The kit itself is reviewed here and covers the basic kit. I won't go into the details, but will dive right into the kit.

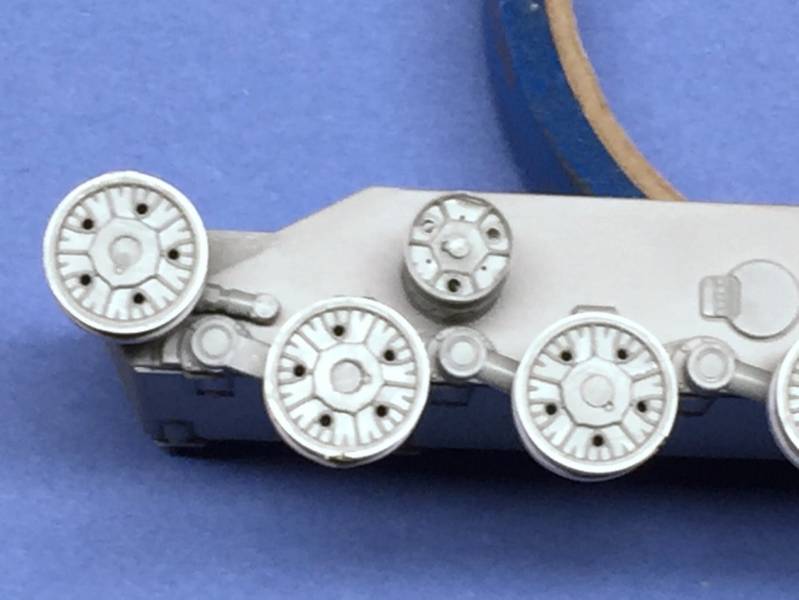

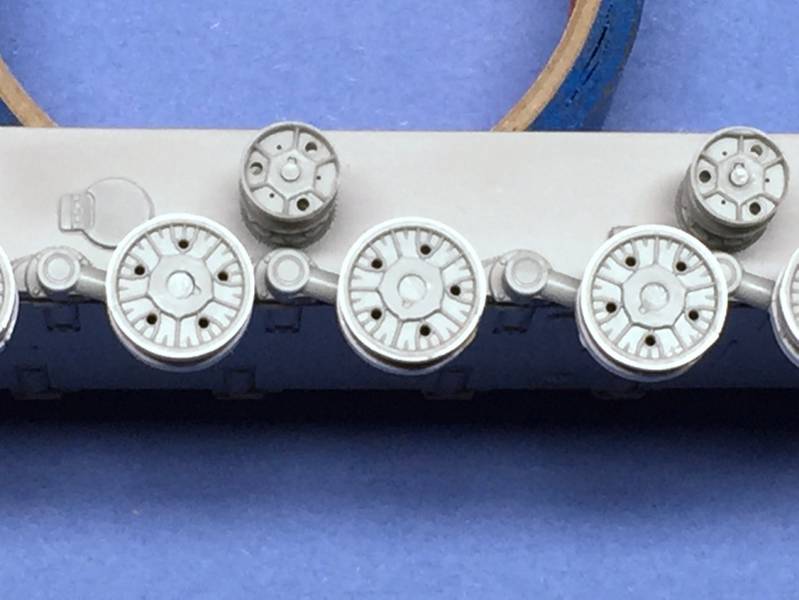

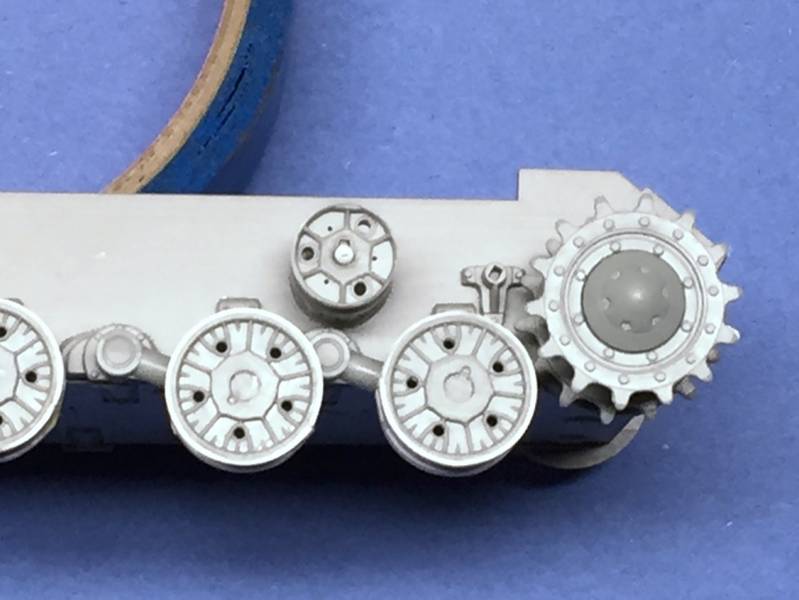

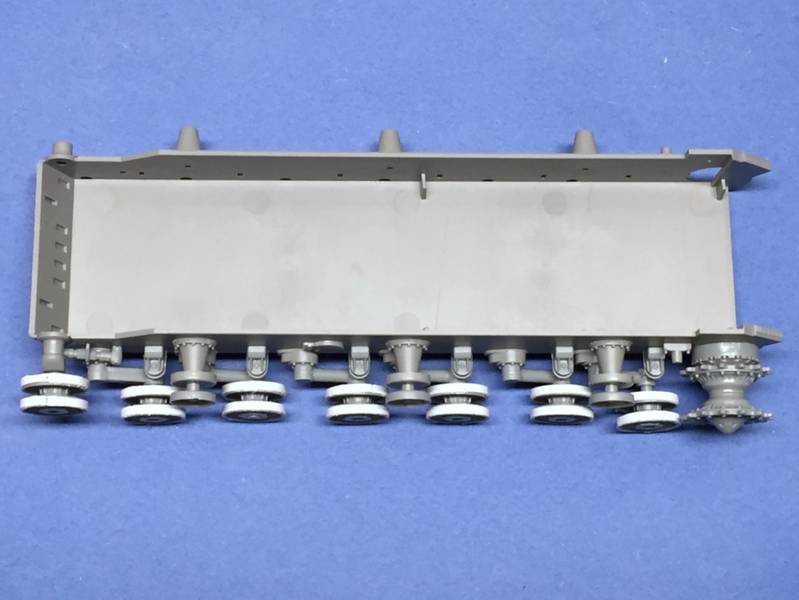

The first step of the instructions starts off, of course, with the running gear. Return rollers, idlers and drive sprockets are all two piece affairs with no photo etch at all. The road wheels, all 14 of them are again two piece assemblies and is the first (and major) part of the kit that needs attention. The road wheels of the IS-1/IS-2 (and by extension the ISU-122/152 family) are 550mm in diameter. This equates to roughly 15.71mm in 1/35 scale. DML kits, no matter the date, are all undersized by approximately .86mm. To correct this, it has been suggested on many sites to use strip styrene to fix this. I found that Evergreen #124 (.020" x .080") is a good match to increase the diameter to bring it more in line with the correct 15.71mm.

Through trial and error and the use of a draftsman's template I found that a 1 7/8" strip was the exact outside diameter of the road wheel so I commenced to cutting them using "The Chopper", an invaluable tool in my little workbench arsenal.

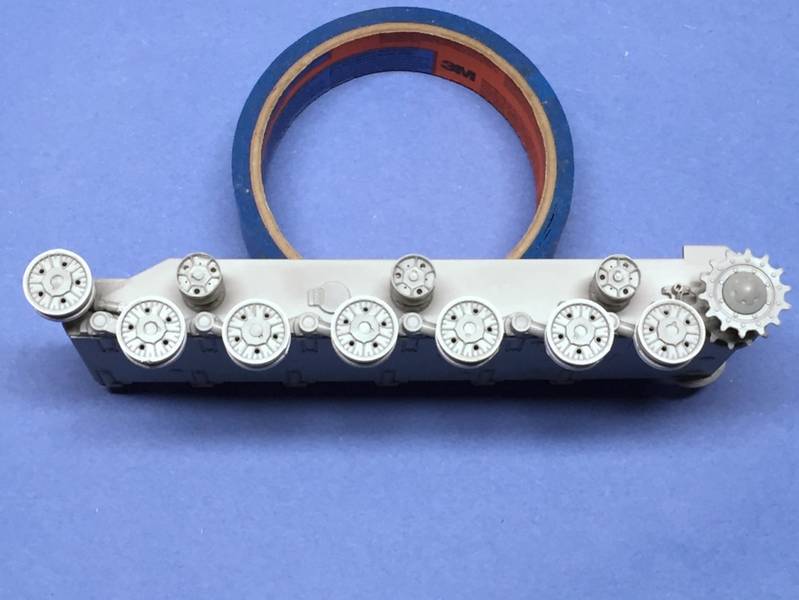

The following shots show the basic flow from stock, to added strip, to a 4BO painted road wheel.

The wheel width is just a hair more than the .020" width of the styrene strips. I tried to remedy this by using Tenax 7R as my cement of choice and slightly pressing down to get some melted plastic squeezed out to the edges. A quick pass with a Flexi File and that seemed to do the trick.

This is the most time consuming part of the build, as you have 14 wheels, each with an inner and outer wheel, so you'll be cutting, gluing, squeezing and filing 28 of these guys. I suggest a good movie playing in the background or some music to while away the time.

The other thing I was thinking of is that you're increasing the OUTER diameter to match the factory specification, but you're not decreasing the INNER diameter to match. Granted, you are building a model of a prototype weapon that never reached production (or the battlefield) prior to the end of the war, but it's something to keep in mind.

Also, I would suggest building them all up, then giving them a good once over and pick your better of the two sides to show off. The road wheel hubcaps are separate affairs (Part B6) so if you make a minor goof on the strip addition, you can simply turn that wheel half to the inside of the lower hull and call it good.

Our next step will involve getting the lower hull suspension installed and fixing the lower hull height.