This build log is the prelude to a full-on Build Review that will serve to inform future purchasers, and will run as far as doing all the plastic – I won’t be painting it anytime soon due to a huge traffic jam at my spray booth.

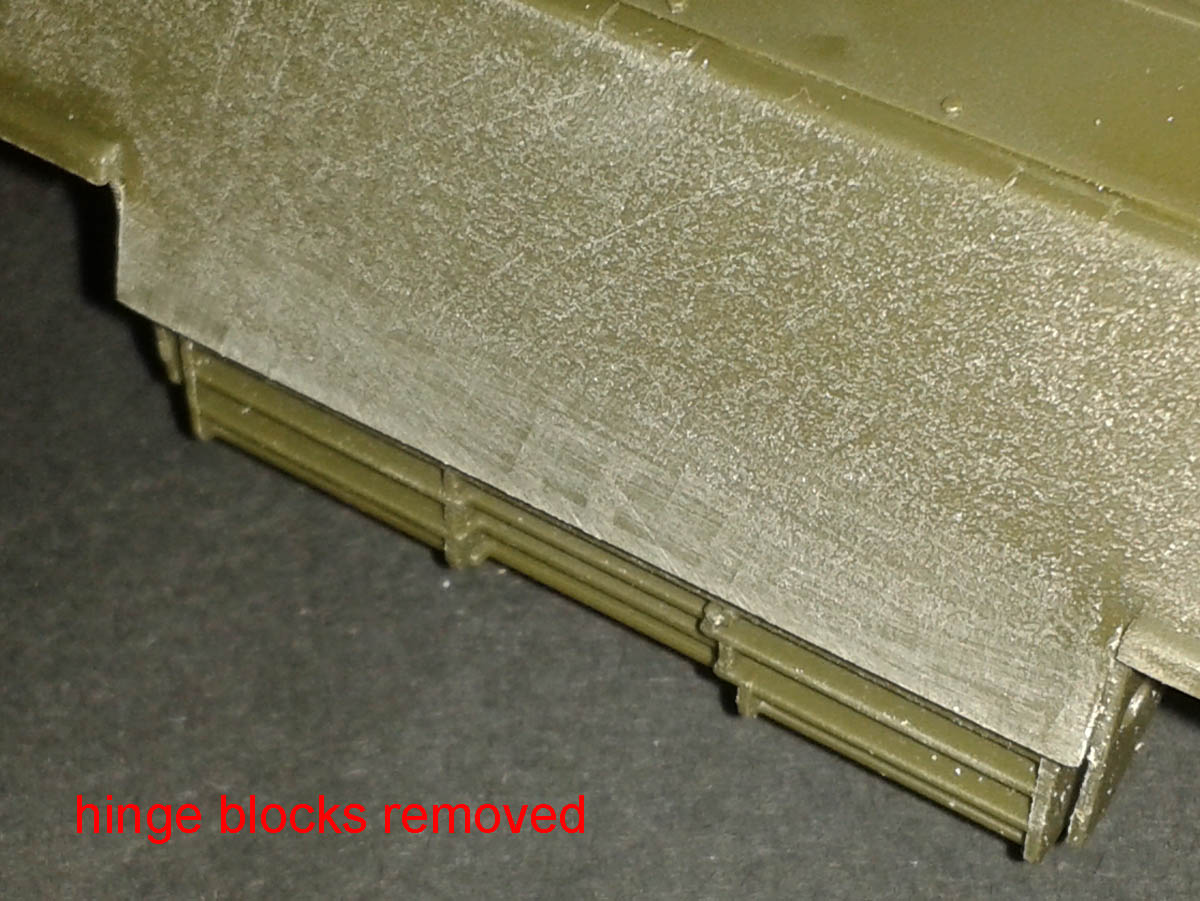

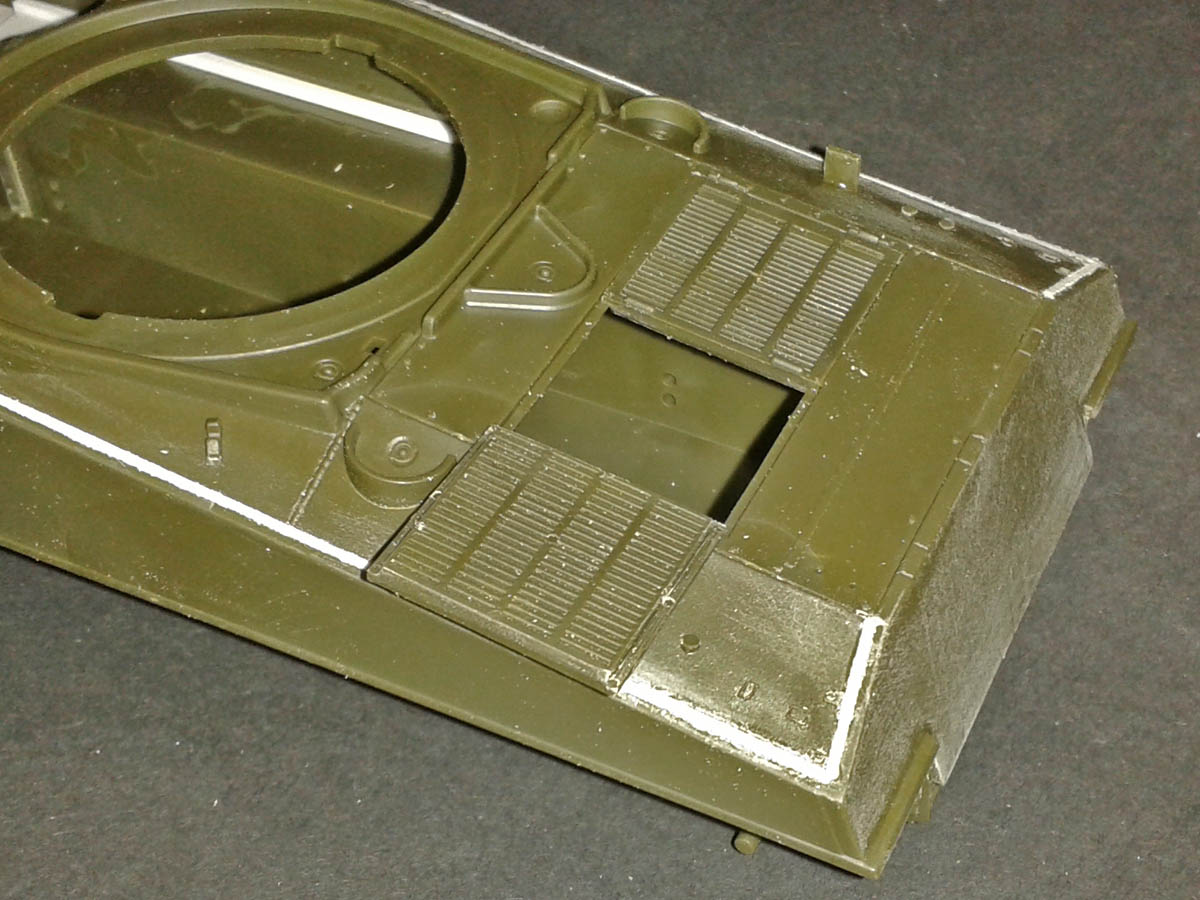

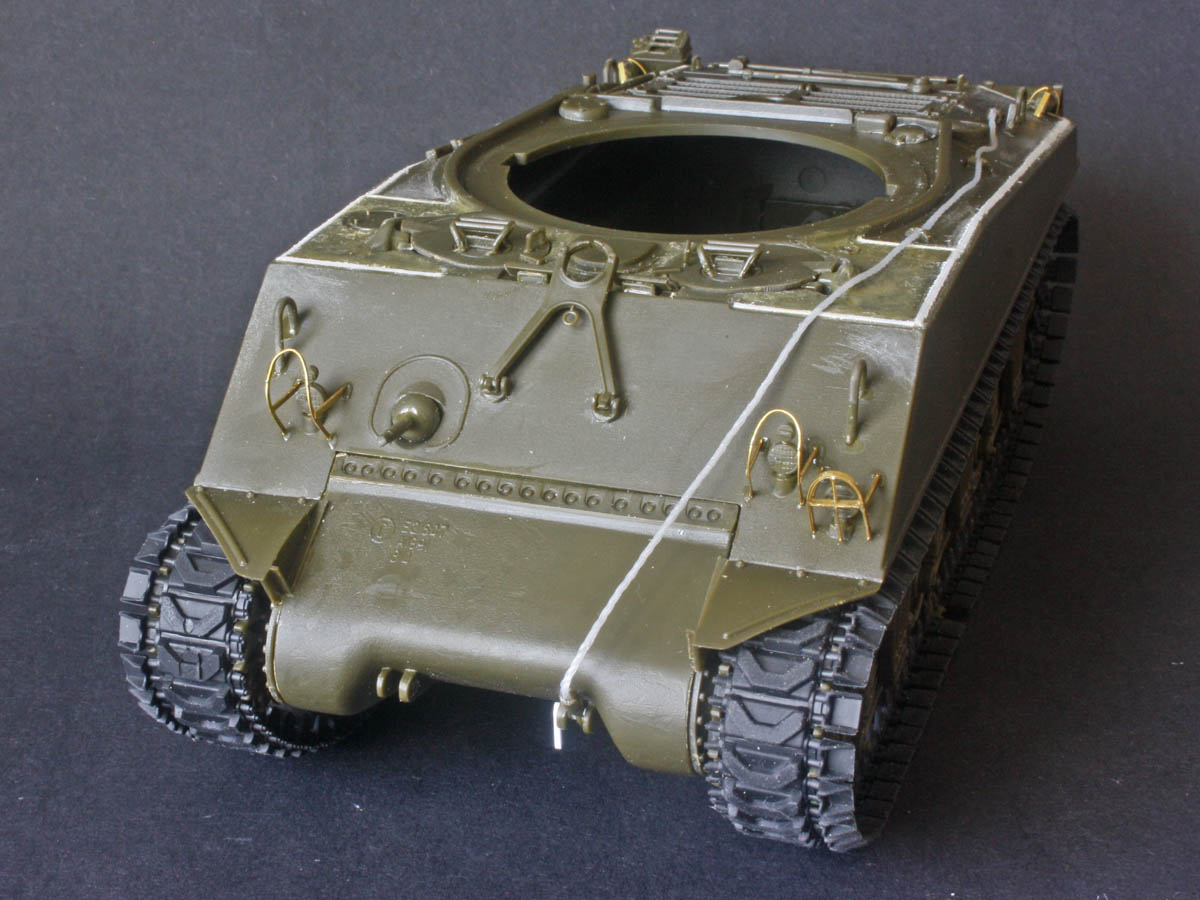

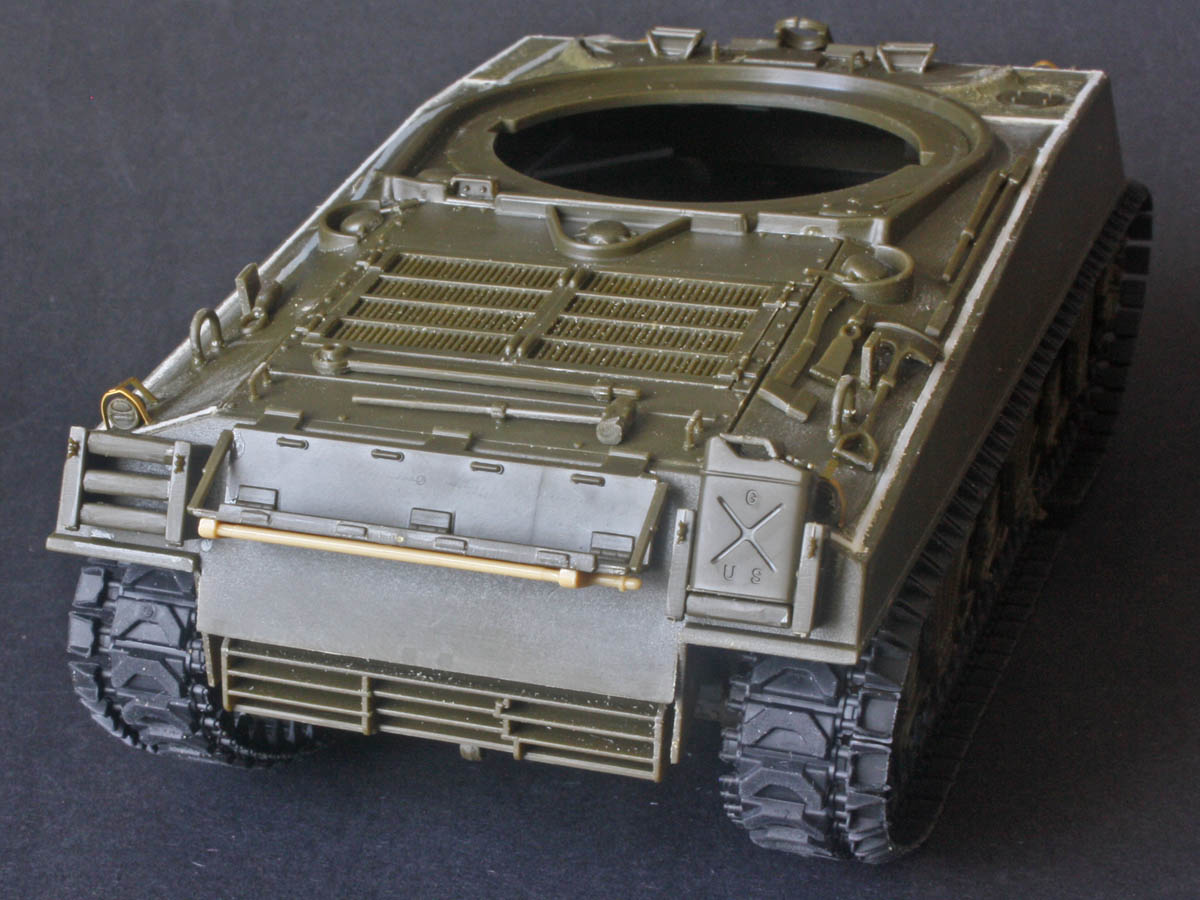

“What’s in the box?” I hear you say. Turns out most of it has been seen before in earlier Academy releases – in fact this entire kit is a re-release of the T34 Calliope that Russ Amott reviewed here two years ago, minus the rocket launchers, and in the more typical Academy green plastic. The hull has been around since at least the Sherman Dozer kit, and is complete with weld “trenches” that purists will feel compelled to fill. The turret opening on top is odd – to fit the 76mm turret with its narrower ring the folks at Academy chose to add a filler inside the old hole, with a groove that looks like you could pop it out to fit the older 75mm turret. The cast texture on the driver’s hatch plate looks nice, and has casting marks, but the shapes of the hatch draining grooves are somewhat off, and the whole plate is too “flat”.

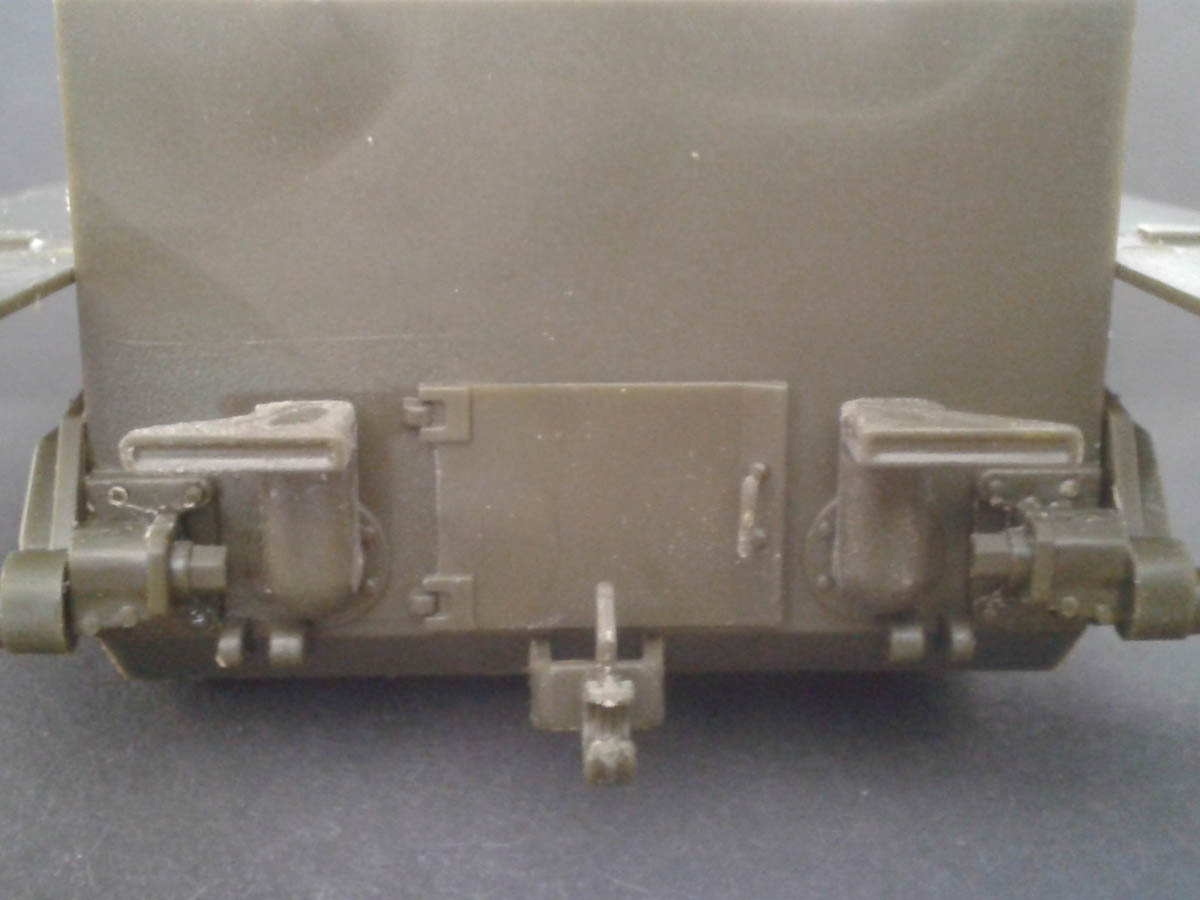

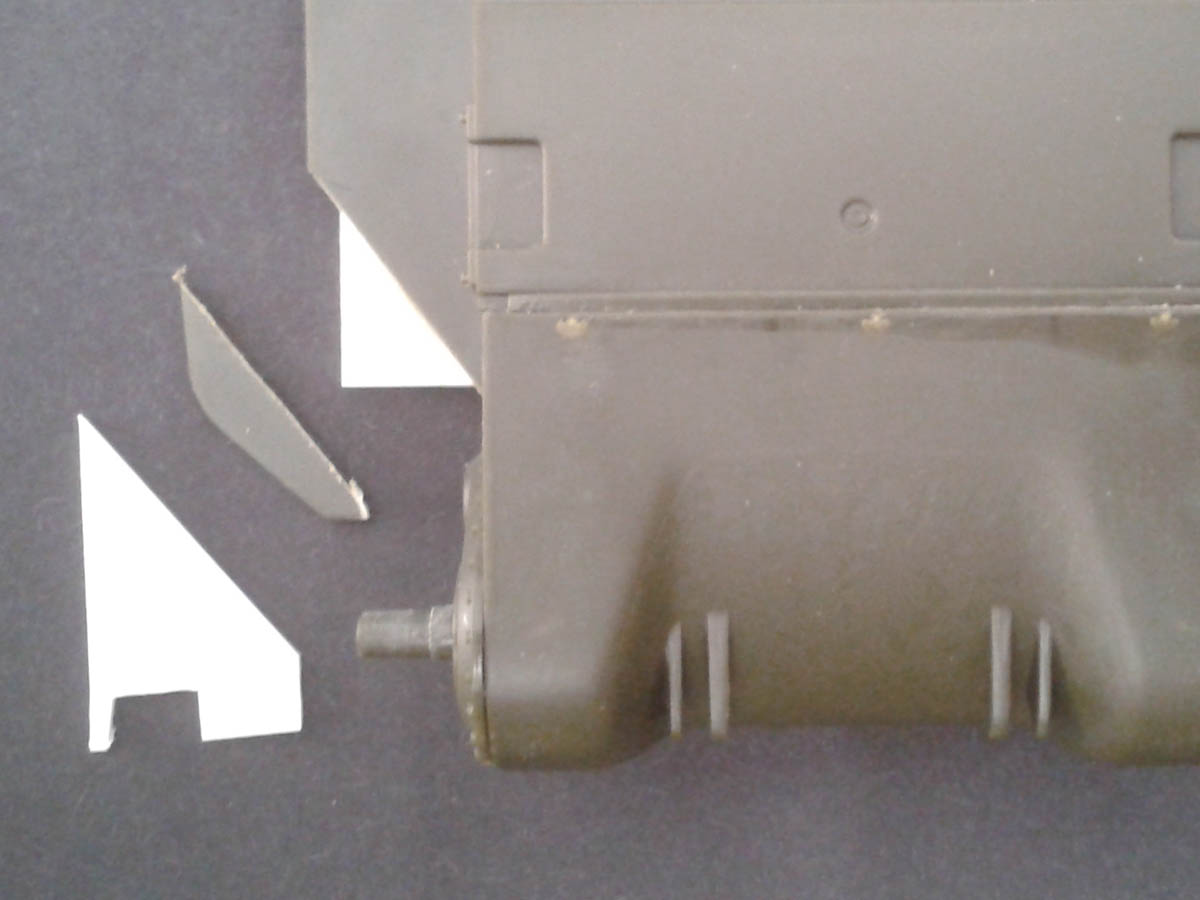

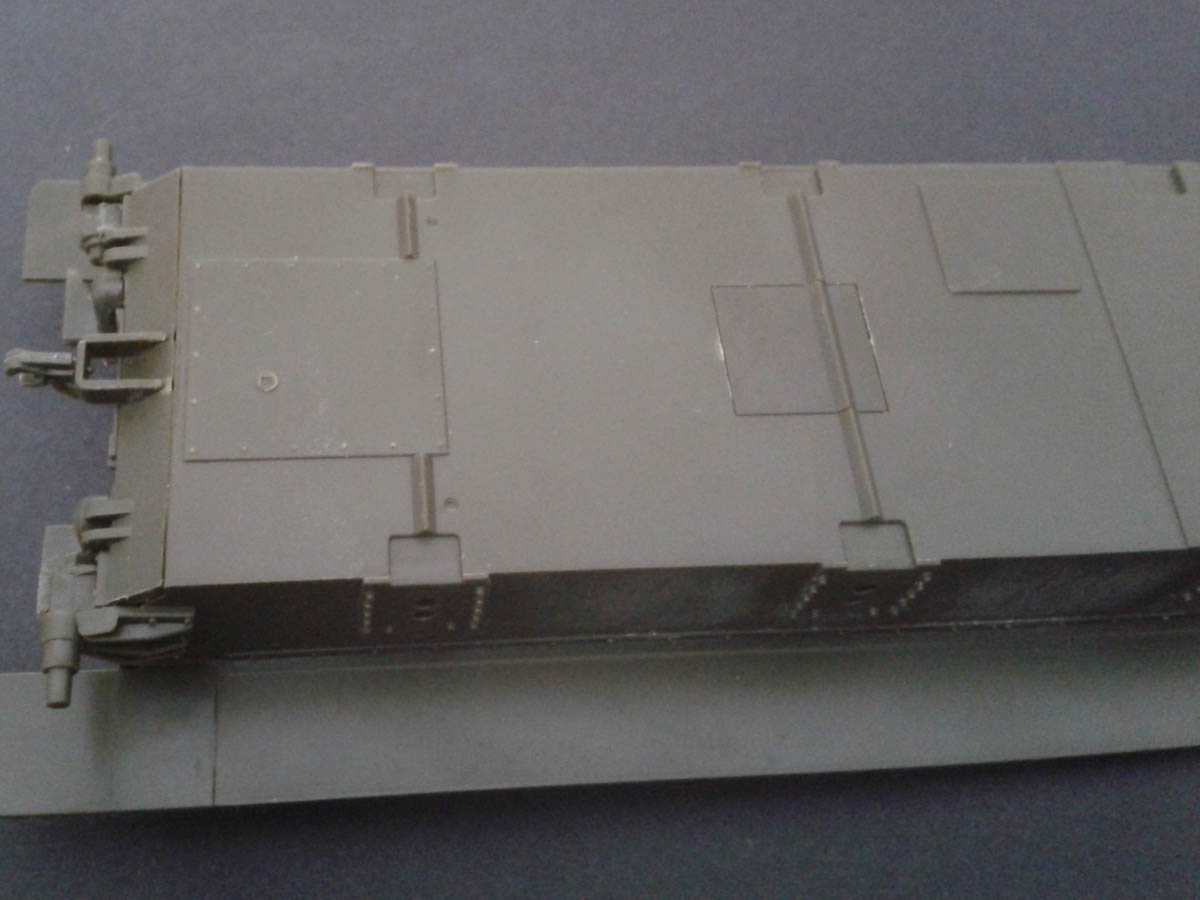

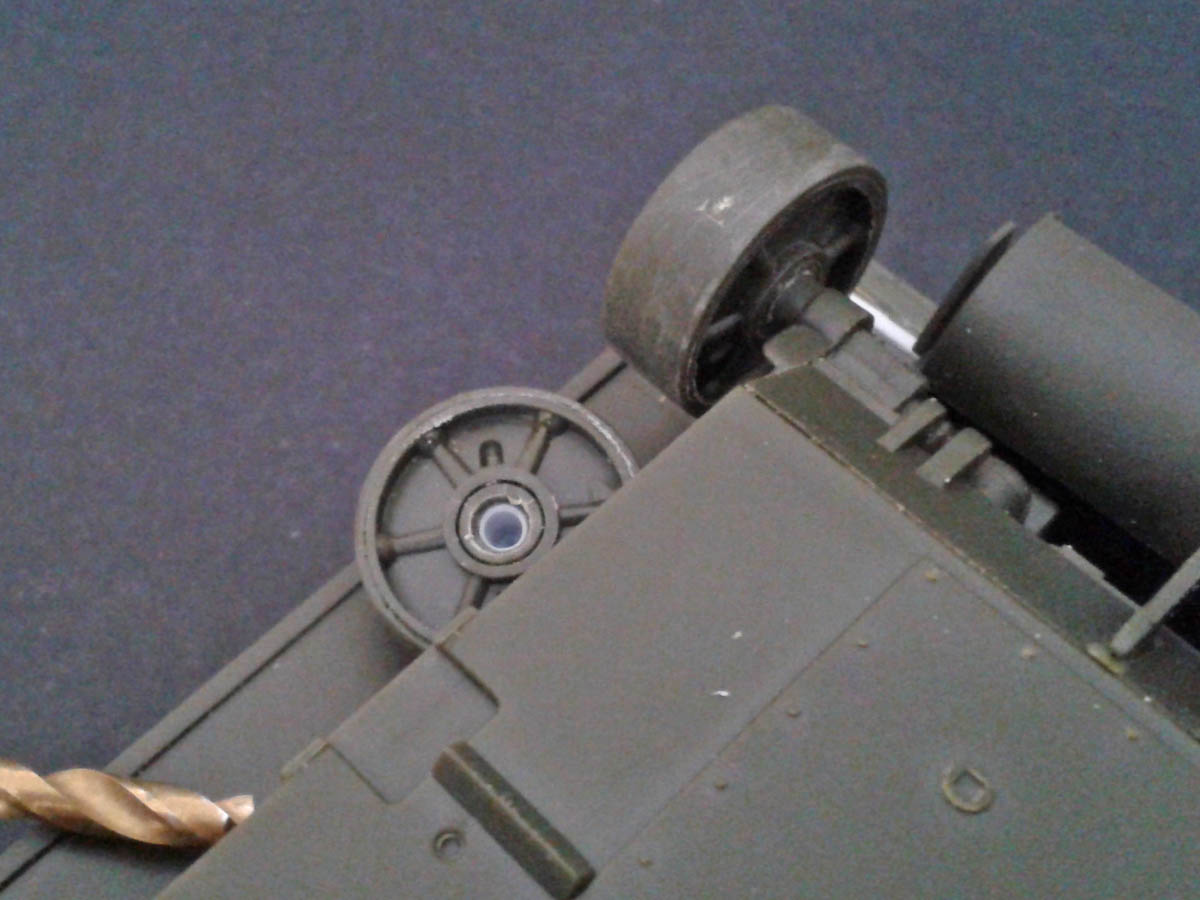

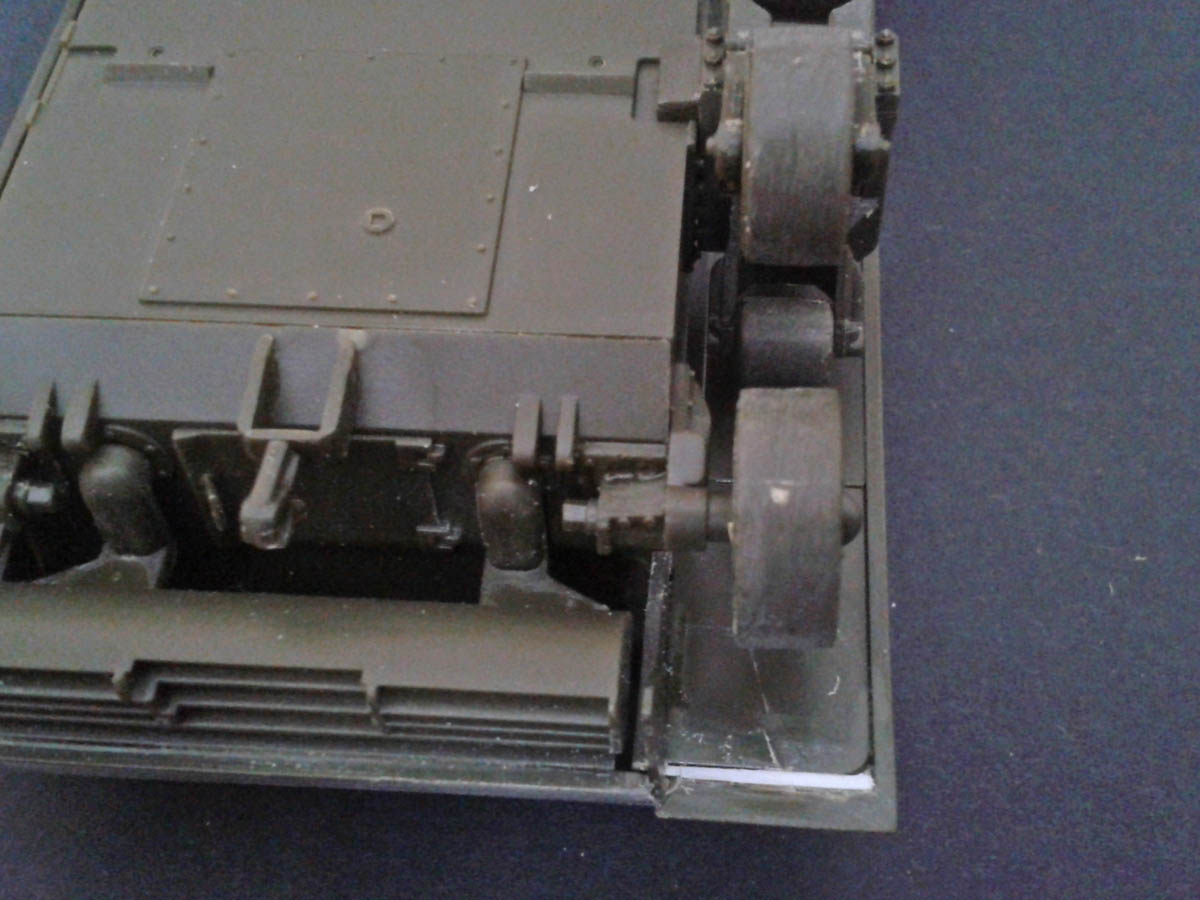

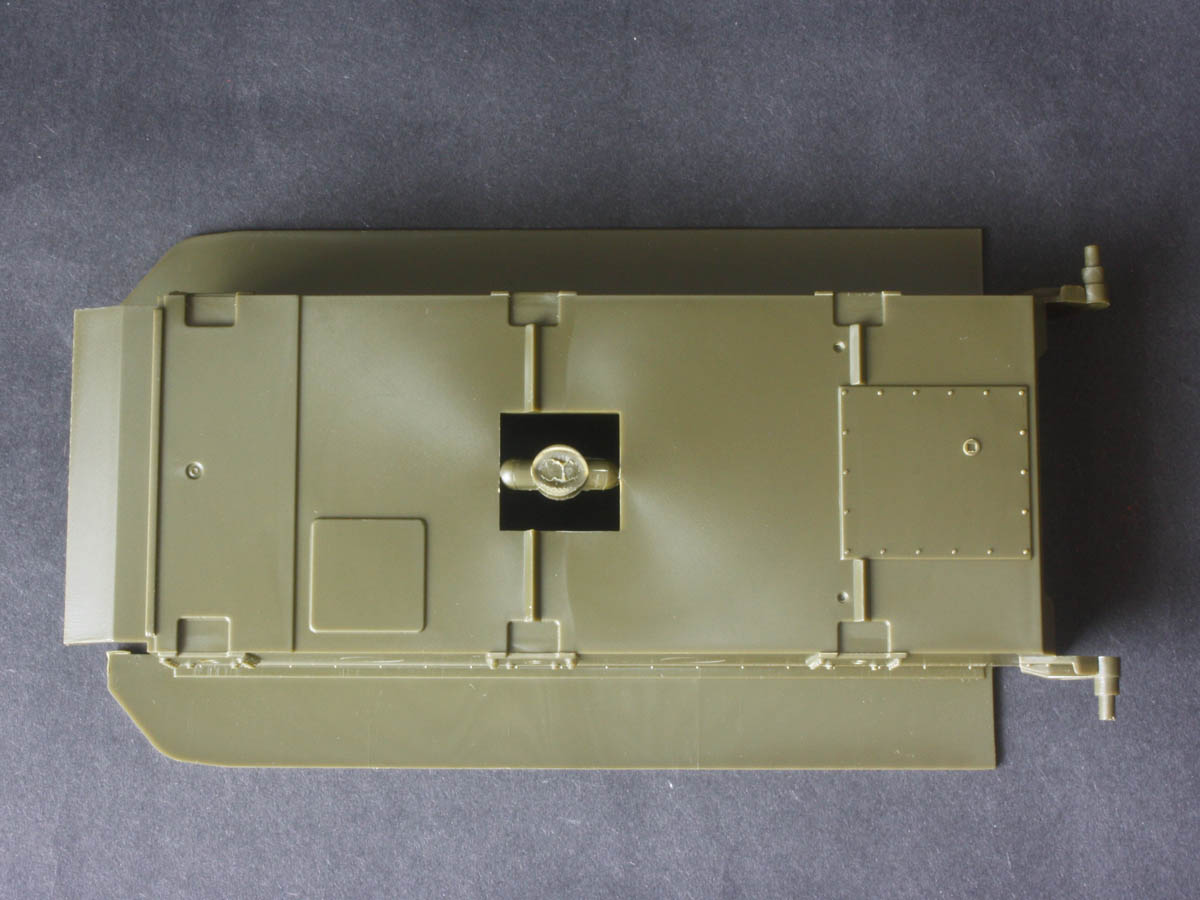

The lower hull tub is from the Israeli M51 Super Sherman, complete with rounded corners on the sponson floors and raised locating circles for the HVSS return roller mounts. Sadly the Floor-Hole Fairy lurking at the Academy factory has been at the centre of the tub, right through the triangular stiffening rib. But these are minor quibbles that we can fix with a little modelling effort, right?

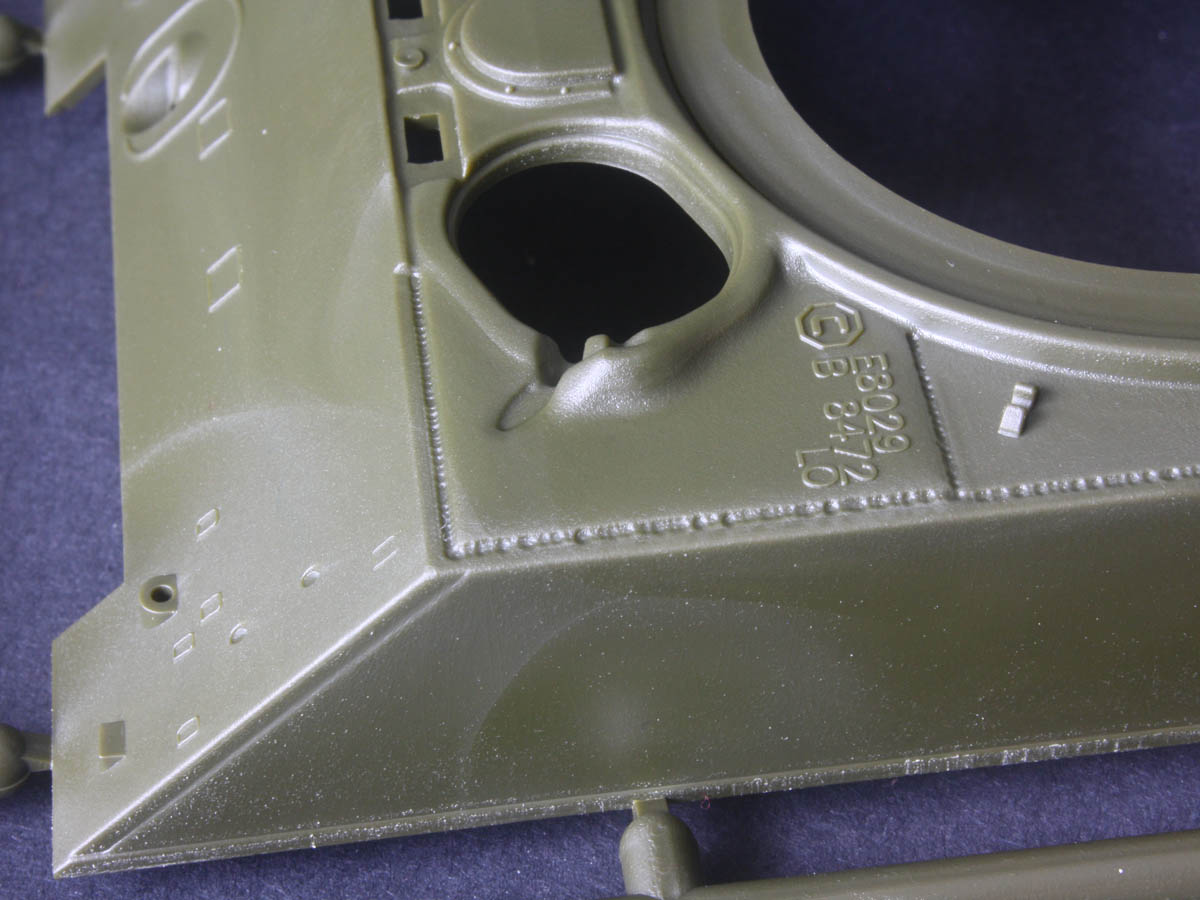

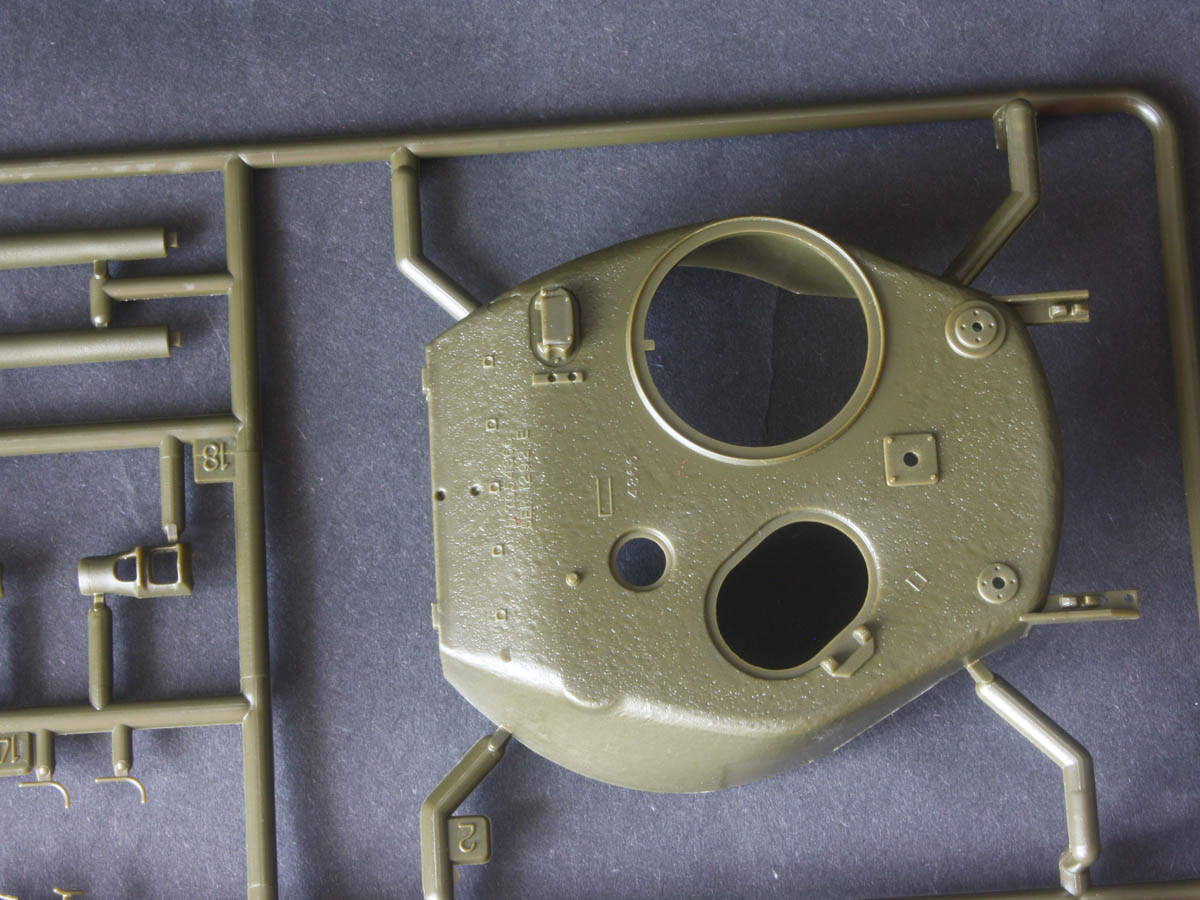

Then comes the turret – I think it first appeared in the M4A2 Russian Army kit (13010), and represents a later version with oval loader’s hatch which became common around Christmas of ’44 in the ETO. There is cast texture, and some fine raised foundry markings. The gun tube is two parts, with a choice of separate thread-protector cap or two-piece muzzle brake. The mantlet again has foundry markings, although the integral lift-ring “ears” need a little TLC. And the ventilator dome on the rear has foundry markings, upside-down! Don’t look for anything inside the turret – there is no breach or anything else. One of the two “vision” cupolas in this kit also hails from the Russian A2 kit.

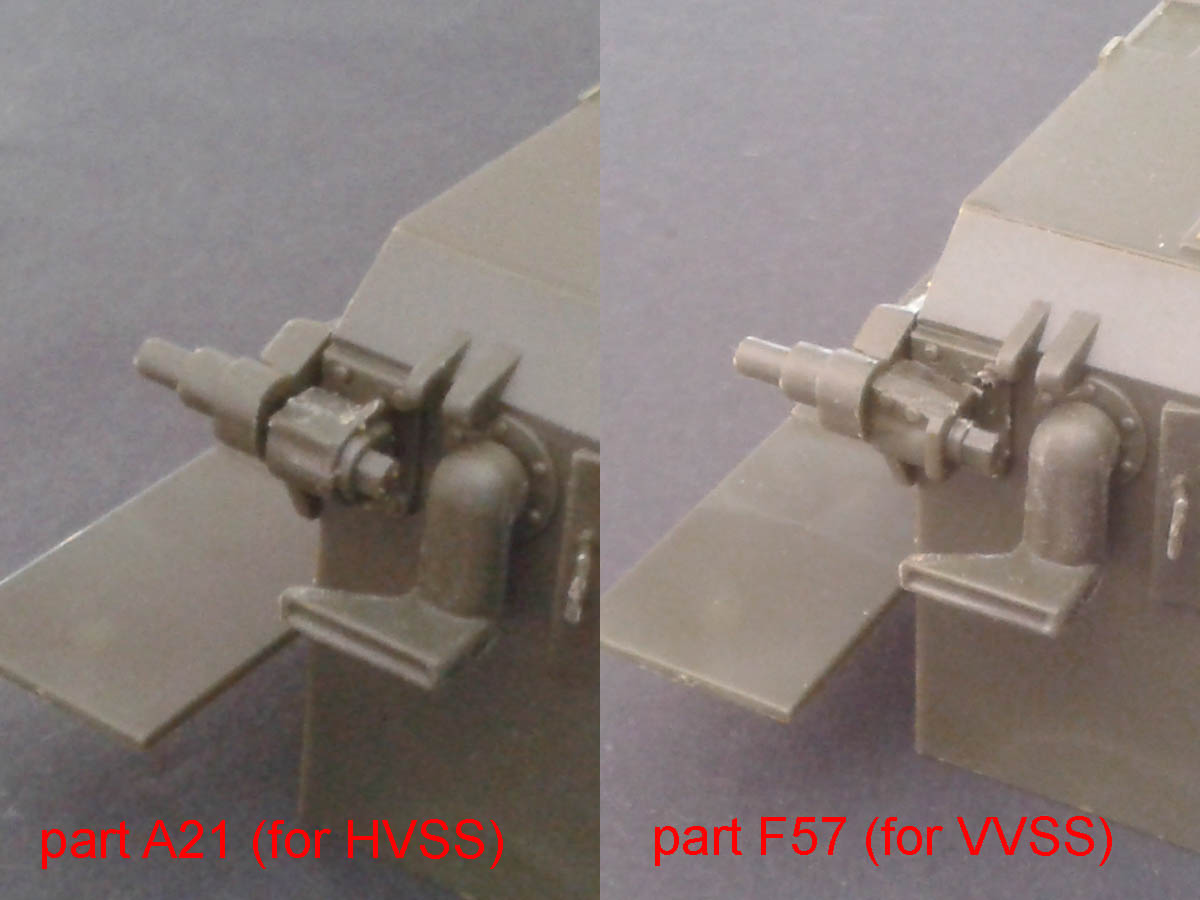

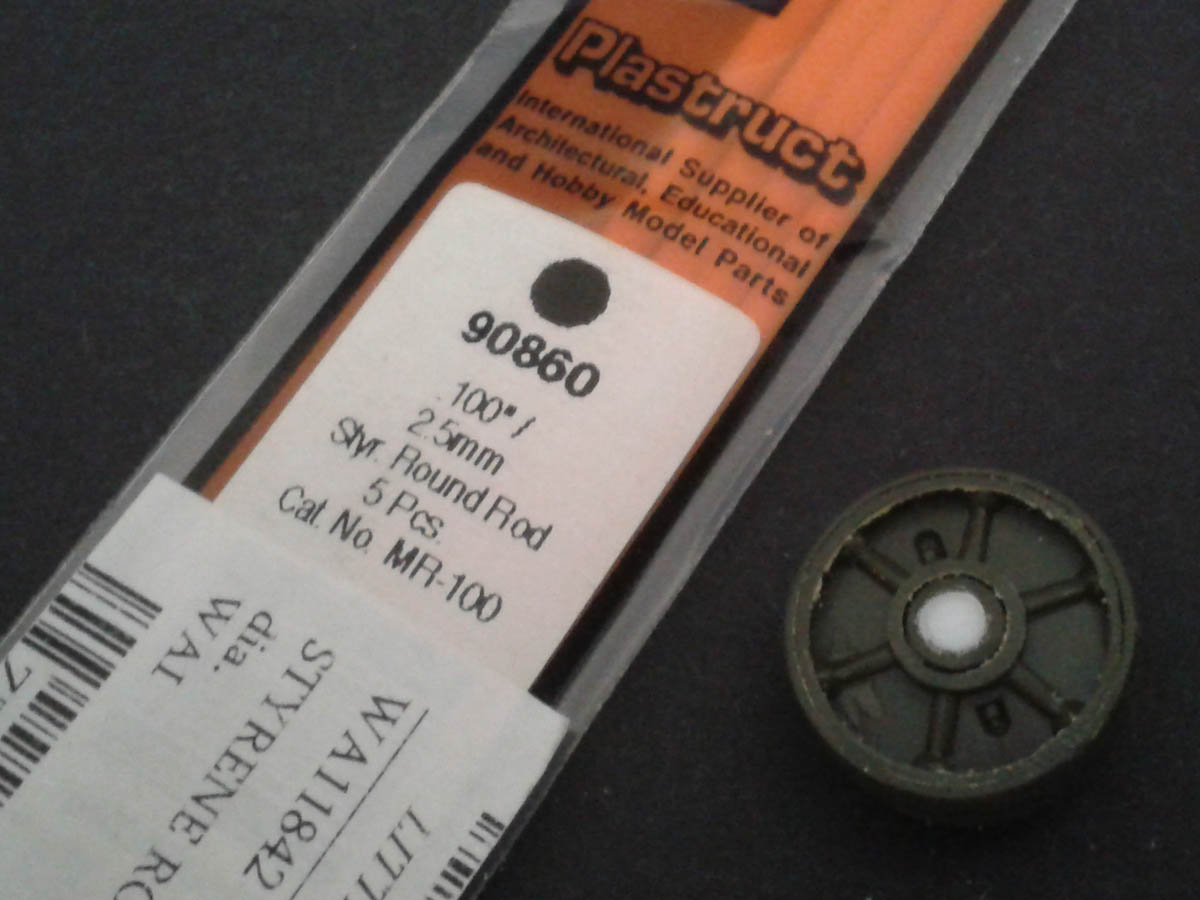

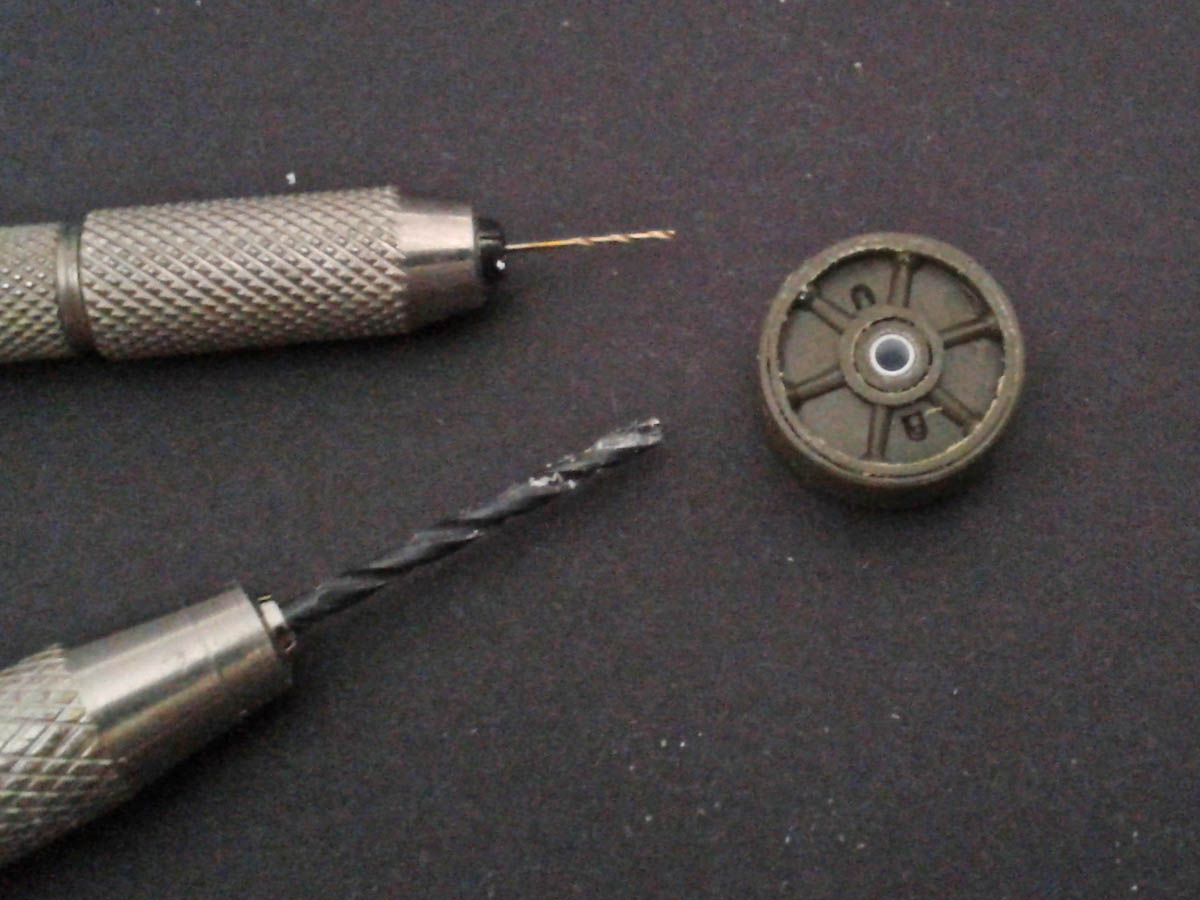

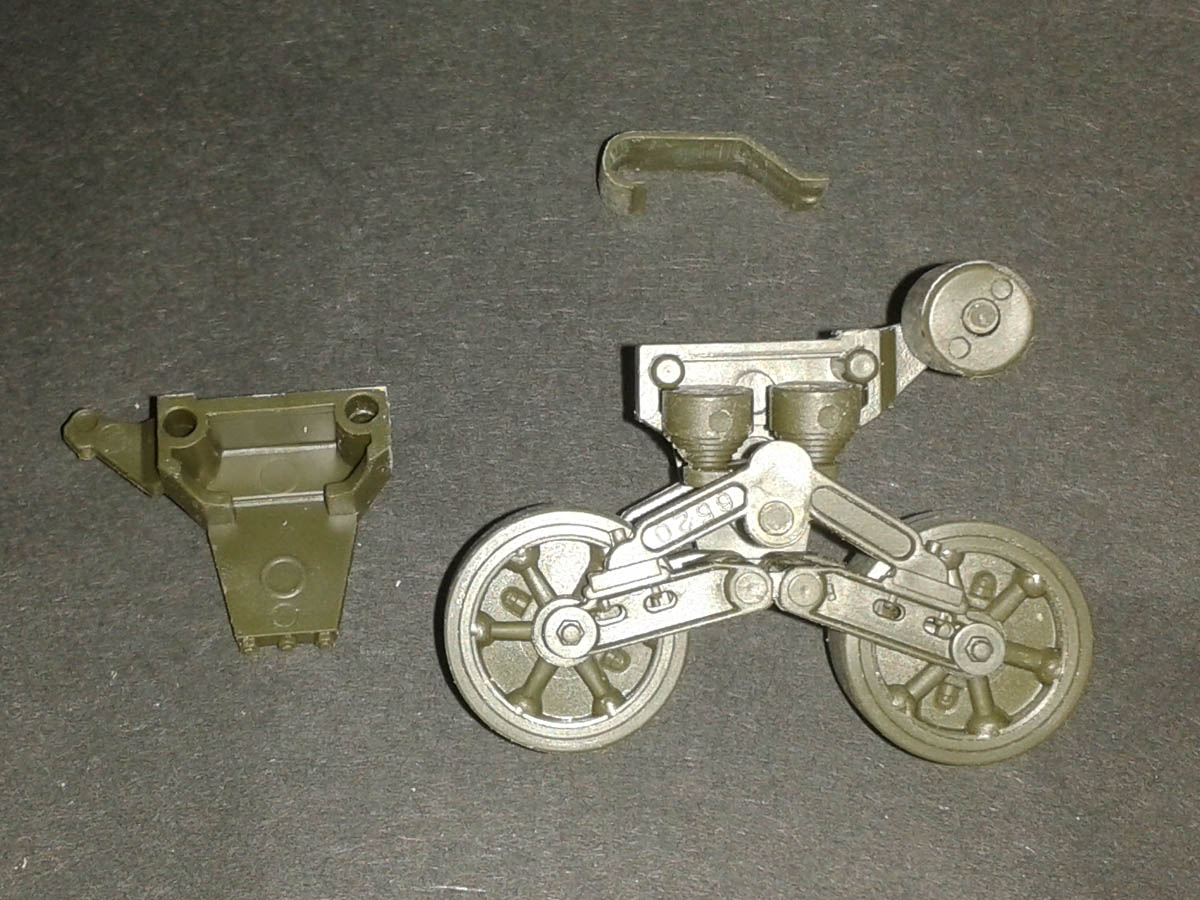

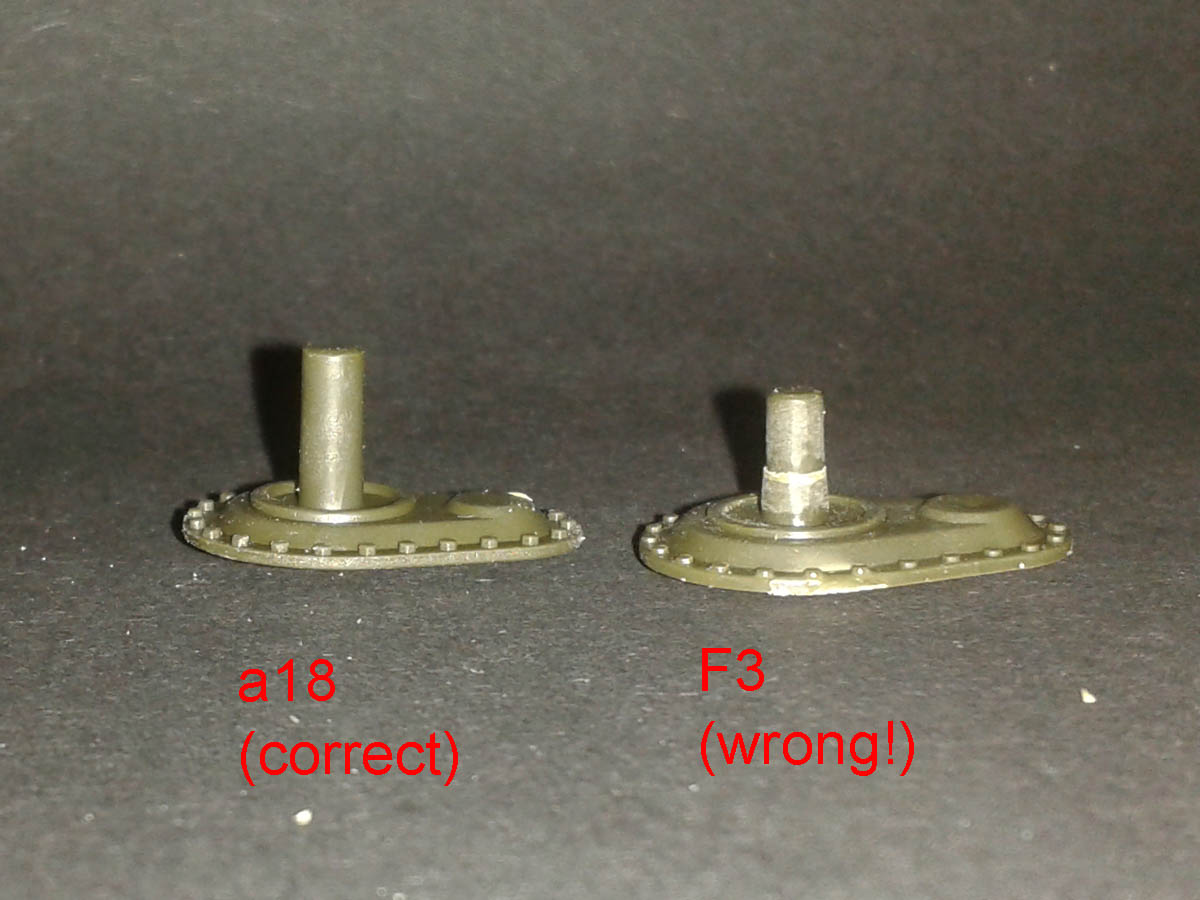

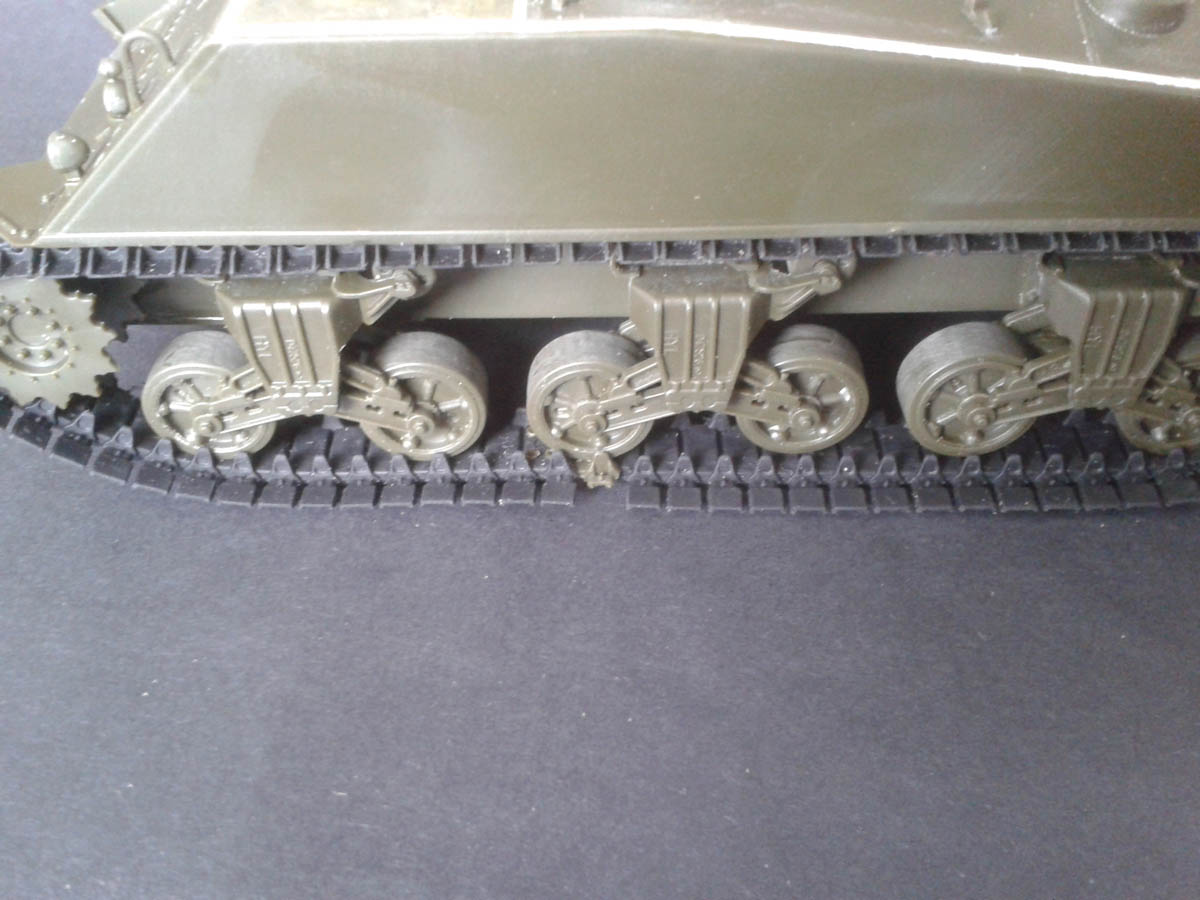

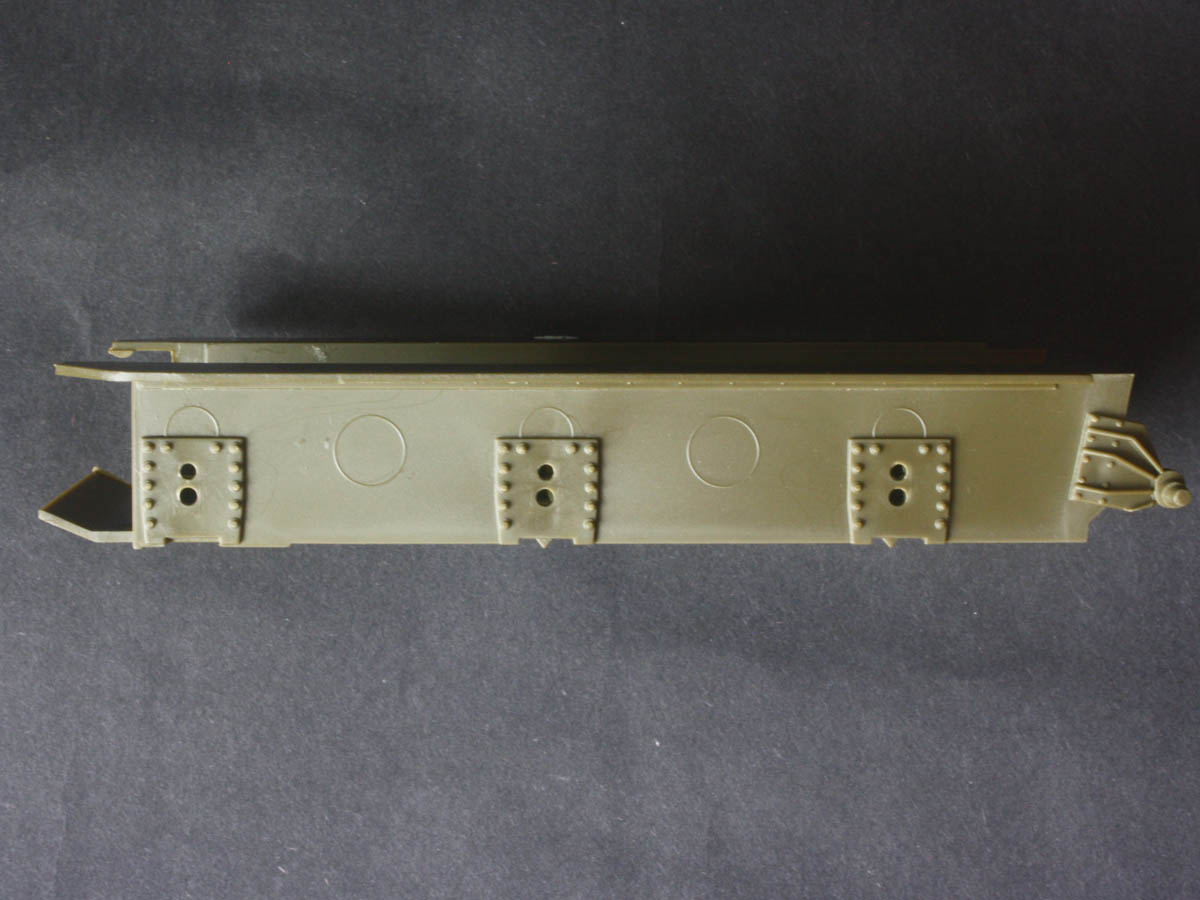

We get the familiar Academy suspension sprue first seen in their M10/M36 series, and it still holds up well. The bogies show their Italeri heritage with “rocking horse” motion, but there is cast lettering and decent detail on the frames and arms. These bogies have the horizontal return-roller arm with pillow block that are too early for this model, so they go into the spares box to uplift another Sherman build down the line. Instead, we get a new sprue of frames with upswept roller arms (from the Calliope kit), more fitting to a late-model M4A3(76)W delivered at the end of ’44. The wheels are a choice of open-spoke or solid-spoke, with the latter being the correct choice for this tank. The mix’n match sprue approach means we also get a selection of drive sprockets and spare sprocket rings, many of which go in the spares box.

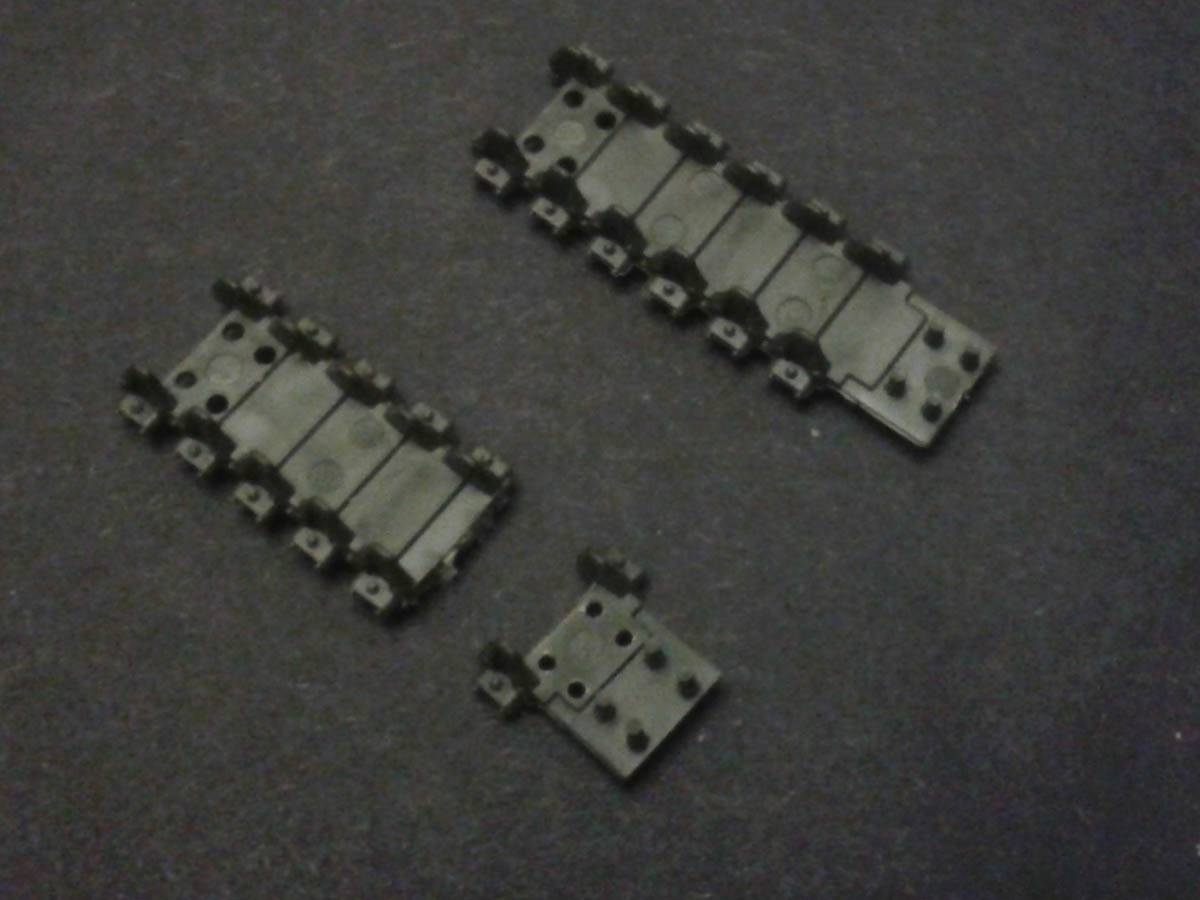

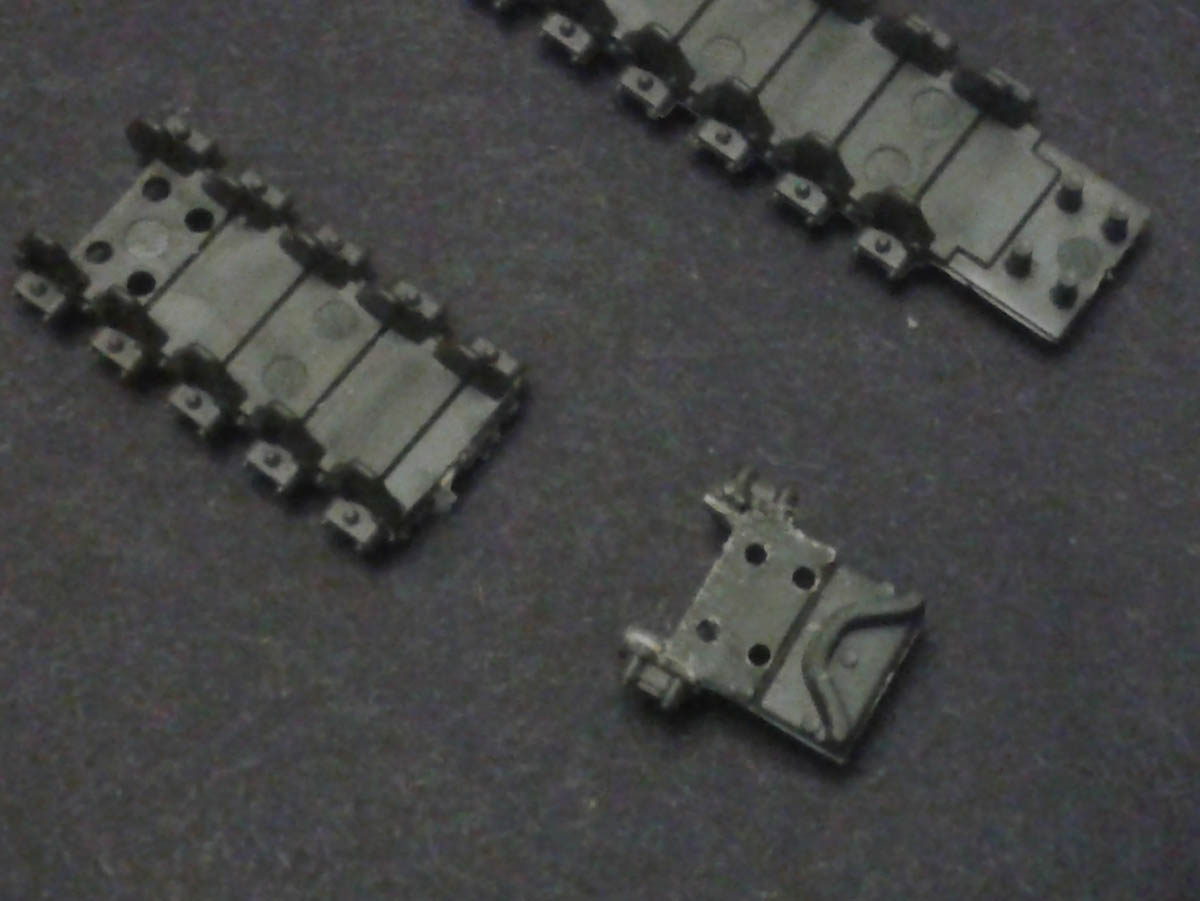

Tracks are the rubber chevron T48s with cast extended end connectors (EECs) to improve flotation in mud. These are provided as vinyl lengths.

Markings are provided for tanks from 69th TB, 761st TB, 709th TB, 752nd TB, and a “beute-panzer”. Of these, the beute-panzer will require the muzzle brake and careful removal of the EECs, while the white-wash cammo’d 709th TB tank is based on a well-known photo of an early M4A3(76)W with the split loader’s hatch (not in this kit), so is not strictly accurate.

Anyway, bear with me as I get stuck in looking for any pitfalls…