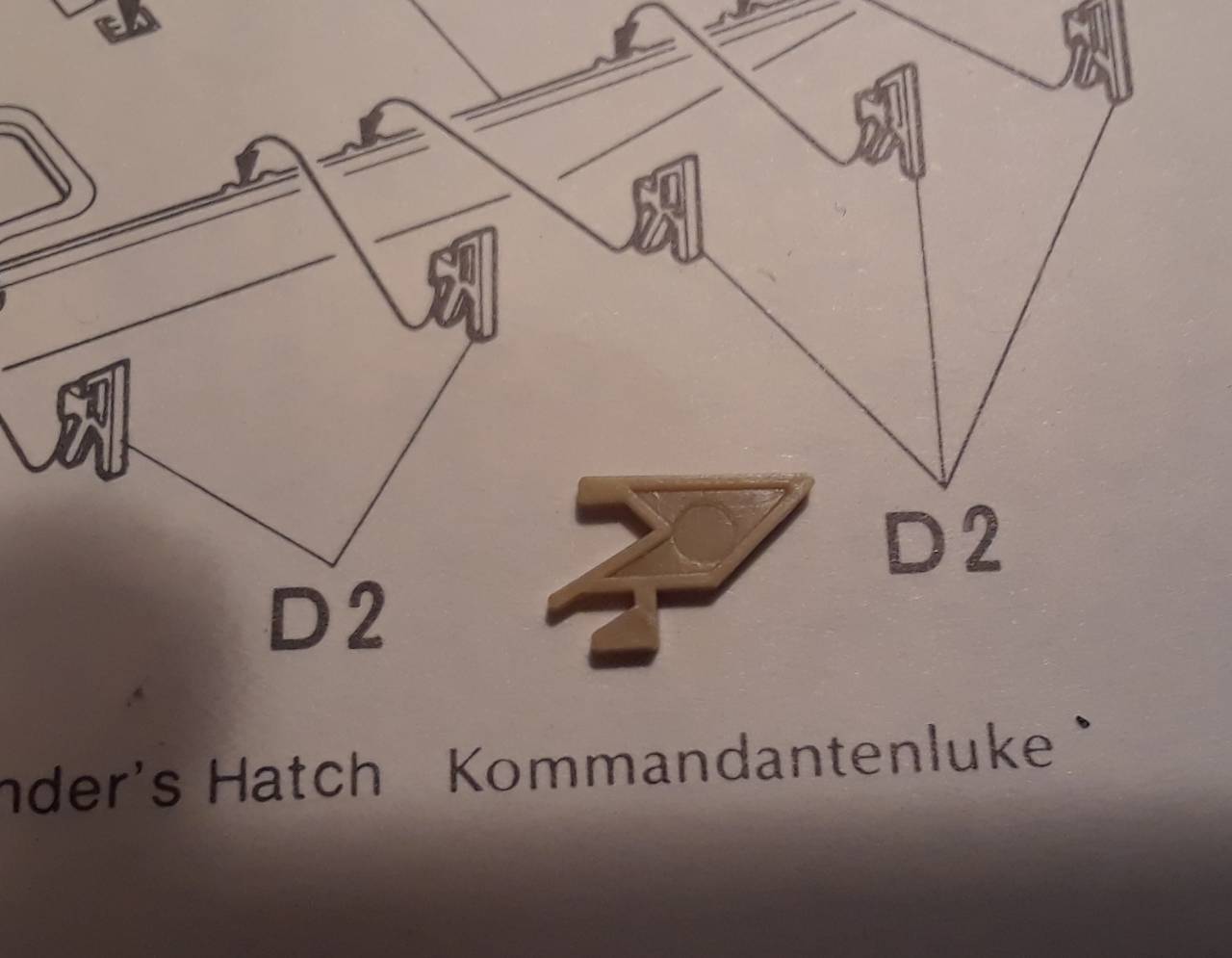

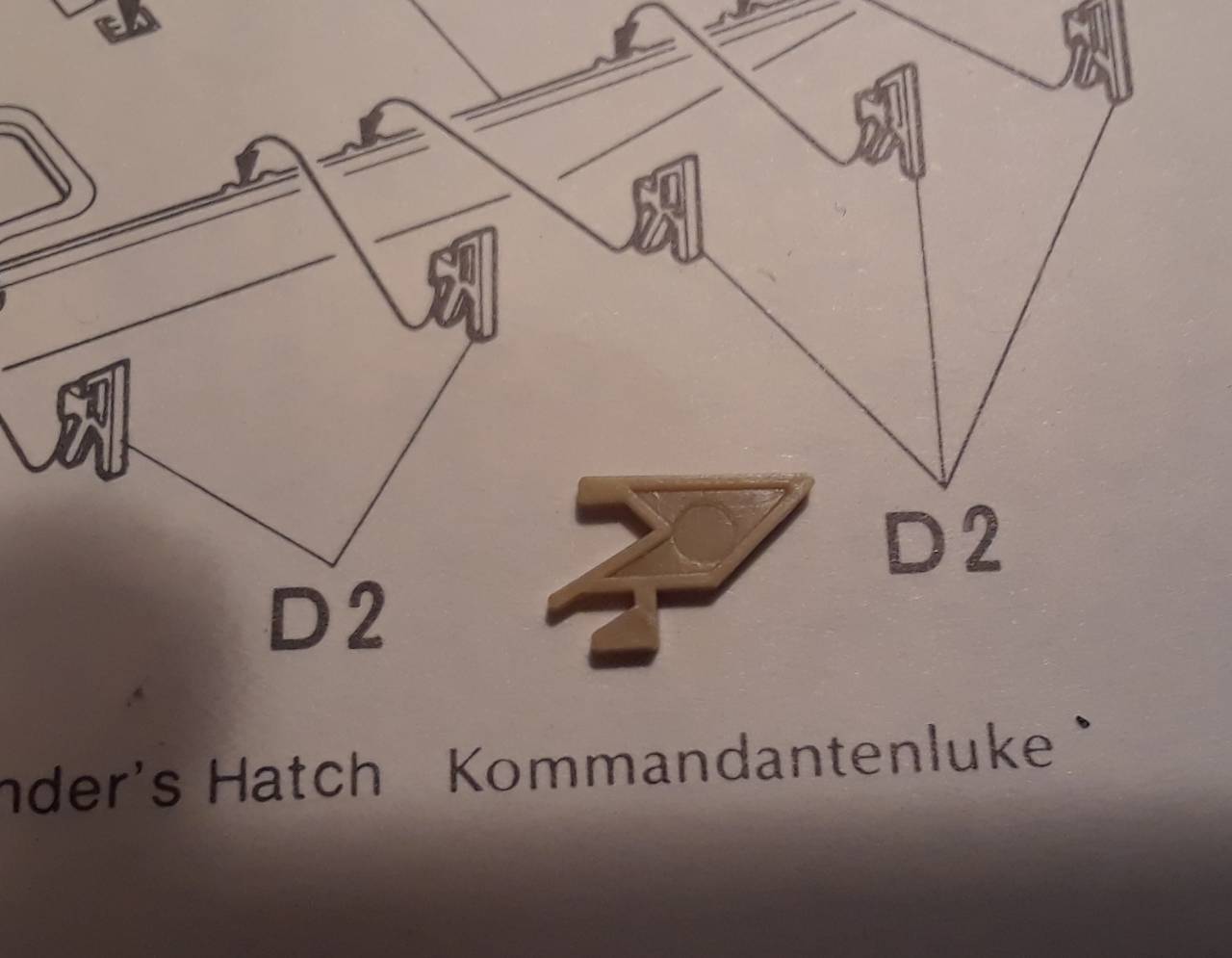

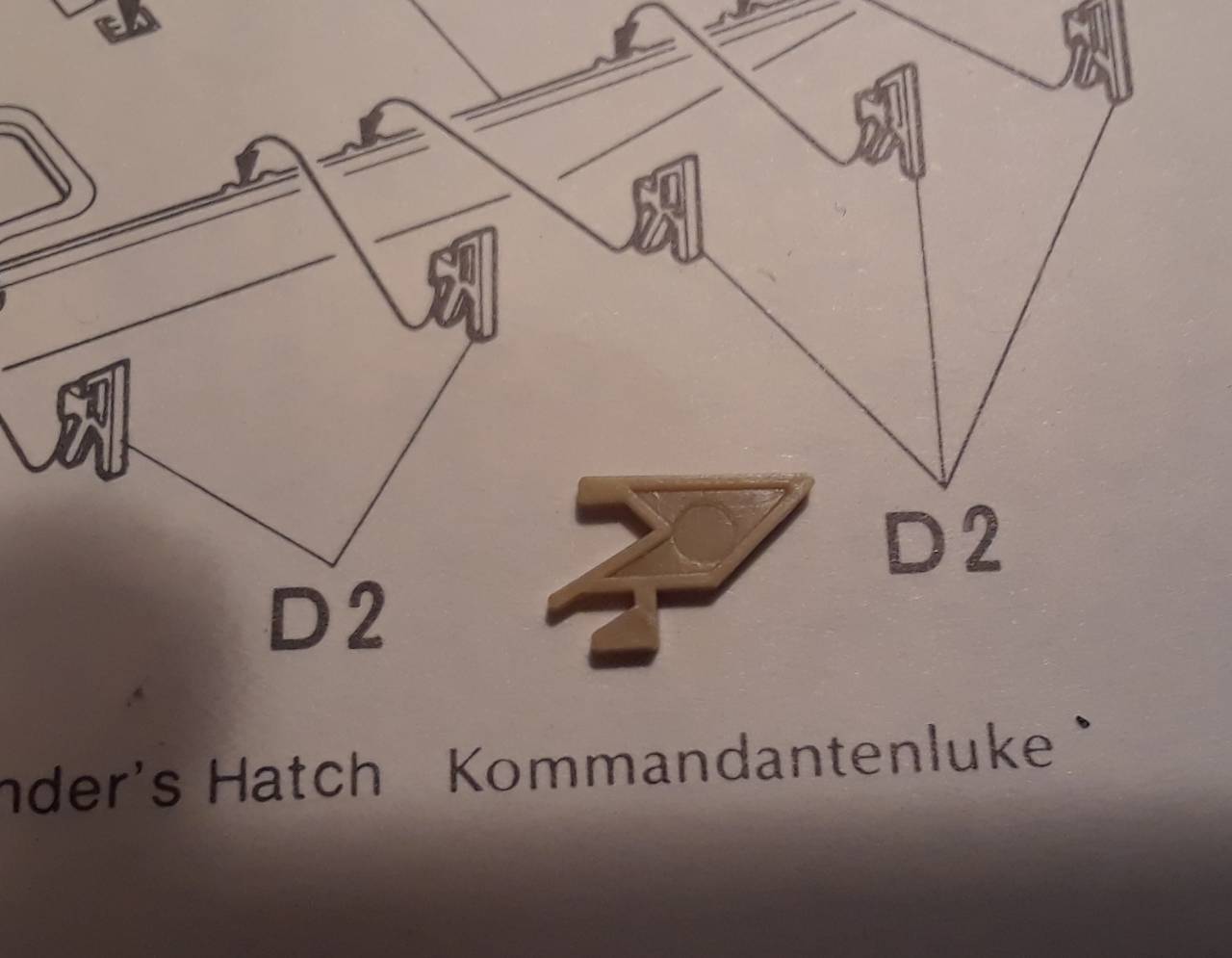

Im running into alot of these mold circles from an old Tamiya kit, how would you fill them?

Some people on here have these pens filled with fiberglass points that allow you to get into tight places and do some sanding.

Someone will pop up with the name of the tool. I would use that and just sand it away.

Gap filling superglue, or make some sprue goo (old sprues dissolved in liquid glue), or Mr Surfacer 500 (liquid).

Quoted TextGap filling superglue, or make some sprue goo (old sprues dissolved in liquid glue), or Mr Surfacer 500 (liquid).

The sprue/glue mixture has its own issues such as it takes an extremely long time for the liquid glue to evaporate. The remaining goop is never as hard as the plastic was in its original, undissolved form.

|