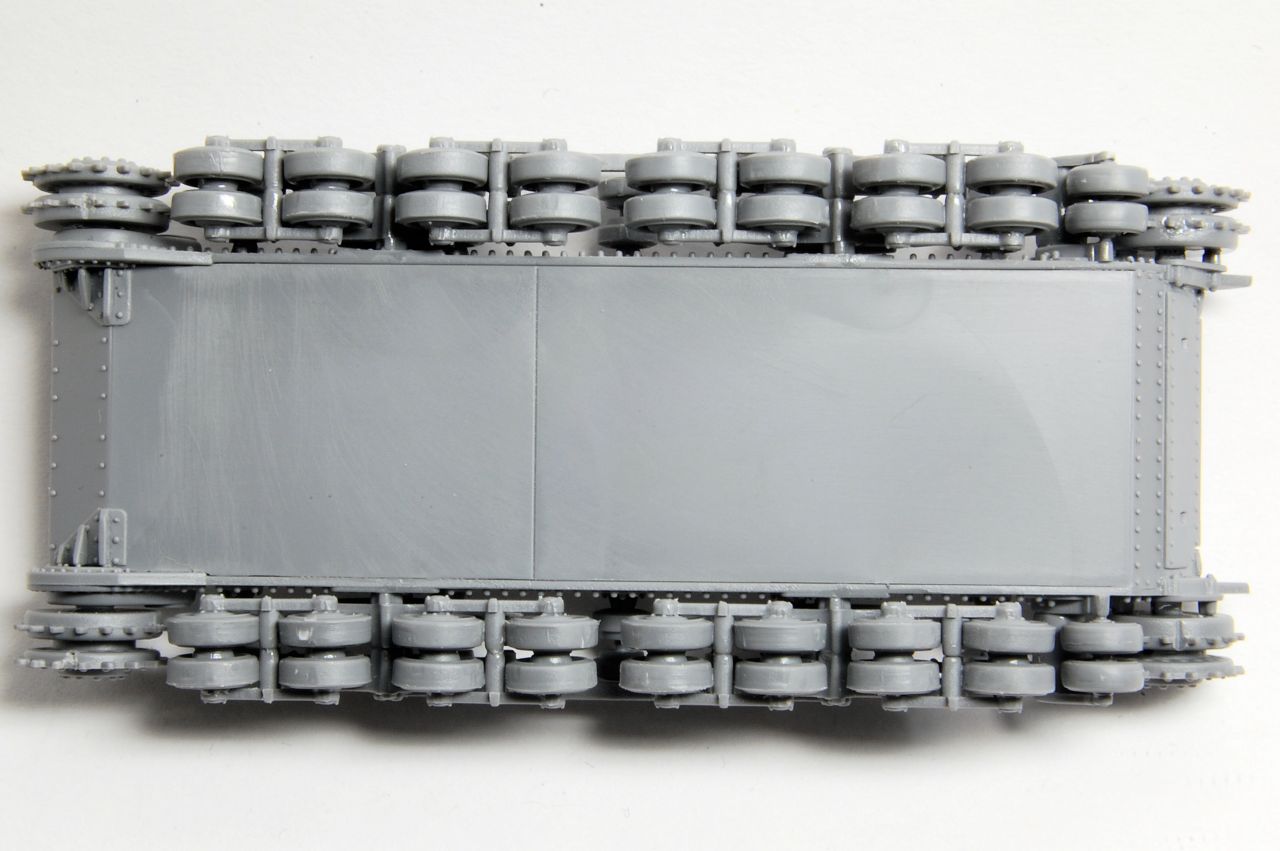

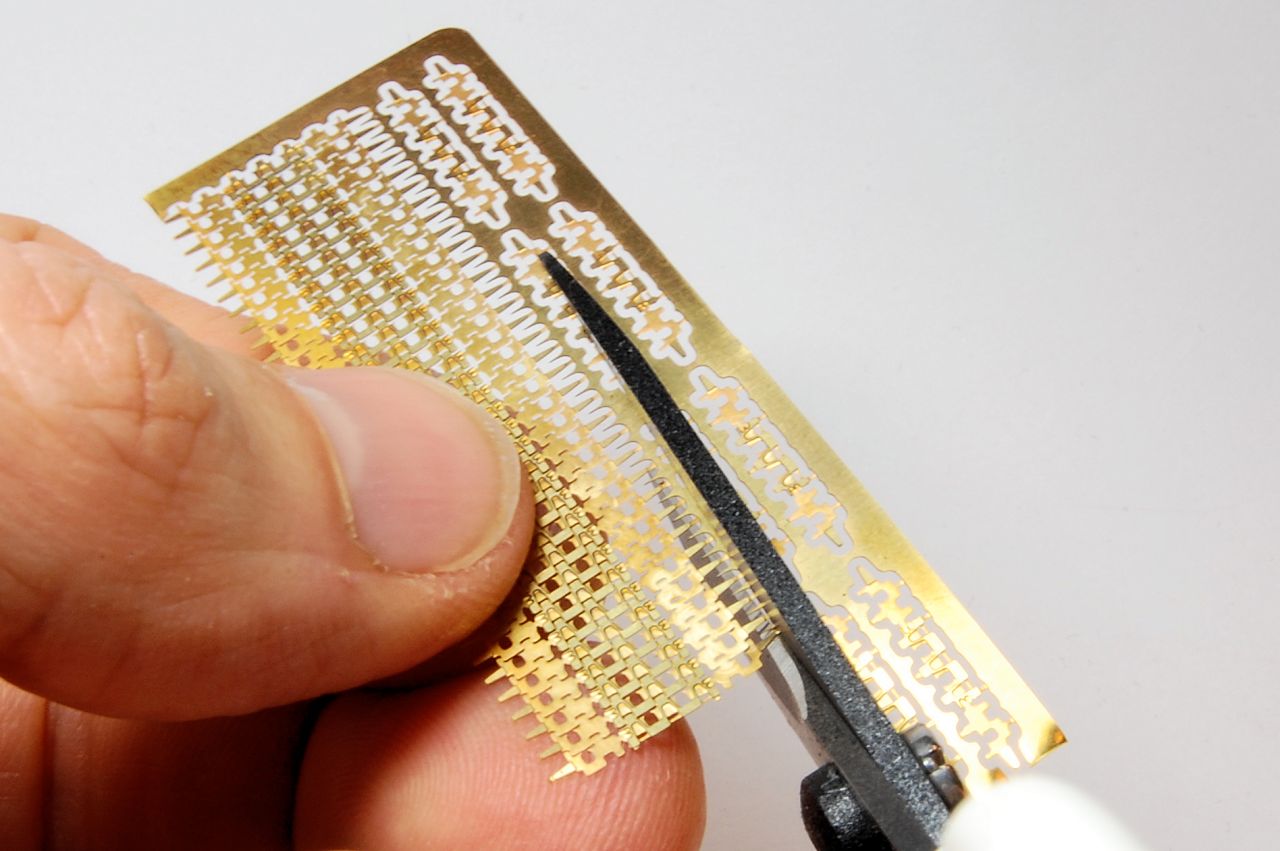

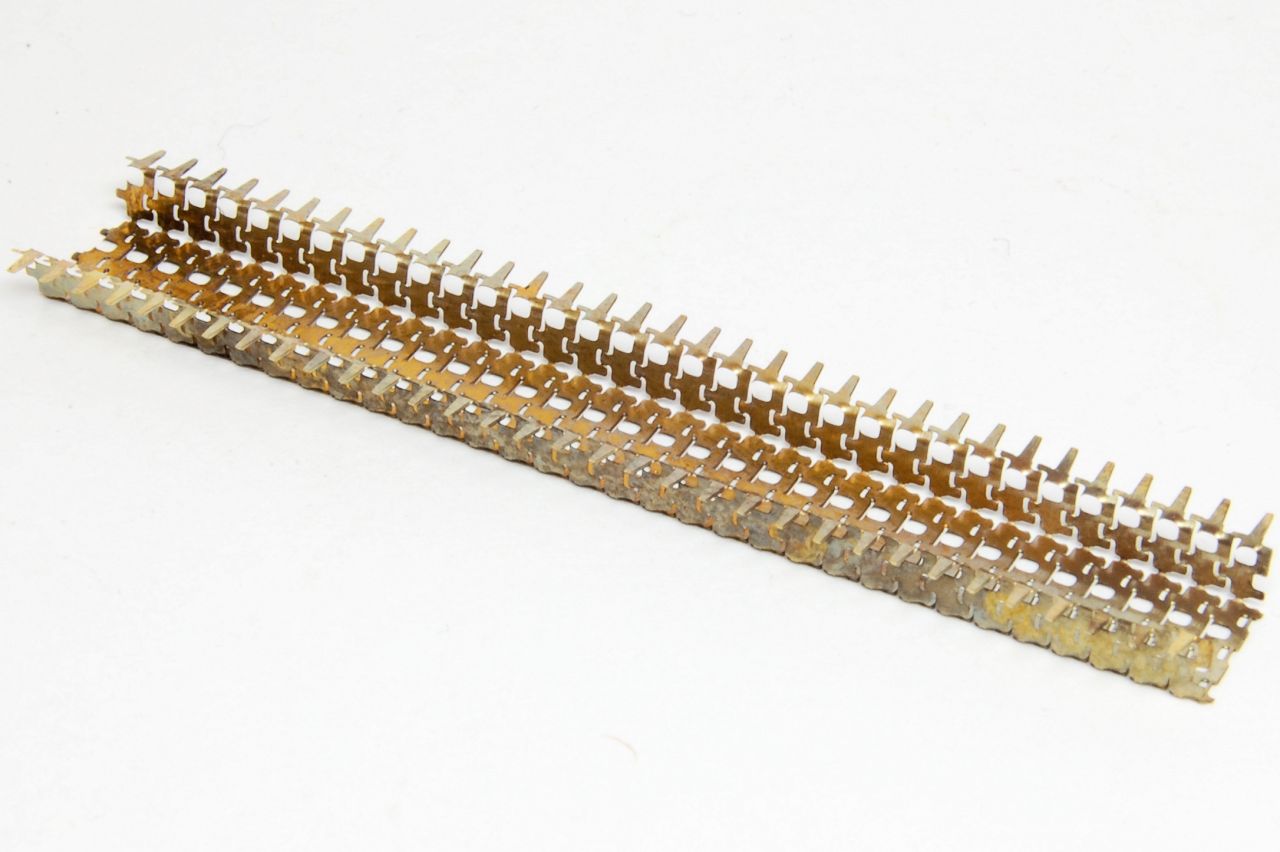

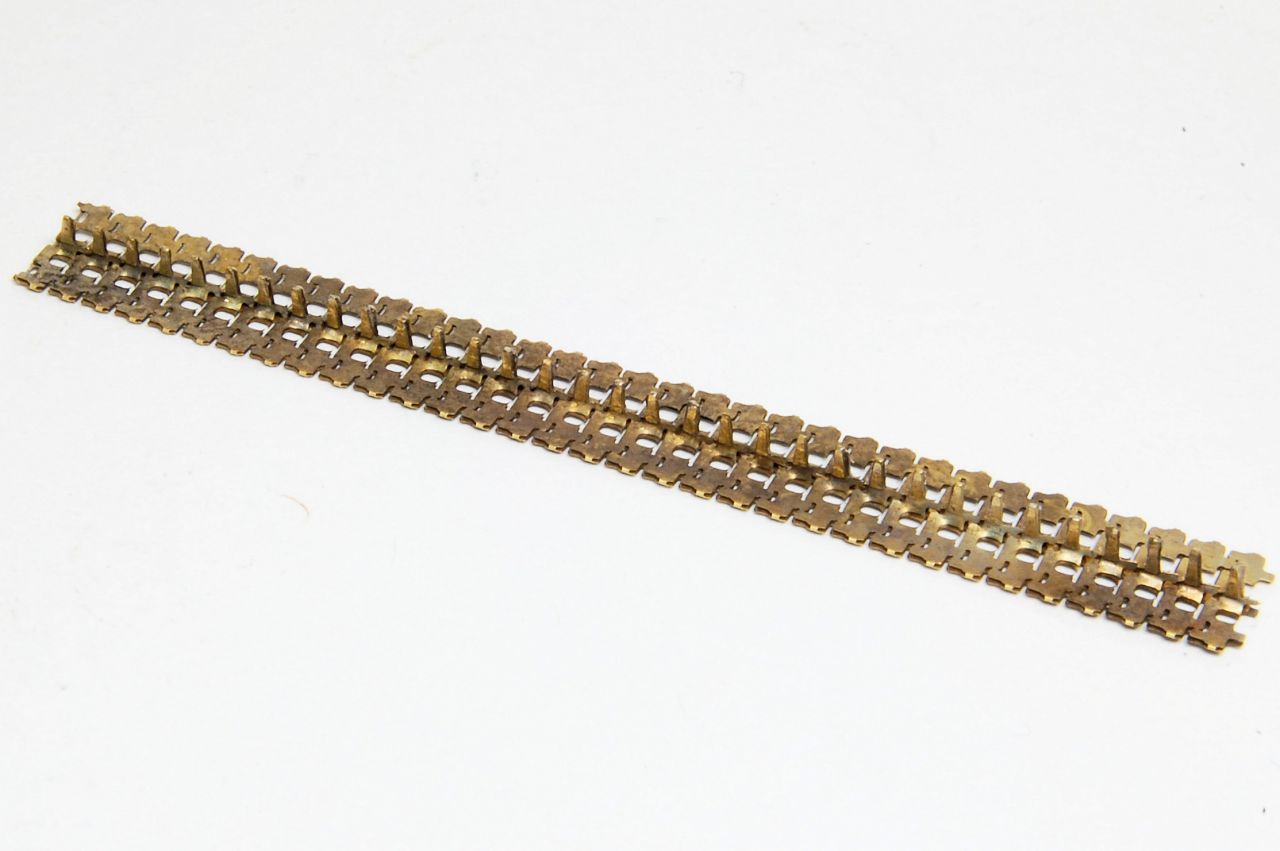

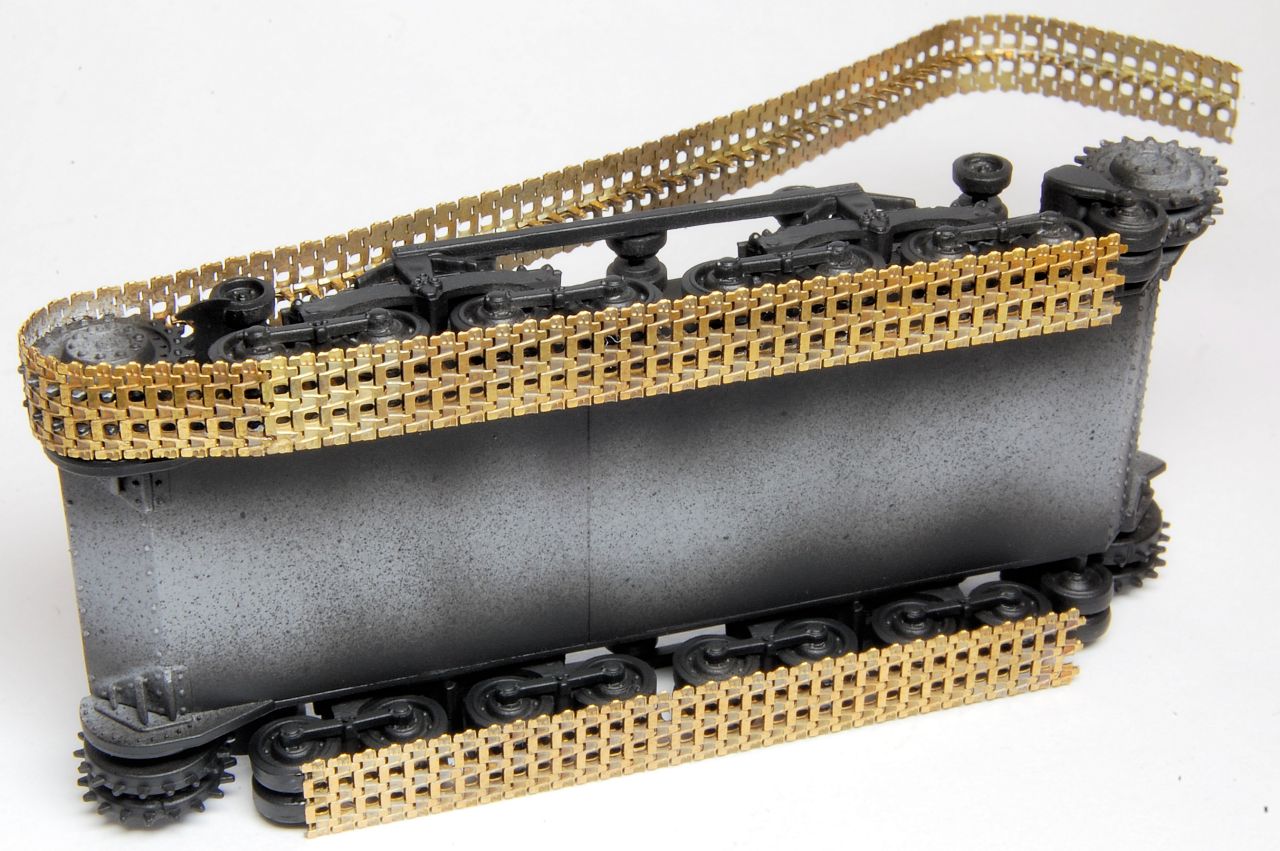

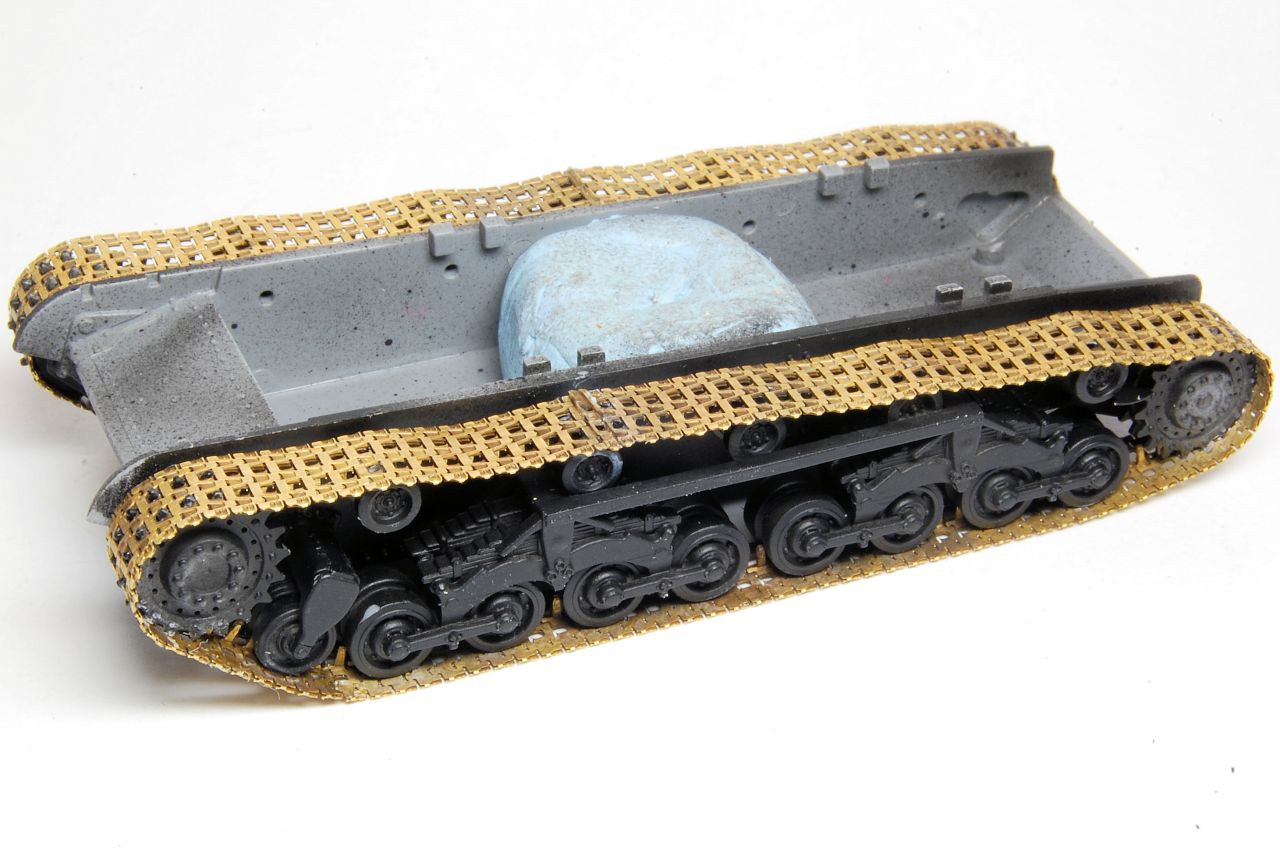

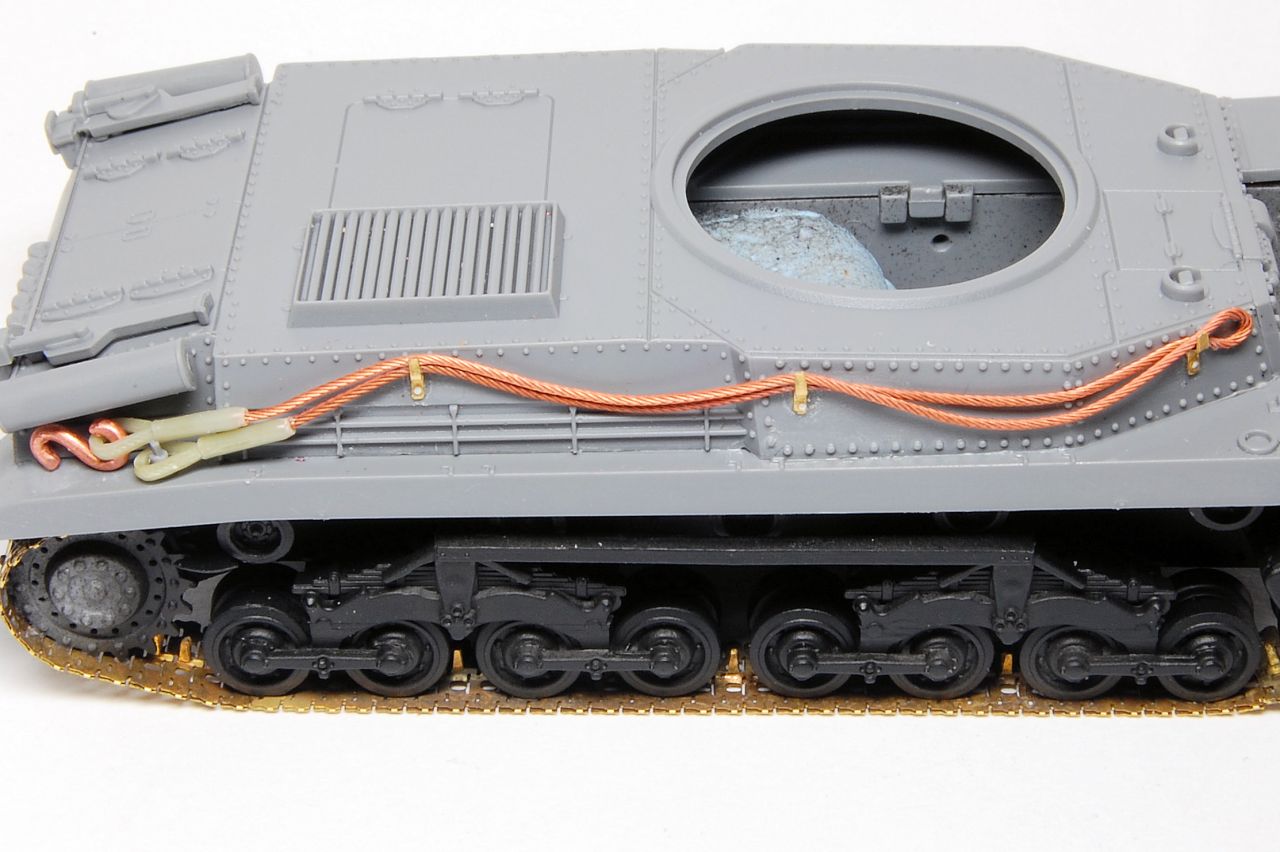

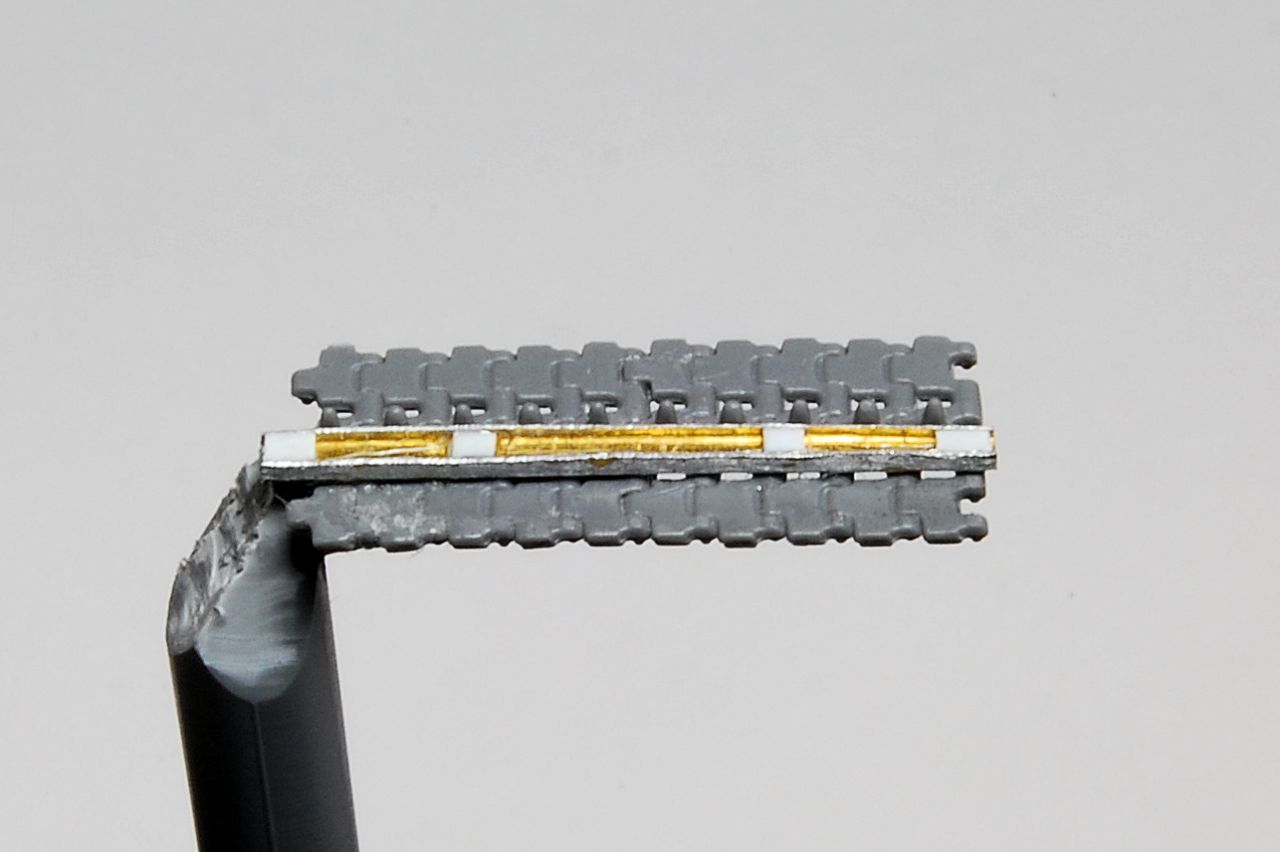

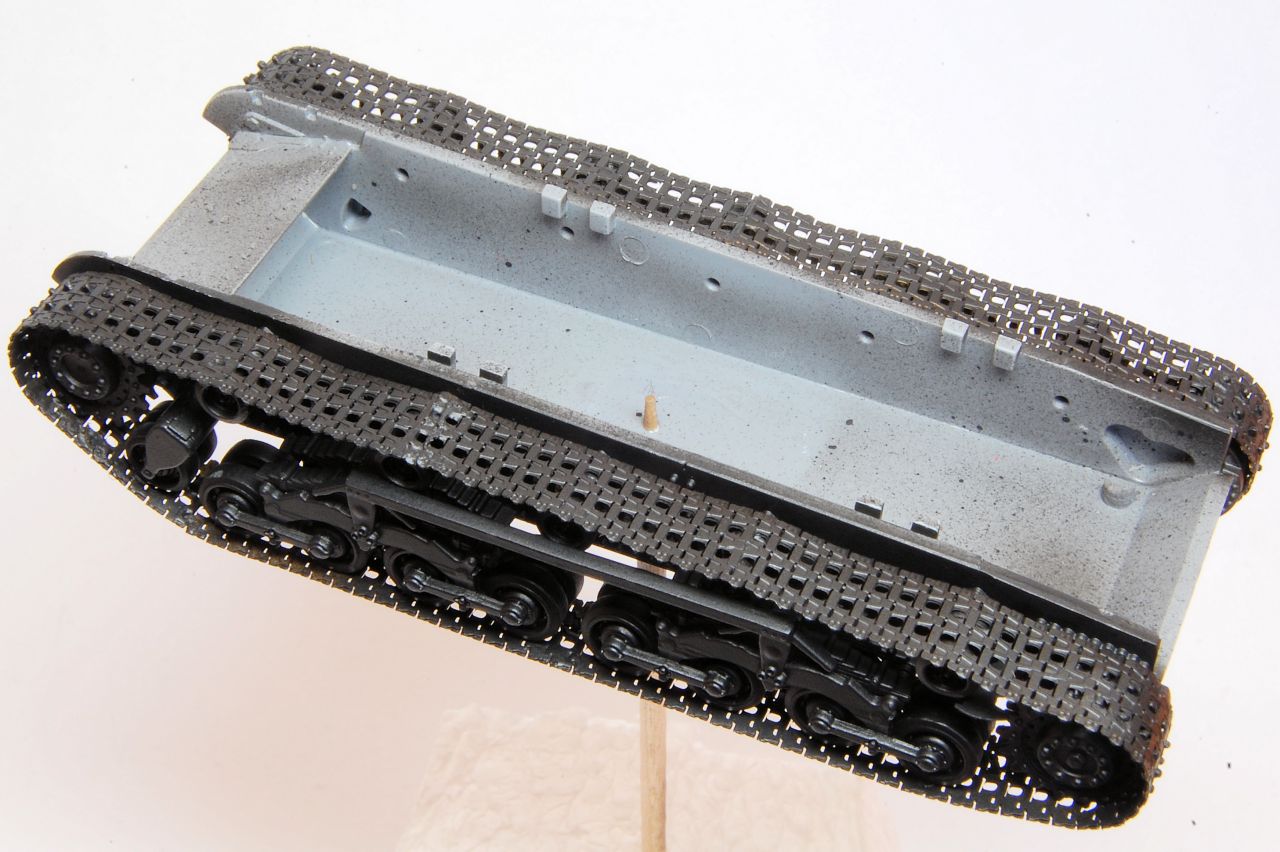

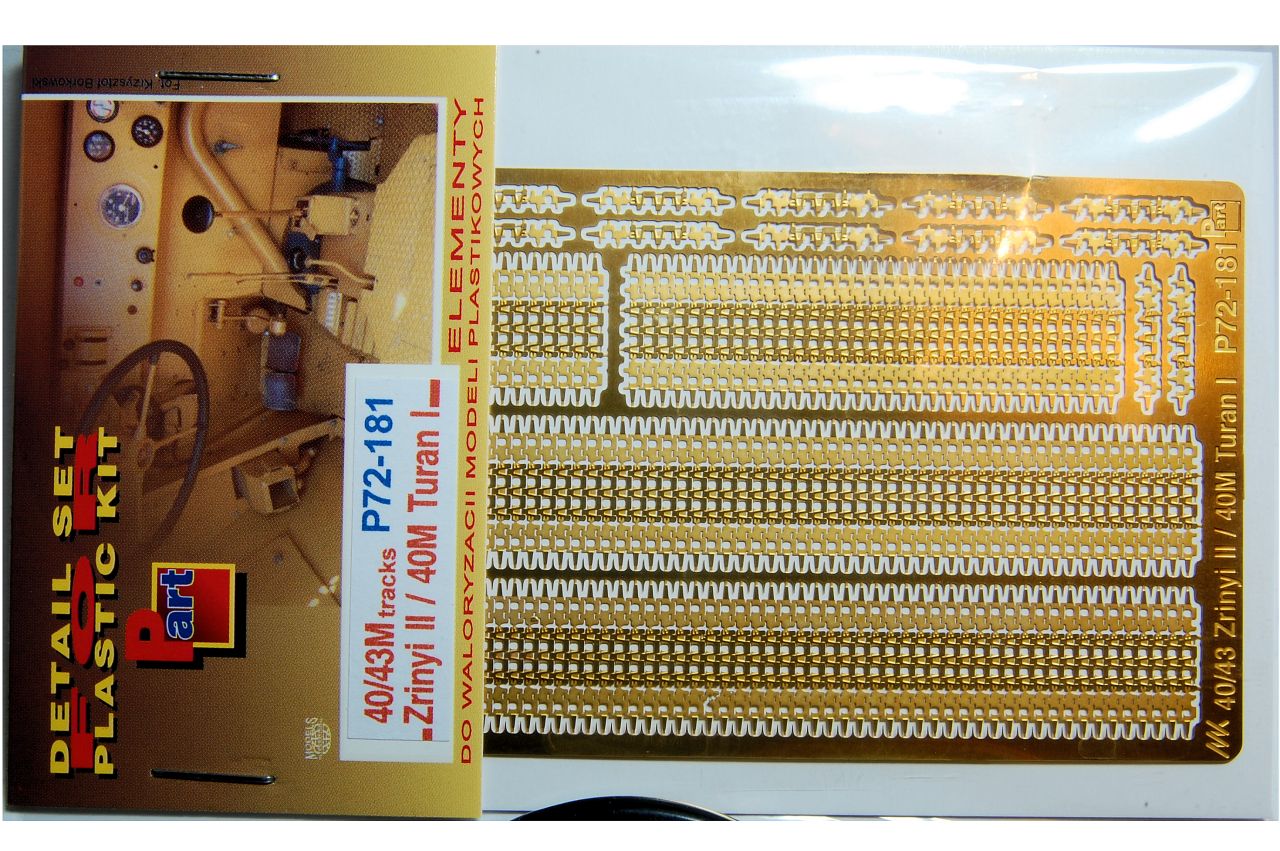

Having enjoyed assembling the IBG tracks twice already, I thought I'd give these a go as part of this build:

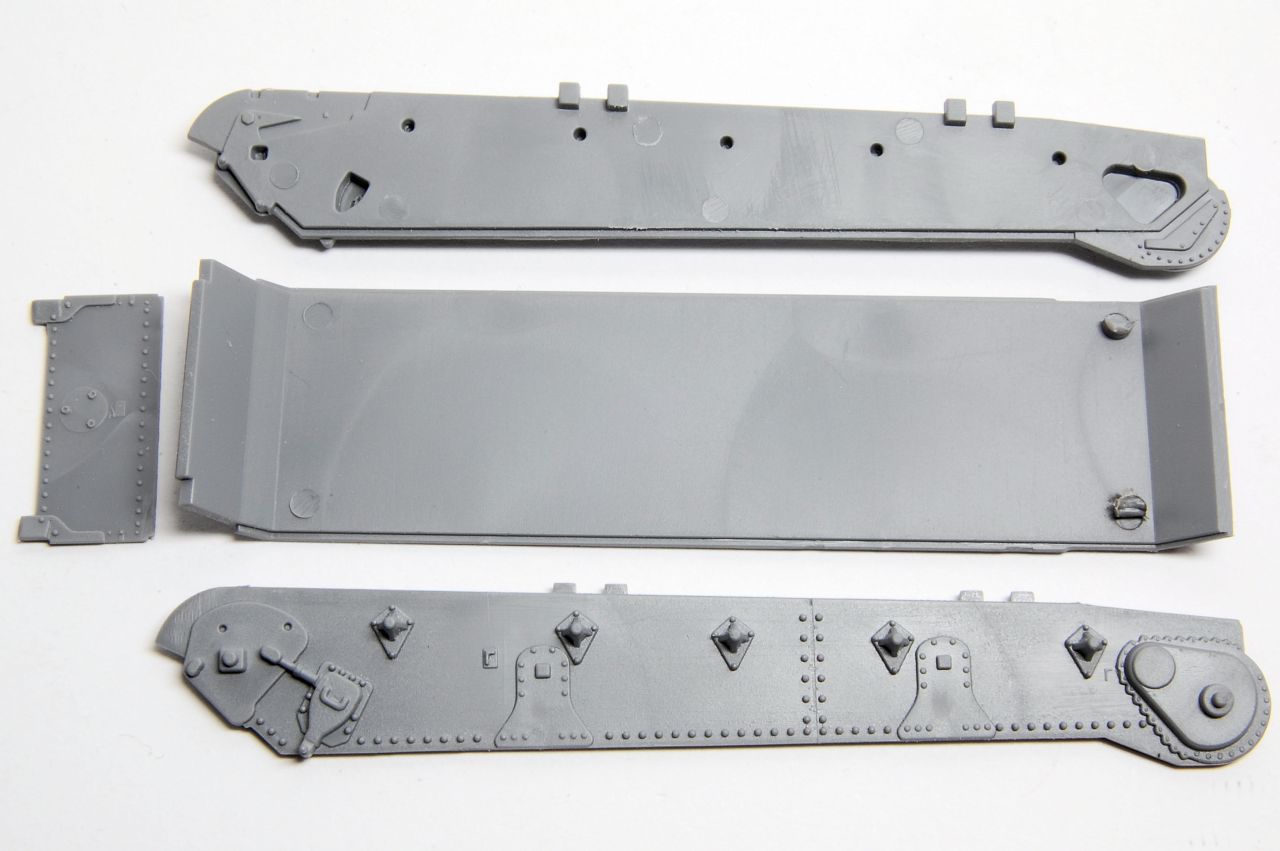

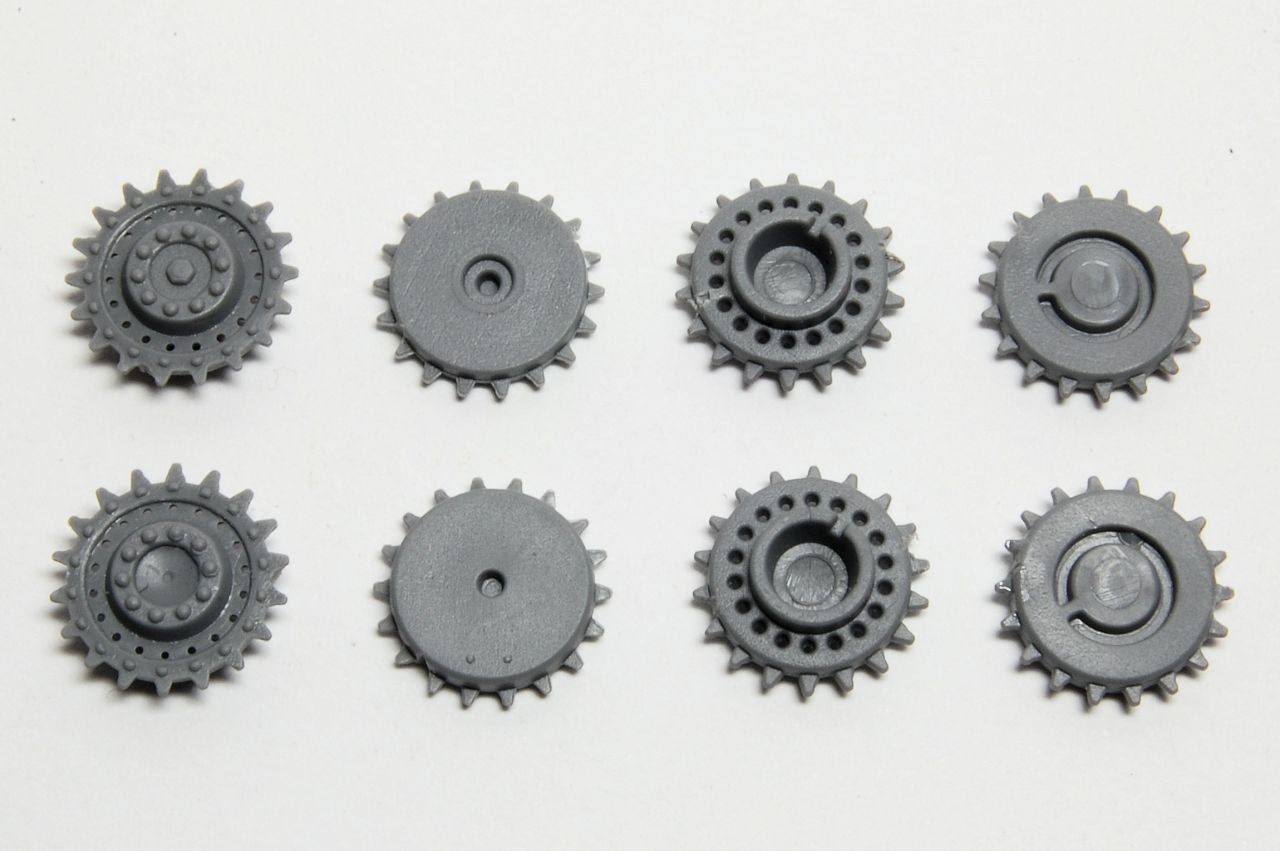

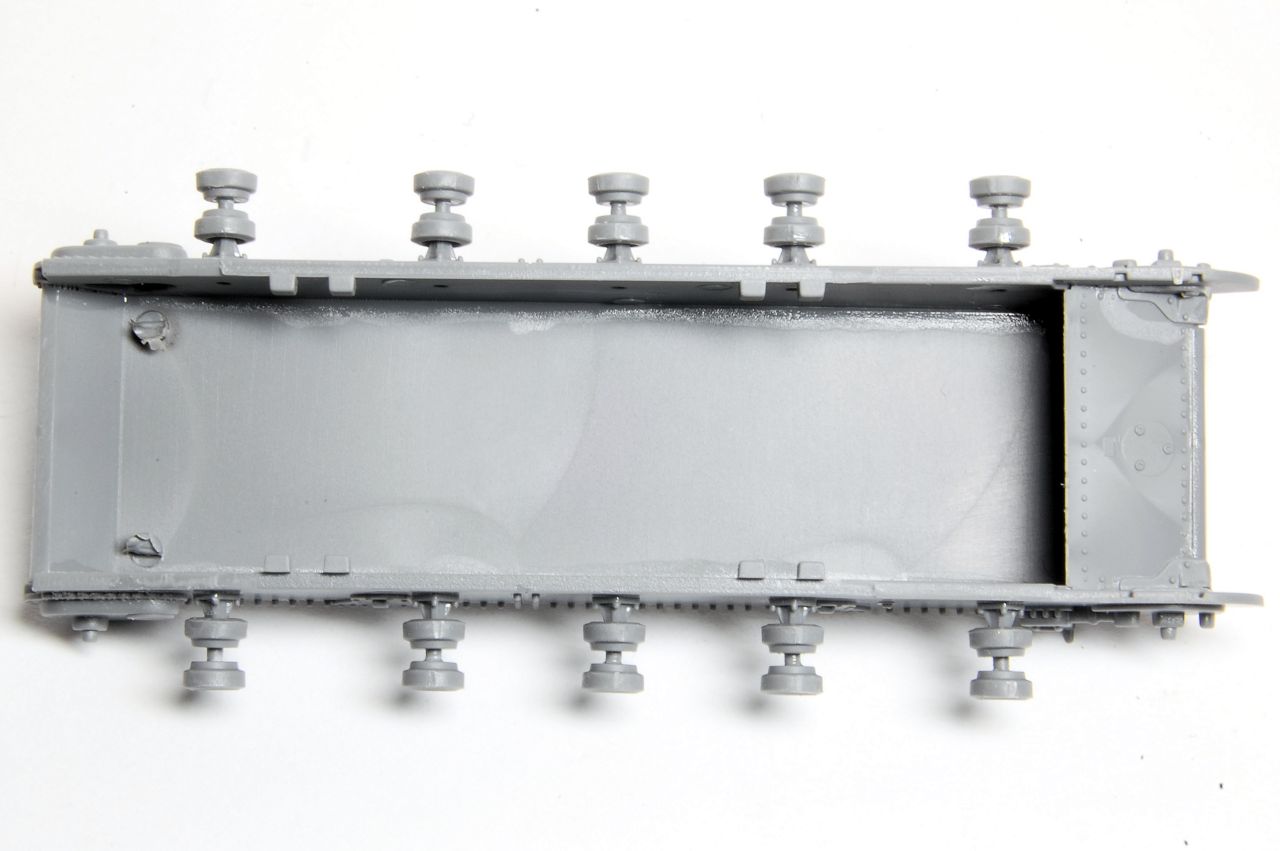

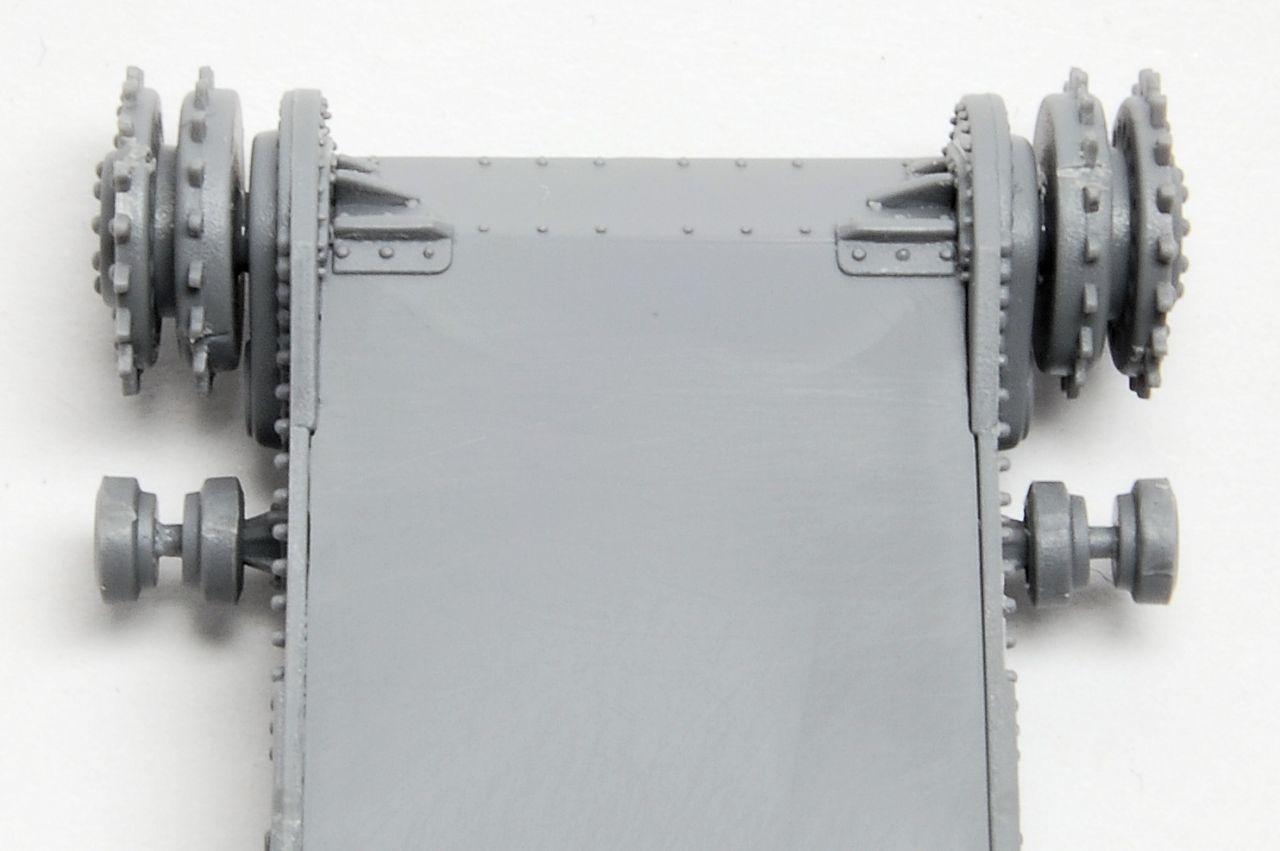

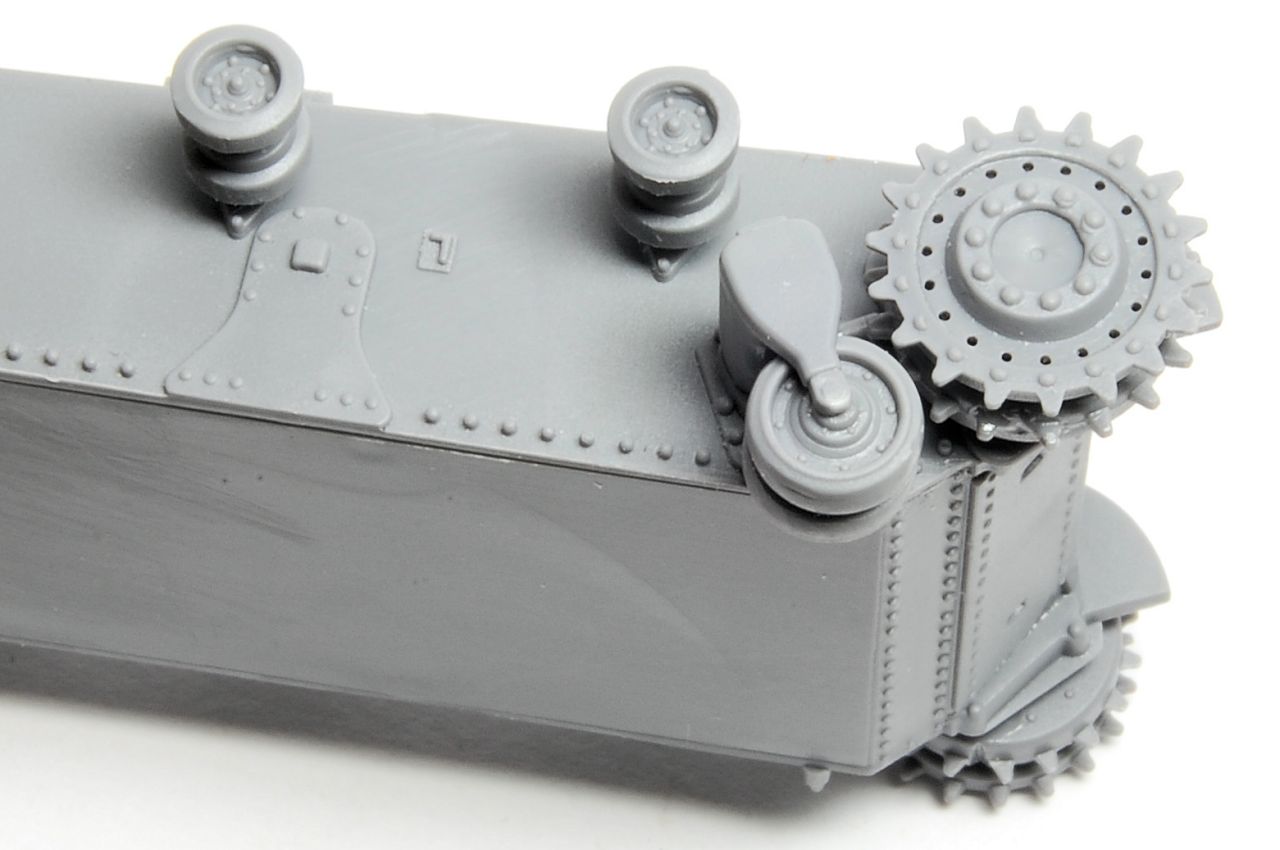

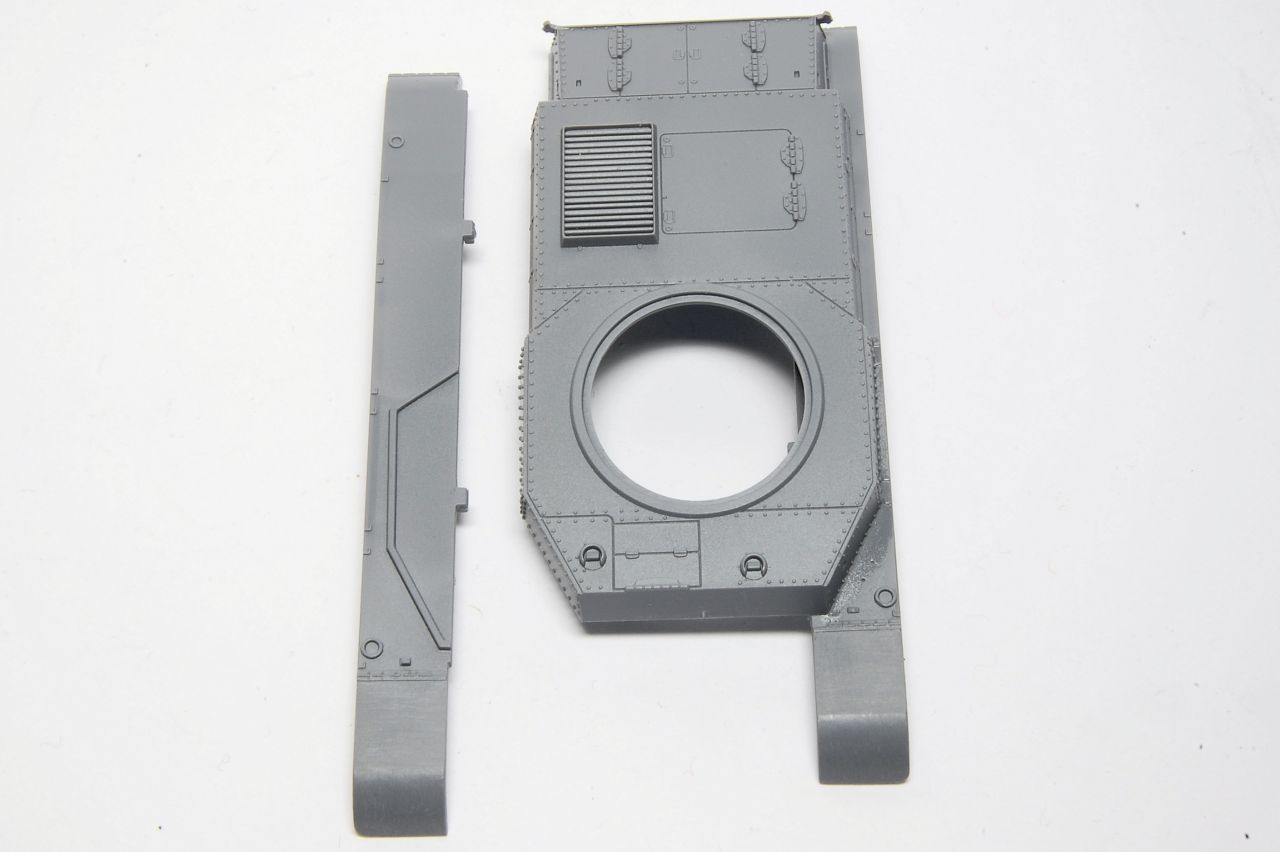

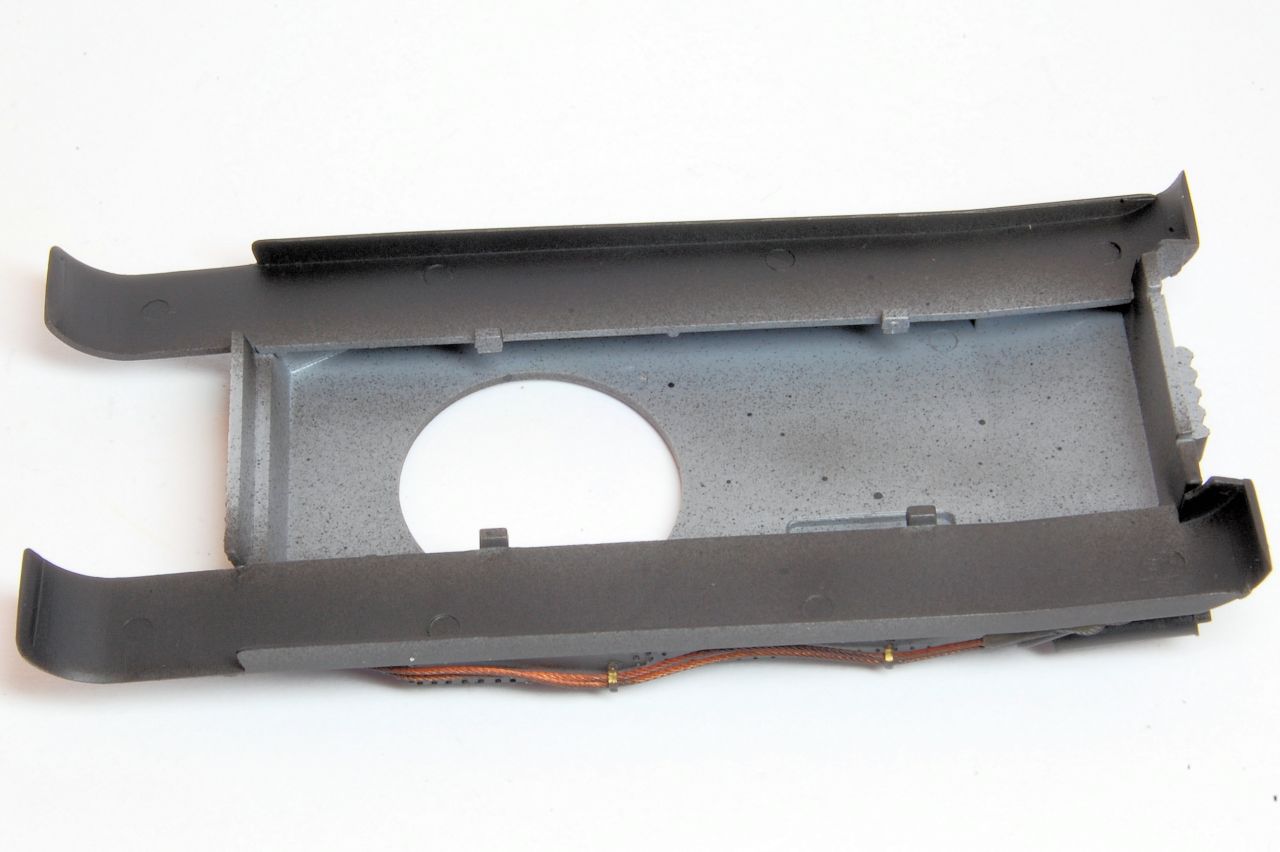

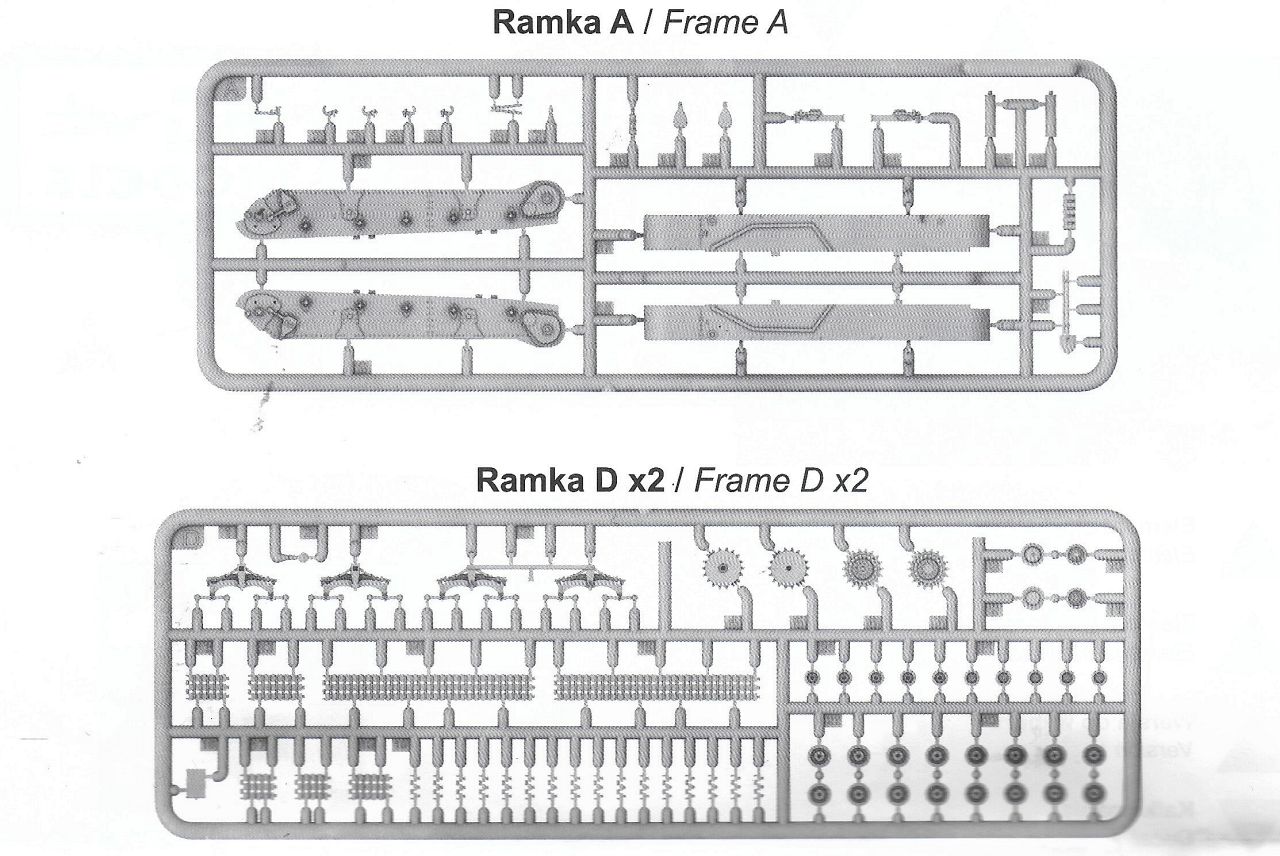

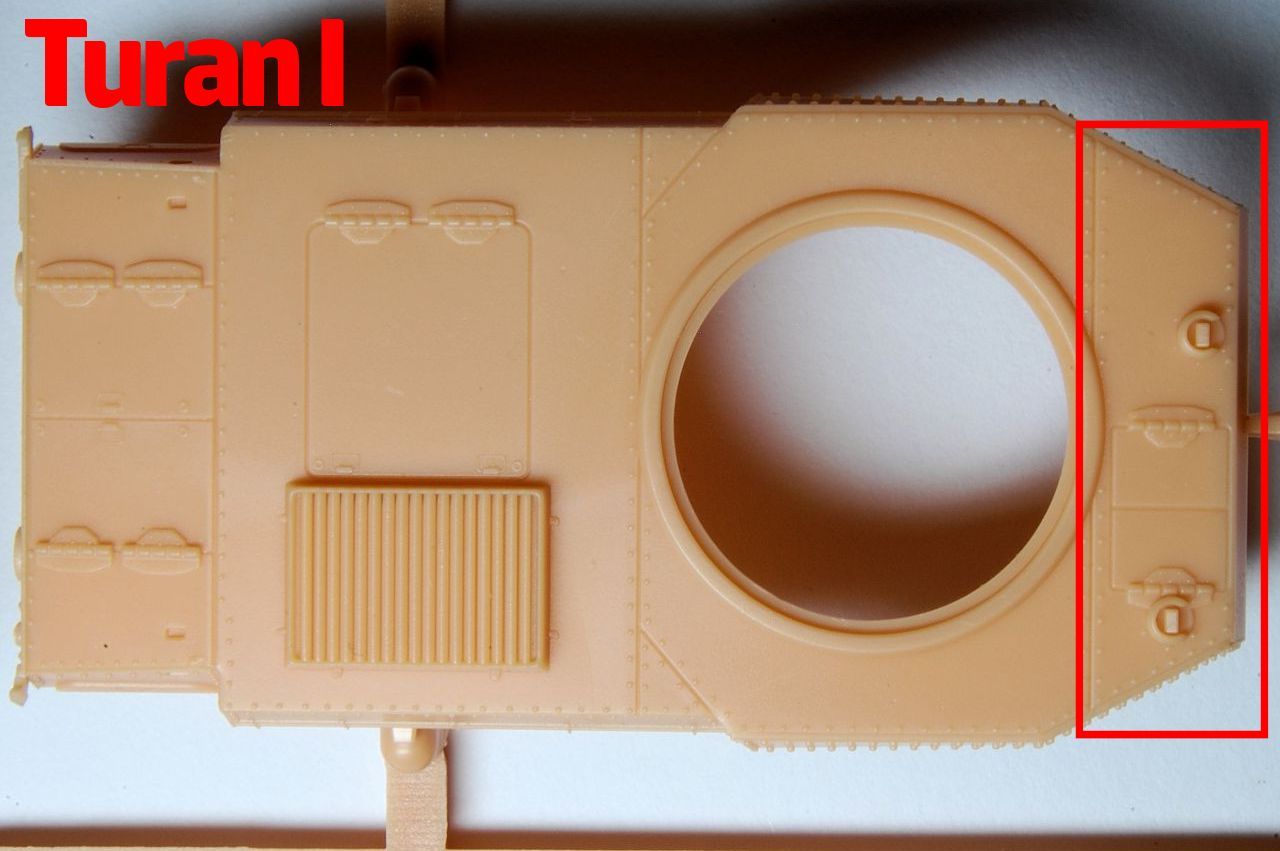

As you'd expect, the IBG Turan II shares some of the same sprues with the Turan I, A and Dx2, below:

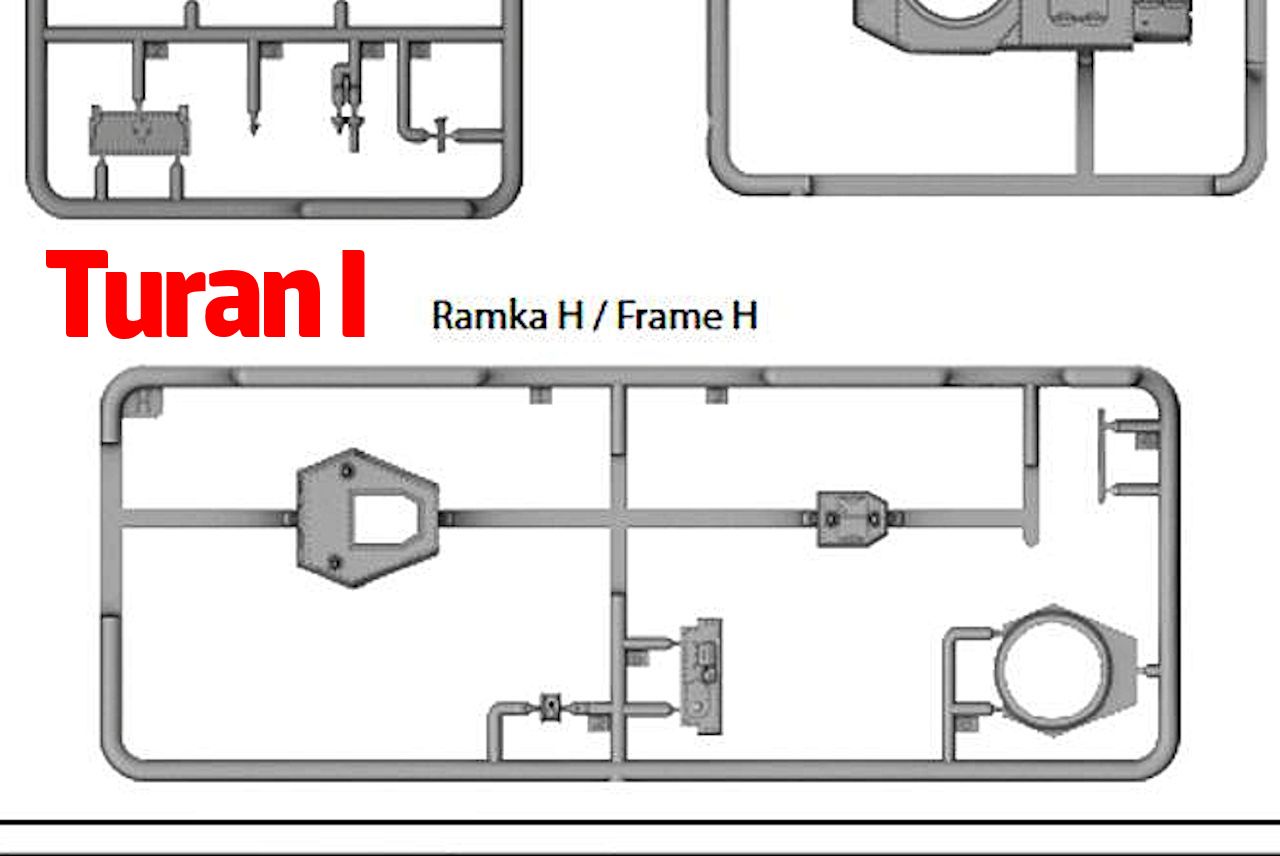

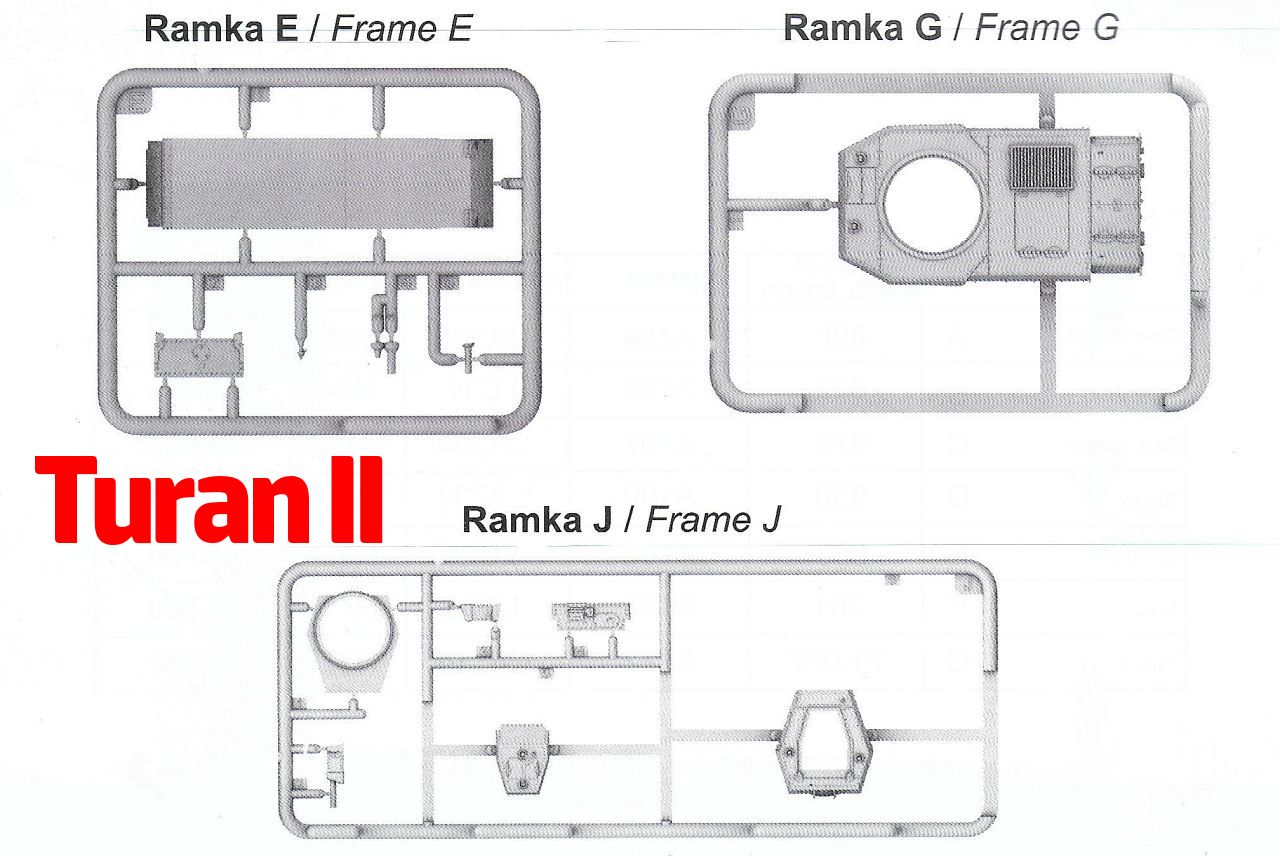

The main difference is sprue J which replaces sprue H:

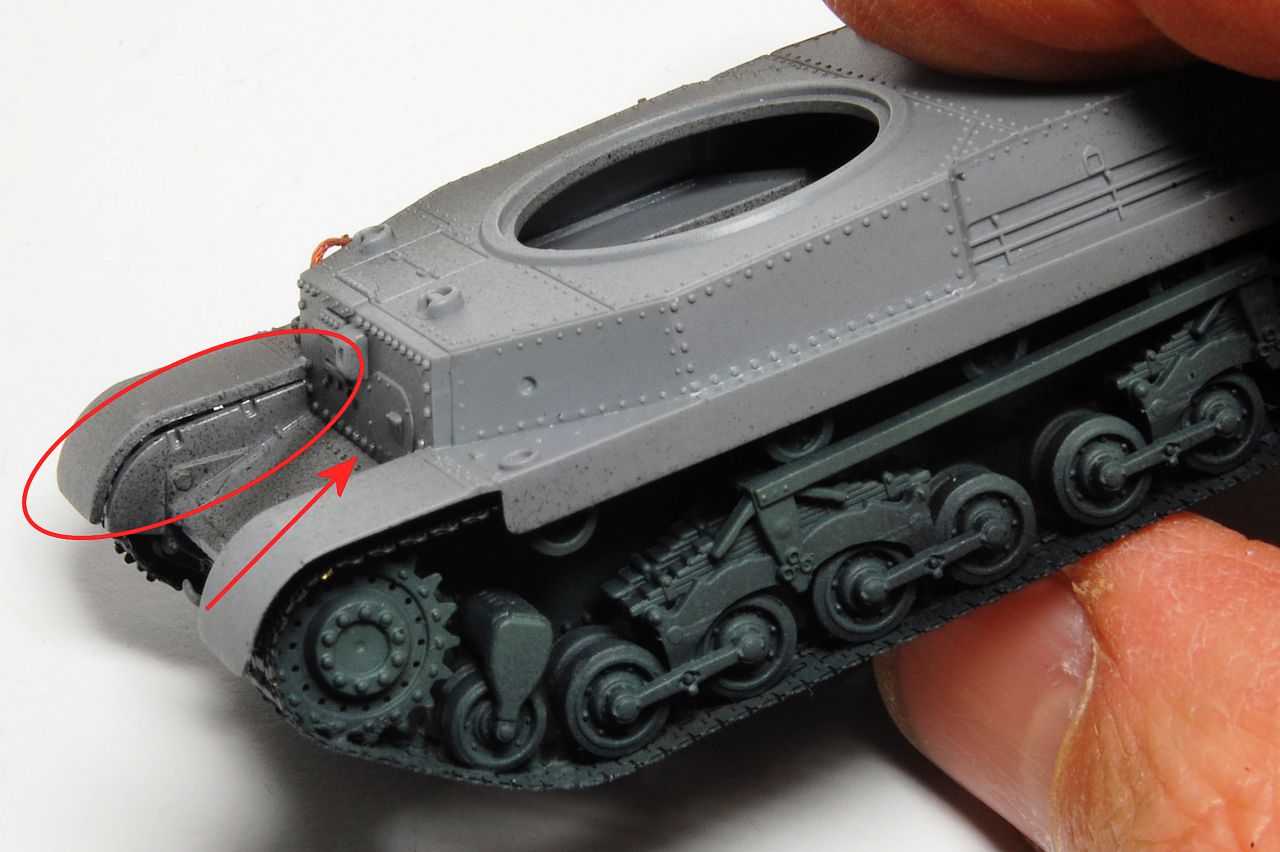

Although there is a sprue G for the upper hull in both kits, it's not the same sprue G in that the driver hatch now folds open forward, instead of opening in two halves sideways. No point in showing the photo of the parts diagram for it from the Turan I kit as IBG inadvertently used the image of the Turan II hull...

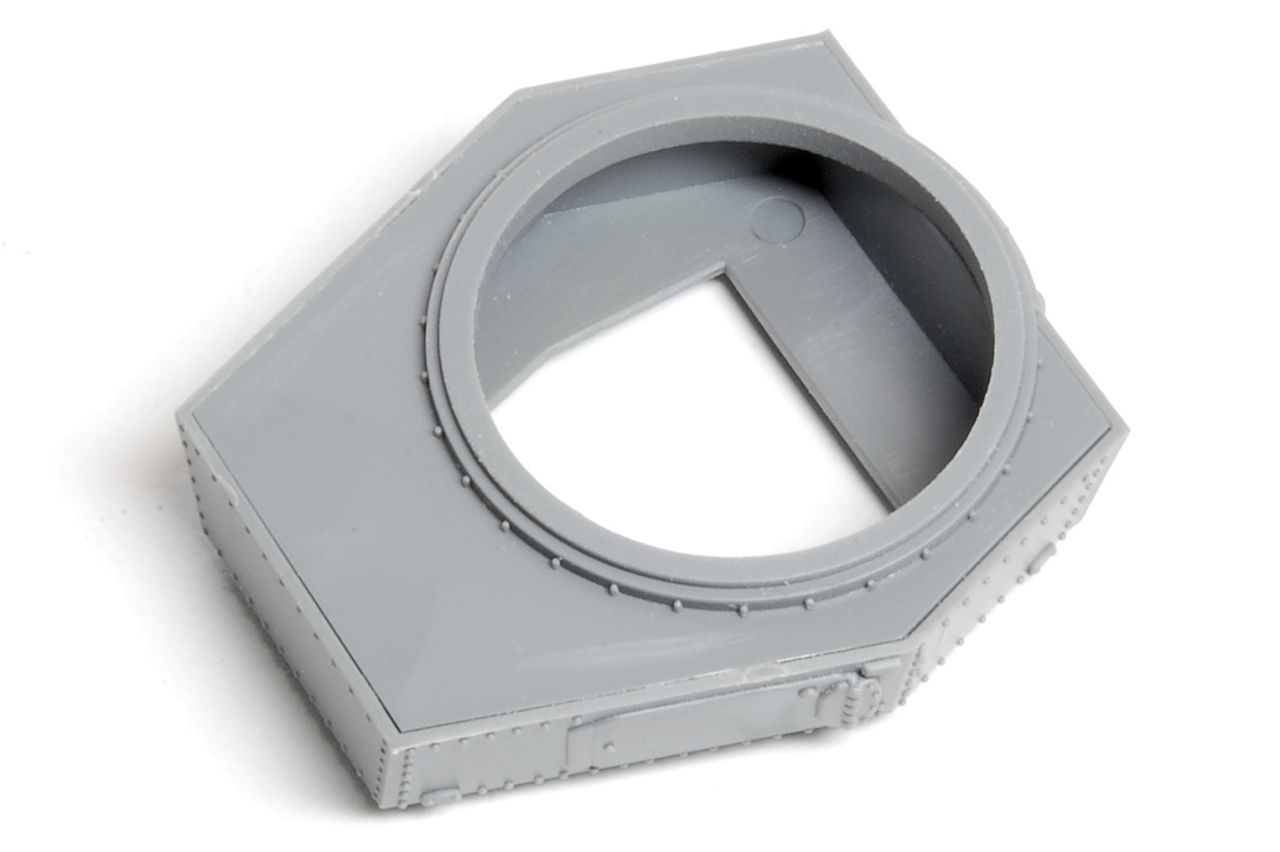

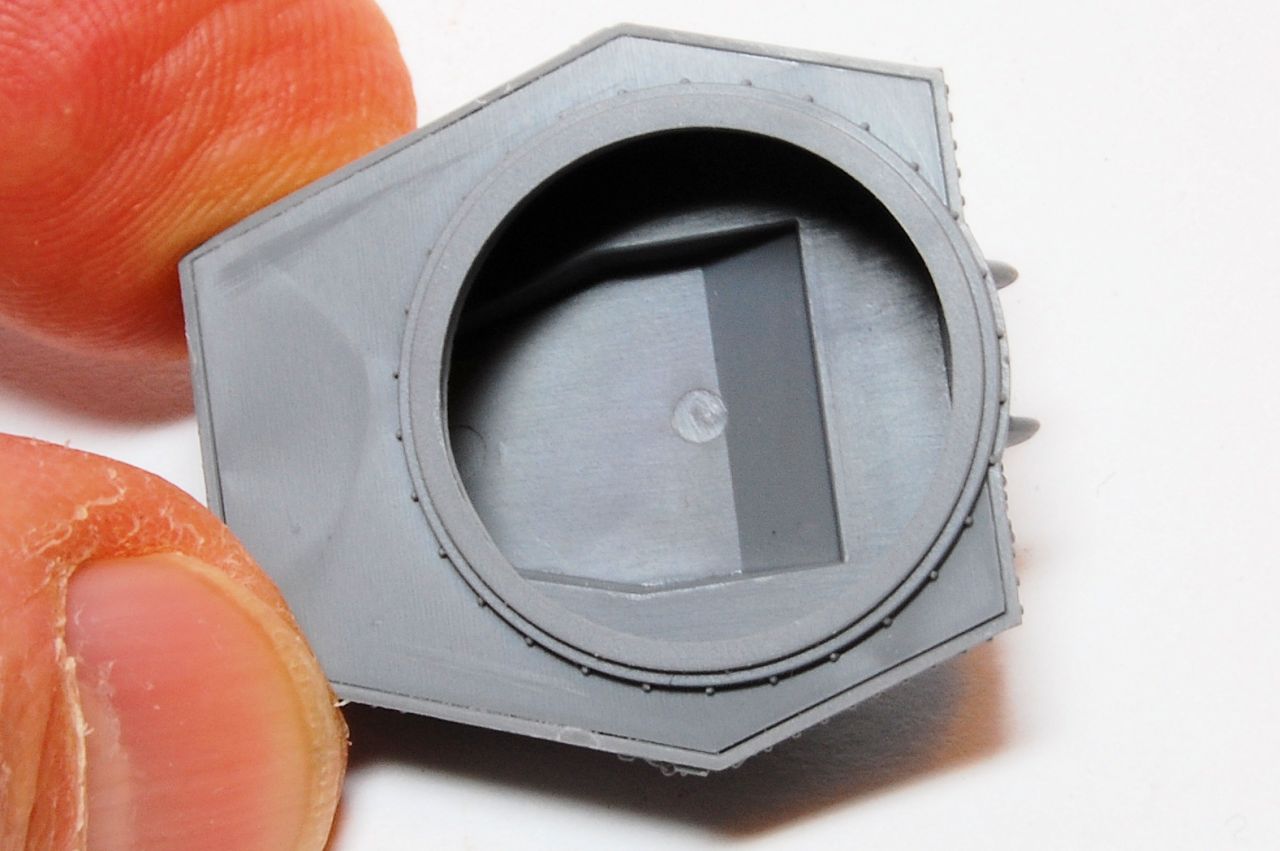

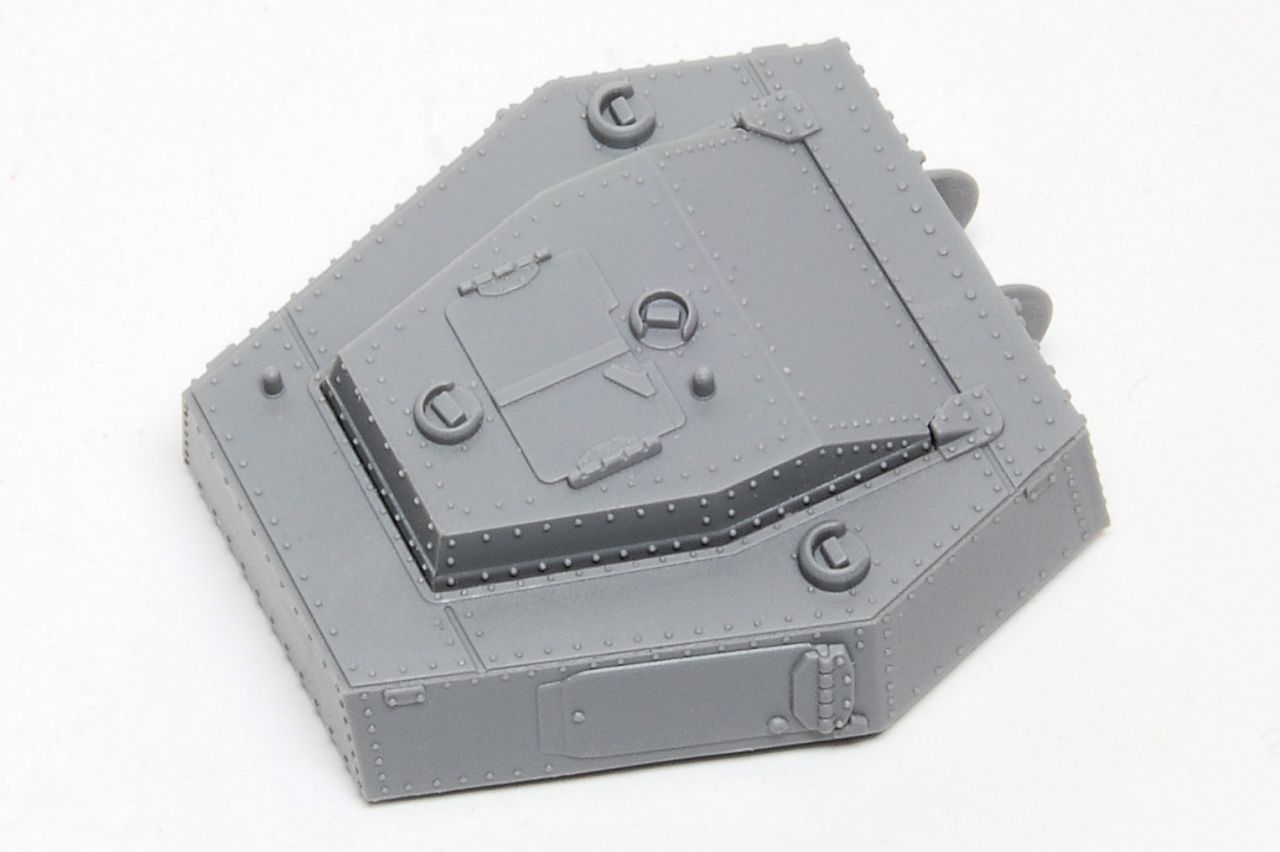

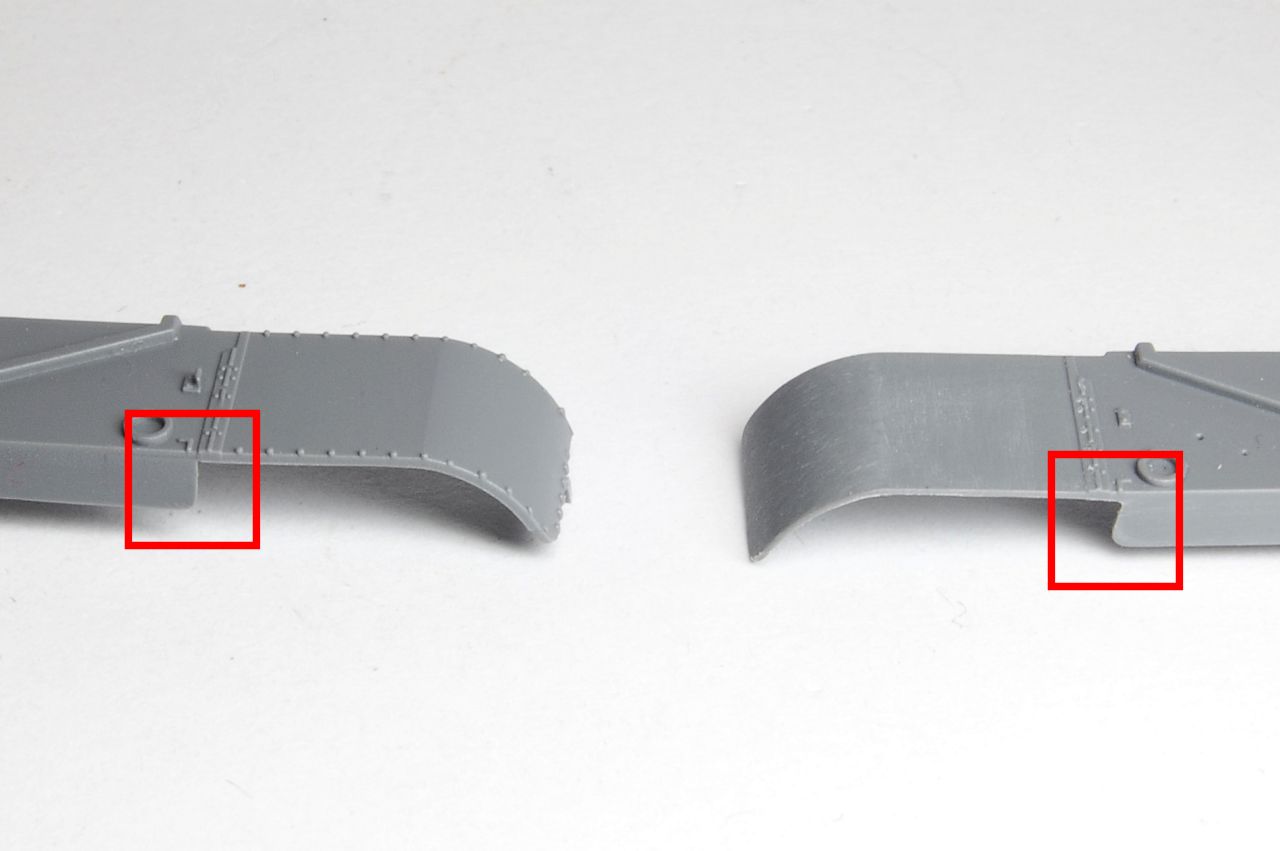

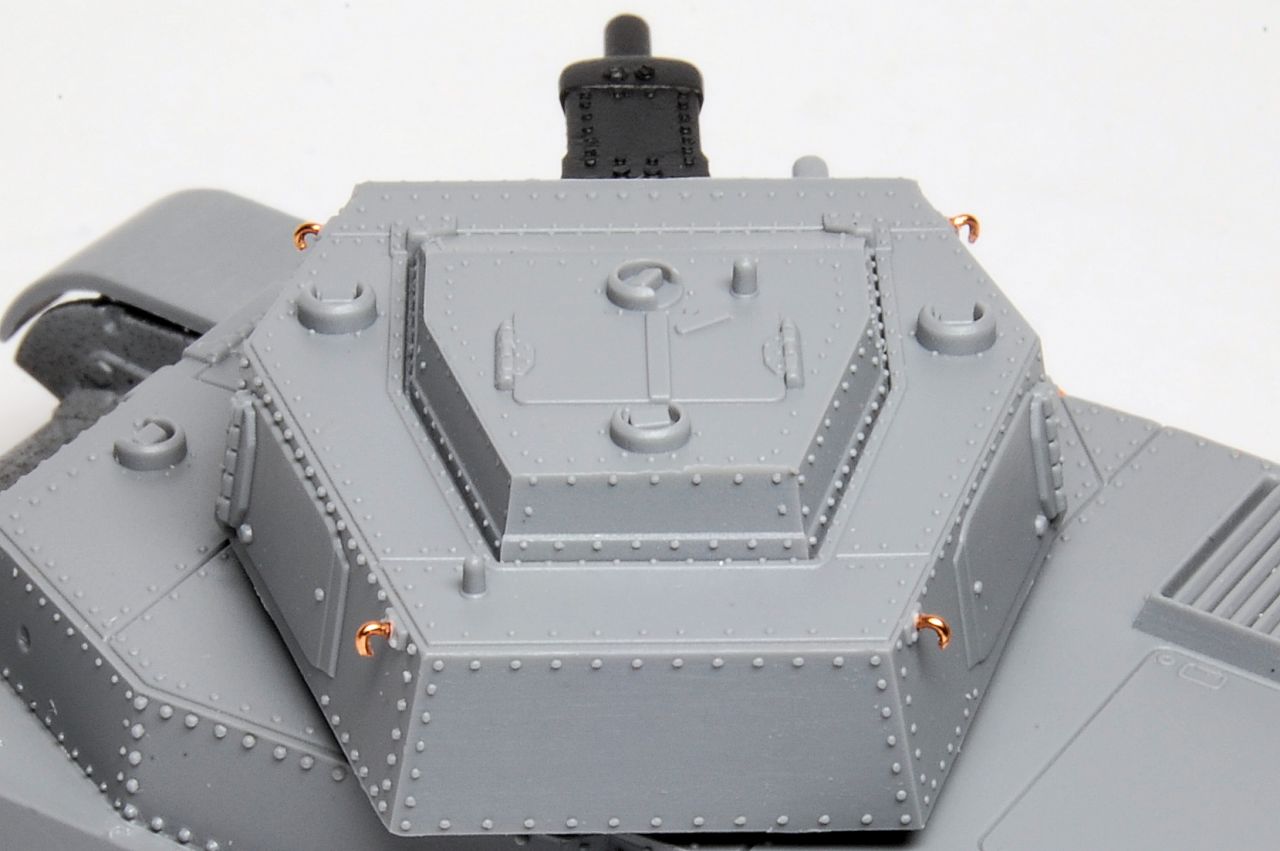

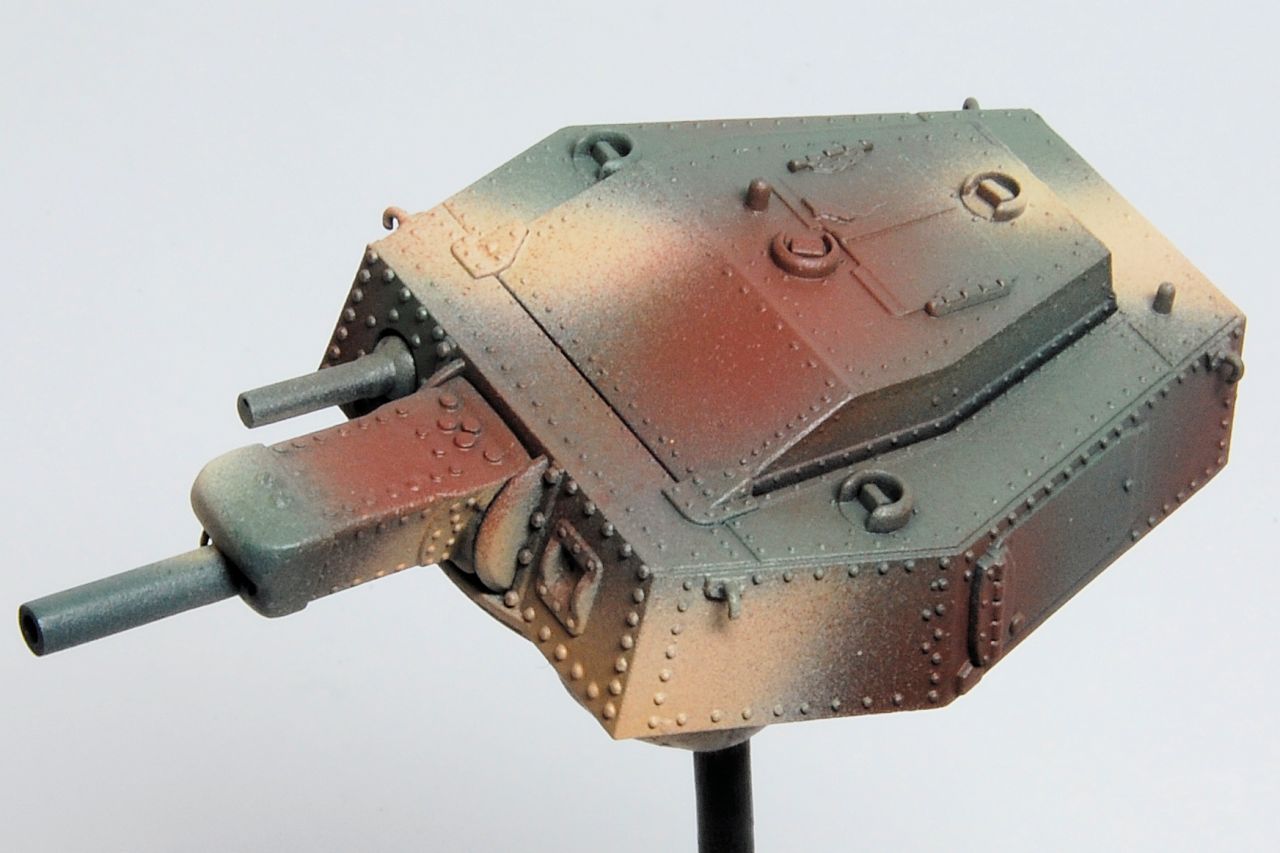

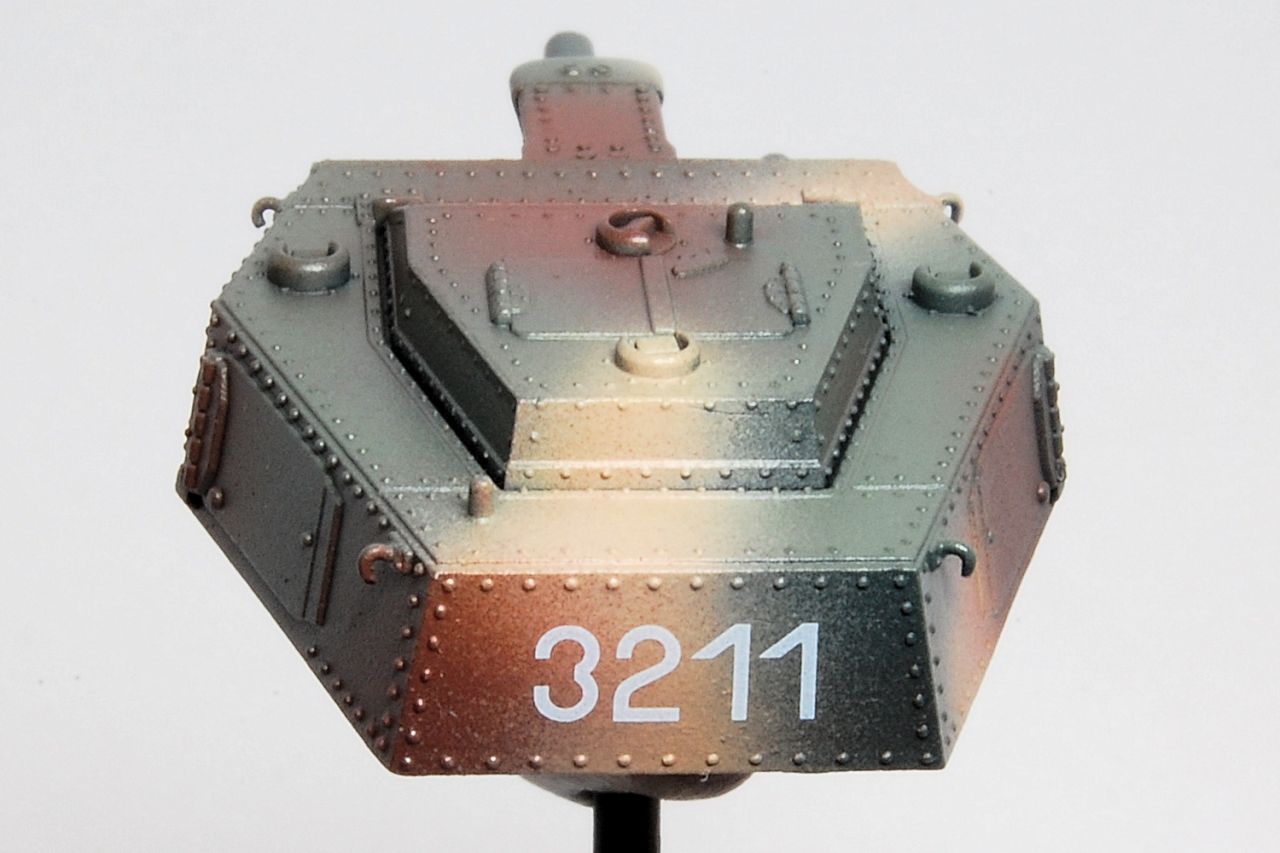

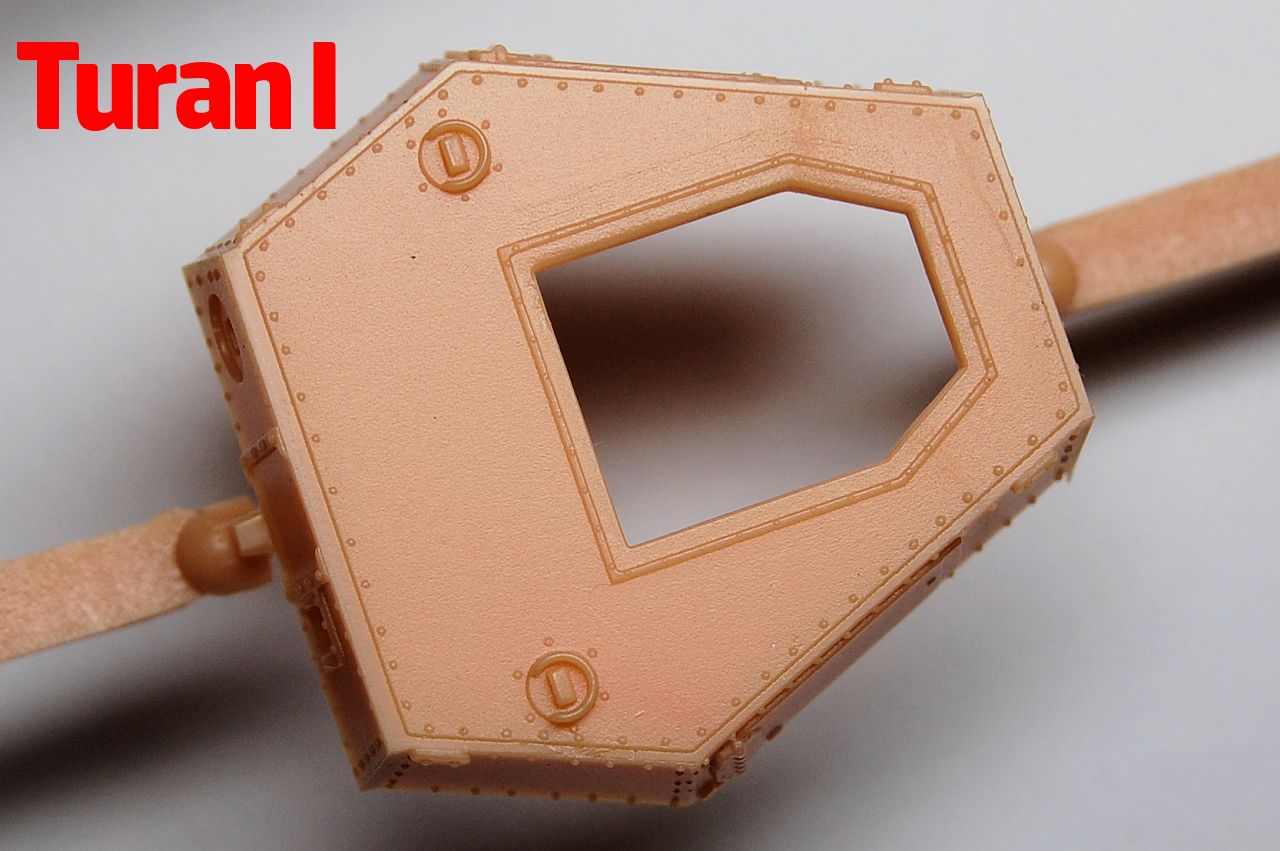

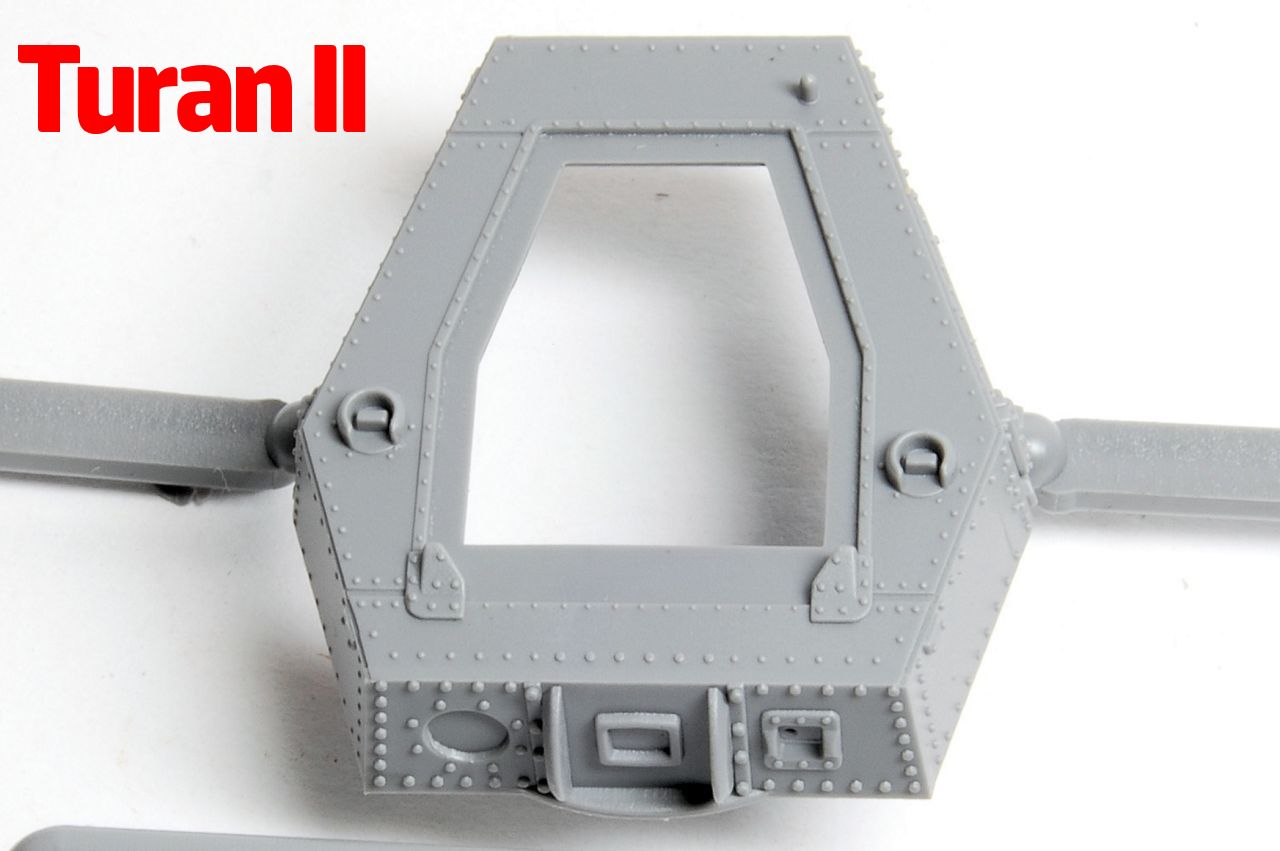

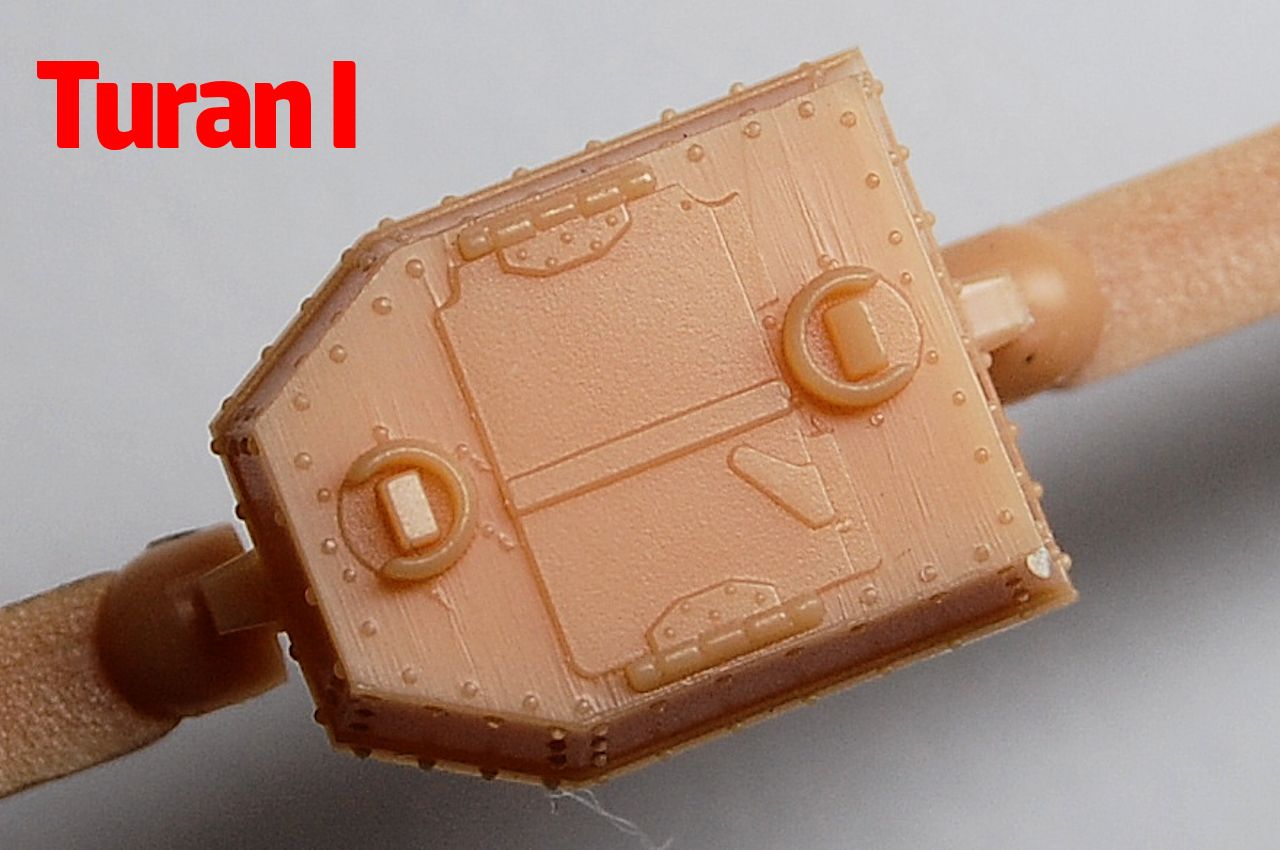

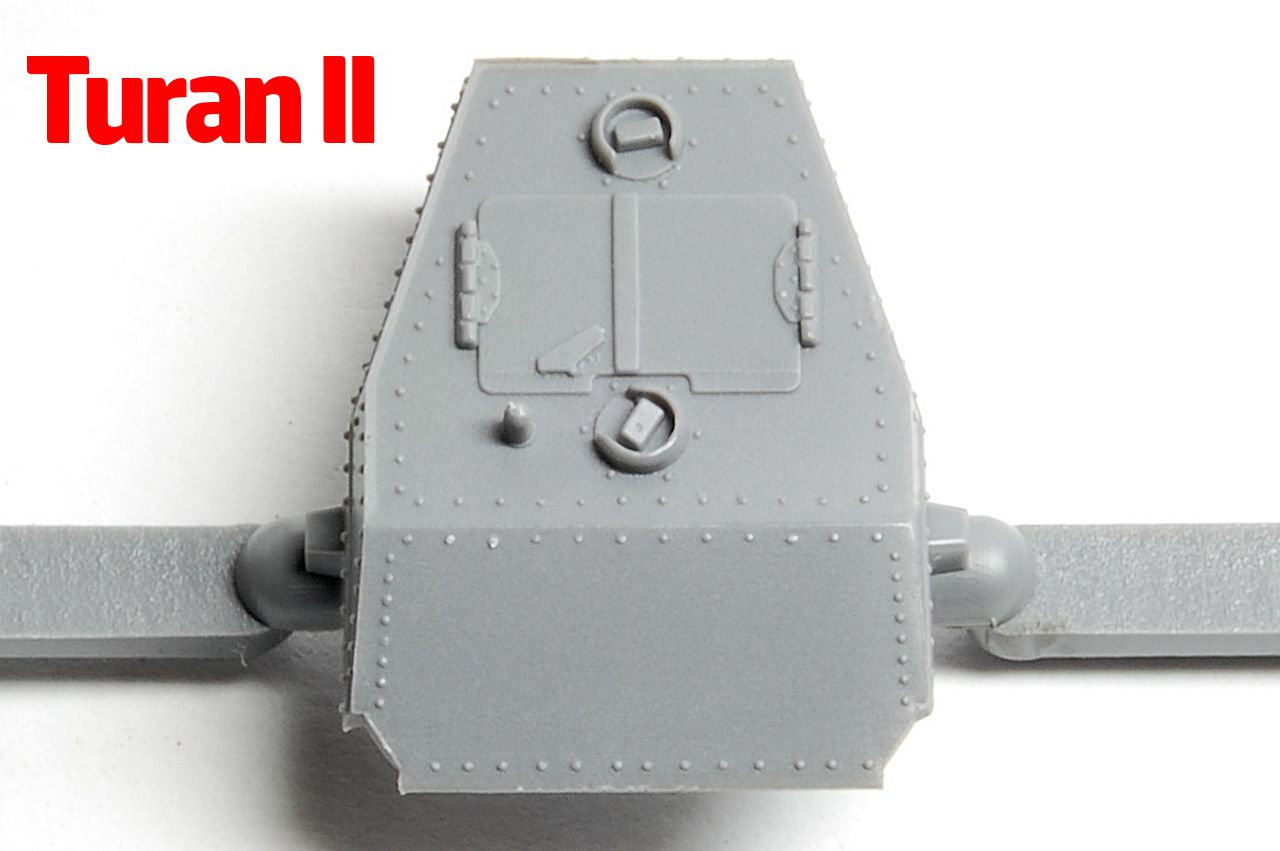

Anyway, here are comparisons of the main turret parts:

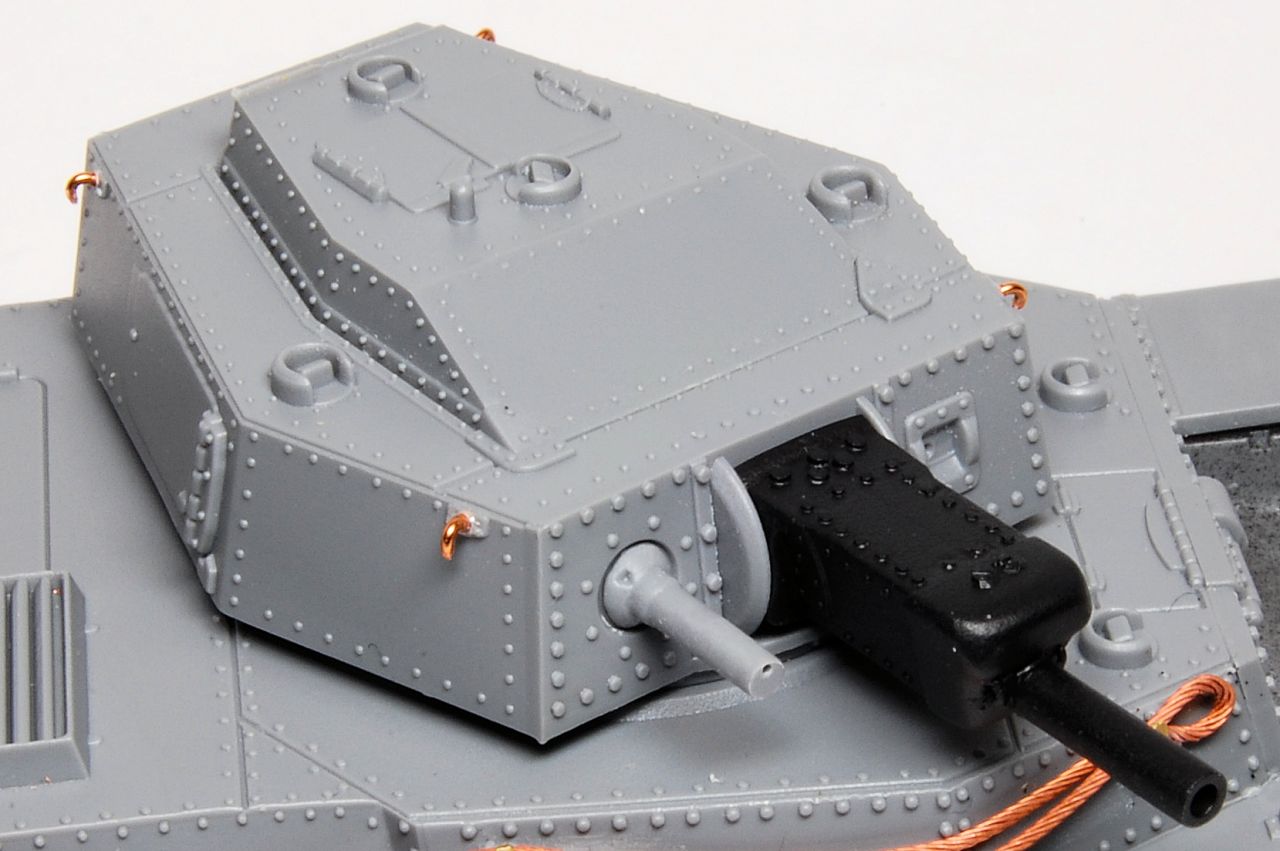

So the Turan II is up-armoured with a thicker turret front, and additional plates on the roof giving a more complex appearance, and the commander's cupola is bigger, wtih a sloping front plate.

Also new is the front plate of the driver position, which now has the hinge for the forward opening hatch just above the visor:

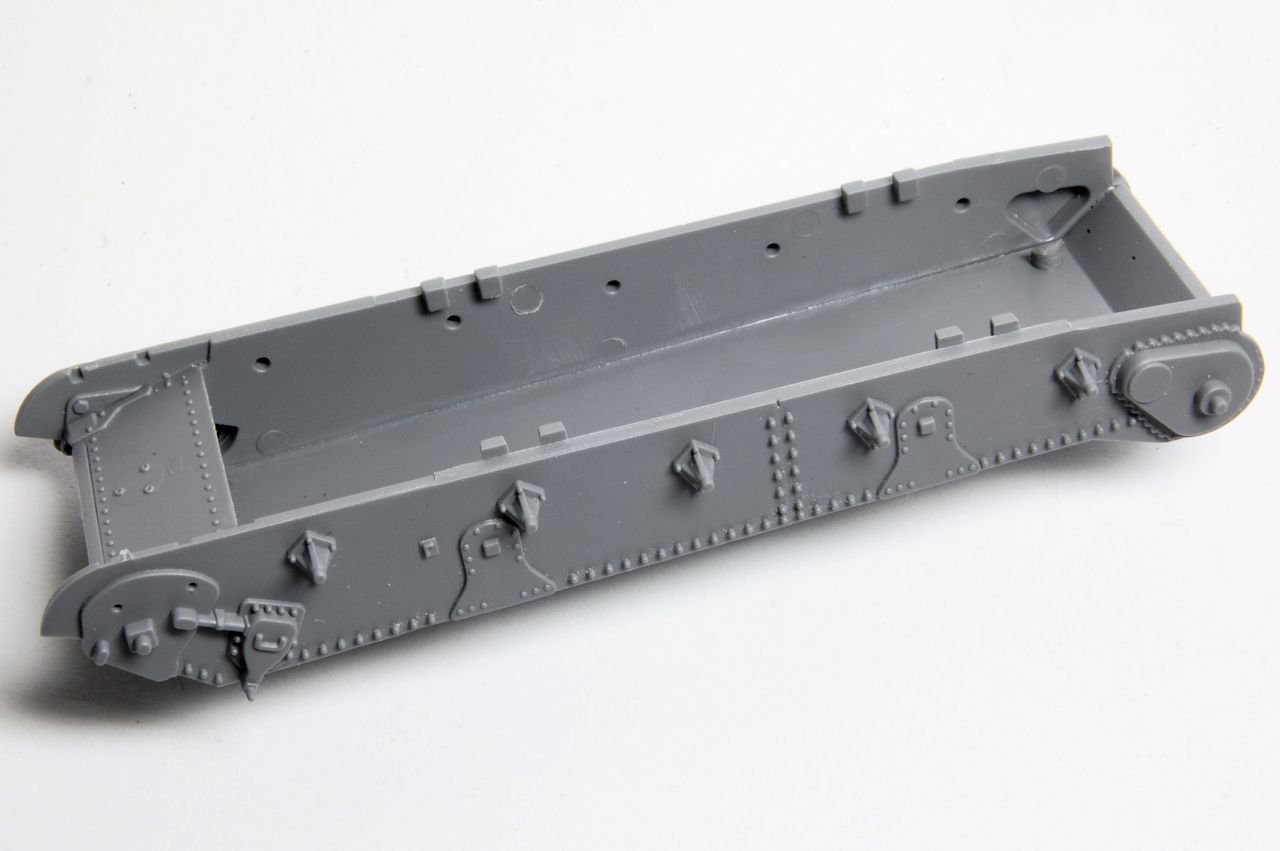

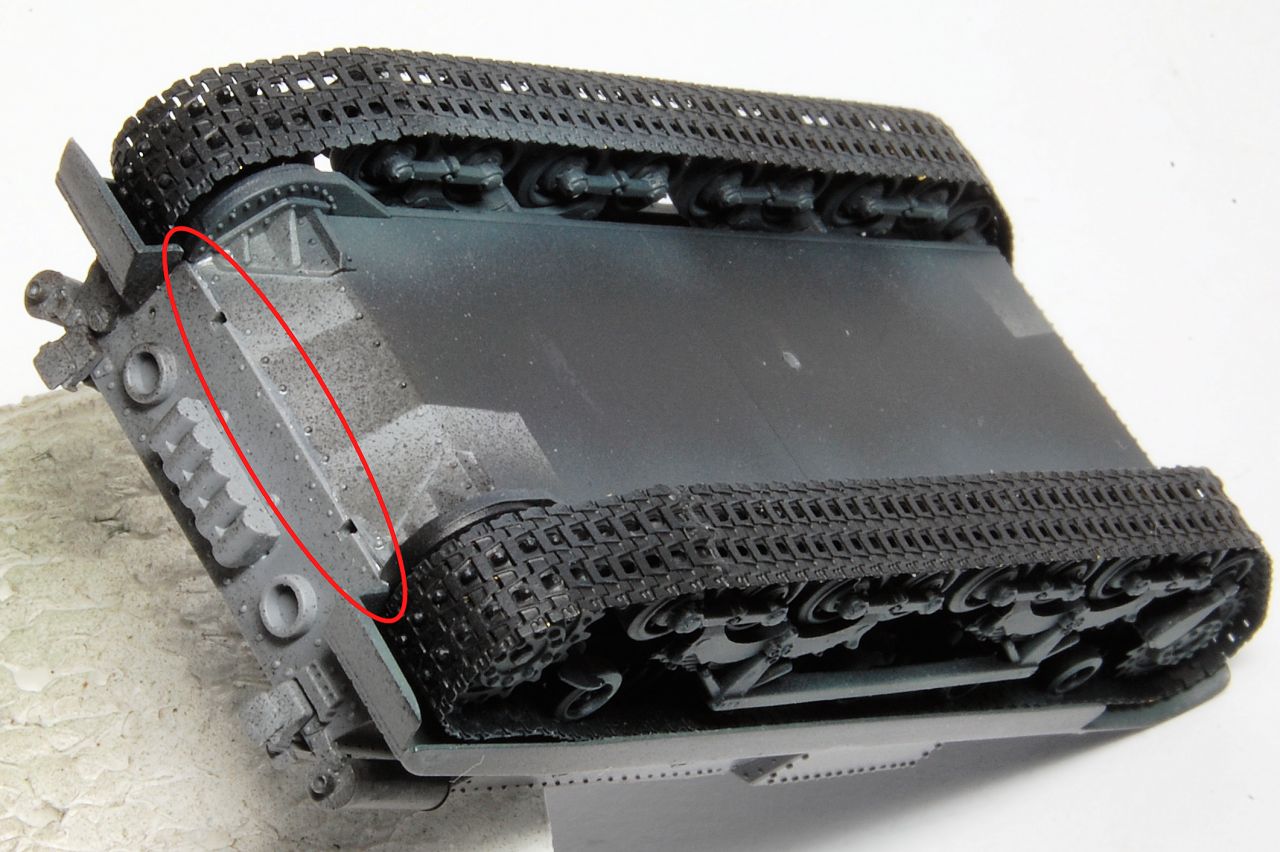

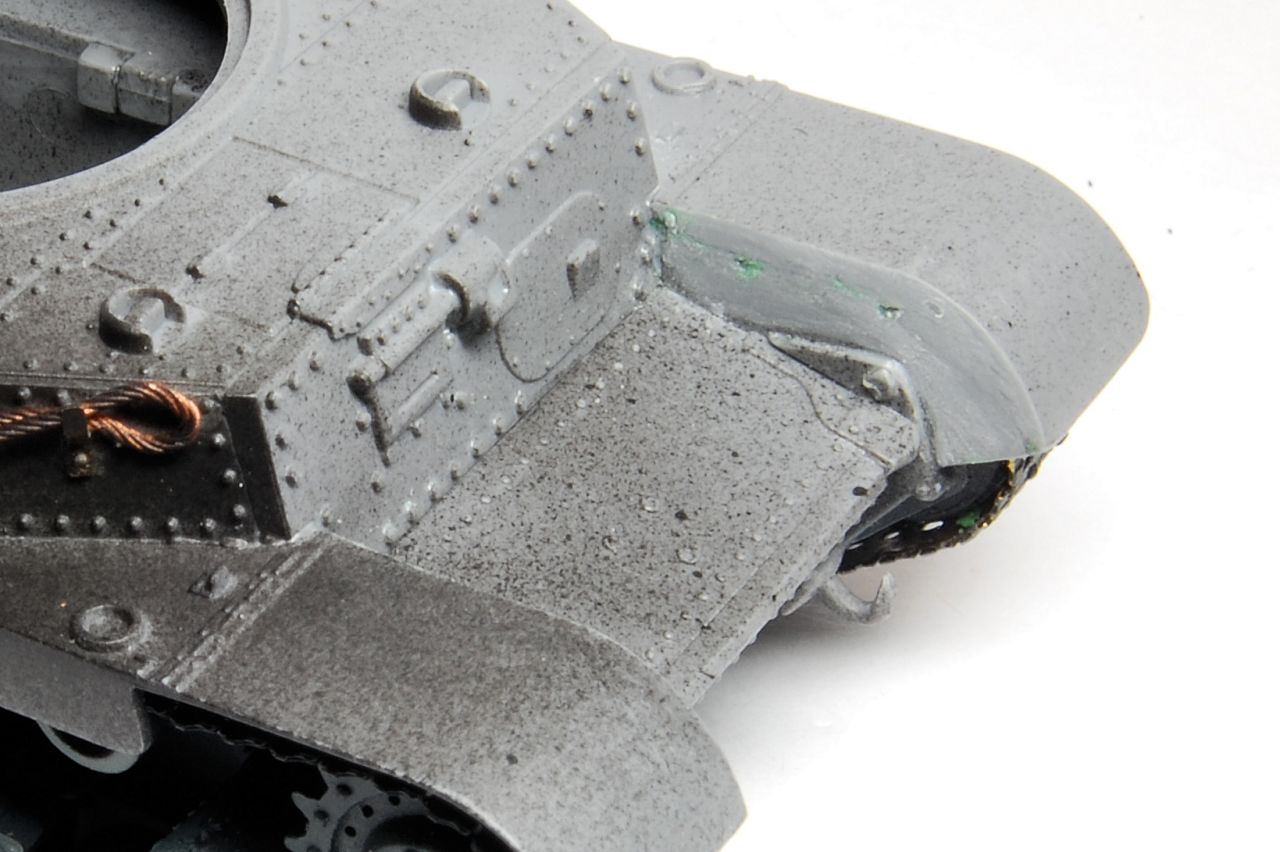

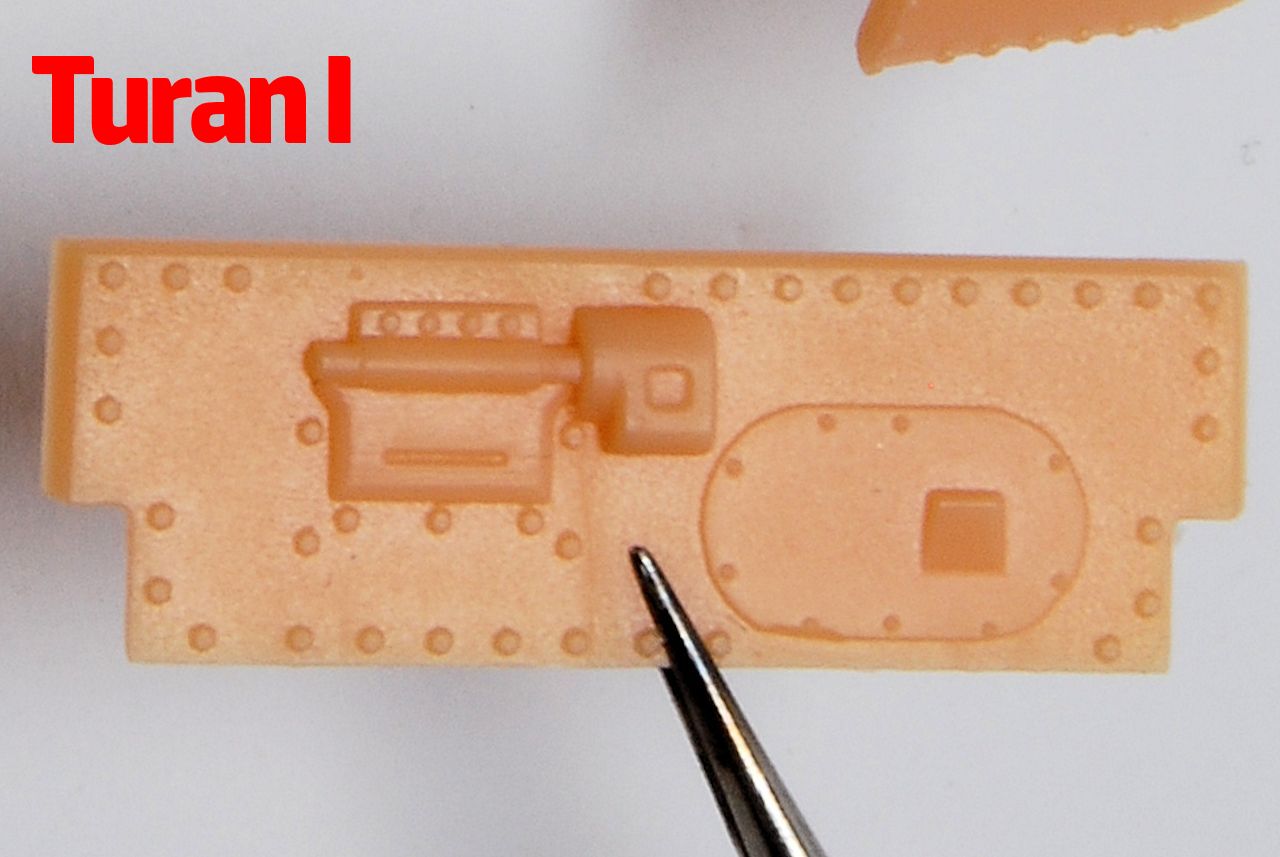

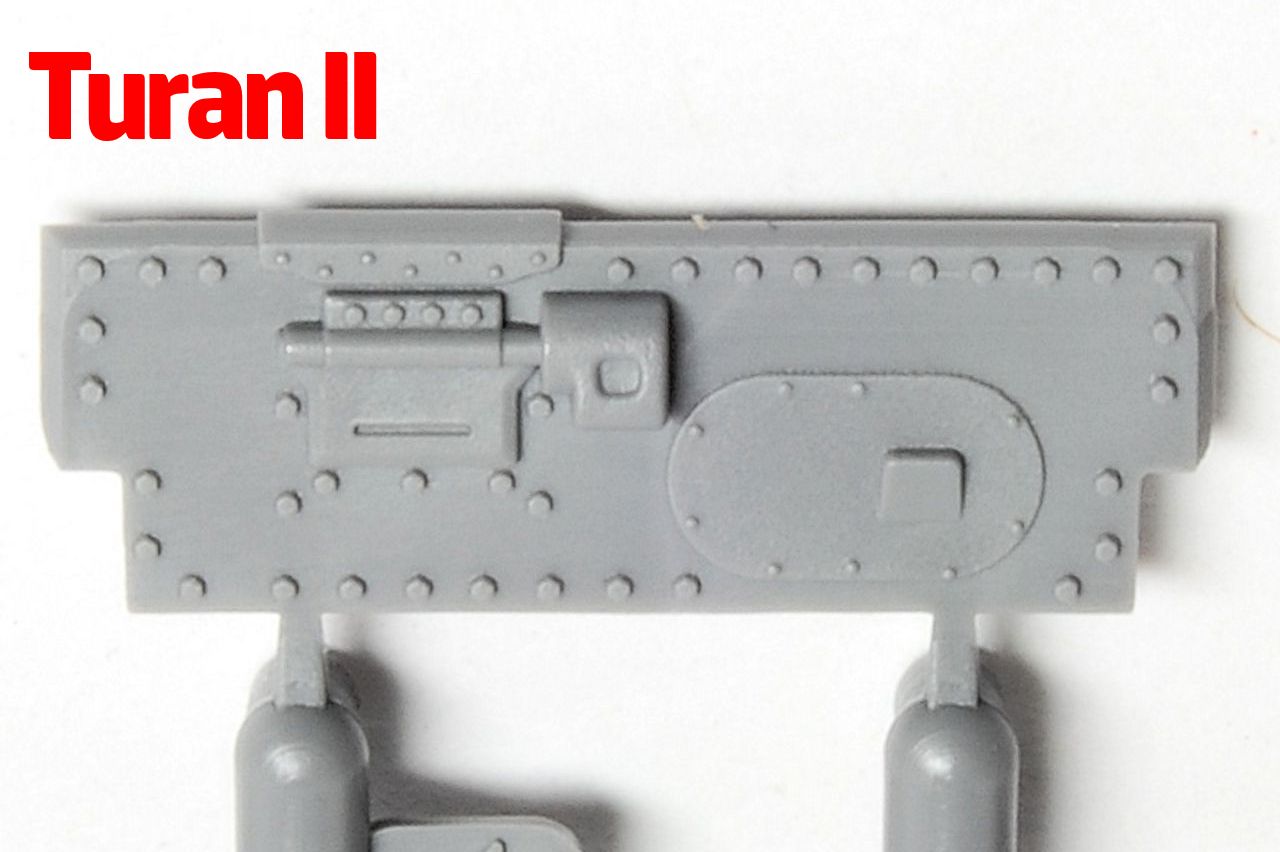

And here's the difference in the hull superstructure:

Perhaps a bit hard to tell at this stage, but the new grey Turan II mouldings look a bit cleaner and the rivets a little more defined than the tan sprues of the I.

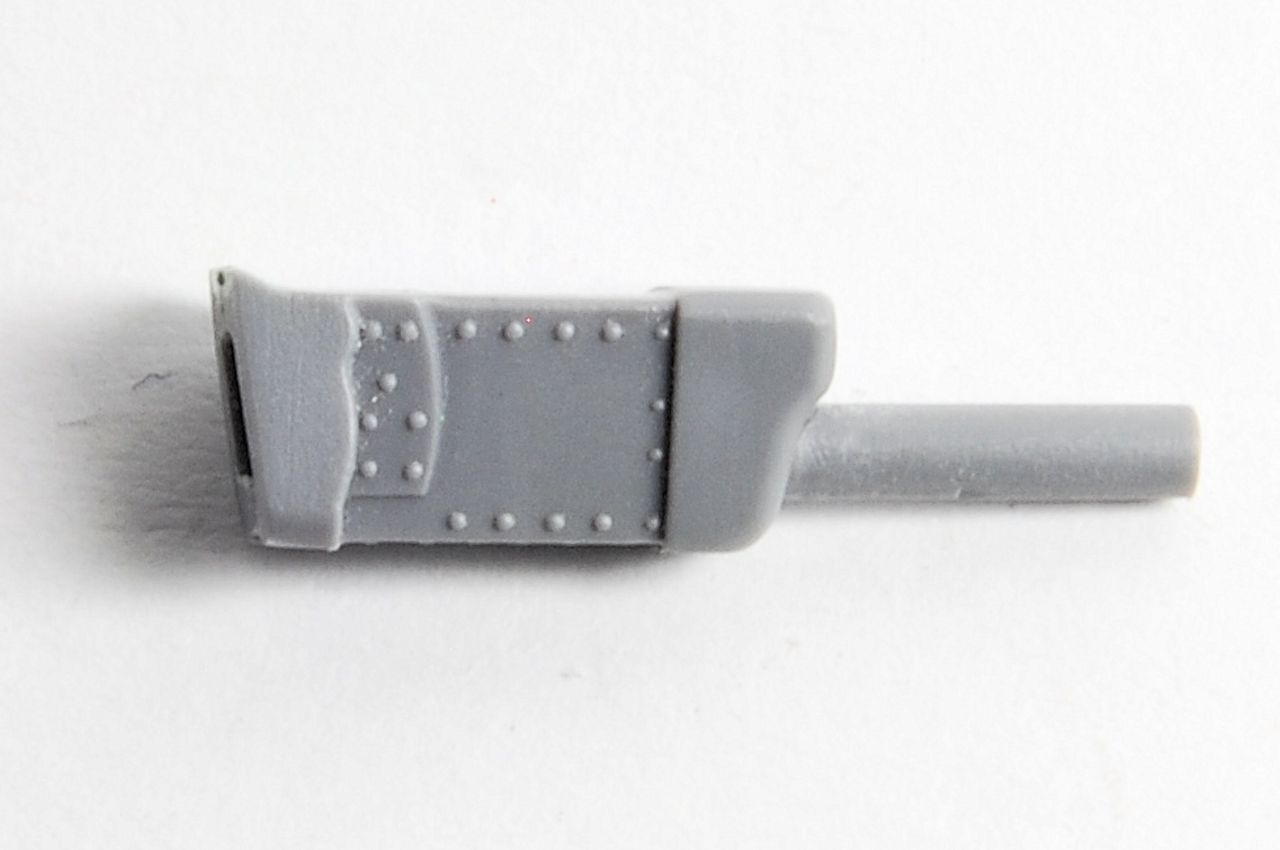

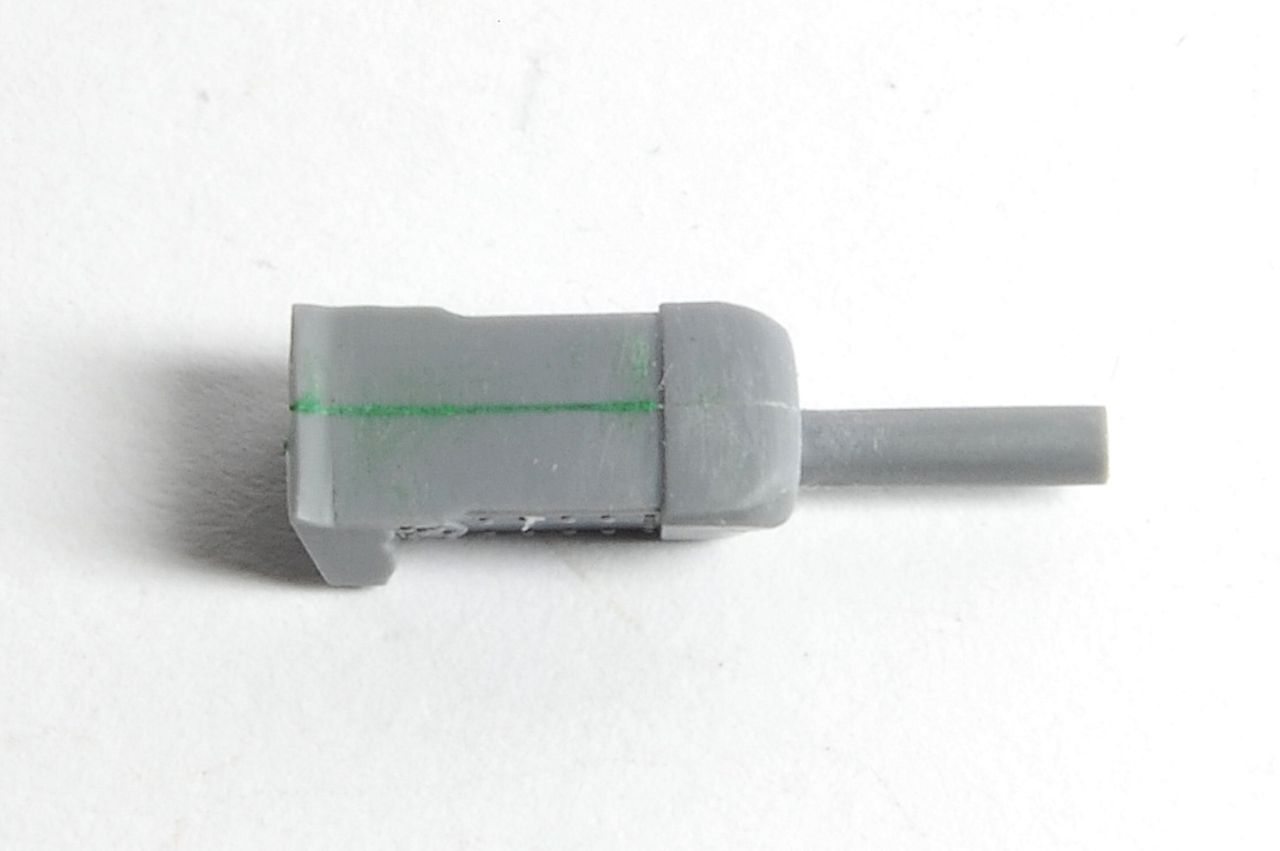

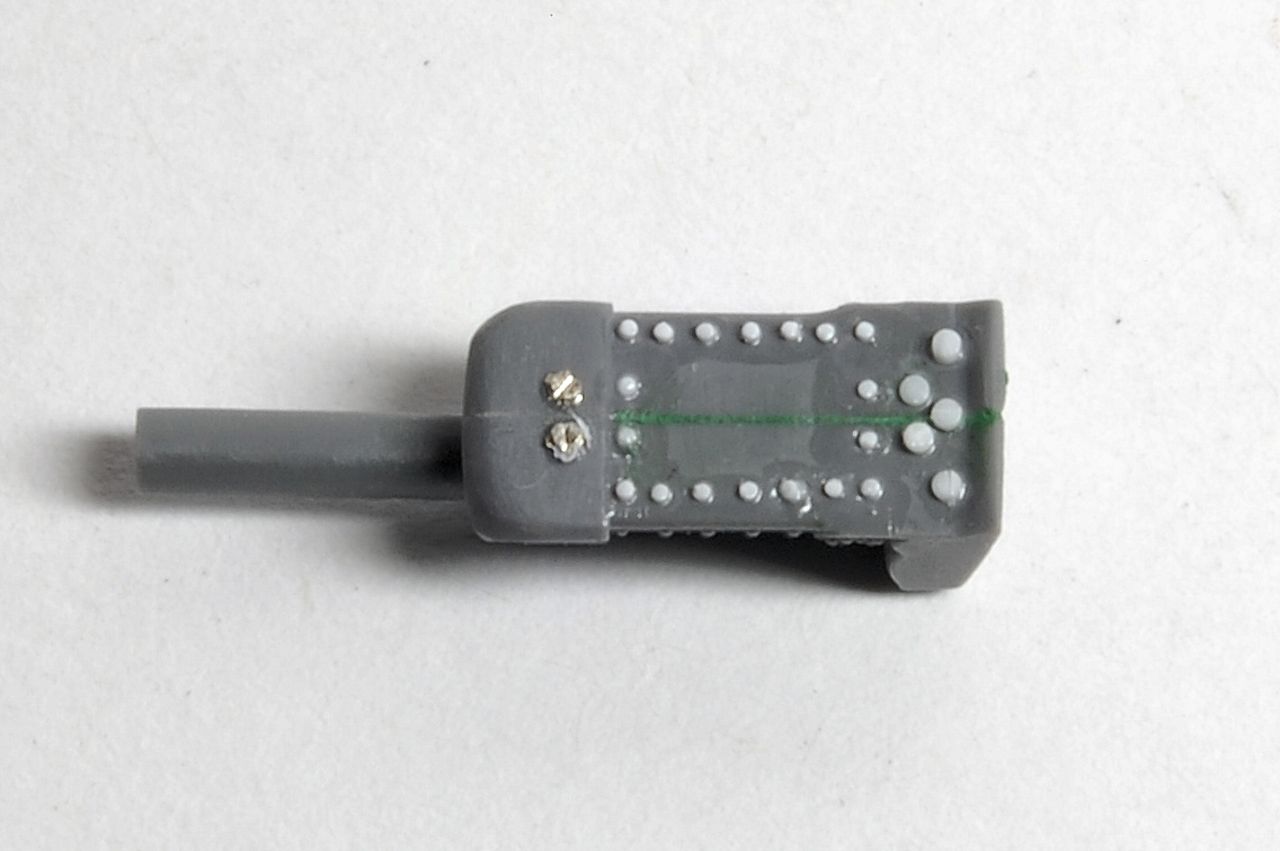

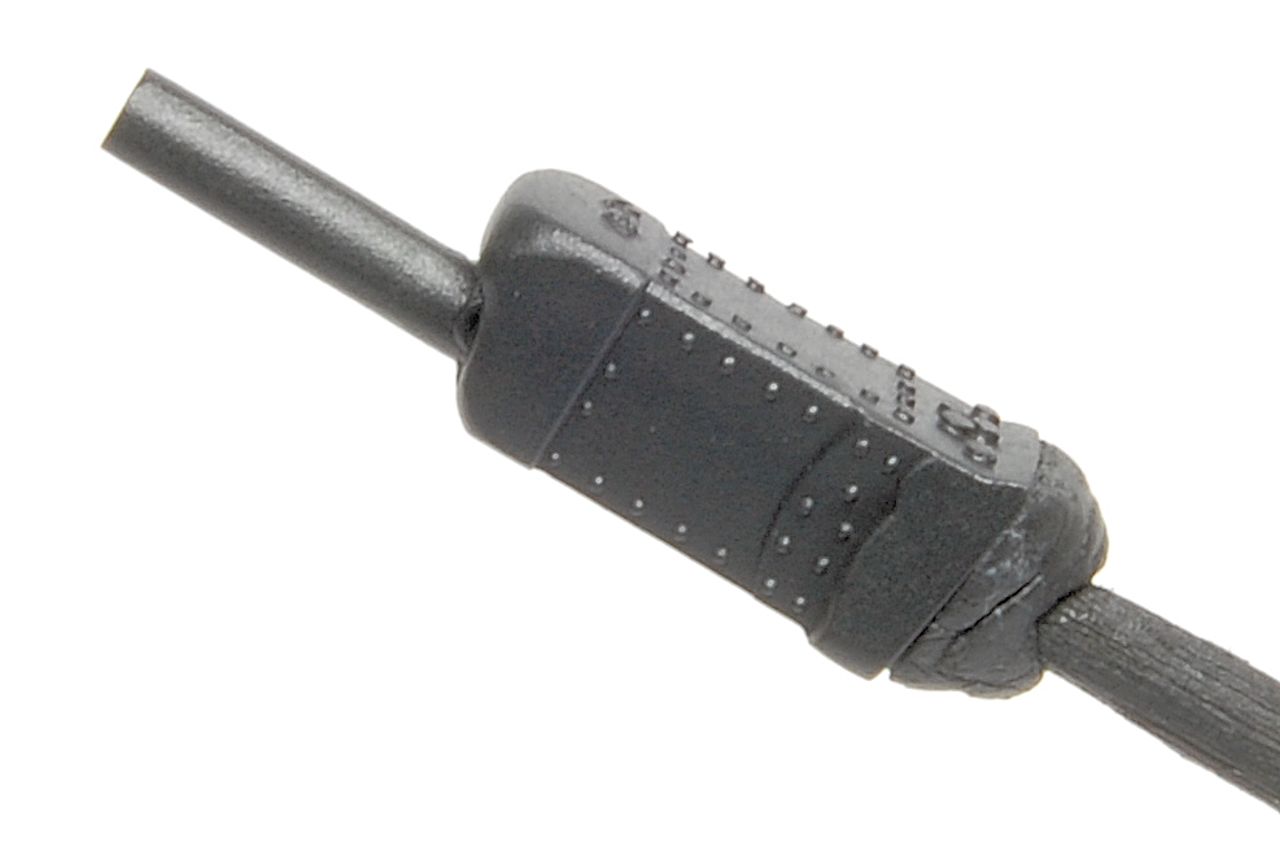

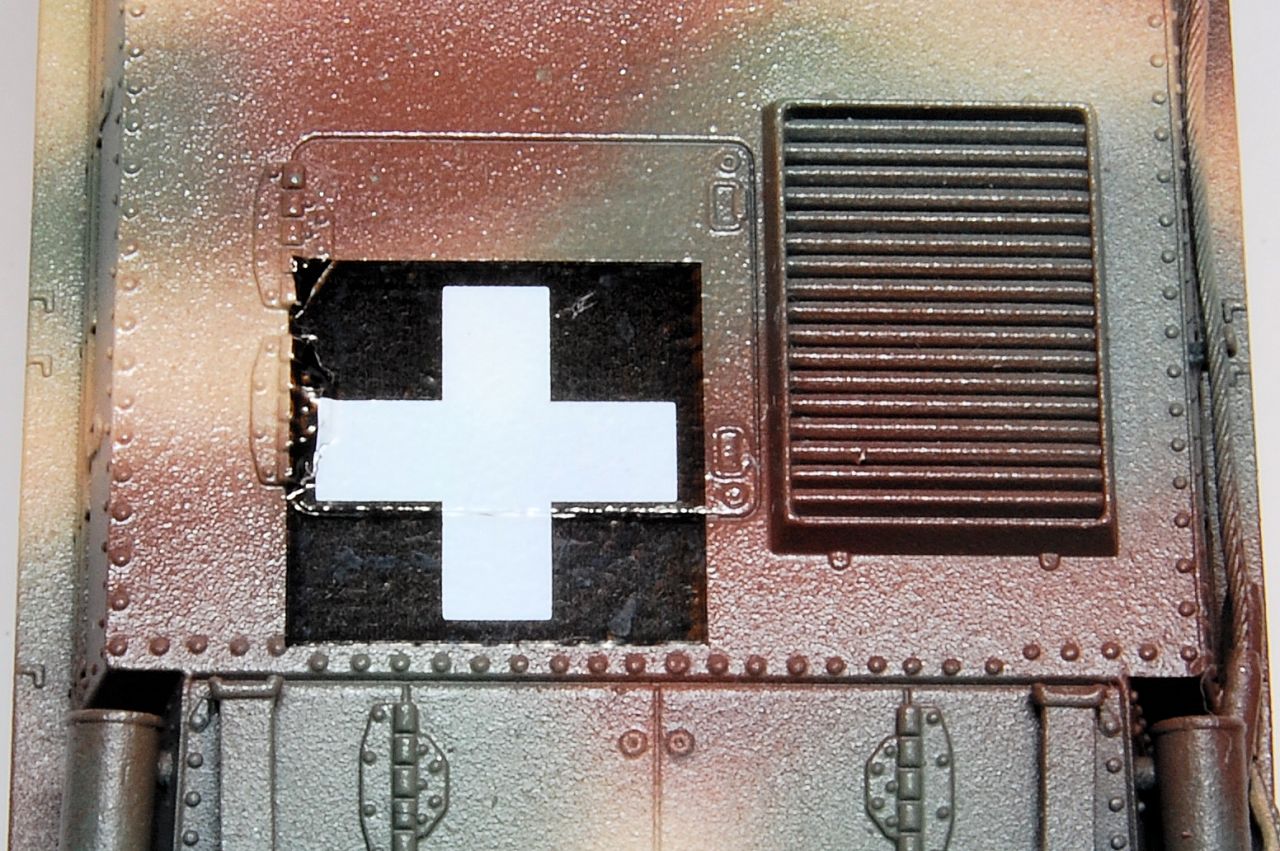

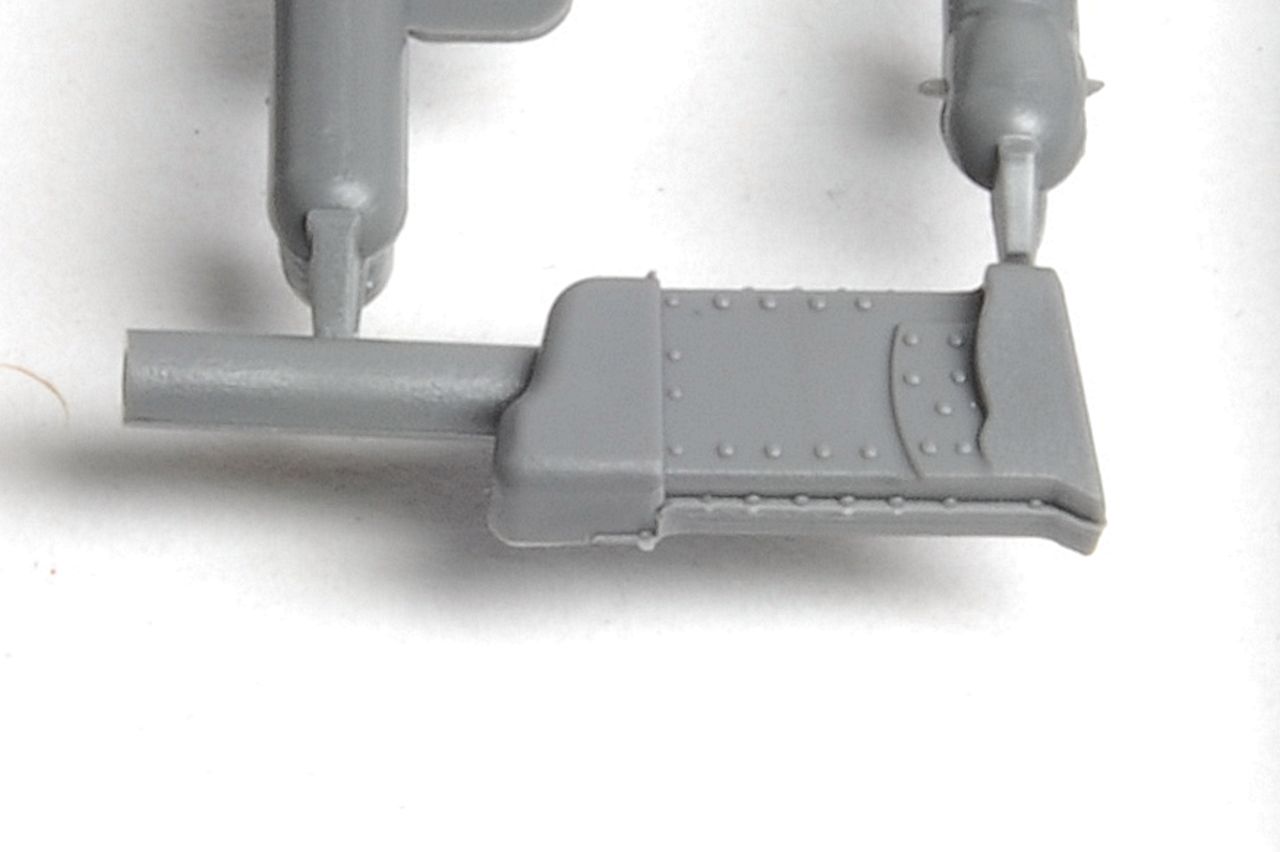

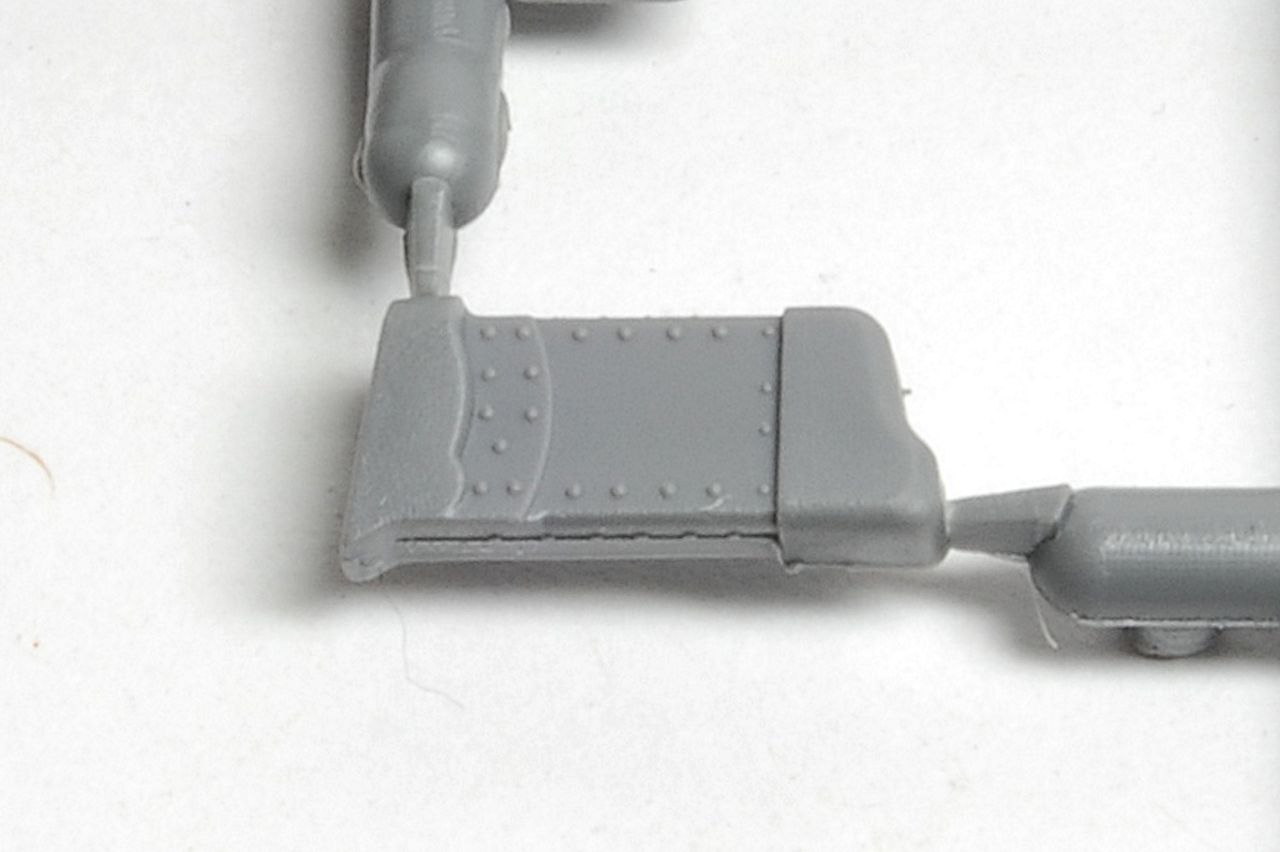

The new gun, changed from 40mm to 75mm, is moulded with the barrel as one slide moulded open ended tube with one half of the recuperator housing:

- and the other half:

Top marks for the slide moulded barrel, but not so sure that splitting the recuperator housing in this way was such a good idea...