Bill, you make some fair points about value decisions, but I'd like to say that I'm very encouraged to have a US domestic armor PE producer again. Ever since "On the Mark Models" dropped out of the picture in the early- to mid-90's, we here in the US have had to rely on overseas companies for our armor PE.

This is not to say that there's anything wrong with Eduard, Aber, The Show Modeling, Voyager, etc. All make some very nice products. However, the shipping and often limited availability has been very problematic, at least for me.

As an example, a fellow member in our AMPS club recently placed an overseas order for several Voyager PE sets. After shopping hard, he found that hese PE sets were only available from an Asian retailer. The cost of the PE was about US$150 (a fair price for what he was ordering), but his shipping cost was over US$50! That shipping added over 33% to his total cost.

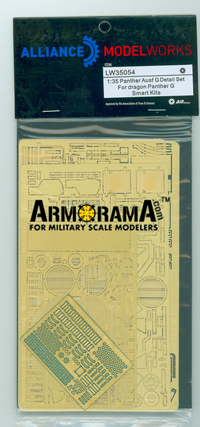

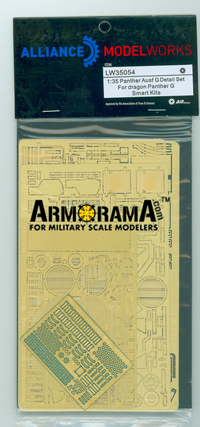

Being able to purchase AM-Works without the killer shipping costs puts a different perspective on the suggested retail price for the Panther G set. (Of course, for our friends outside of the US the opposite side of the coin comes into play!)

So, as I mentioned above, IMO, the AM-Works PE is a very good to excellent value. It's vvery well engineered and designed, so the quality is as good or better than any other manufacturer and the costs are very competative.

Here's a couple pictures from an up-coming article for our AMPS club newsletter on the "history" of PE German Tool Clamps that illustrate the engineering and design. (When compared to other, earlier designs for PE tool clamps, this engineering superiority really stands out, but you'll have to read the full article to see all the photos.)

These clamps are from the Alliance Model Works Tool Clamp set #LW35046. This set retails for about US$10 and provides parts to assemble 136 individual working tool clamps in 2 diferent types (early and late), in three different sizes (small, medium, and large) for each type!

Not only do you get enough parts to make tool clamps for a veritable entire Panzer Abteilung, but the parts are carried on an adheasive plastic backer sheet, so they don't have to be cut off a fret and cleaned up before assembly. (This is why in our article the AM-Works PE parts are called Generation 3.5 tool clamps...)

This method of delivery for PE parts has long been used in a limited manner by companies that produce PE for model trains, etc, but almost no one until now has regularly supplied armor model PE in this way. Again, for my money, this is another valuation factor to be considered.

Anyways, sorry to "hijack" your review here, Bill, but (I guess it's obvious...) I'm pretty pumped about what AM-Works is doing and how they're doing it...

BTW: The "Unauthorized and Incomplete History of Photo-Etched German Tool Clamps" can be found in the V2, N8 issue of the "Wildcat" at:

AMPS Central SC "Wildcats" Keep up the good work Bill!