How to make a metal plate

12

Comments

Step Two:

This procedure is a choice you will have to make about how you want the patterns to form. Just make sure you do a random pattern oppose to a uniform one. The randomness of the pattern adds variable interest to the overall look of the completed steel plate. But as always, you decide.1. I started off by taking the smallest brush with its short bristles and dipped it into the rust pot and dabbed it onto the cardboard. I made small dabs at various intervals, randomly. Then, I took my medium size brush and did the same but with much longer dab strokes moving around at various areas. I left small spaces at various intervals as to not cover some of the black spray paint I did earlier. Itís good to let some of that black show through.

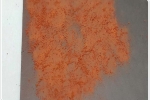

Pigment added to card. Just squash the coarser ones with a brush until it looks like the one in the photo below (click to expand)

The coarser pigment crushed to a powder (click to expand)

The enamel thinner I use (click to expand)

Soaking the pigment with the solution (click to expand)

The result of the enamel thinner drying (click to expand)

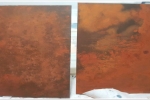

The results of two different patterns made with the rust pigments. Try using both standard and light rust (like in the pics below) to vary the colors of the rust (click to expand)

Here you can see the various patterns you can get. Most of these are pure luck. Here, I used Migís old rust. So the rust color is darker than the other rust color, I used for this tutorial. Notice the metallic edges of the steel plate. Thatís the effect you get by applying the metallic color to the edges that you will do in the last step. (click to expand)

Migís Light rust on the left & Standard rust on the right (click to expand)

Comments

Is there any advantage to using cardboard, or is it just because it is cheaper?

JUL 24, 2019 - 11:11 AM

I can think of a some:

1. Cheap to come by. AKA, easily available.

2. light weight

3. Easy to work with, in terms of application.

4. Does not need a lot of tooling

JUL 24, 2019 - 08:53 PM

The markings you see could be hand written in usually white or yellow paint stick, and may be the plate identity or tracking number, a heat number, order number, grade of steel, and maybe the gauge/thickness and also length x width.

Some places may line mark that information down the length of the plate, with what is essentially an inkjet printer (or some places use a set of stencils on a wheel - thatís old school)

Or there might also be a printed tag/sticker attached to an end with ID/Heat/grade and probably some bar code.

Not all plates would be scaled up and rusty. Stainless steel or other specialty metal plates like nickel or titanium alloys would be pickled clean, and would be somewhat shiny, or even ground and would be very shiny and clean.

If itís regular carbon steel and fresh off the rolling mill, I think the metal with have a more blue/gray coloration from the mill scale/oxide. If they sit out for a long time the oxide/rust will grow and it becomes the red/brown.

And plated unless they are belt ground are rarely totally smooth. There will be some pits (would be small in most models), there could be some firecrack pattern from the rolls that may repeat - many other things get transferred from the rolls or vacuum lifters etc.

AUG 14, 2019 - 01:52 PM

Copyright ©2021 by Charles King. Images and/or videos also by copyright holder unless otherwise noted. The views and opinions expressed herein are solely the views and opinions of the authors and/or contributors to this Web site and do not necessarily represent the views and/or opinions of Armorama, KitMaker Network, or Silver Star Enterrpises. All rights reserved. Originally published on: 2019-07-24 16:57:22. Unique Reads: 16478