Hello Everyone,

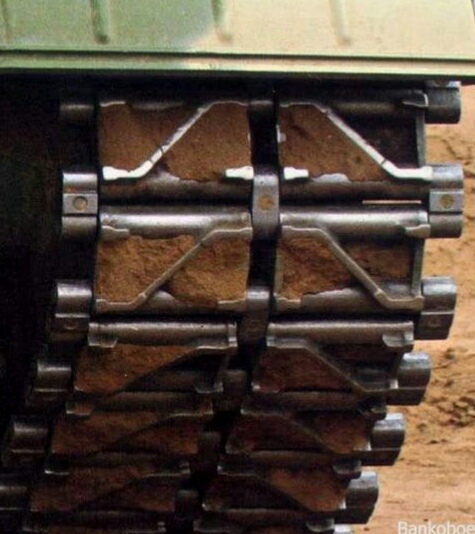

I haven’t posted anything in while, mostly due to my not having worked on a proper kit of any subject in a few years. What I have been doing, scale model-wise, is working on Friulmodel tracks to replace the kit originals on a few previously completed AFVs.

I’m posting in this thread since this entry covers a few topics already mentioned here: Rust vs dirt, and bare metal contact points.

I’ve developed a somewhat simple technique, that I call the ‘Calico Method’, for painting metal tracks. After trying and failing with homebrewed chemical oxidizers (I’m too cheap and lazy to try to get the profession stuff available on the market) and traditional weathering techniques, I reverted back to my trusty artist’s oils and chalks to obtain the same effects.

Prep each track run in the usual way:

1. Remove the flash and/or mold lines from each track link.

2. Drill out the connecting pin holes on each track link.

3. Clean all the track links by gently scrubbing them in a bath of liquid soap and water.

4. Allow all the track links to thoroughly dry.

5. Cut the wire to ‘pin’ length.

6. Assemble the track links into track runs by connecting the proper number of links together with the wire ‘pins.’ Assemble any remaining tread links into a number of spare track runs.

7. Gluing the pins: Optional. On my first set I used a drop of CA glue at the end of each pin to hold it in place. By the second set of tracks I built I realized that the tension and friction between the tracks and the wire lengths is enough to hold the wire ‘pins’ in place, without having that annoying blob of glue at the end of each pin that may require cleanup and may also resist paint.

Use oils to mimic the steel color obtained by the oxidizing chemicals:

1. Place a puddle of black oil paint on a palette and add a few dollops of titanium white oil paint, and mix until a desired dark gray hue is obtained. NOTE: It needn’t be a metallic color since the bare metal will show through at the completion of Step 3.

2. Liberally apply the gray color as a sludge wash across both the tops and bottoms of the track length.

3. Remove the excess wash by dabbing it with paper towels and cotton swabs. Be sure to also articulate each pivot point and wipe in-between to ensure there is not a thick buildup of the wash that may be visible when spooled around a sprocket or idler wheel.

4. Leave the resultant ‘steel’ tracks to dry for the better part of a week.

Use oil chalks to recreate the slight rust and dirt/dust/dried mud of either a well-maintained vehicle or one operating in an arid/desert zone:

1. Using a sharp blade, shave a range of colors of oil chalk stick colors into mounds of loose chalk on a palette. These are the colors I’ve been using:

a. Off-White

b. Desert or Dingy Yellow

c. Light Brown

d. Dark Brown

e. Black

2. Apply a coat of the appropriate mixing agent/thinner for the chalk brand and type onto each length of track. With the brand I have, tap water works just fine.

3. Apply the colors by dabbing the loose chalk onto the treads with a bristle brush in a loose checkerboard pattern across the top and bottom of each track run, hence the ‘Calico Method’. This is similar to Georg Eyerman’s technique:

https://armorama.kitmaker.net/features/7385 NOTE: Dabbing loose chalk onto the liquid on the track run applies a thinner layer of pigment than mixing each chalk color into a liquid and then dabbing it onto the treads. Doing it this way allows more of the ‘steel’ color to show through.

4. Blend the checkerboard dabs together loosely, to resemble the colors on the pelt of a calico cat.

5. Once dry, remove the excess chalk using a large, bristle brush.

6. Rub the pigment off the track guide horns and contact points with a dry cotton swab. (The cotton swabs thath have a combination pointy end and paddle shaped end found in the makeup section of large department stores work well.) This leaves the metal semi-bare, with a hint of dirt and grime, and not bright & shiny as sandpaper or a file does.

7. Finally, seal the paint by applying a coat of clear matte to each side of each tread run.

This method isn’t for everyone, and is probably not appropriate nor accurate for depicting vehicles that operate in muddy terrain. However, if you believe it may suite your needs and you wish to try it, please first attempt it on a short, spare run of AM indy-link metal tracks.

Keith