Whats the easiest way I can make weld beads in 1/35?

I see some people use strips of styrene or is that putty?

Thanks

Jim

AFV Painting & Weathering

Answers to questions about the right paint scheme or tips for the right effect.

Answers to questions about the right paint scheme or tips for the right effect.

Hosted by Darren Baker, Matthew Toms

Weld beads

jvazquez

Joined: September 26, 2006

KitMaker: 857 posts

Armorama: 811 posts

Posted: Thursday, March 12, 2009 - 08:58 AM UTC

GeraldOwens

Joined: March 30, 2006

KitMaker: 3,736 posts

Armorama: 3,697 posts

Posted: Thursday, March 12, 2009 - 09:12 AM UTC

Quoted Text

Whats the easiest way I can make weld beads in 1/35?

I see some people use strips of styrene or is that putty?

Thanks

Jim

Either. Some people like to use hobby putty or epoxy putty (or even gel-type superglue) applied between two strips of tape to define the edges. Texture the bead with a small screwdriver or the tip of a hobby knife. Lift the tape before the material sets.

Some prefer to glue a strip of styrene and soften that with a slow setting liquid cement and texture with a blade while it's soft. Alternatively, if you have a tool like a pyrogravure (a modified wood-burning tool) or a hot knife (a soldering iron with an X-acto blade on the end), you can use heat to soften and texture the plastic strip instead of solvent. This last technique is more dangerous, obviously, and less forgiving of mistakes. On some modern vehicles, the welds have been cleaned up with a grinder, so all you see is a rounded raised area. In that case, the half round styrene strip now sold by Plastruct is a good choice. Just cement it in place and you're done.

You can also buy pre-made weld beads. Several photoetch makers sell brass weld beads that you simply superglue in place. Alternatively, Archer Dry Transfers now sells three dimensional resin weld beads on decal film that you apply like any regular decal.

JimMrr

Joined: January 03, 2007

KitMaker: 1,505 posts

Armorama: 382 posts

Posted: Thursday, March 12, 2009 - 09:17 AM UTC

Iv seen a really great weldbead tool made from an old syringe needle. The pointy bit gets ground off and a divet is cut half way down the tube (hard to explain..)..you just use liquid cement or putty and press these in one after the other and its very convincing..

SIRNEIL

Joined: July 30, 2007

KitMaker: 658 posts

Armorama: 599 posts

Posted: Thursday, March 12, 2009 - 09:21 AM UTC

Hi james

this link should help you https://armorama.kitmaker.net//features/220&page=1

this link should help you https://armorama.kitmaker.net//features/220&page=1

Removed by original poster on 03/12/09 - 21:27:19 (GMT).

jvazquez

Joined: September 26, 2006

KitMaker: 857 posts

Armorama: 811 posts

Posted: Thursday, March 12, 2009 - 11:36 AM UTC

Once again Thanks guys!

I promise one of these years I will start posting some of my work, if I ever really finish a project...

I promise one of these years I will start posting some of my work, if I ever really finish a project...

UncaBret

Joined: May 11, 2008

KitMaker: 767 posts

Armorama: 672 posts

Posted: Thursday, March 12, 2009 - 12:59 PM UTC

Quoted Text

Both.

That was helpful.

HONEYCUT

Joined: May 07, 2003

KitMaker: 4,002 posts

Armorama: 2,947 posts

Posted: Thursday, March 12, 2009 - 07:50 PM UTC

Hey James

The easiest way to make weld beads depends on your skill level. Some can handle putty well and therefore that may prove easiest for them, whereas the strip styrene can be made to work well with a steady hand. If you mask off the bead lines in question, both can produce good tidy results, which can then be roughed up a little as required as some of the welding was crude, yet effective for it's purpose.

Brad

Hmmm. With insight? There were actually two questions.

The easiest way to make weld beads depends on your skill level. Some can handle putty well and therefore that may prove easiest for them, whereas the strip styrene can be made to work well with a steady hand. If you mask off the bead lines in question, both can produce good tidy results, which can then be roughed up a little as required as some of the welding was crude, yet effective for it's purpose.

Brad

Quoted Text

The answer was to the point. How else can that question be answered?

Hmmm. With insight? There were actually two questions.

HONEYCUT

Joined: May 07, 2003

KitMaker: 4,002 posts

Armorama: 2,947 posts

Posted: Thursday, March 12, 2009 - 09:27 PM UTC

Quoted Text

Quoted TextHmmm. With insight? There were actually two questions.

And I chose to answer the second one. Any law against not answering them all? You seemed to handel the "insight". Besides, what do making weld beads have to do with painting?

So you saw the first and decided it would take too much effort to be civil and provide some information..

There's no law against it being in "Painting", or to kindly inform James that it should be moved either. Thoughts?

Grumpyoldman

Joined: October 17, 2003

KitMaker: 15,338 posts

Armorama: 7,297 posts

Posted: Thursday, March 12, 2009 - 10:18 PM UTC

OK.... the question has been answered, Maybe it's time to move along and forget whether you like or dislike how it was answered, or whether you like, or dislike the way it was answered. Everything after the answers serves no purpose except to start another argument. If you do not like how Gary answers questions, try using the hide user button.

SSGToms

Joined: April 02, 2005

KitMaker: 3,608 posts

Armorama: 3,092 posts

Posted: Friday, March 13, 2009 - 06:26 AM UTC

One more post NOT having to do with weld bead techniques and I will lock this topic.

Petty bickering doesn't help the guy who wants to learn.

Petty bickering doesn't help the guy who wants to learn.

MLD

Joined: July 21, 2002

KitMaker: 3,569 posts

Armorama: 2,070 posts

Posted: Friday, March 13, 2009 - 12:52 PM UTC

Three other methods spring to mind for making/simulating weld beads.

Archer Dry transfers make a dry transfer, rub down product.

Aber makes photoetched weld beads as does at least one other manufacturer... Part?

Some folks use lead fly fishing fly tying wire superglued onto the kit or into carved channels/groves and texture this.

Mike

Archer Dry transfers make a dry transfer, rub down product.

Aber makes photoetched weld beads as does at least one other manufacturer... Part?

Some folks use lead fly fishing fly tying wire superglued onto the kit or into carved channels/groves and texture this.

Mike

woody6968

Joined: March 02, 2006

KitMaker: 454 posts

Armorama: 380 posts

Posted: Saturday, March 14, 2009 - 07:14 AM UTC

hi james .

i use a length of streched spure soffened with liquid polly , its easy cheap and effective ,ive took a few pics of this method ive used on my m2a2 i'll put the pics up tomorrow so you can see the results ,, good luck with which ever method you choose .

i use a length of streched spure soffened with liquid polly , its easy cheap and effective ,ive took a few pics of this method ive used on my m2a2 i'll put the pics up tomorrow so you can see the results ,, good luck with which ever method you choose .

Posted: Saturday, March 14, 2009 - 07:29 AM UTC

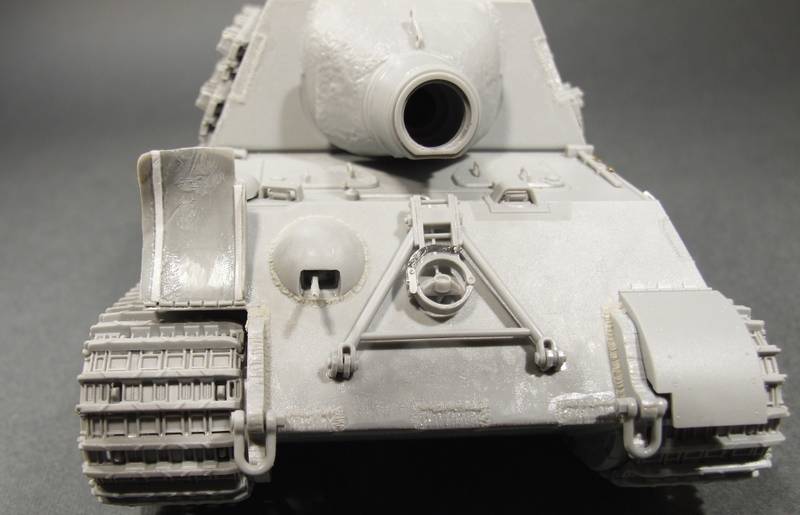

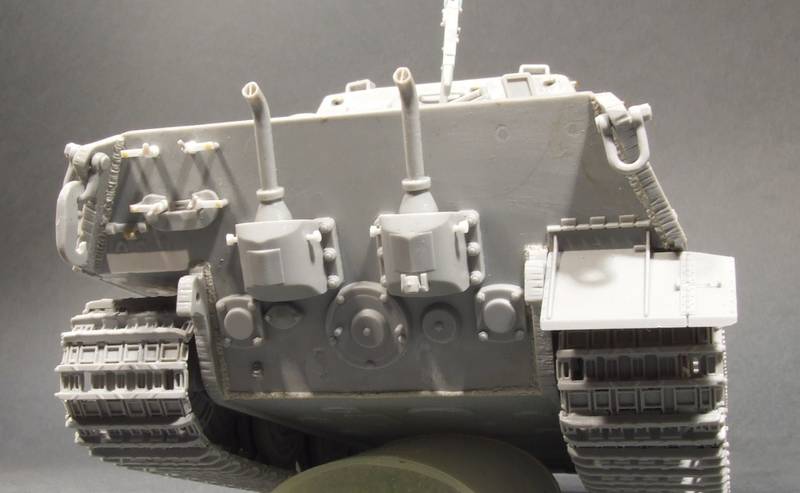

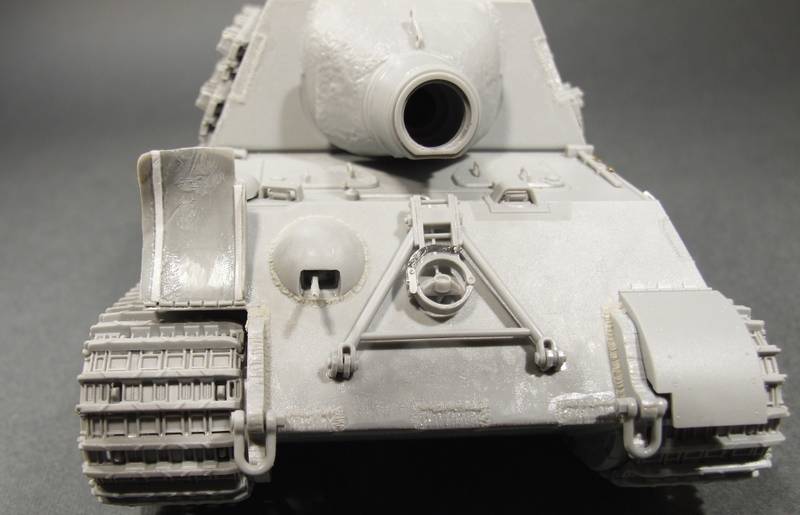

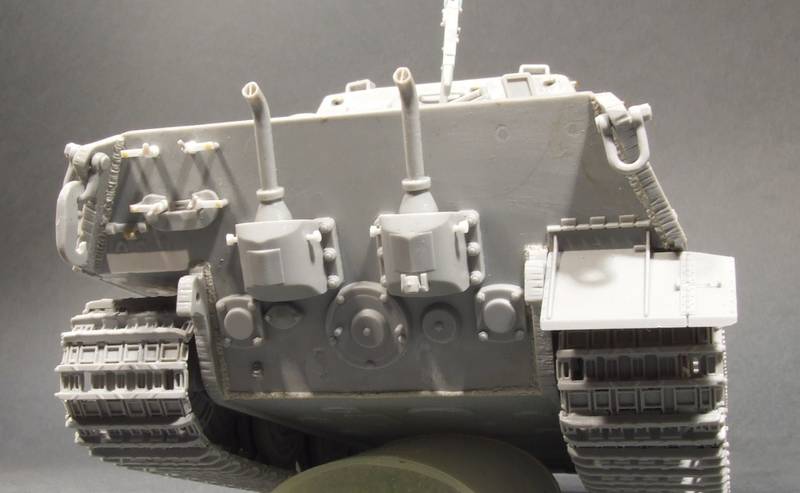

Hi James. A few months ago, I built a Dragon Jagdtiger, just to try out some of the welding affects that have been talked about. I tried both stretched sprue and 2 part putty, and felt the 2 part putty was so much easier. Ive read since that tamiya plastic is the bees knees for this method ... so that may be use ful.

Definatly read the Lee Lloyd method .... Direct Link ... and the modified hypodermic needles.

I used magic sculpt ... which allowed me to remove and work each weld until i was happy. Below are 2 images of how it turned out. I was happy enough with it for a first attempt.

Its a great technique to carry with you .. very handy for hiding appropriate joints and even around added details.

Definatly read the Lee Lloyd method .... Direct Link ... and the modified hypodermic needles.

I used magic sculpt ... which allowed me to remove and work each weld until i was happy. Below are 2 images of how it turned out. I was happy enough with it for a first attempt.

Its a great technique to carry with you .. very handy for hiding appropriate joints and even around added details.

woody6968

Joined: March 02, 2006

KitMaker: 454 posts

Armorama: 380 posts

Posted: Monday, March 16, 2009 - 01:01 AM UTC

heres a few pics james..

easyco69

Joined: November 03, 2012

KitMaker: 2,275 posts

Armorama: 2,233 posts

Posted: Friday, August 02, 2013 - 01:14 AM UTC

What about using silicon for a weld bead?

|