Cavalier STUG III Ausf G Zimmerit

I then decided to add a set of Eduard PE to it. Well, in March of 2003, I was sent on a 17 month deployment to Iraq and this kit got packed away. Now, January 2015, I have decided it is time to finish this kit. Here is where I am at now.

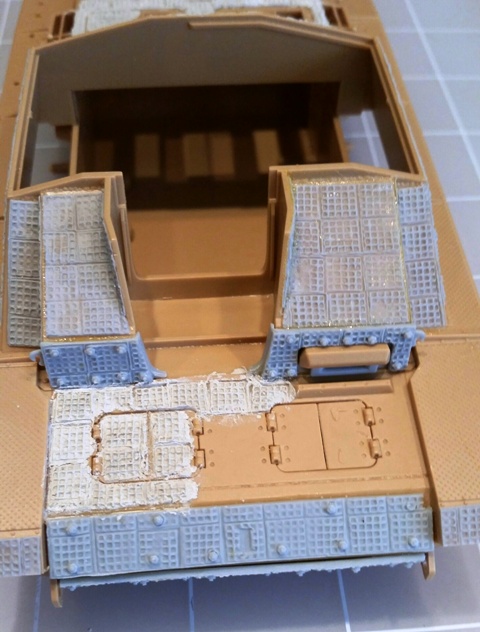

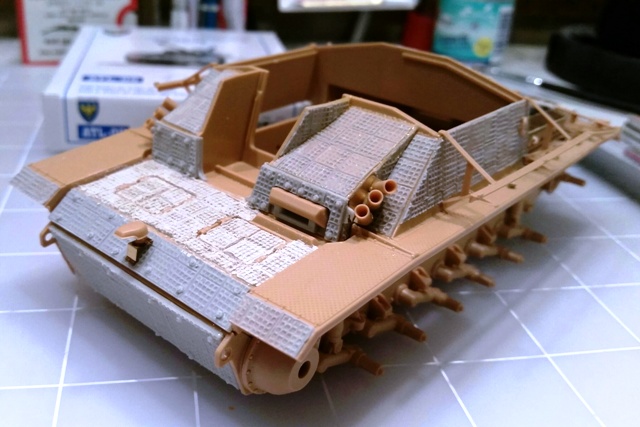

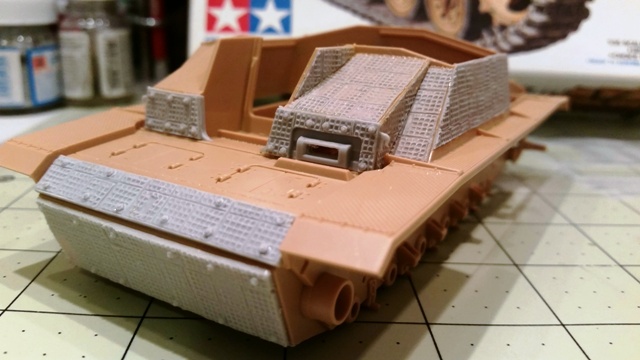

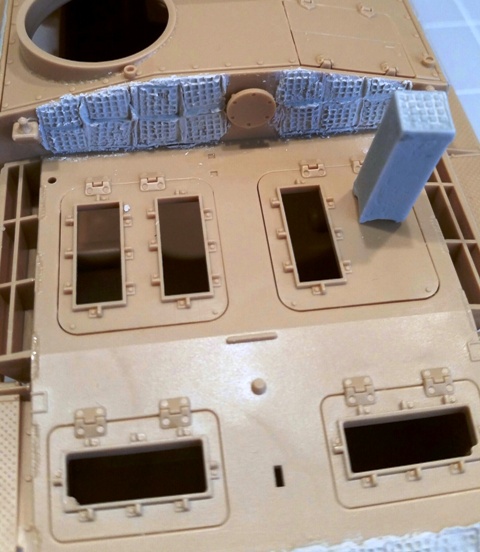

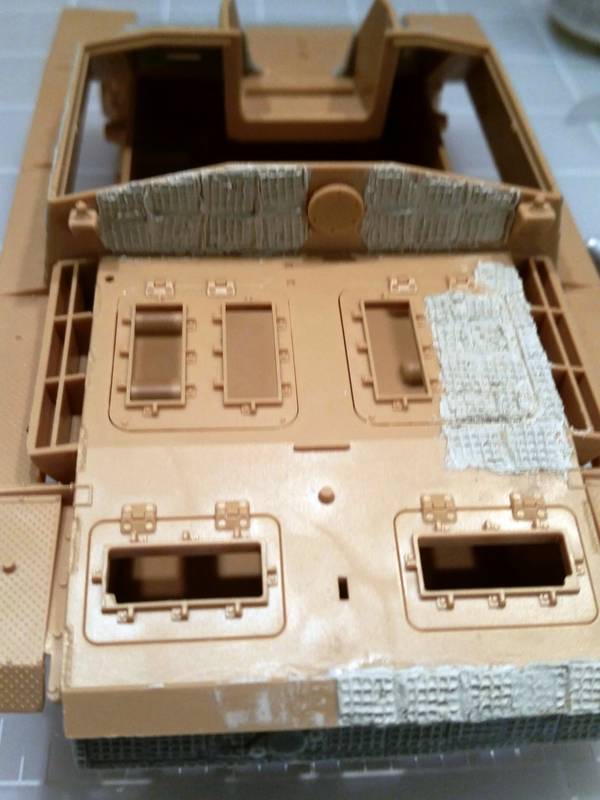

Here is the kit with the Cavalier Zimmerit parts added. You have to add zimmerit by hand because Cavalier did not provide enough zimmerit parts for the entire vehicle.

In this photo, the bottom part is a Cavalier resin replacement. The Waffle pattern zimmerit on the top surface is being done by hand with a small tool that Cavalier provides.

This is my first time ever trying to make zimmerit. I know its not going to be perfect. The goal is to get the experience and finish the kit. I'm having fun with it so far.