Hi there

I've made a start on the new version of Dragon's Tiger, reviewed HERE. Being primarily an Aircraft modeller, this will all be pretty much new territory for me, so I hope you'll make the necessary allowances.

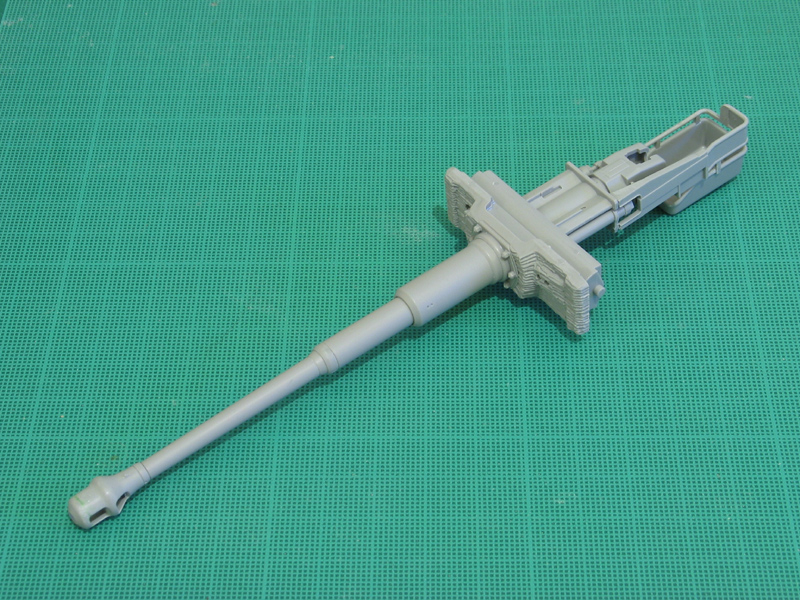

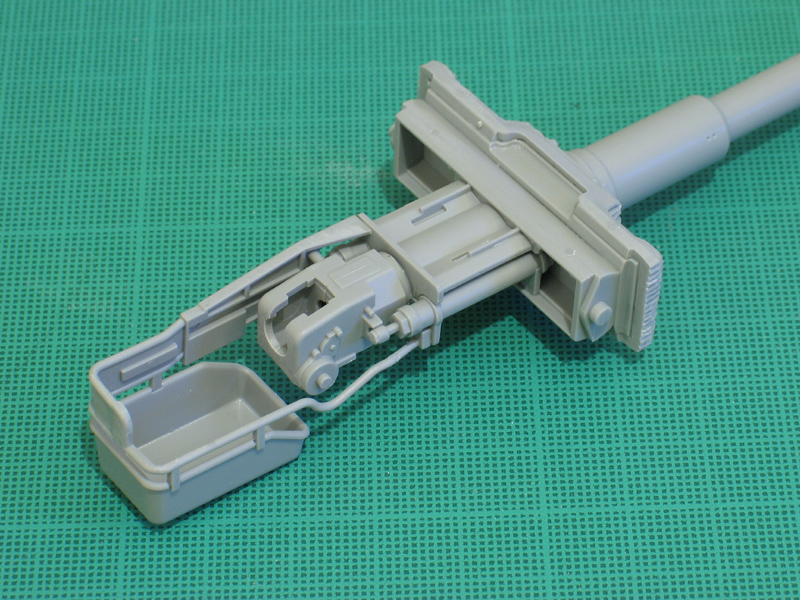

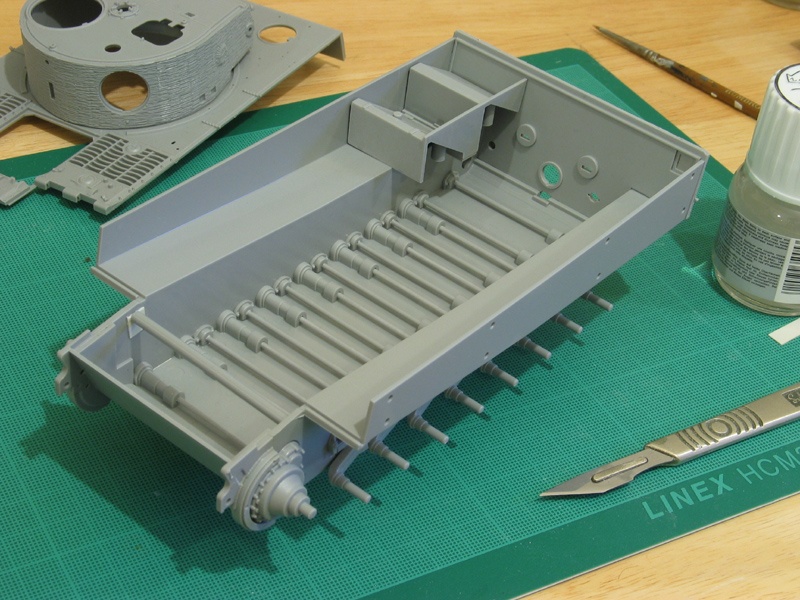

The main hull and suspension has gone together neatly enough:

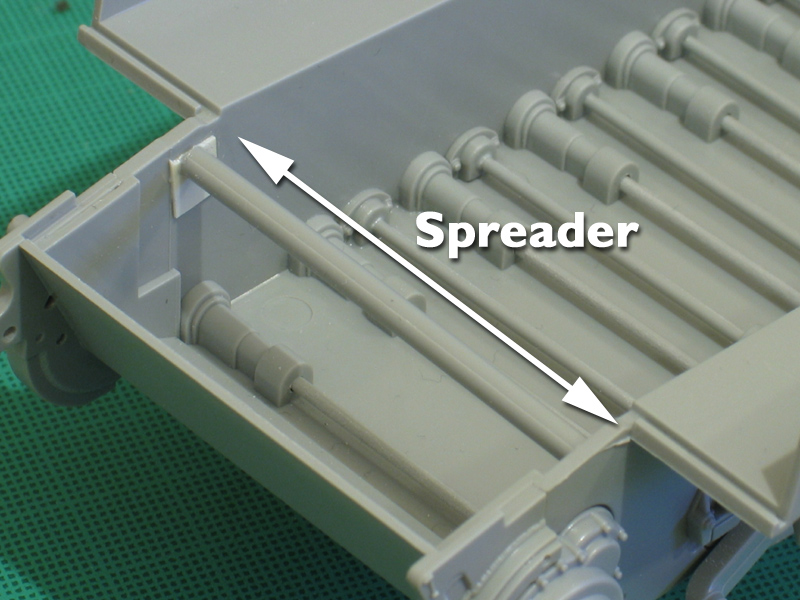

As I noted in the review, the hull sides bow inwards. The rear is taken care of when the end section (Part D3) is added, but I've fitted a spreader bar at the front to help keep things parallel:

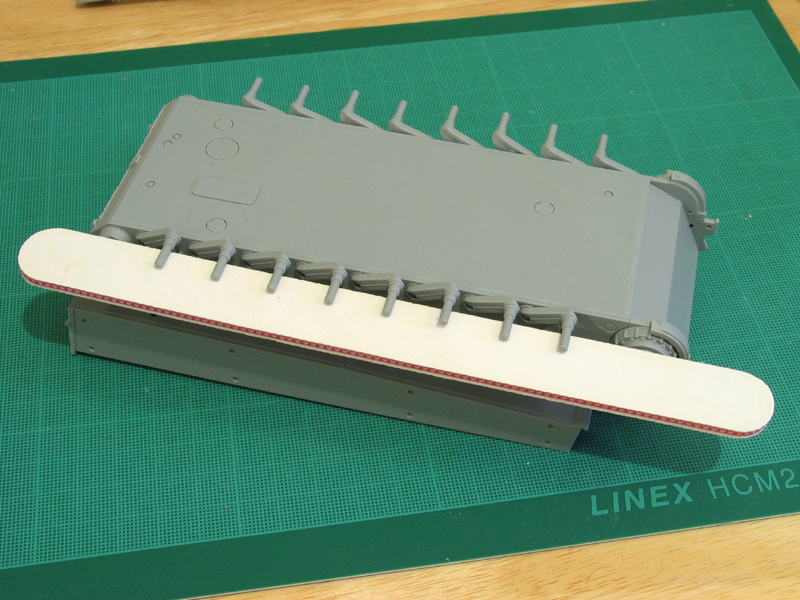

To begin with, I only attached the suspension rods with a drop of cement at the far end. This allows the arms to flex somewhat and I thought it might allow a realistic degree of movement. But as the day's gone on, I've begun to worry that, left like that, the suspension will be too flimsy and slowly sag under the weight of the finished model - the arms are already settling at noticeably different angles. Therefore I've decided to level everything up, using a sanding stick as a guide, and cement the arms firmly in place:

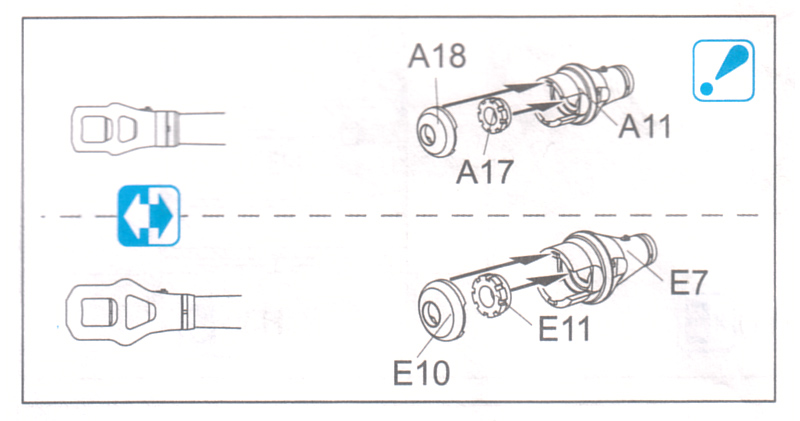

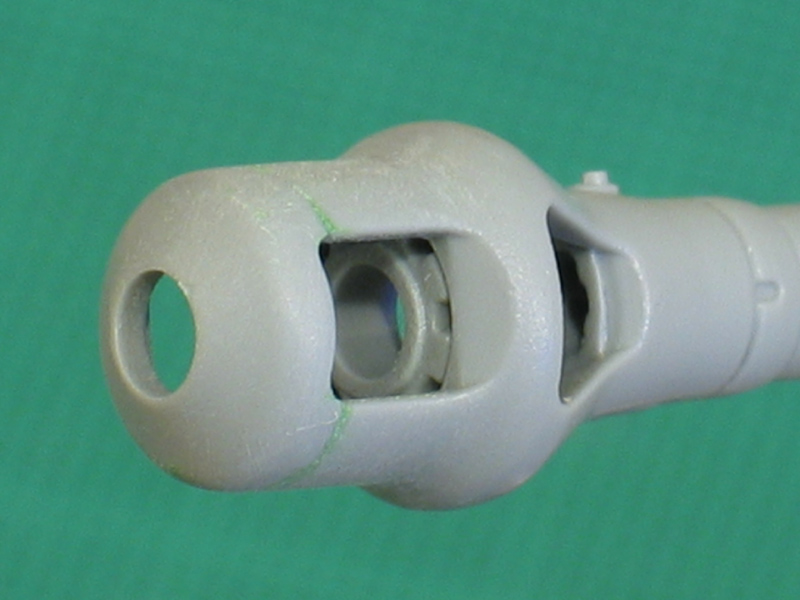

Now here I'll have to risk showing my ignorance of tank anatomy. I presume the full-sized rear tensioning wheel was adjustable between the two raised stops? The kit parts (B26) are loose with a much greater arc of travel. Anyway, here's my beginner's question before I cement them in place: Was there a standard "neutral" position for a tank at rest, or is anything between the stops fine (presumably the same on both sides...)?

All the best - and I'll blunder on now...

Rowan