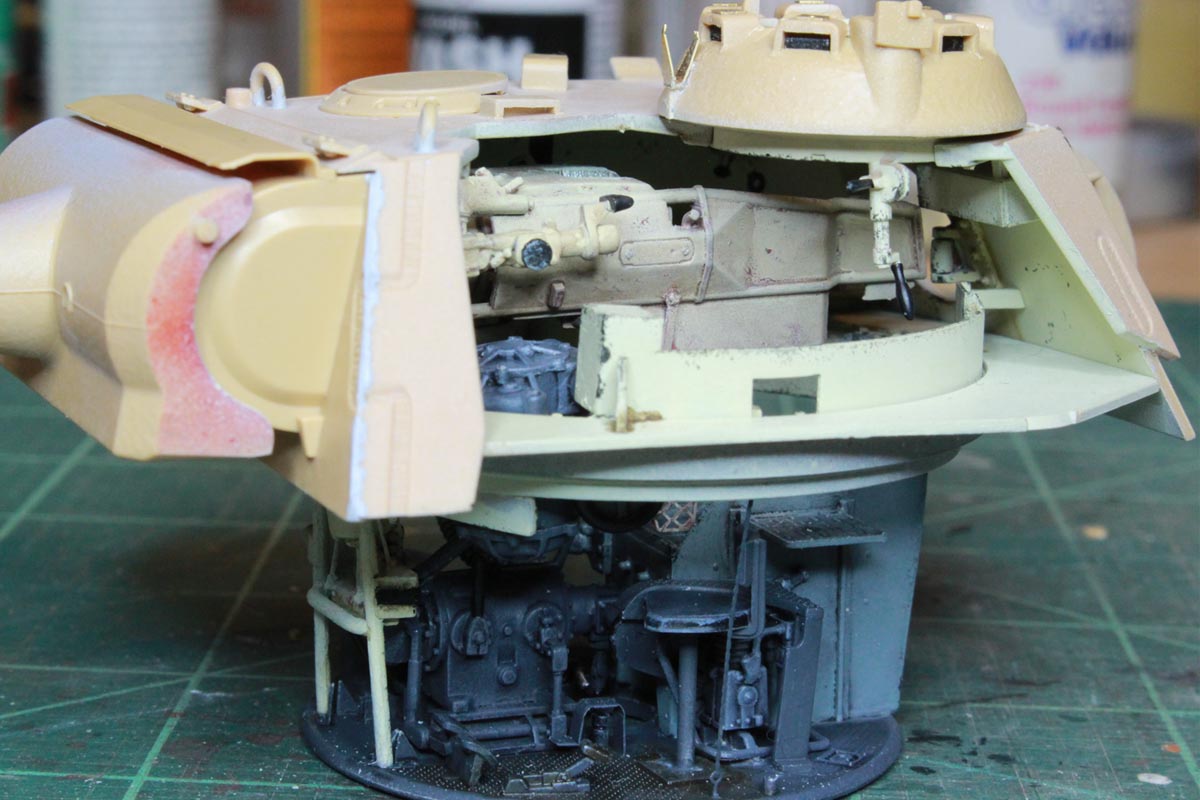

Rye Field Cutaway Panther G

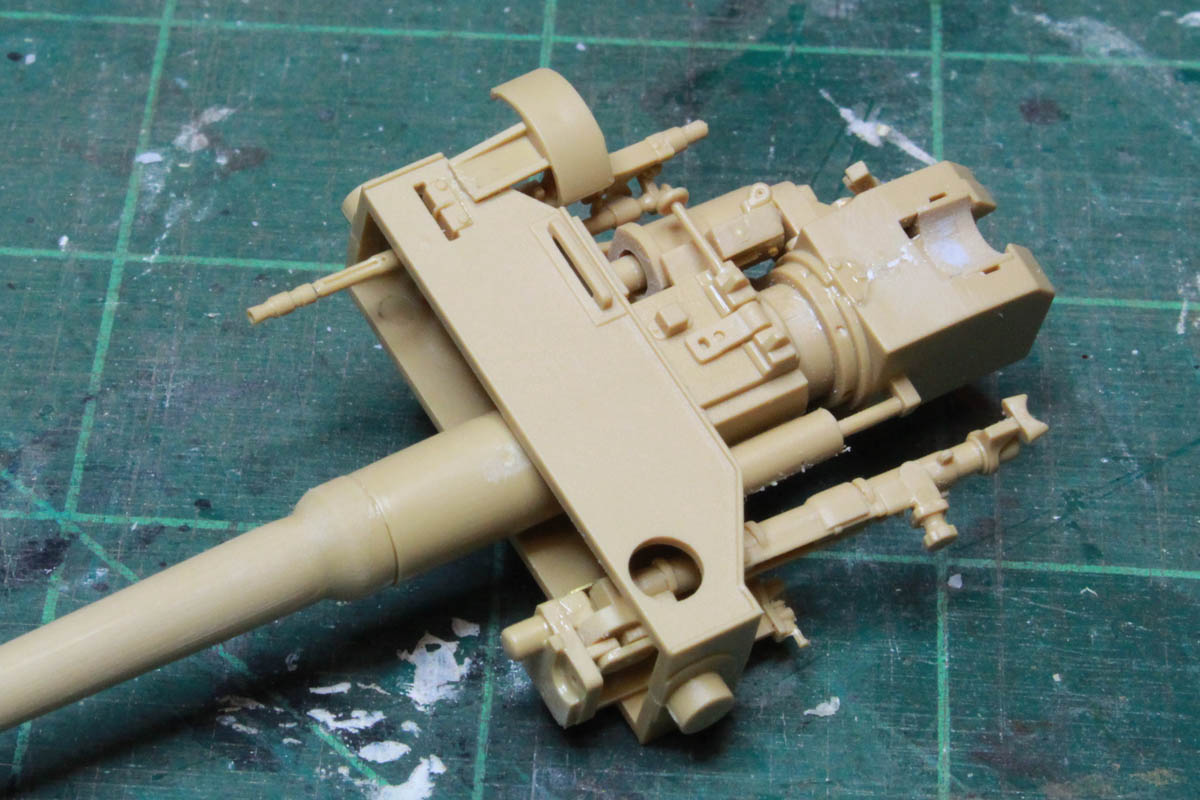

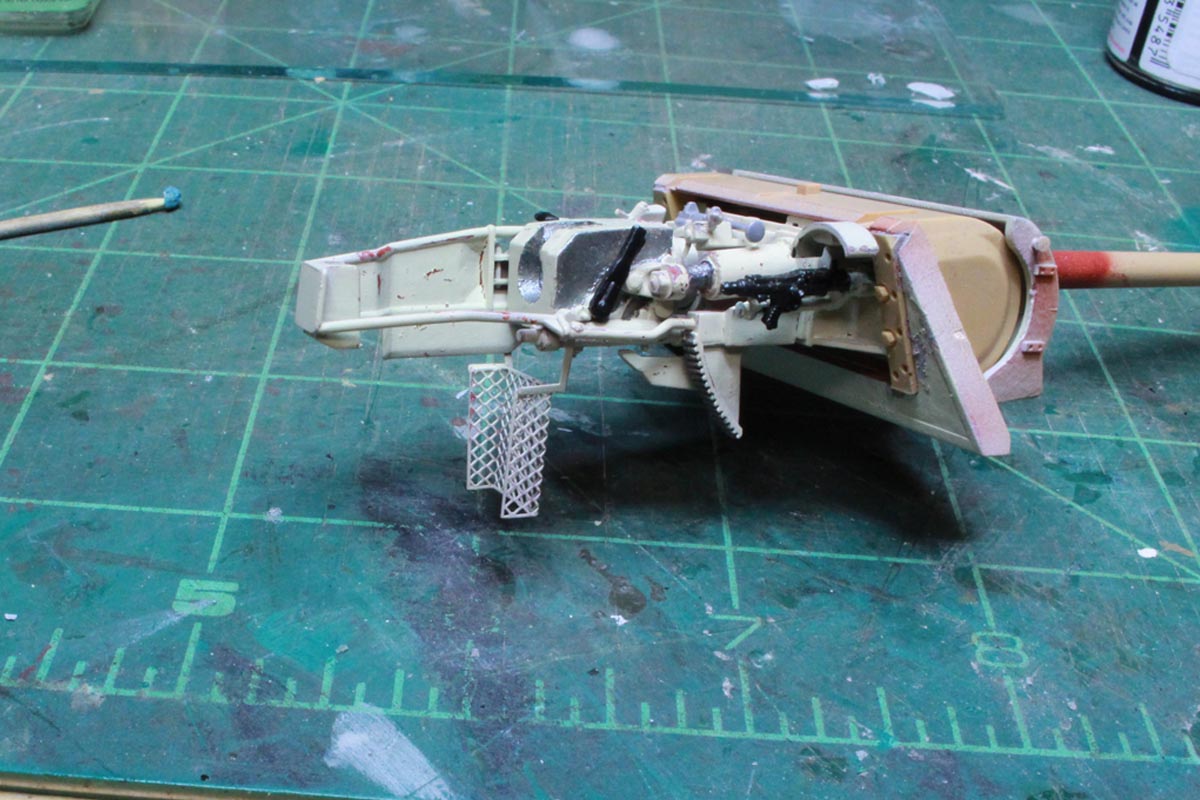

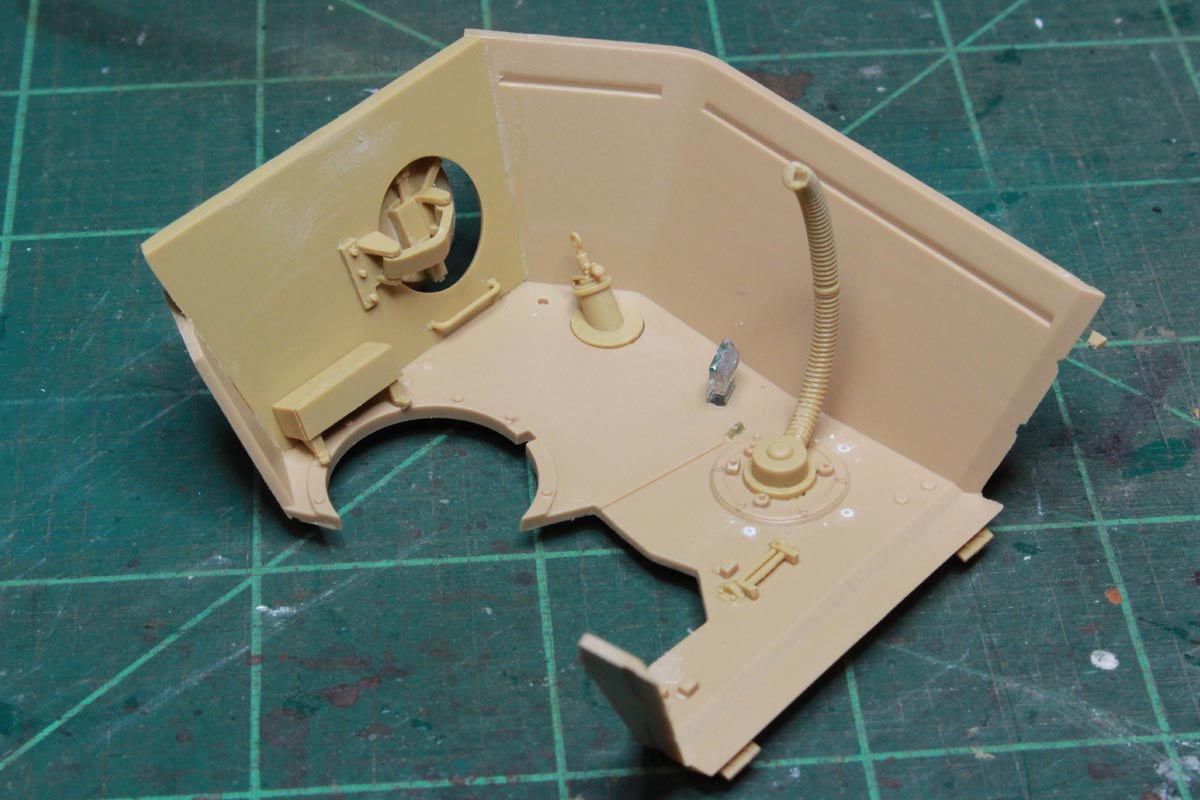

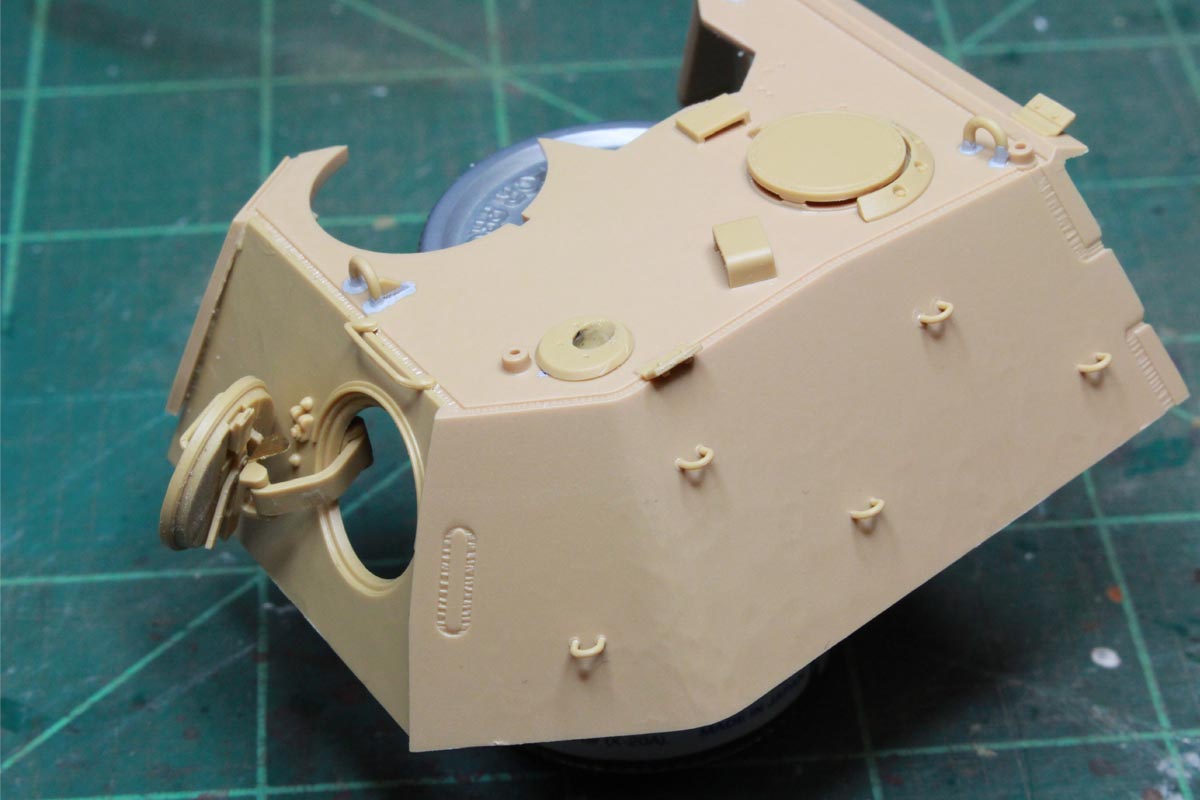

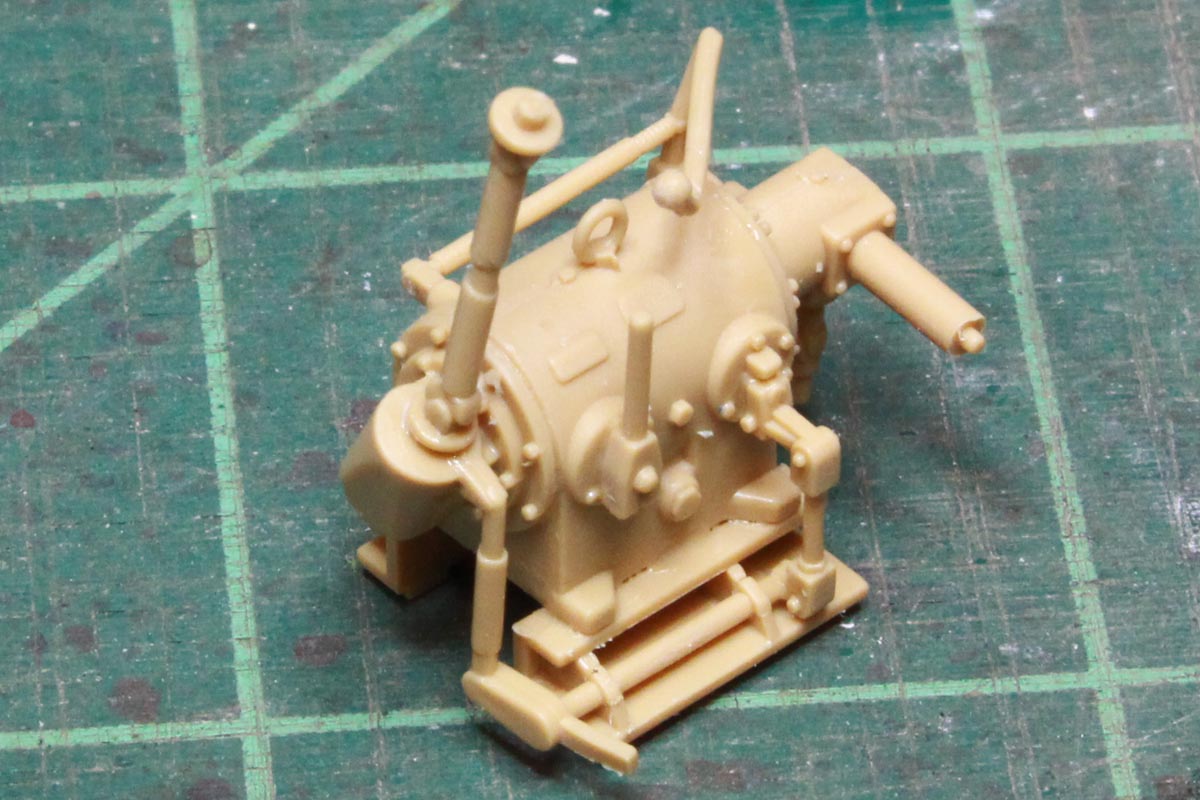

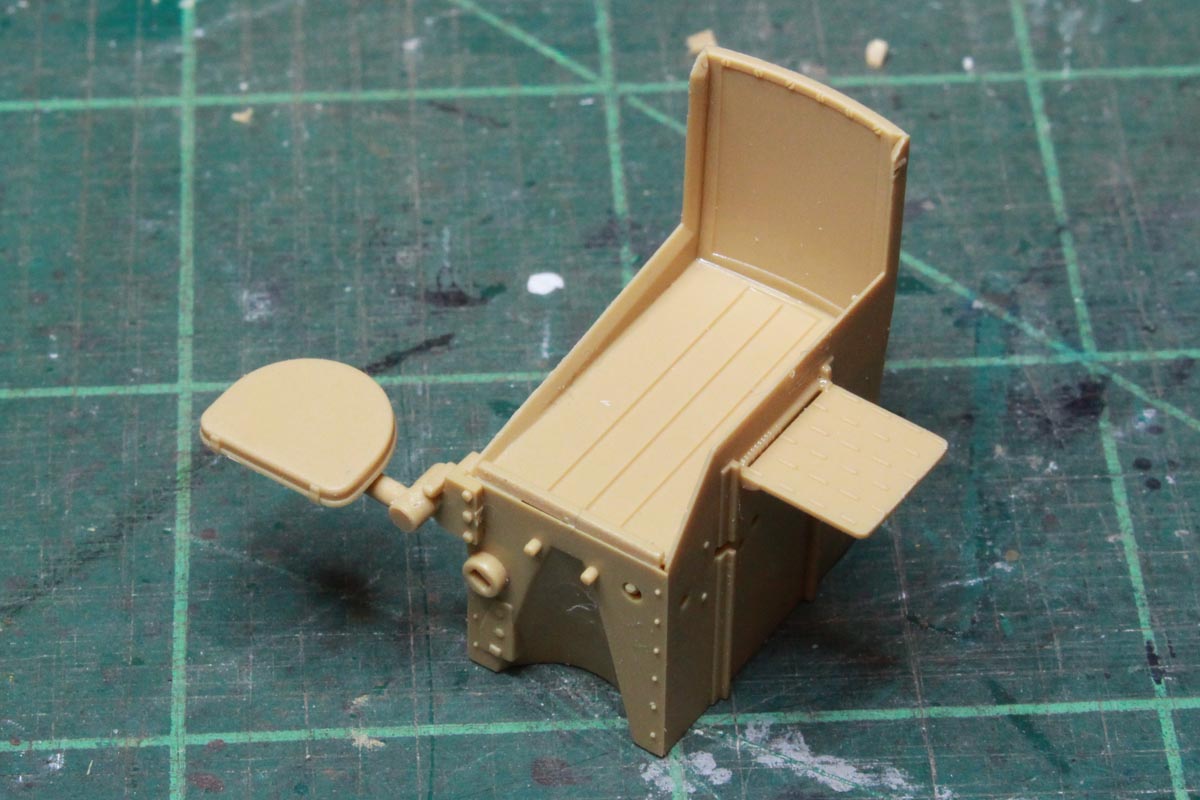

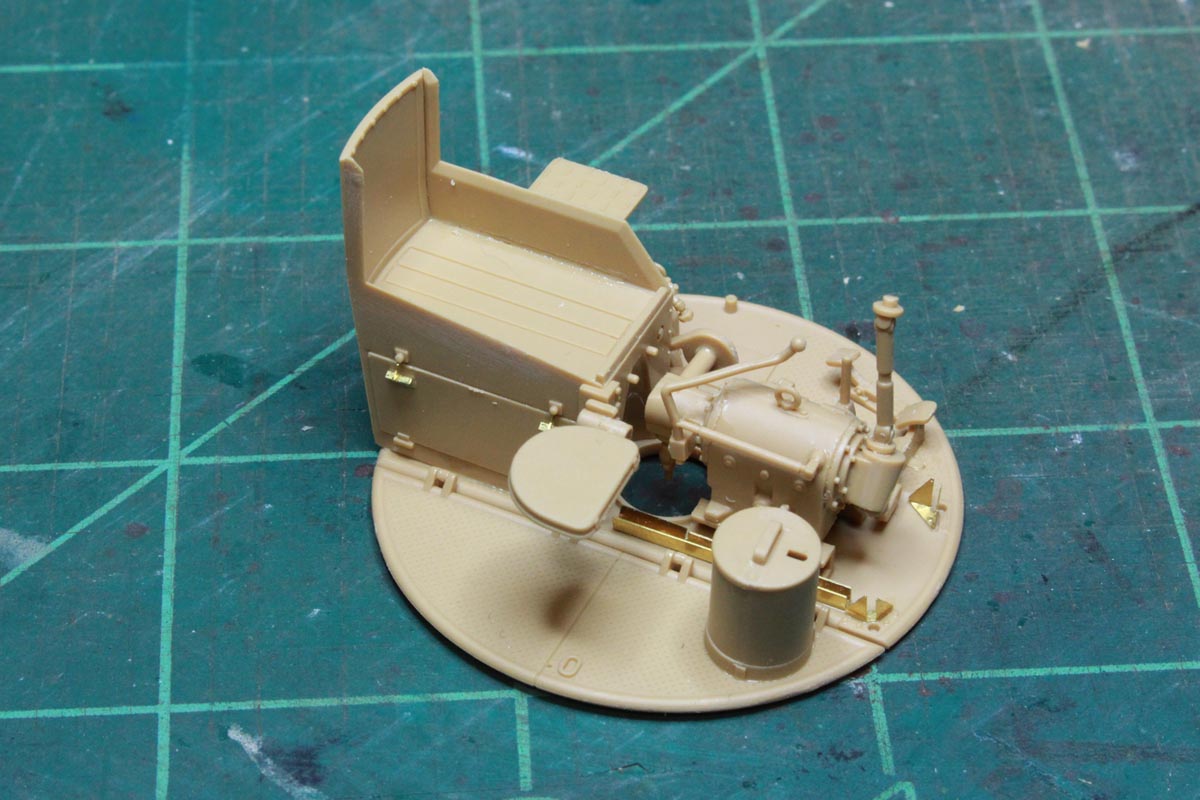

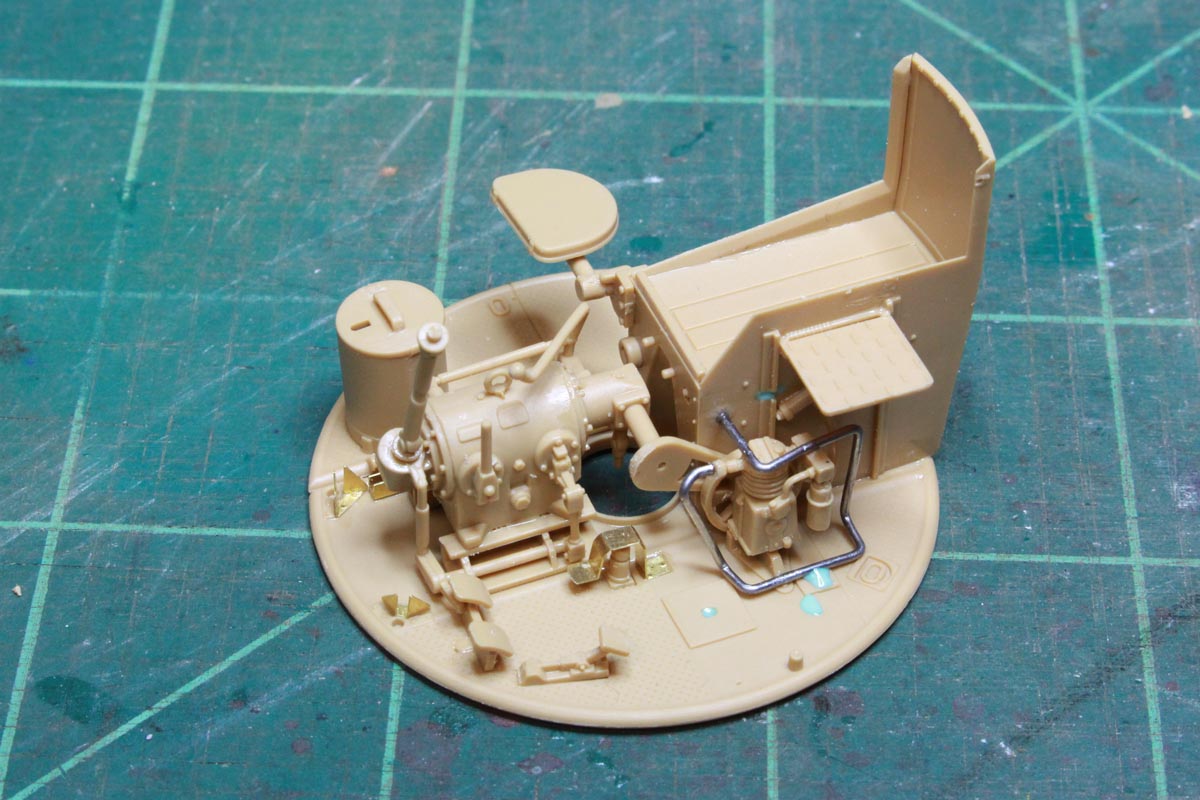

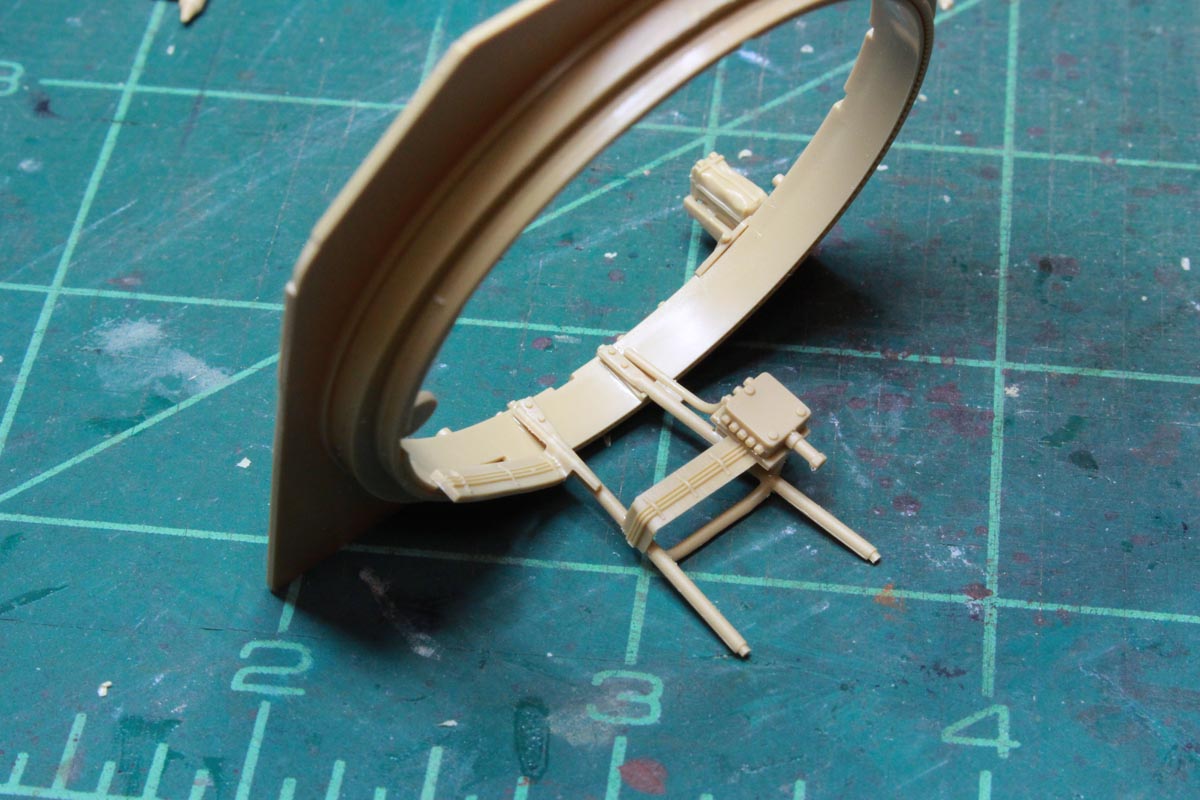

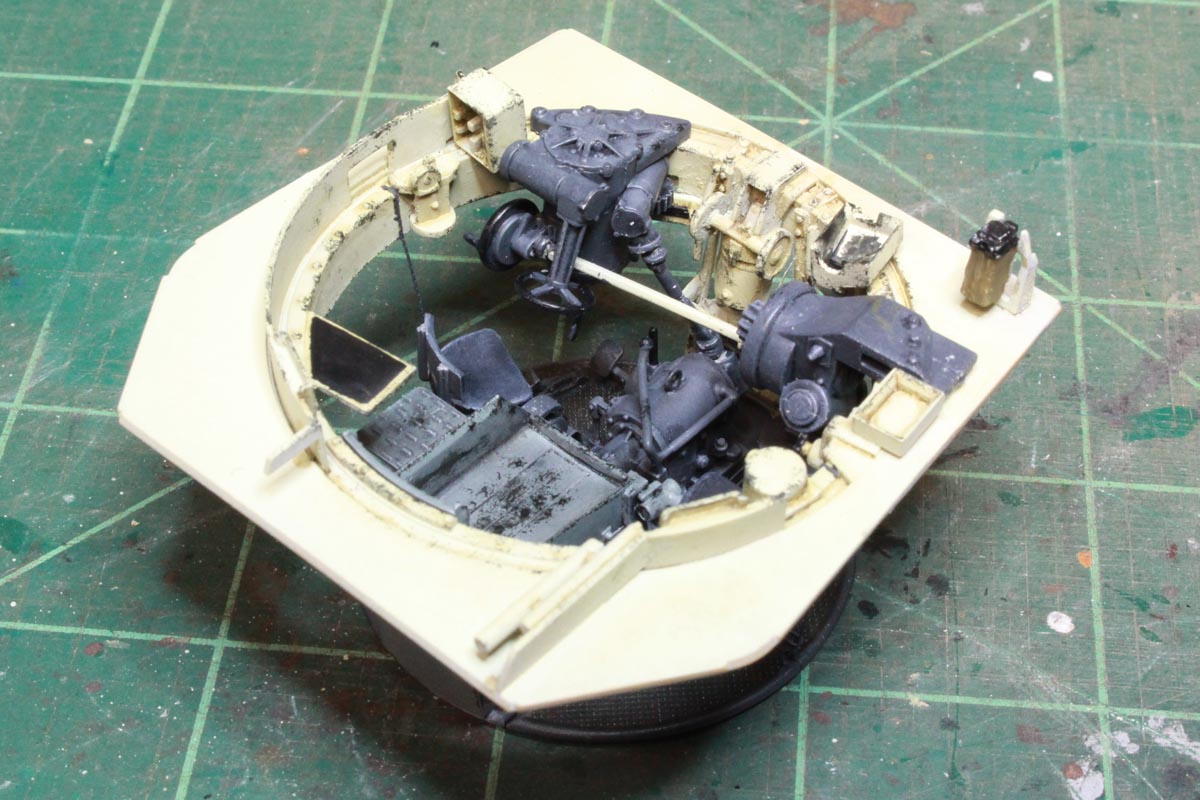

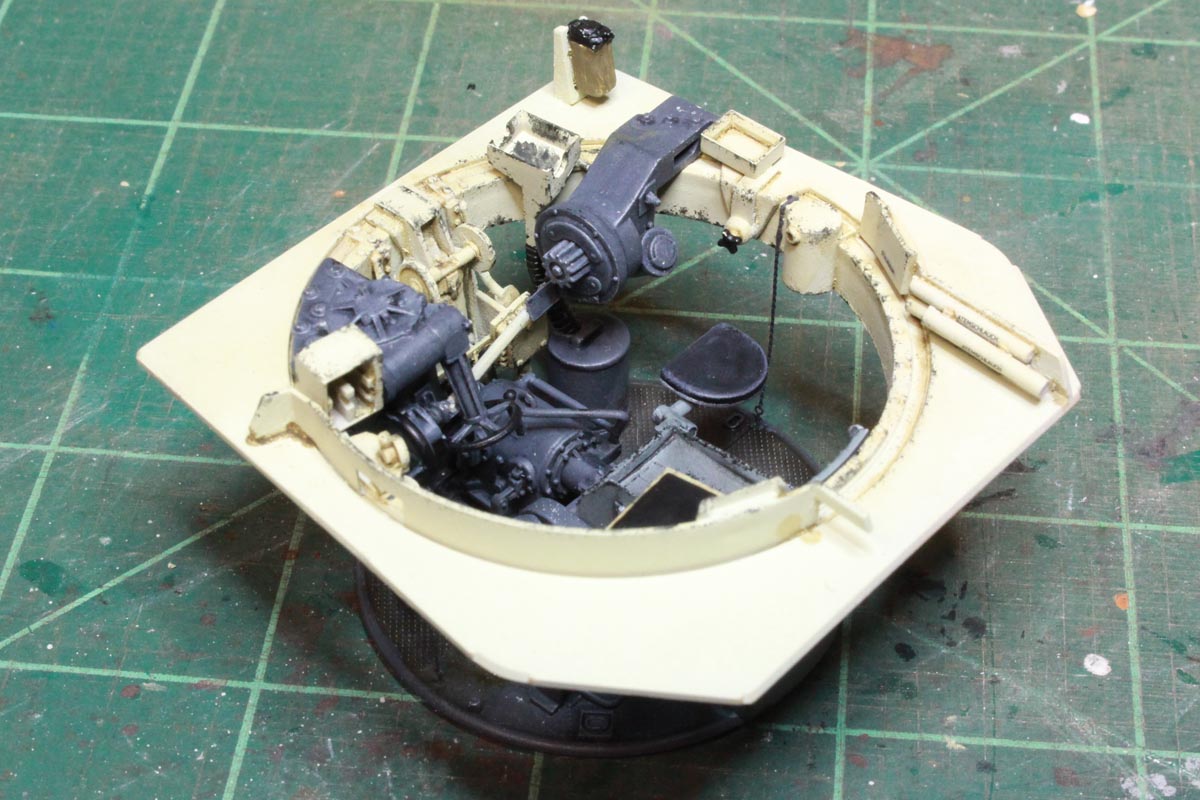

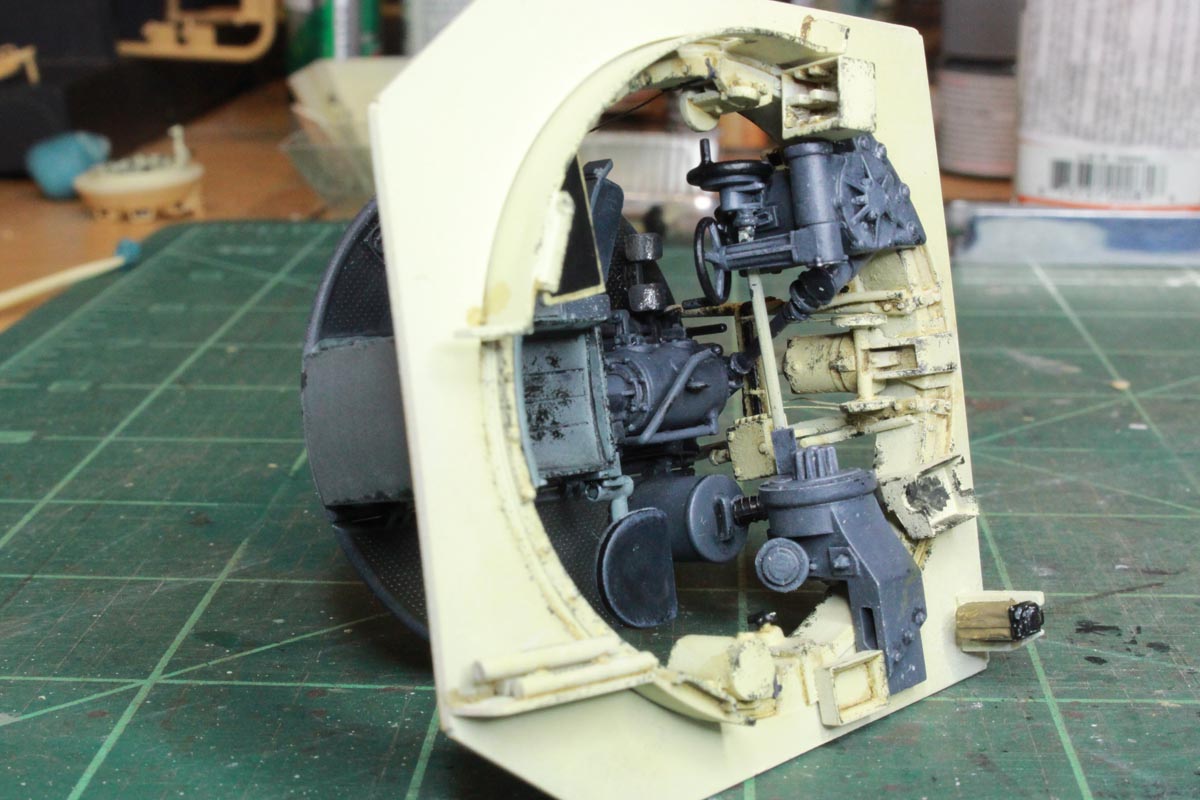

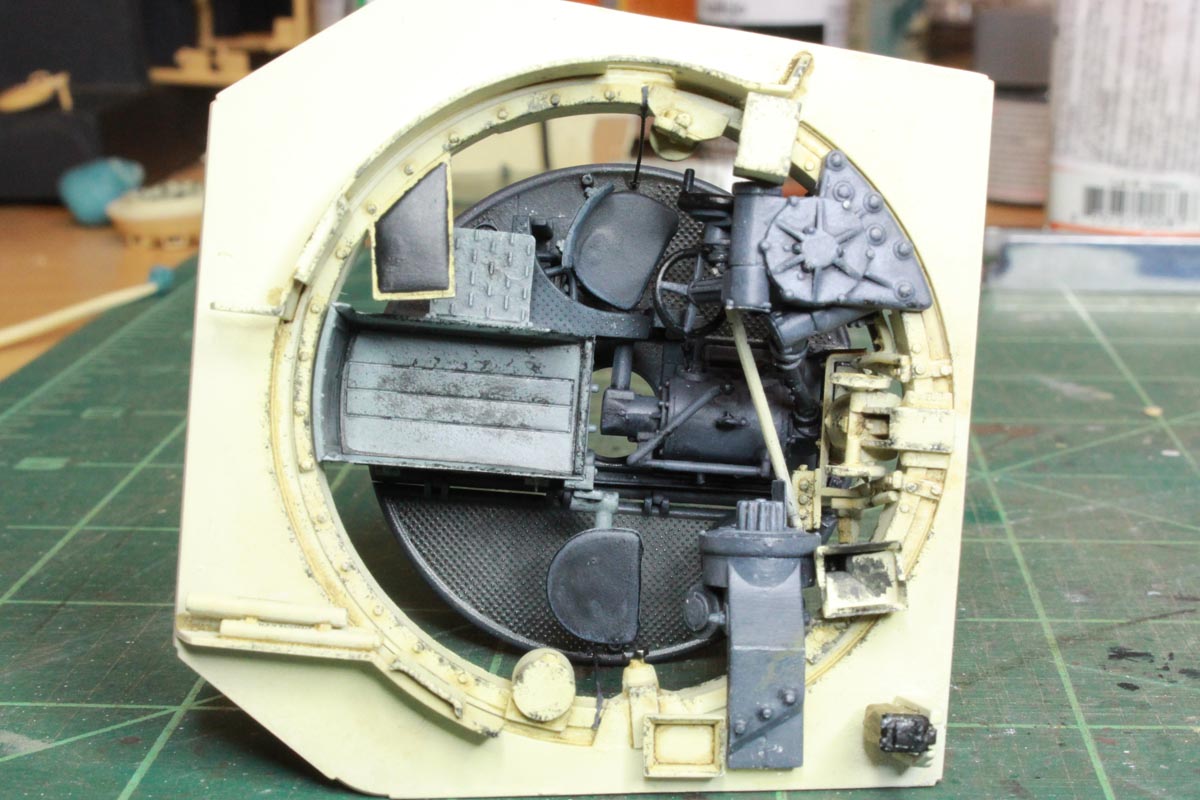

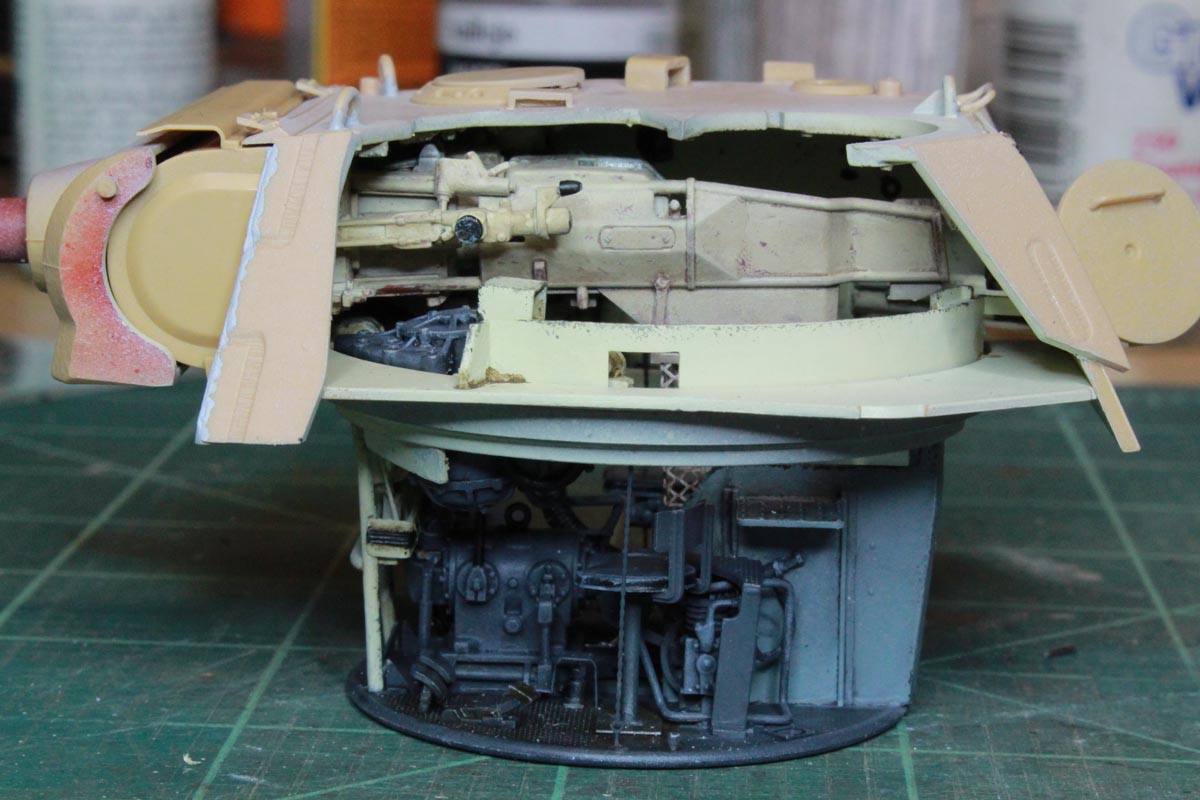

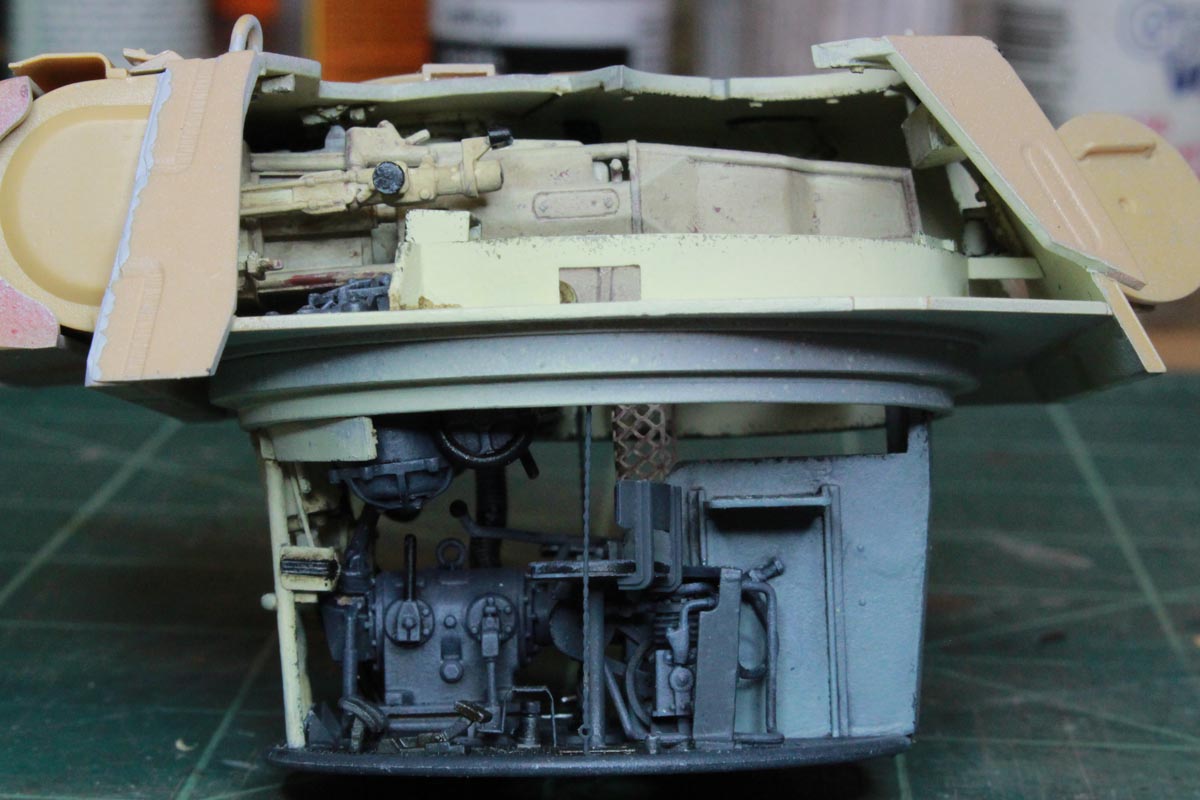

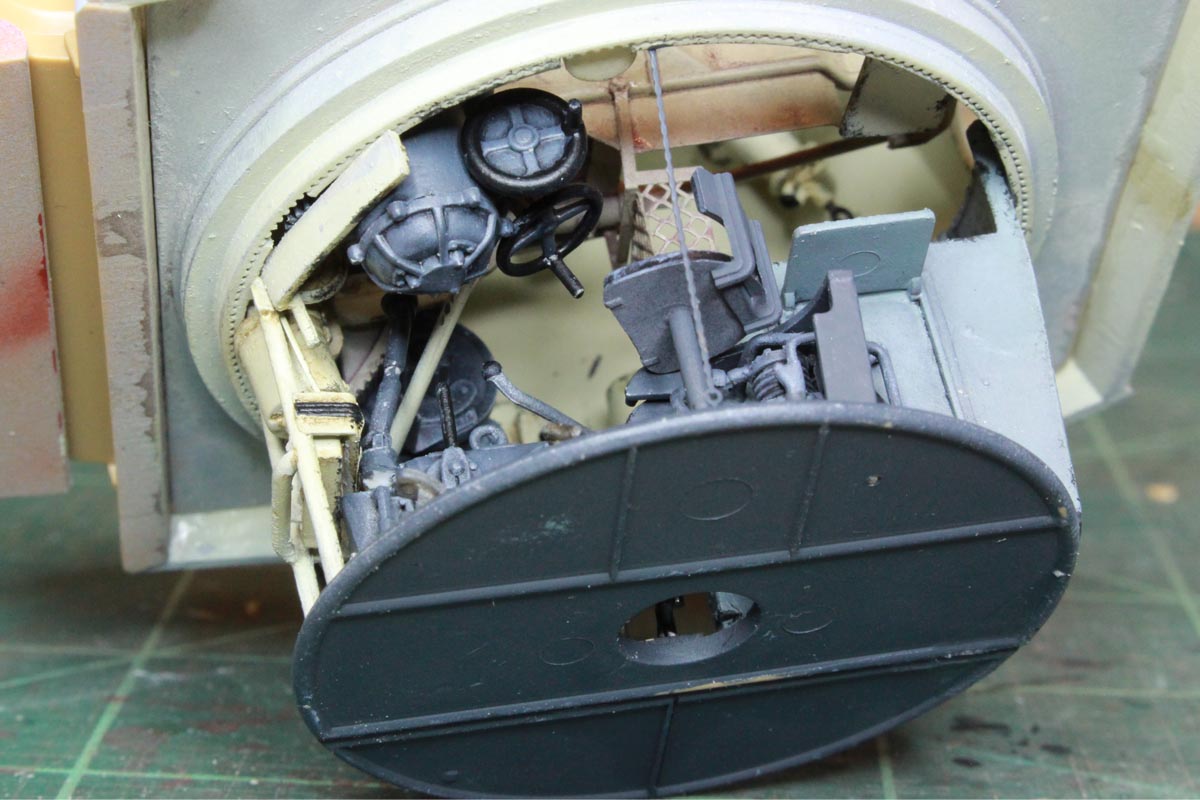

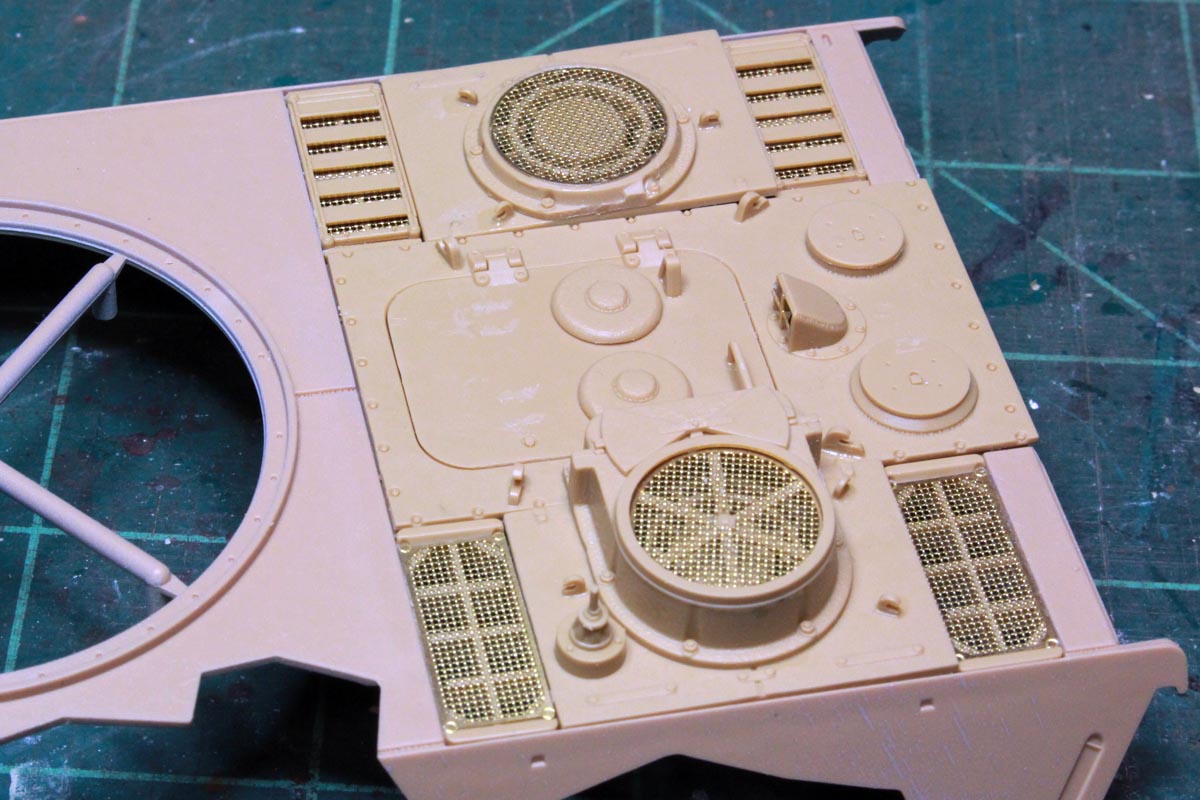

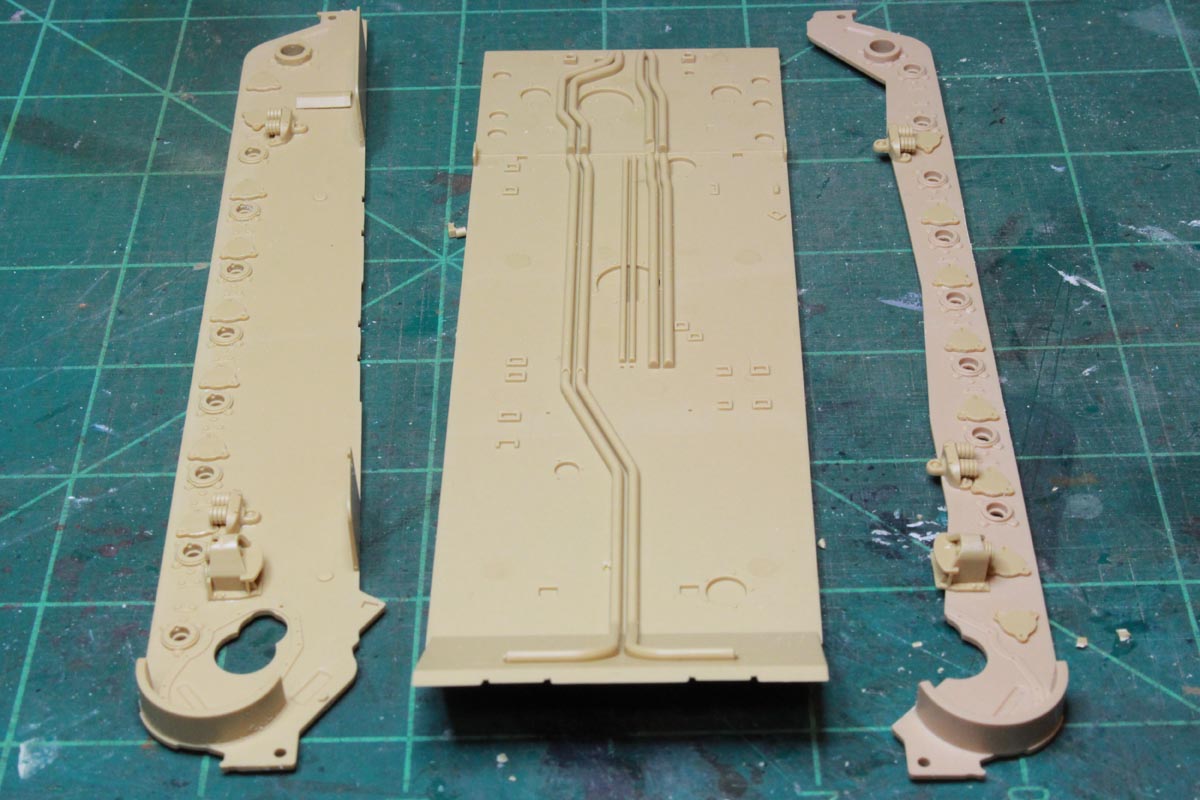

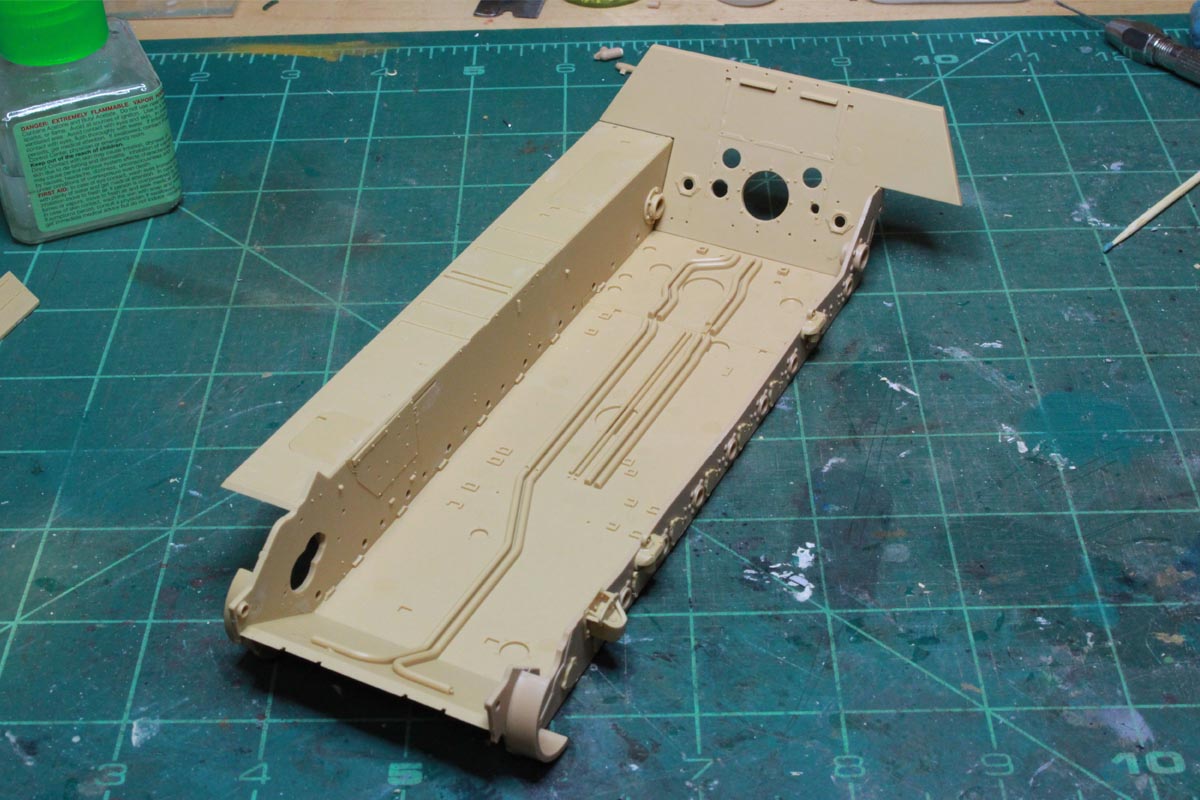

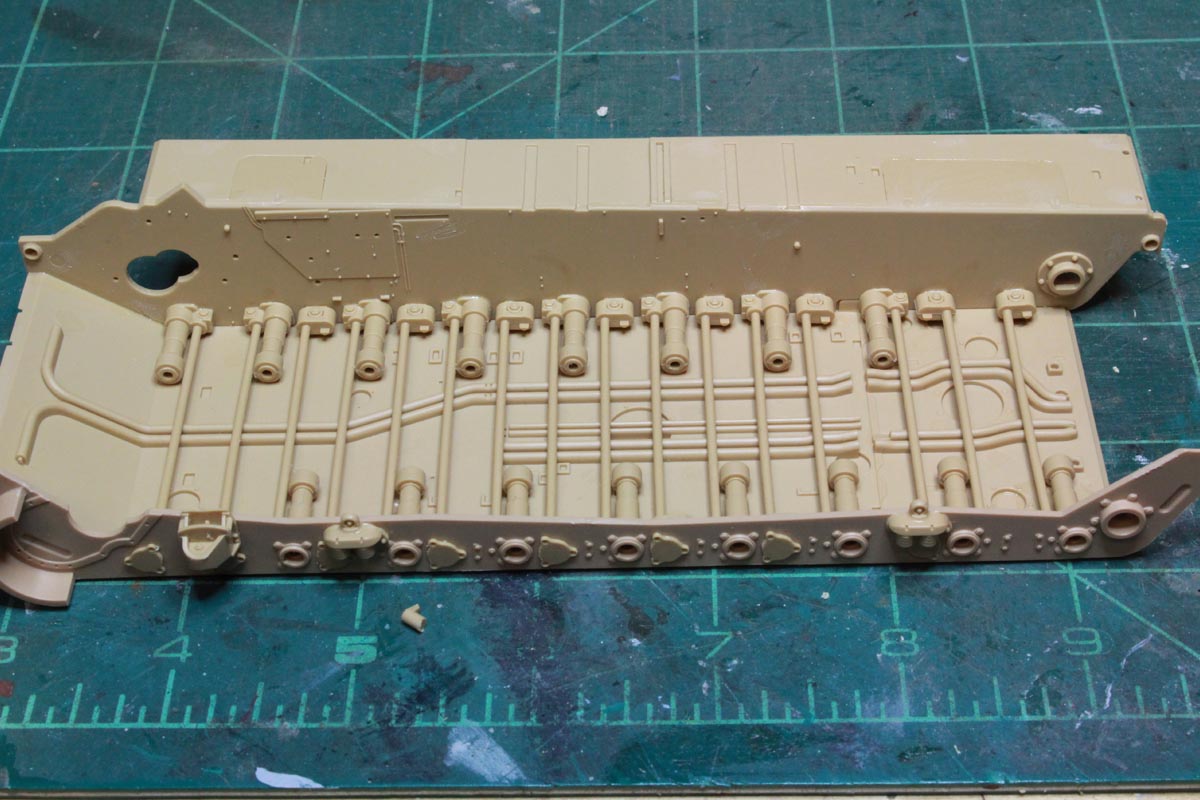

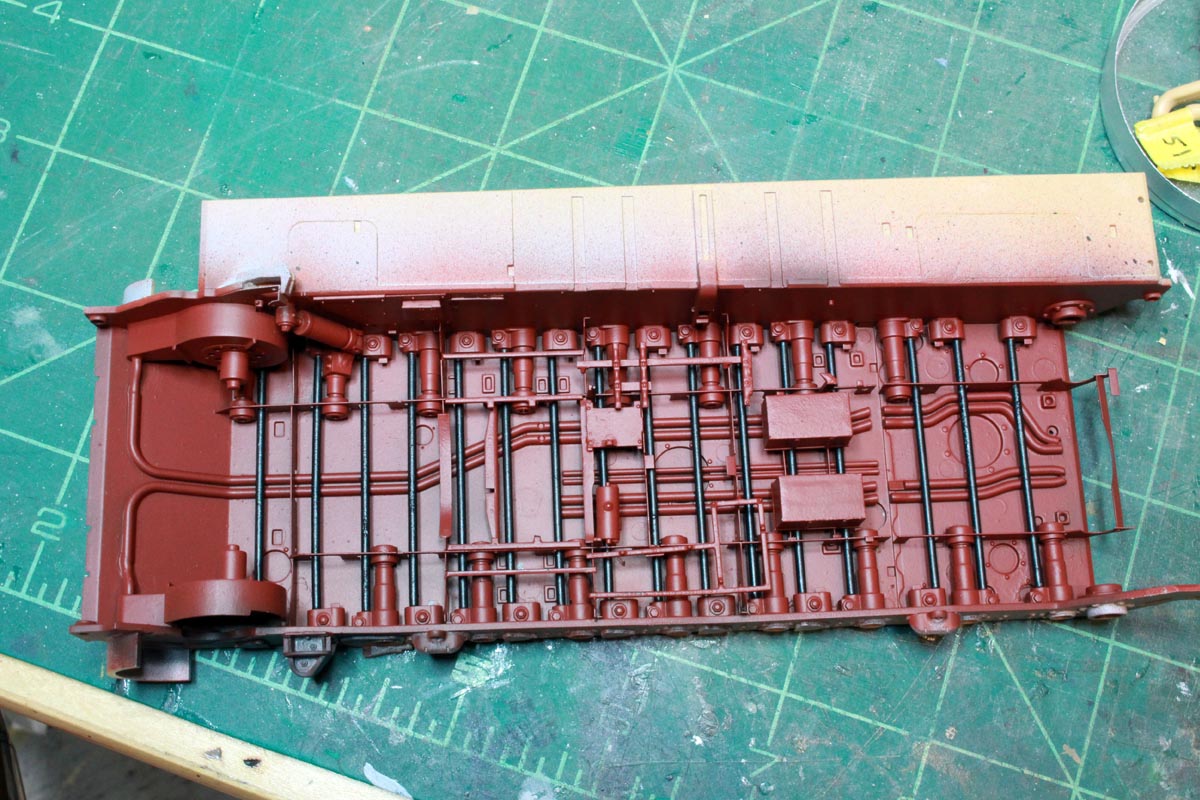

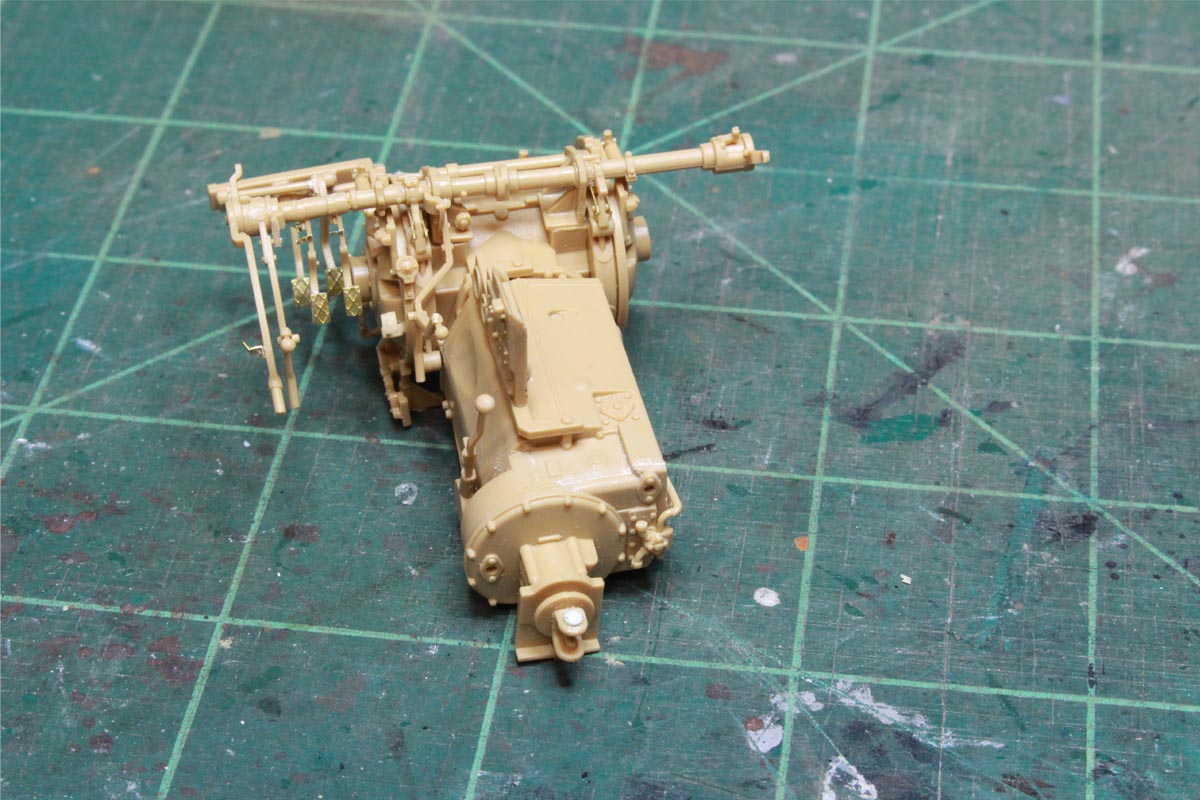

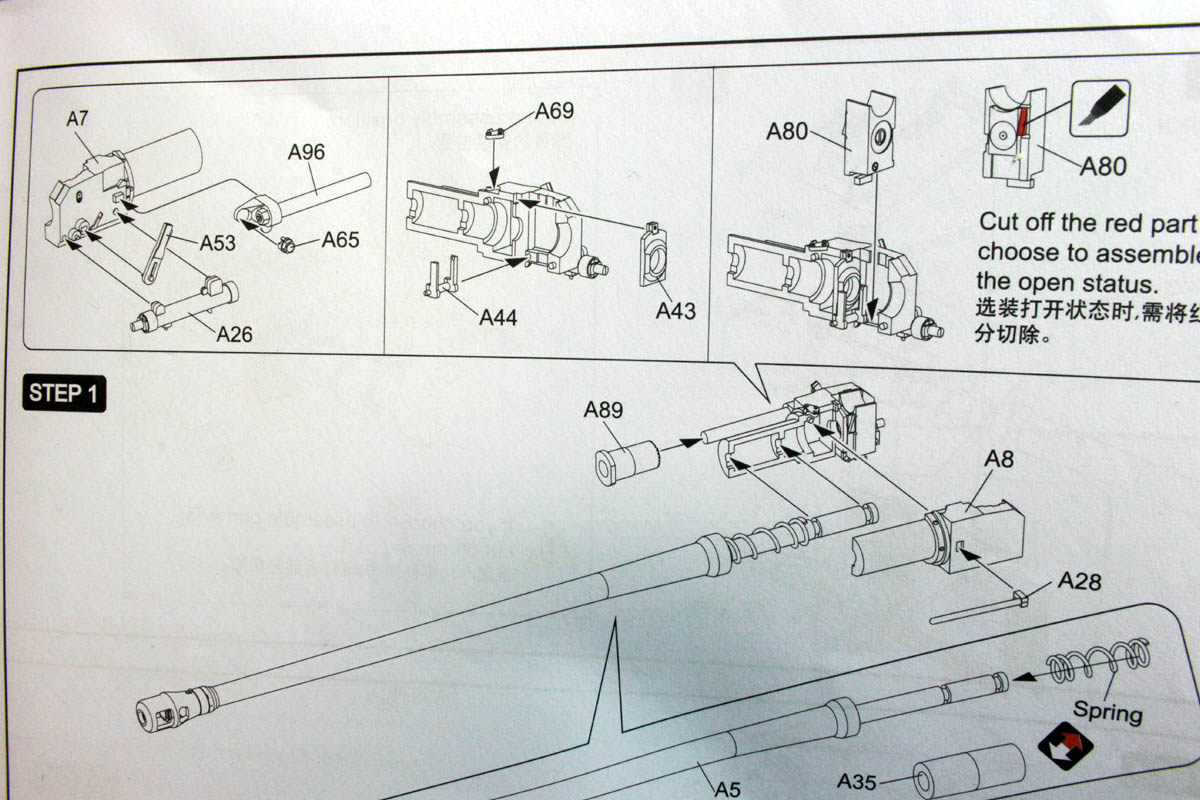

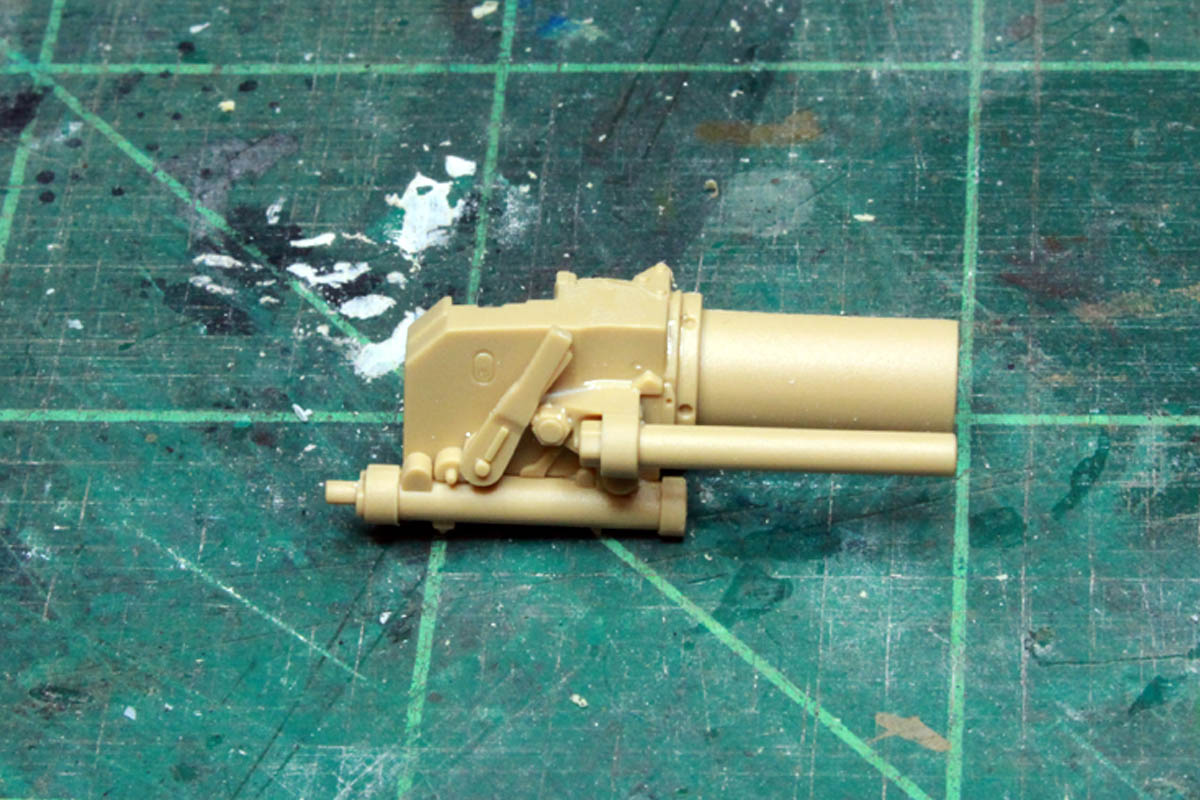

it is now time to do a build blog on this bad boy! After getting my nerve up I dove in. In a break from seemingly normal tank building convention, RFM has you start construction with the main gun, and not the usual running gear. the amount of detail present is impressive, with the 75mm breech alone taking 11 pieces.

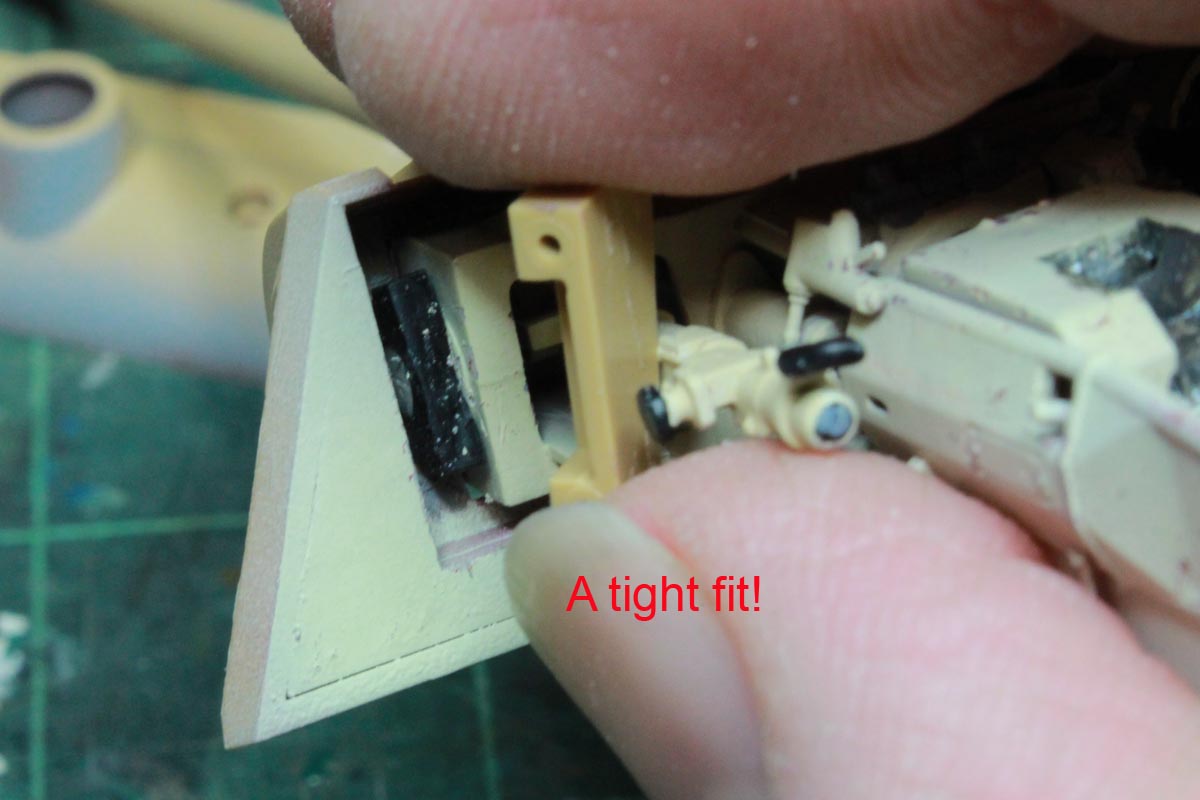

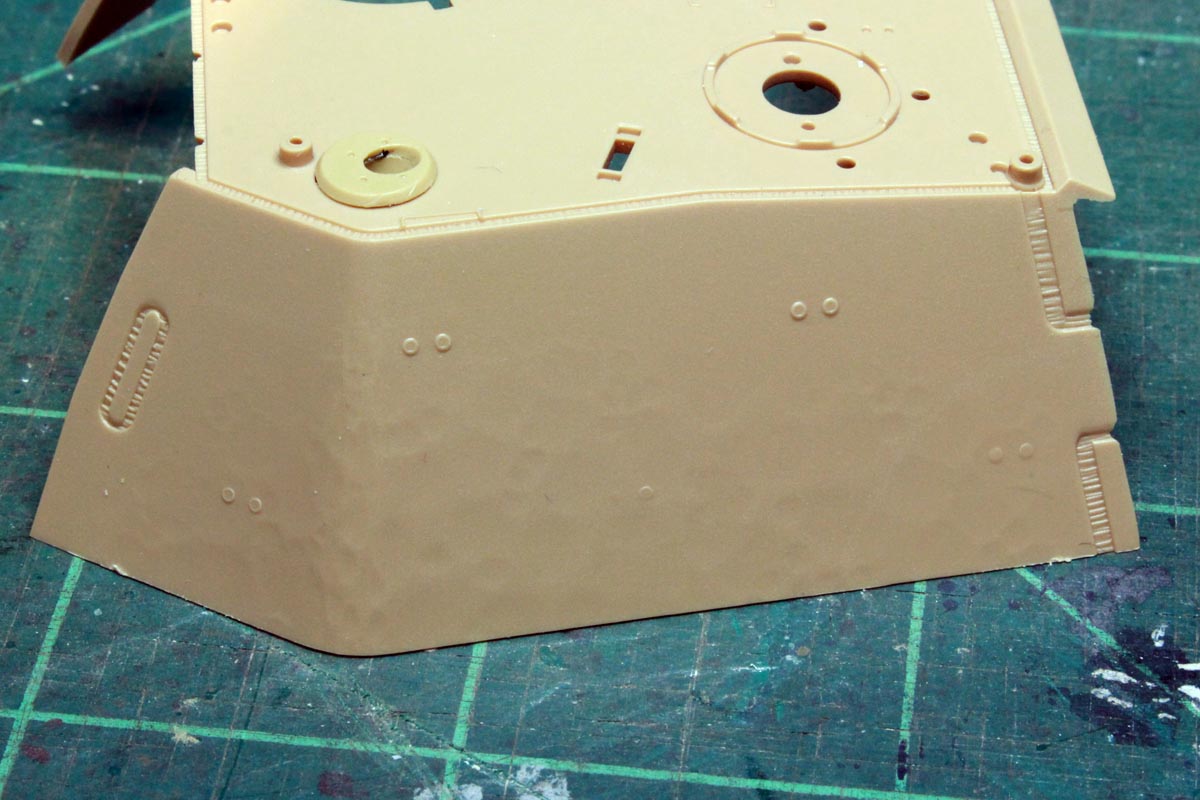

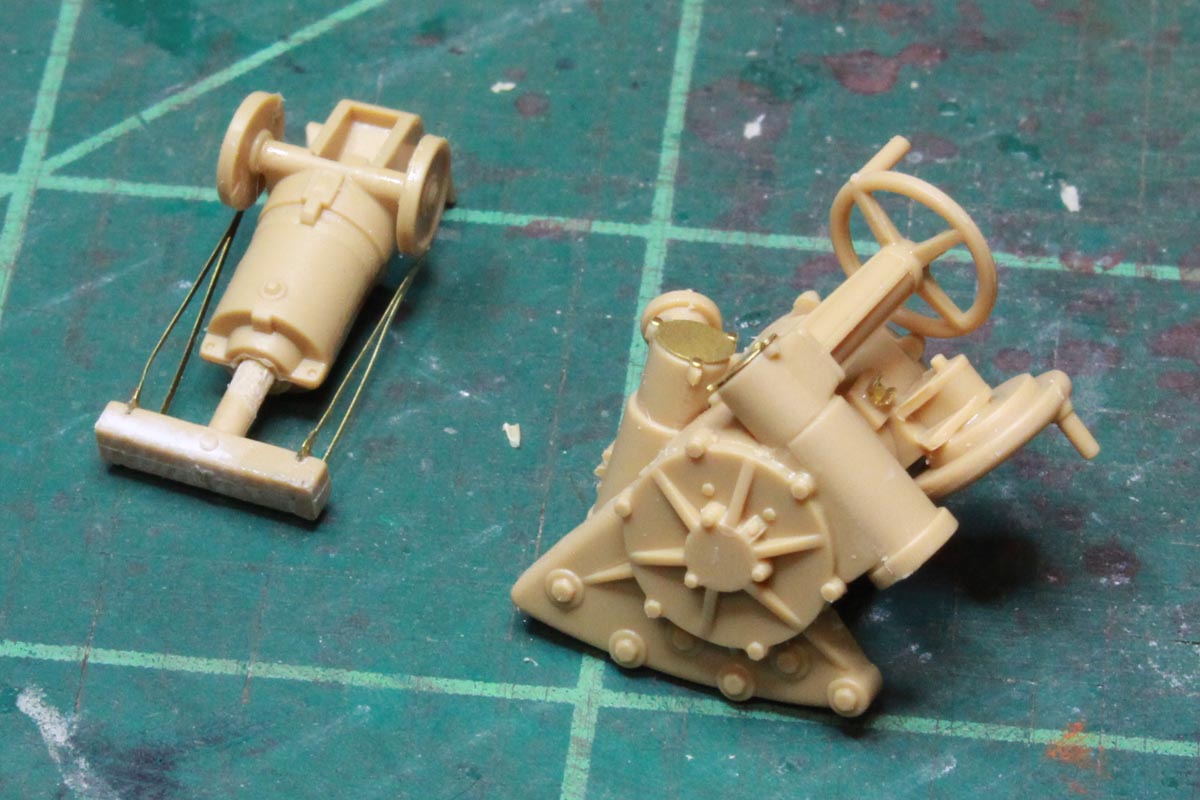

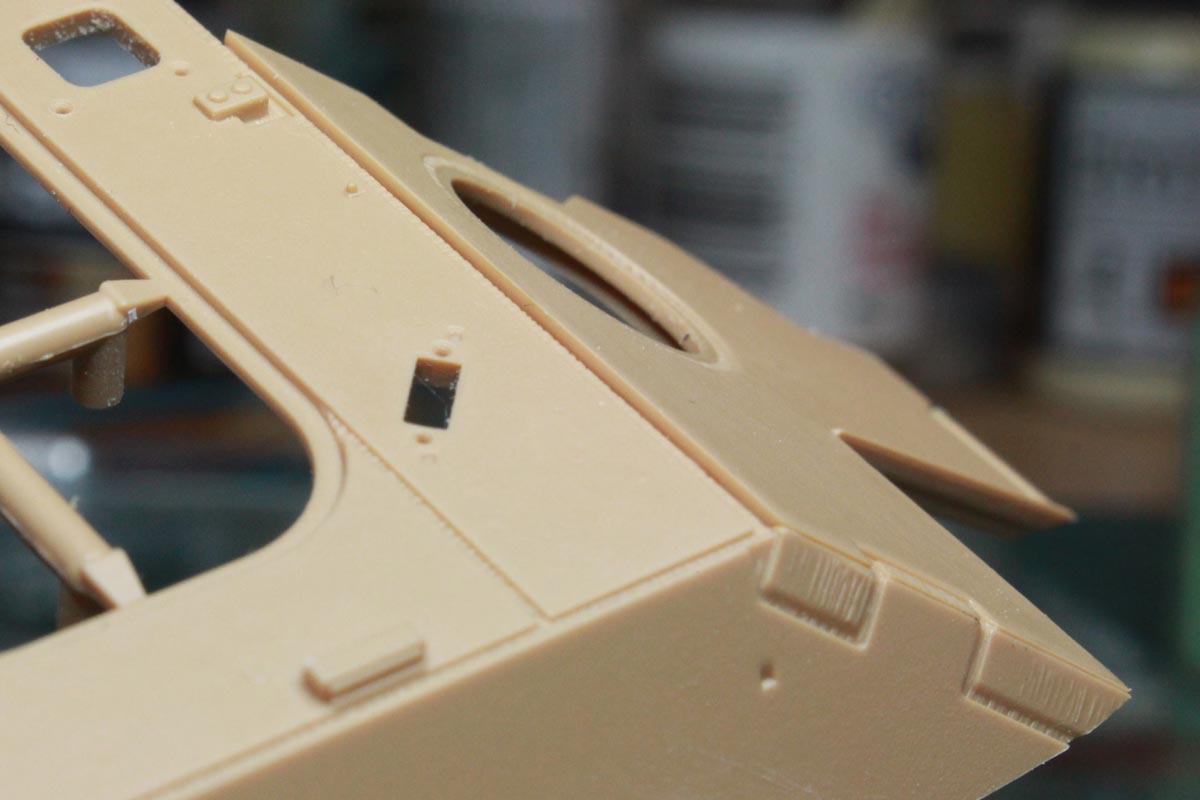

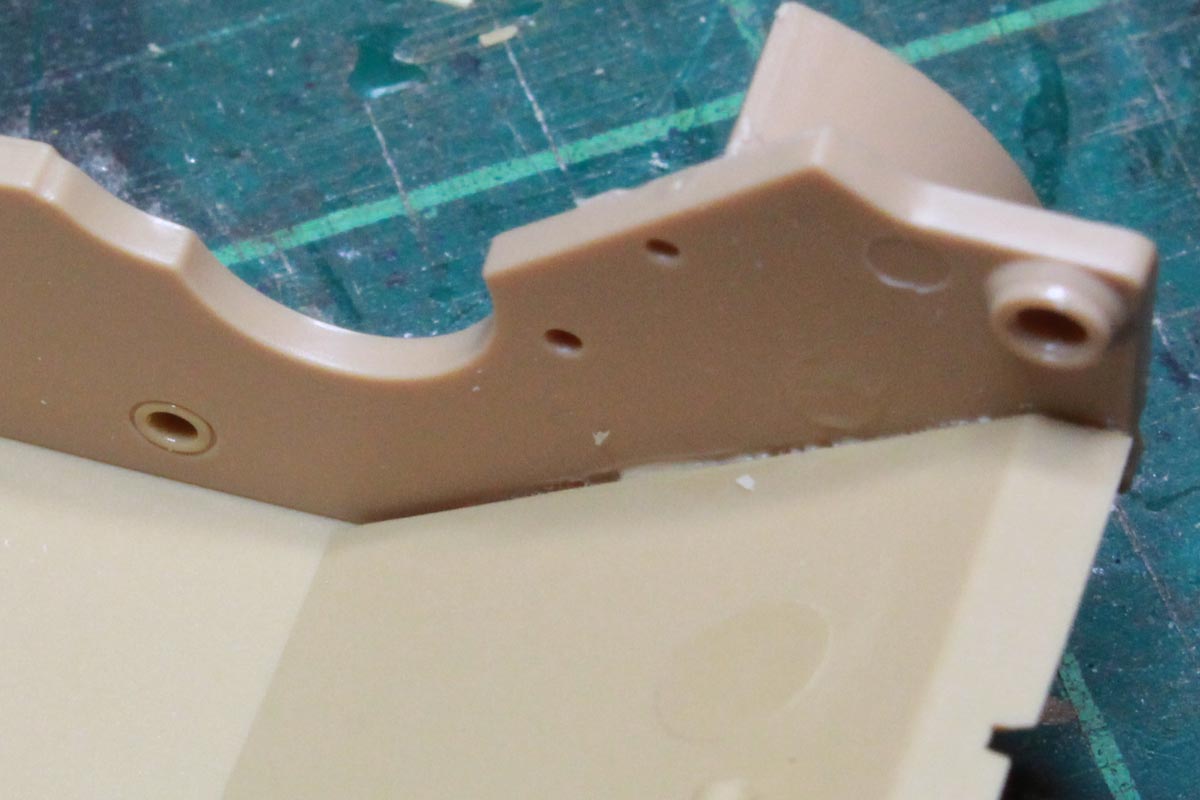

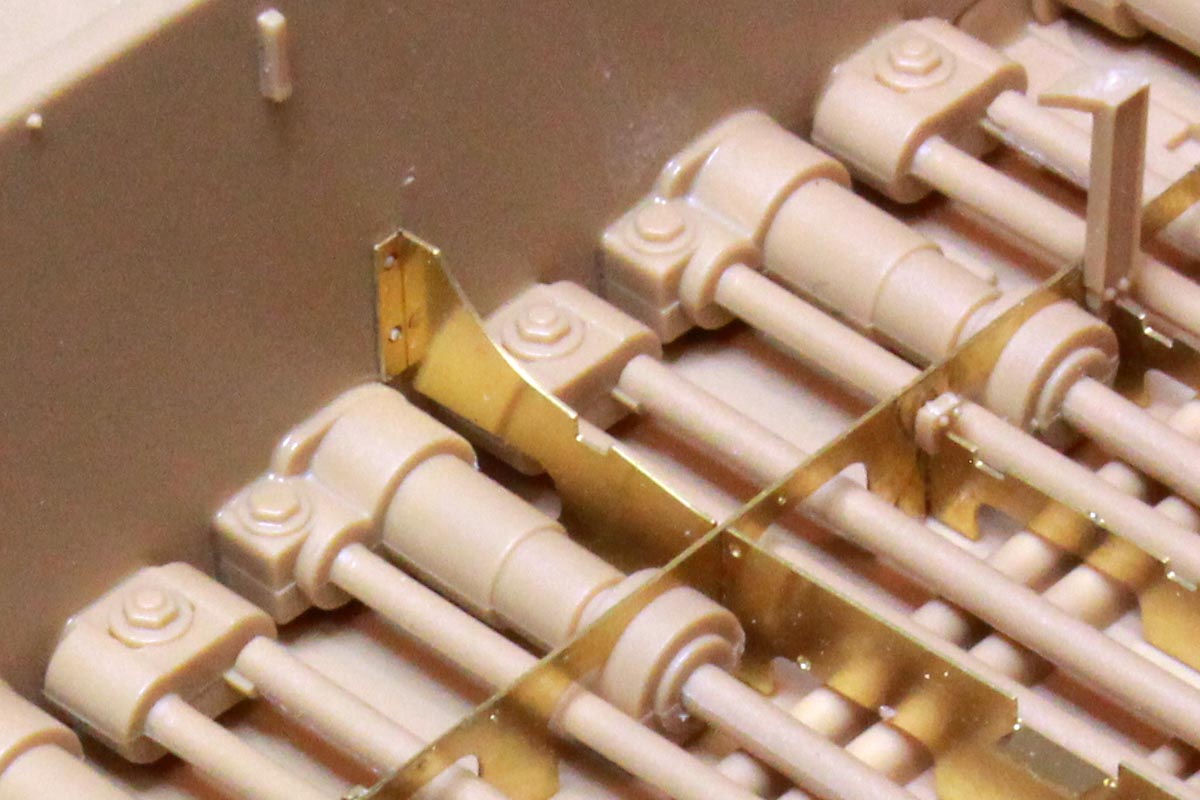

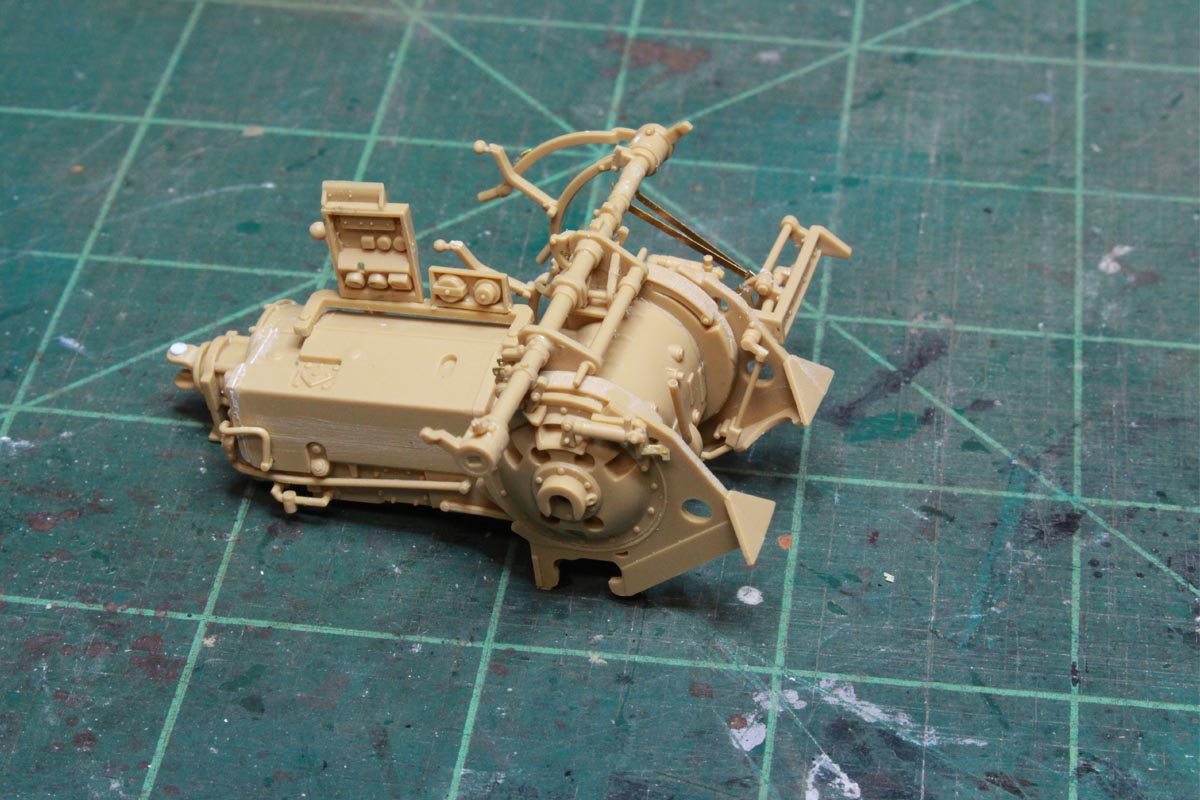

The width of the breech block did need to get shaved down a bit for a good fit, and there was a sink hole present that I missed when I did the in-box review:

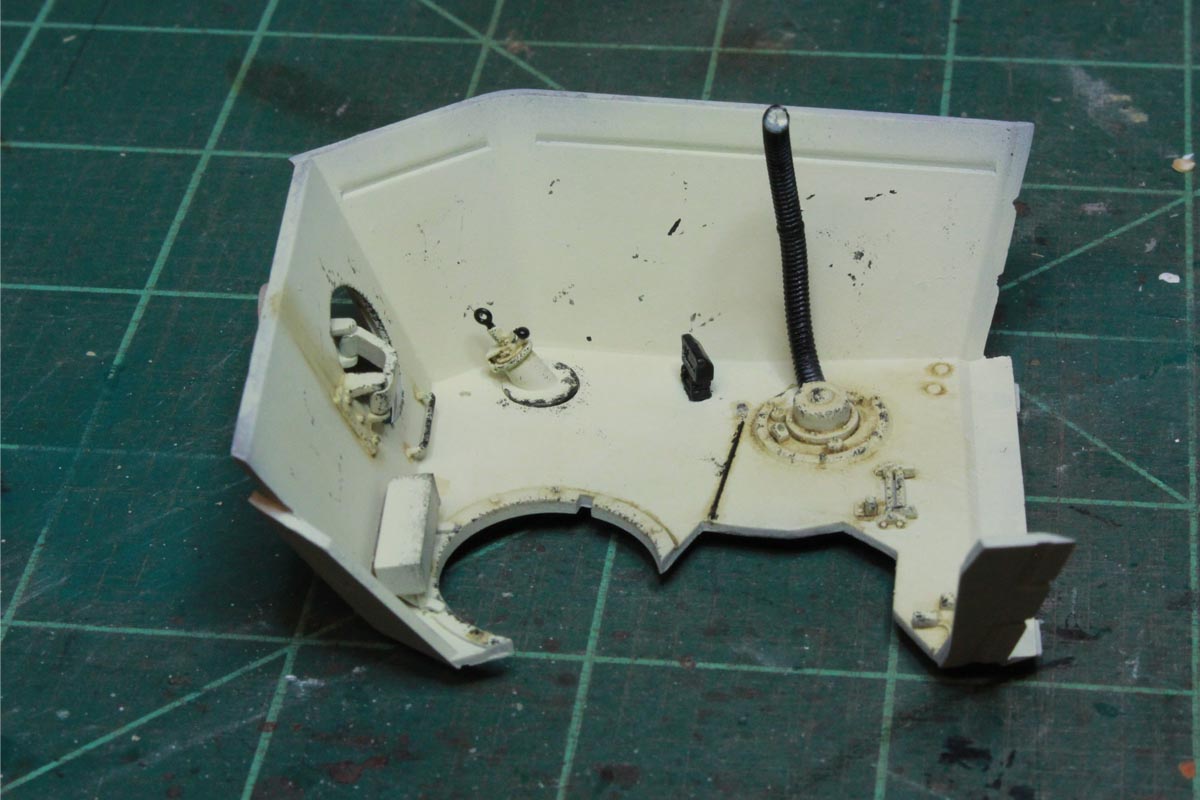

and it might be better to leave pieces A26,53,65 & 96 off of A7 until you have the two halves of the breech together around the gun barrel, less chance of damage. A little bit of filling os required on the breech as usual.

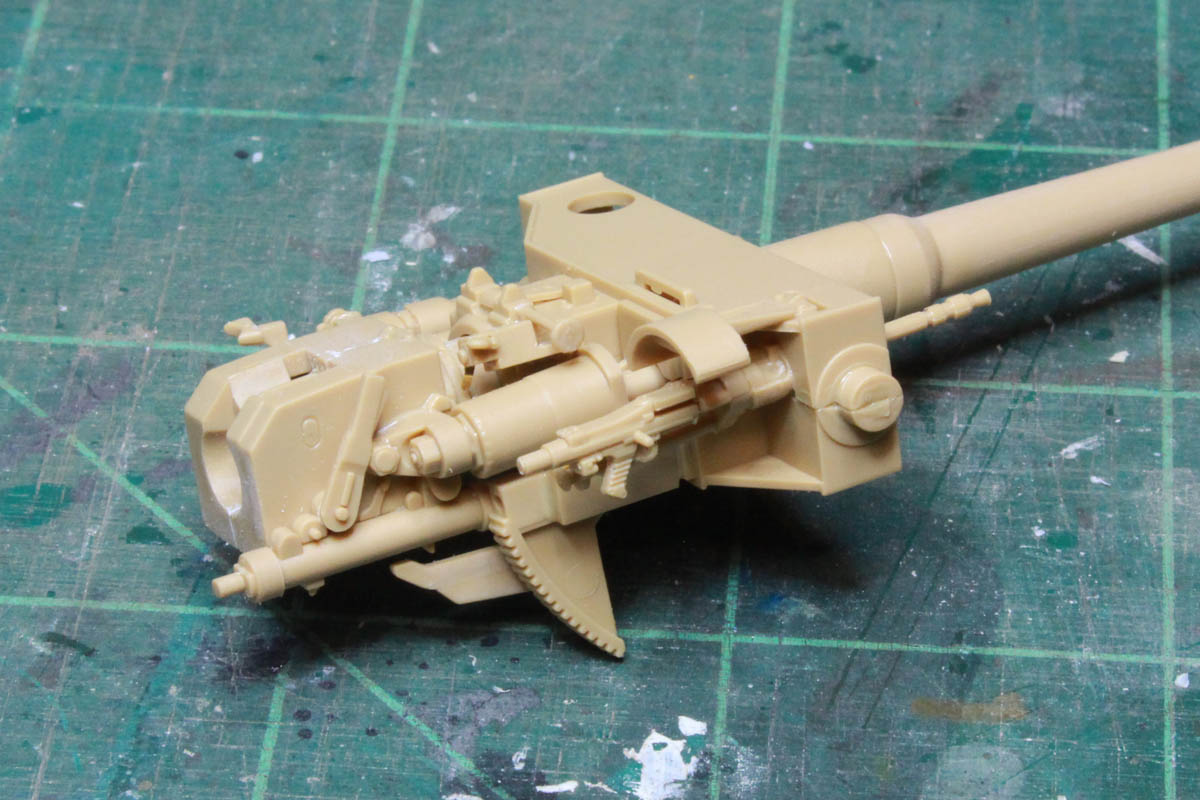

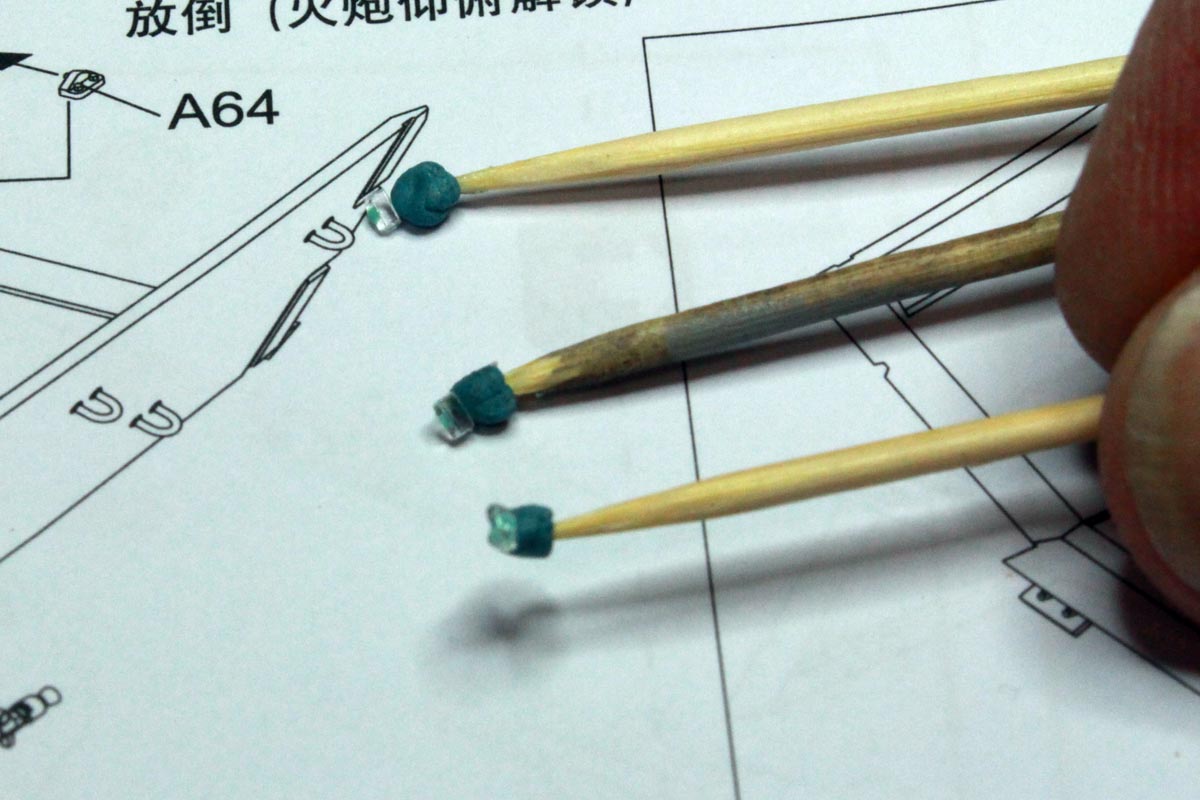

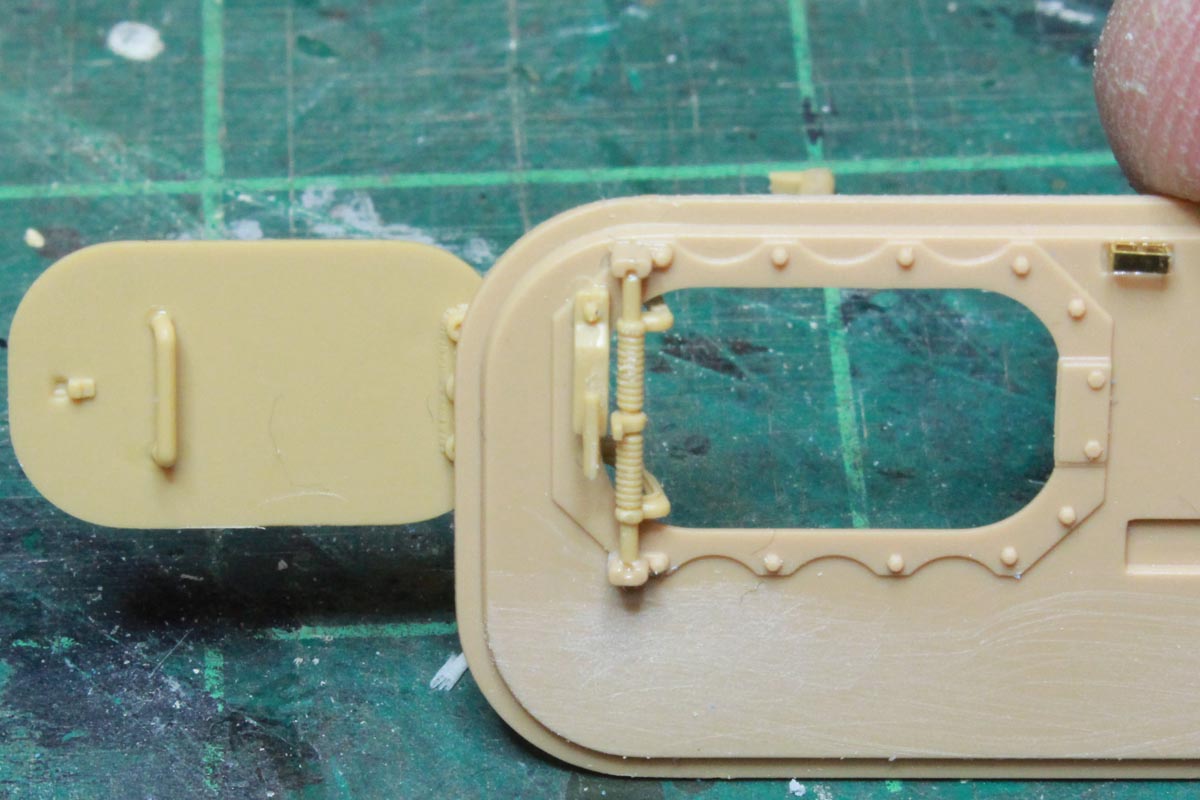

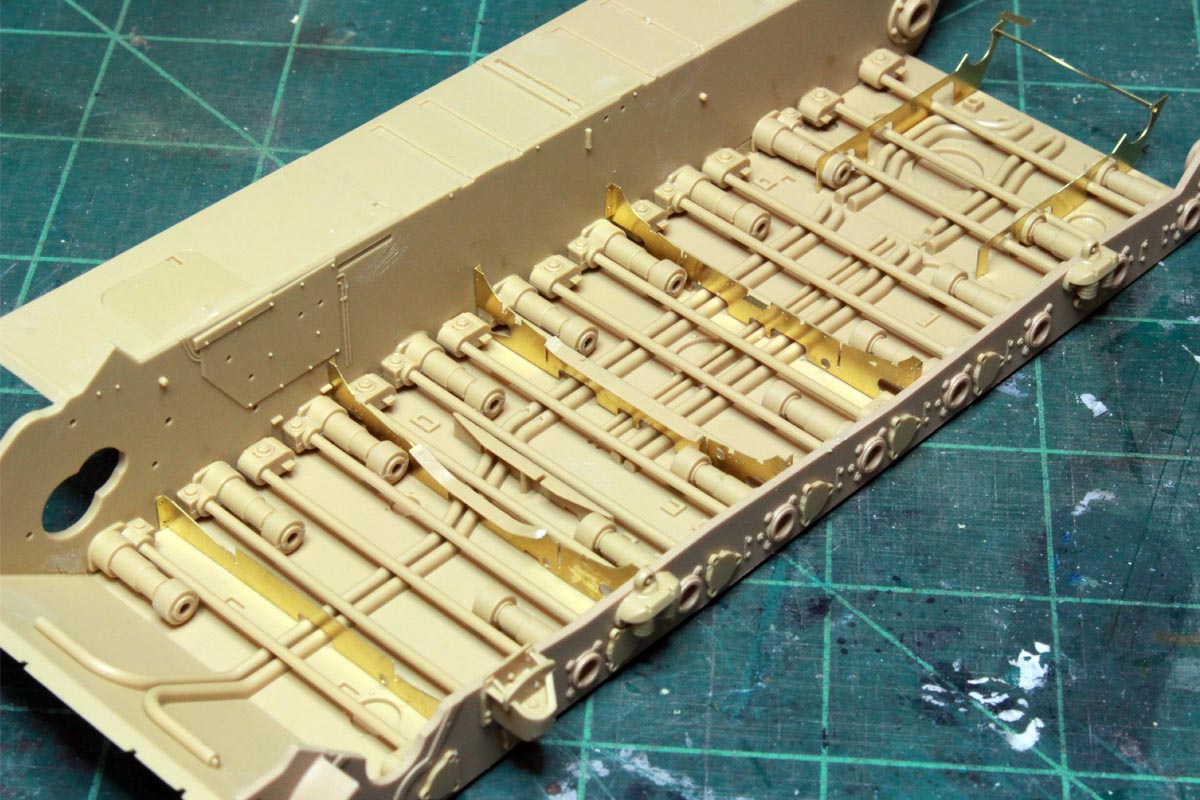

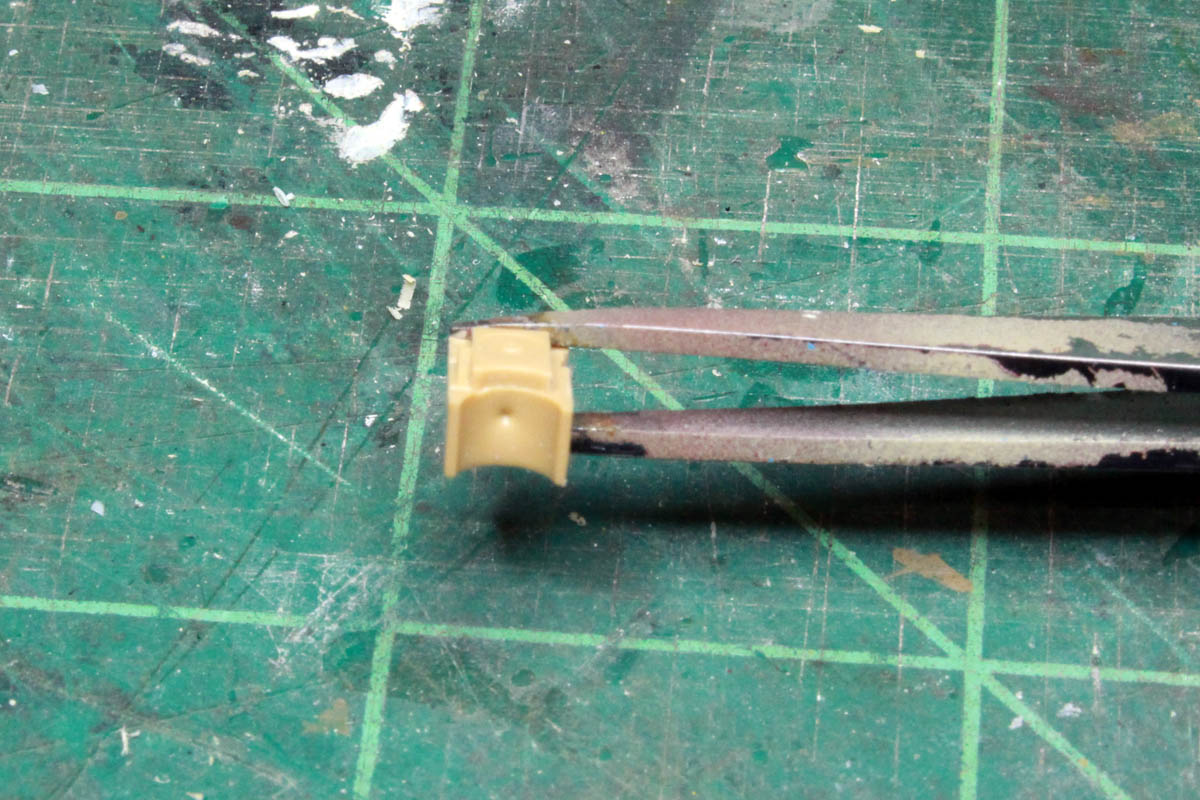

By trimming off a small piece on the breech block as shown you can show the gun with an open breech as well.

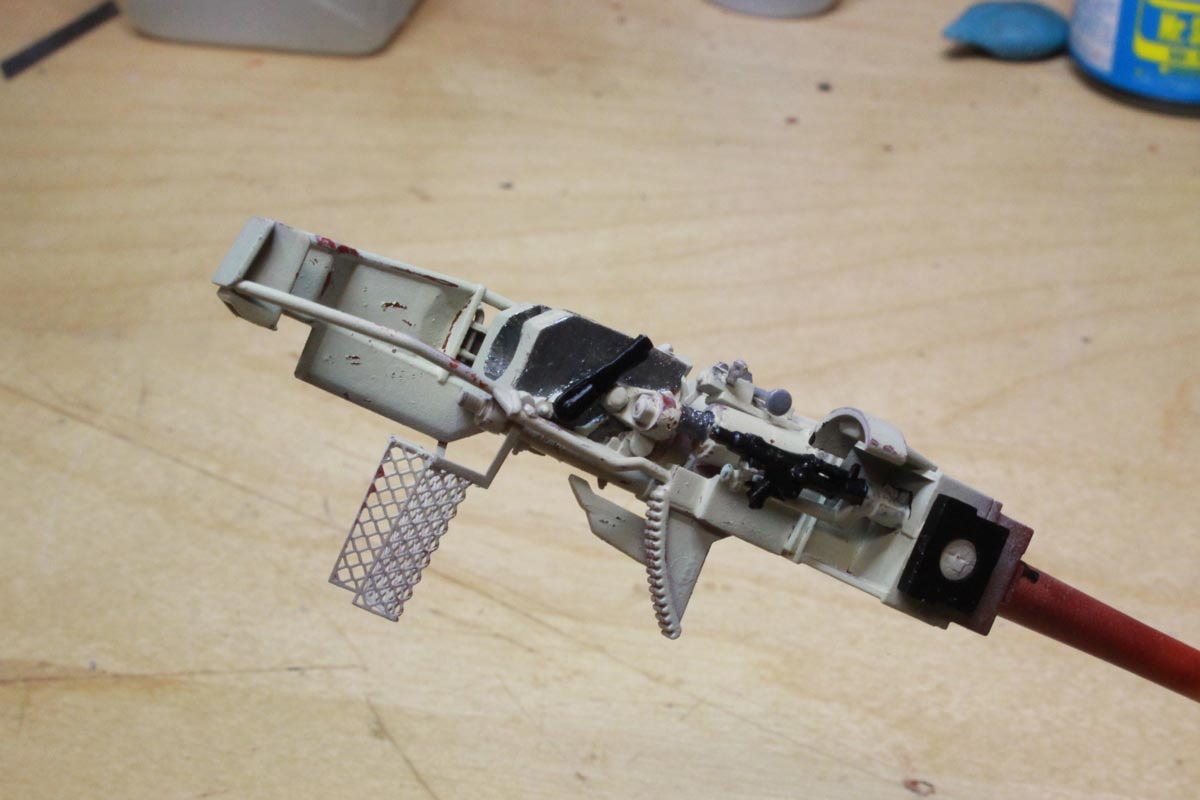

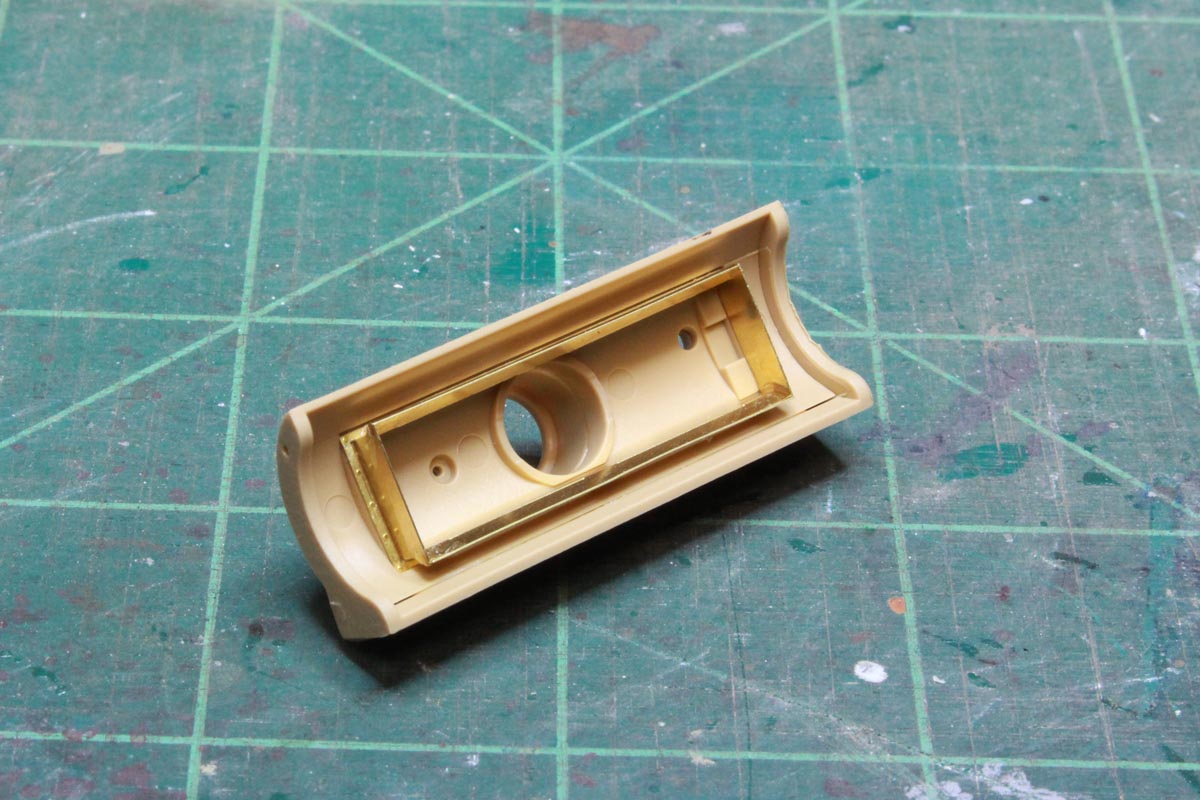

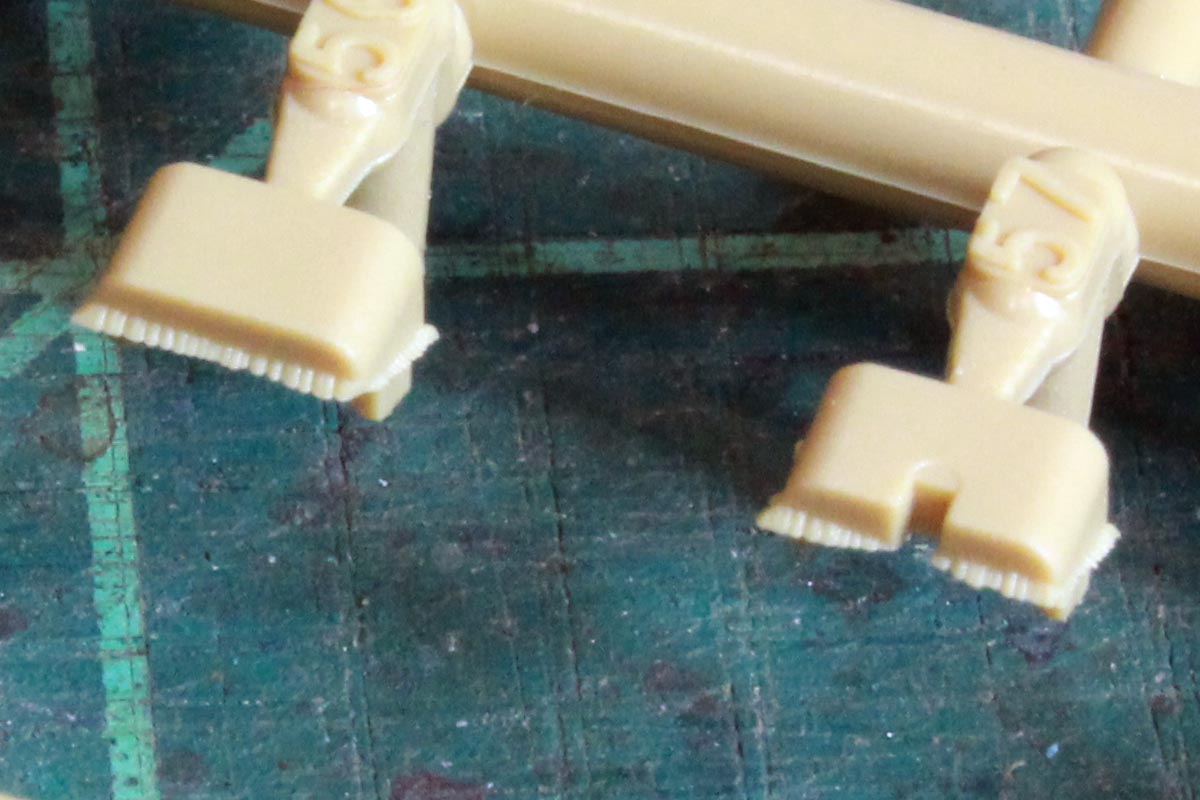

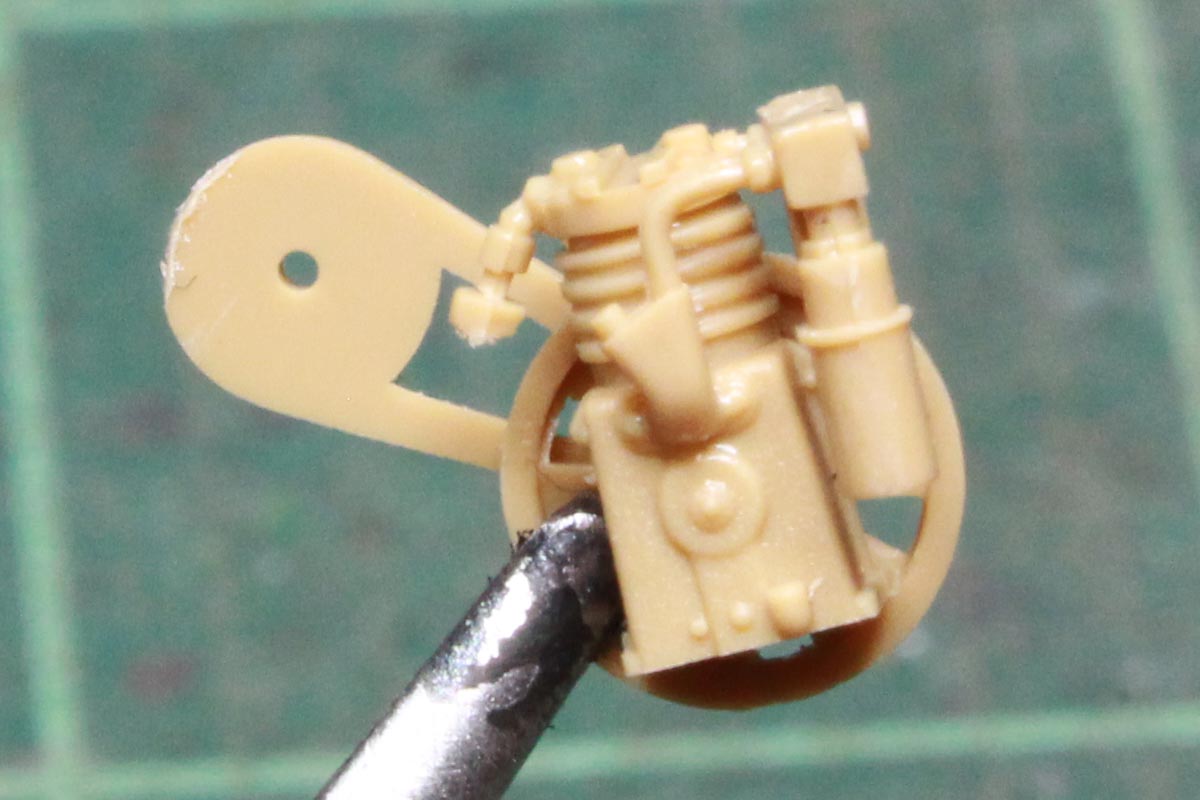

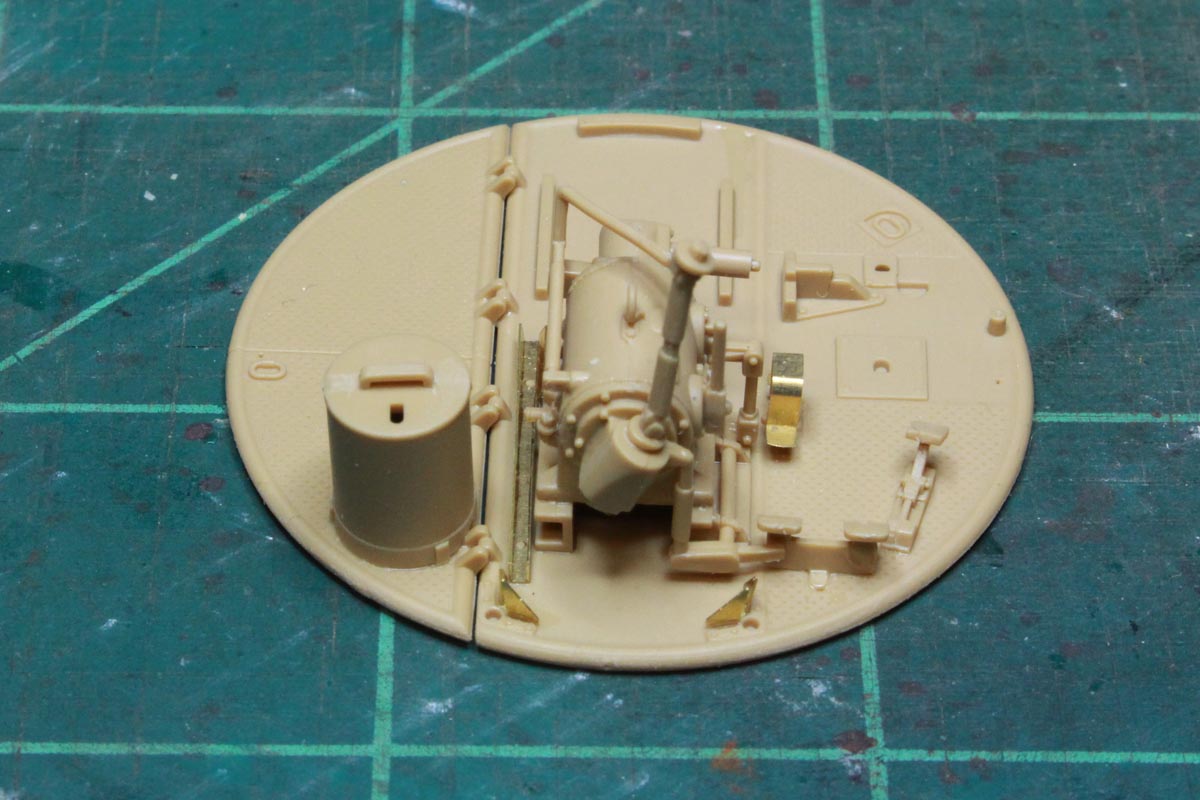

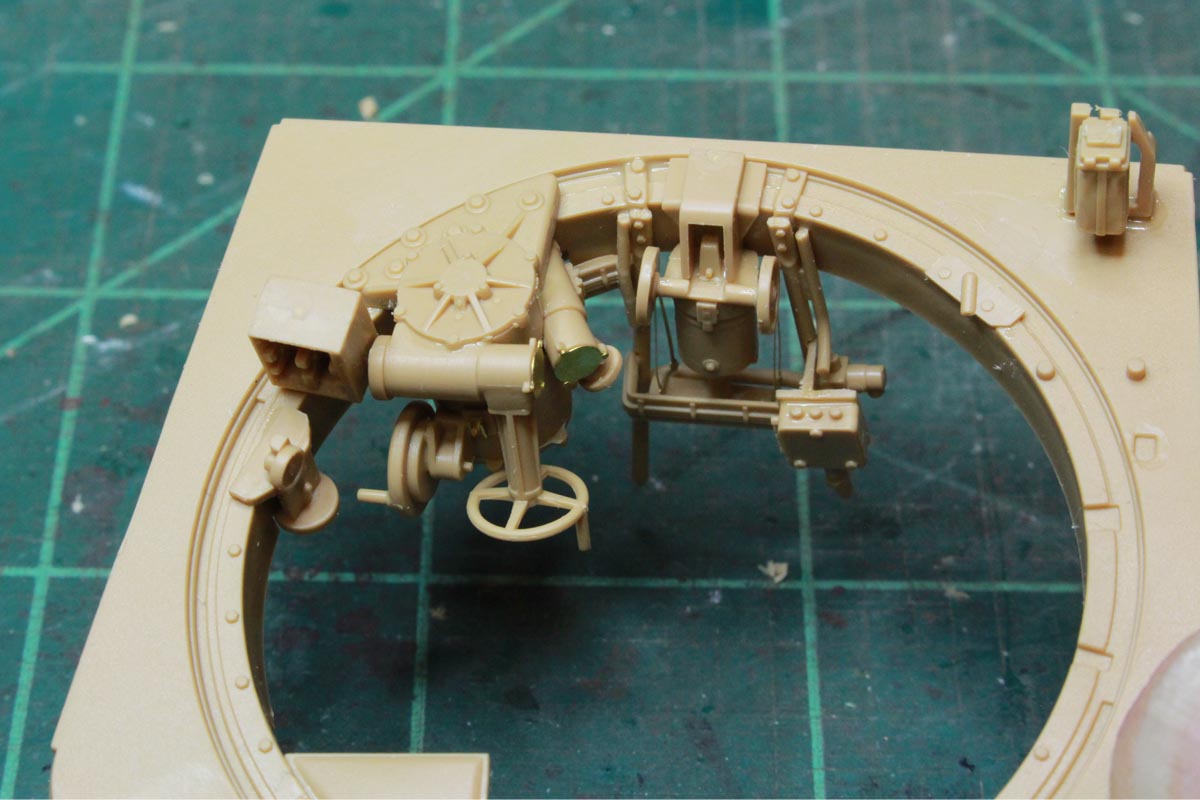

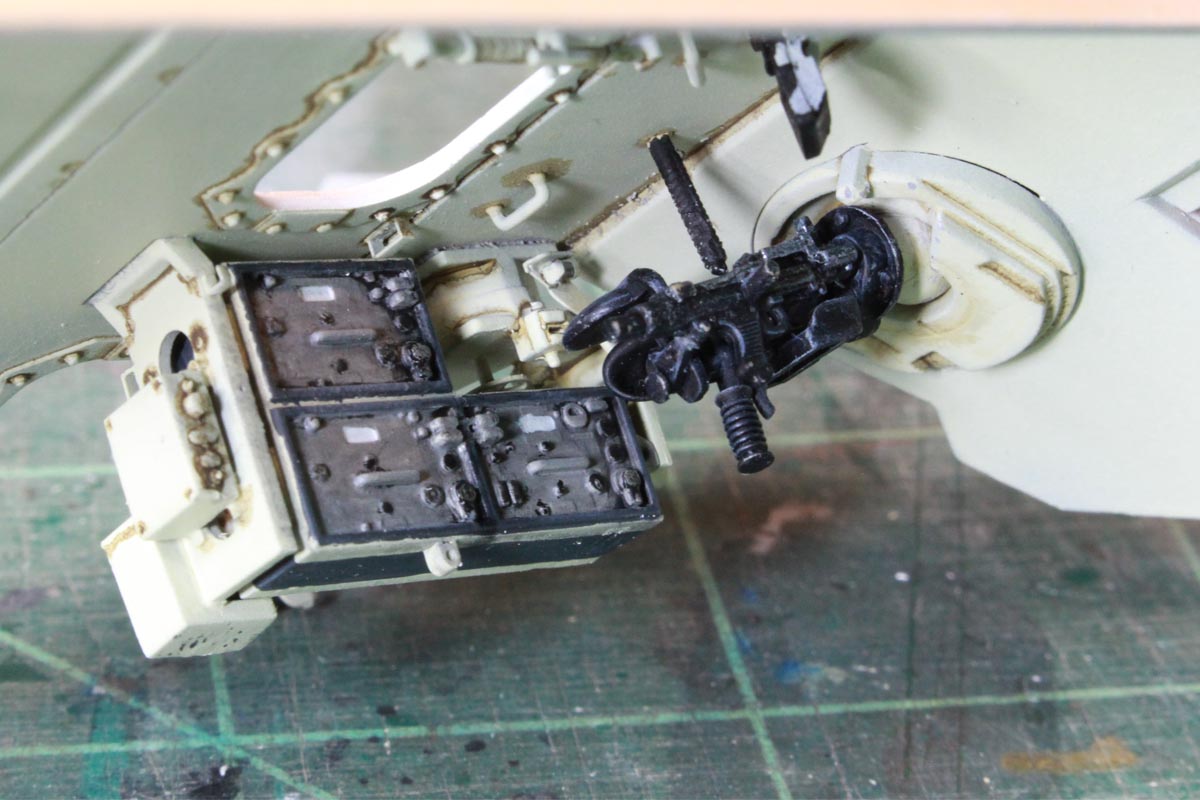

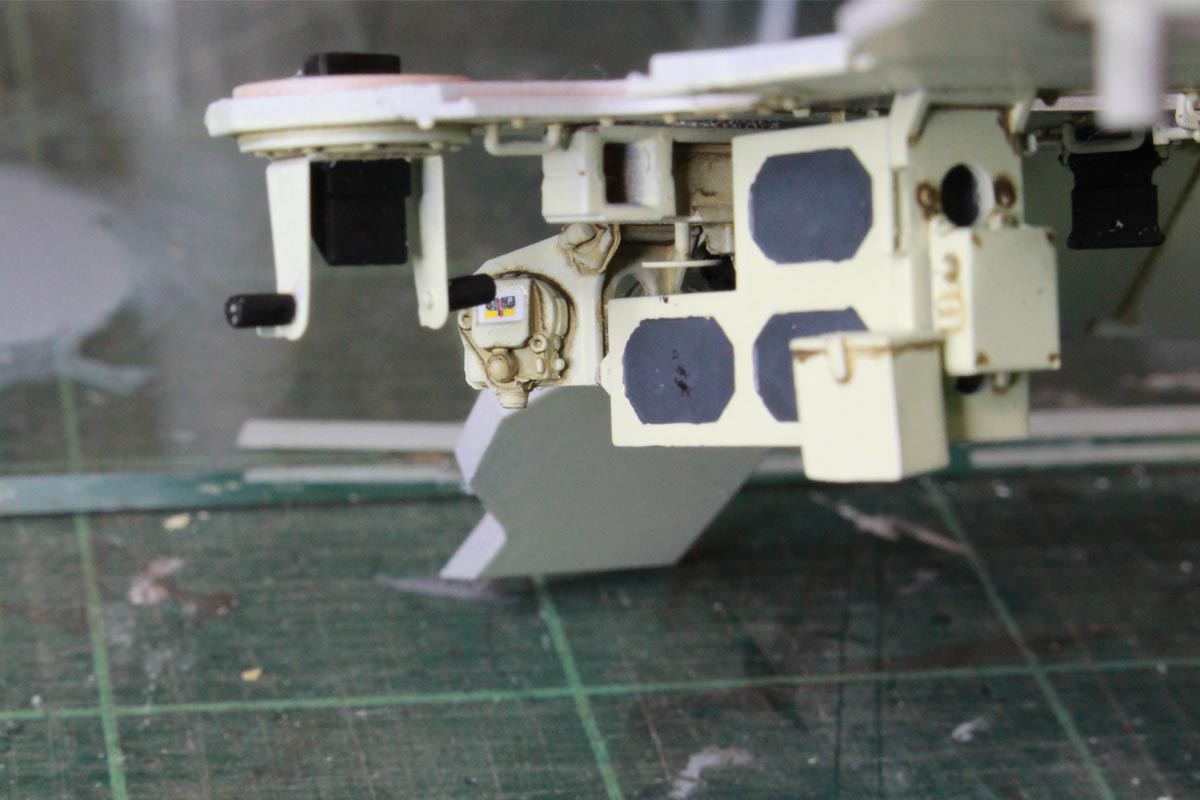

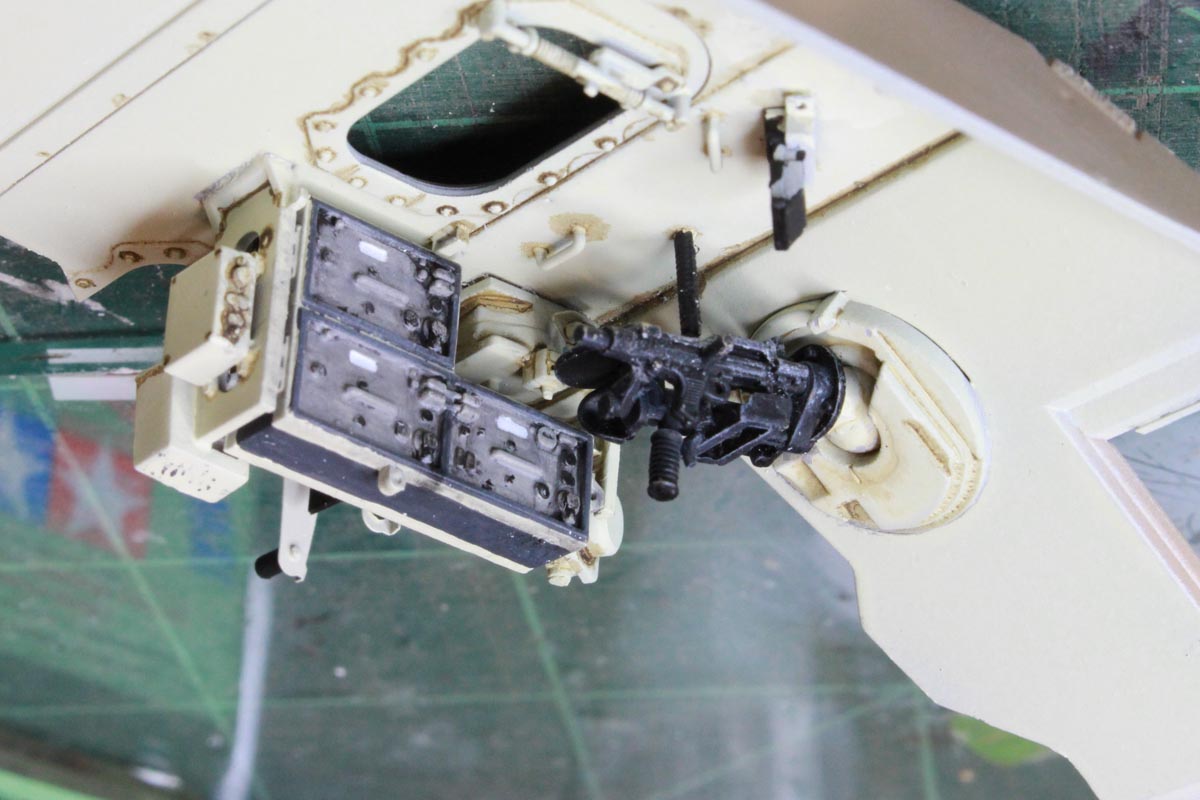

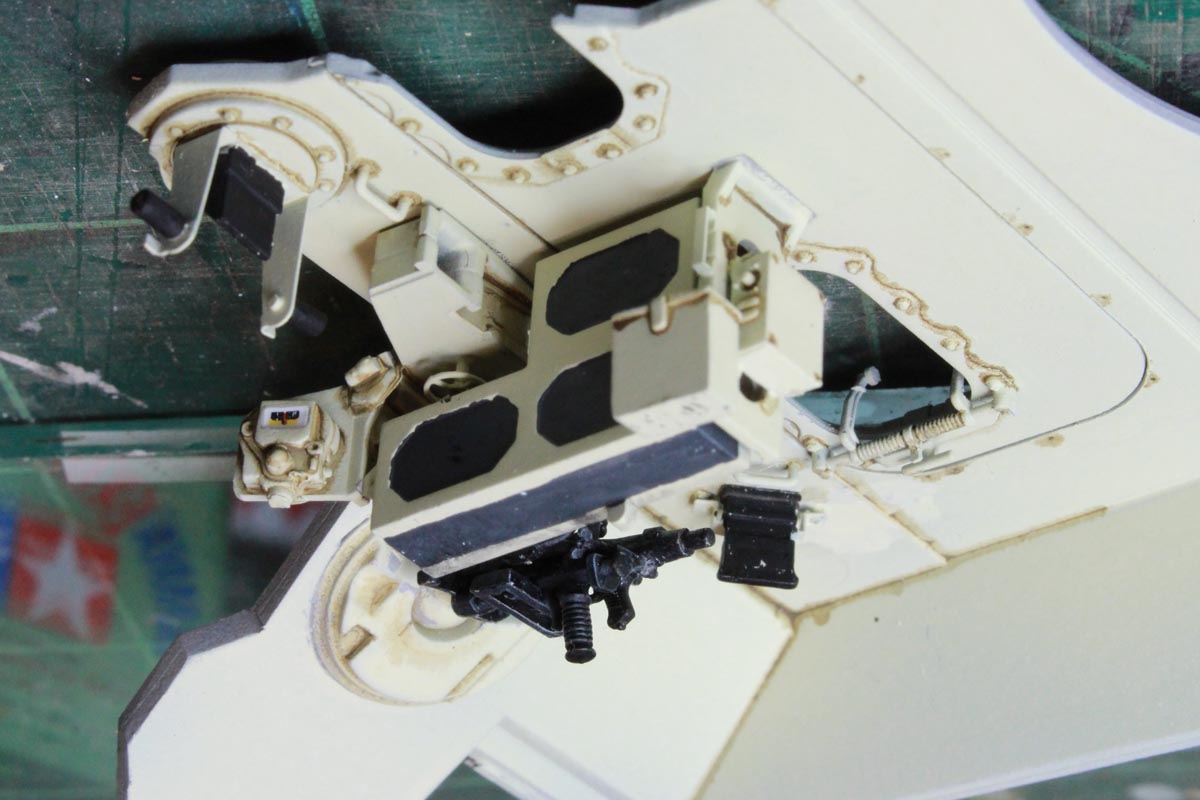

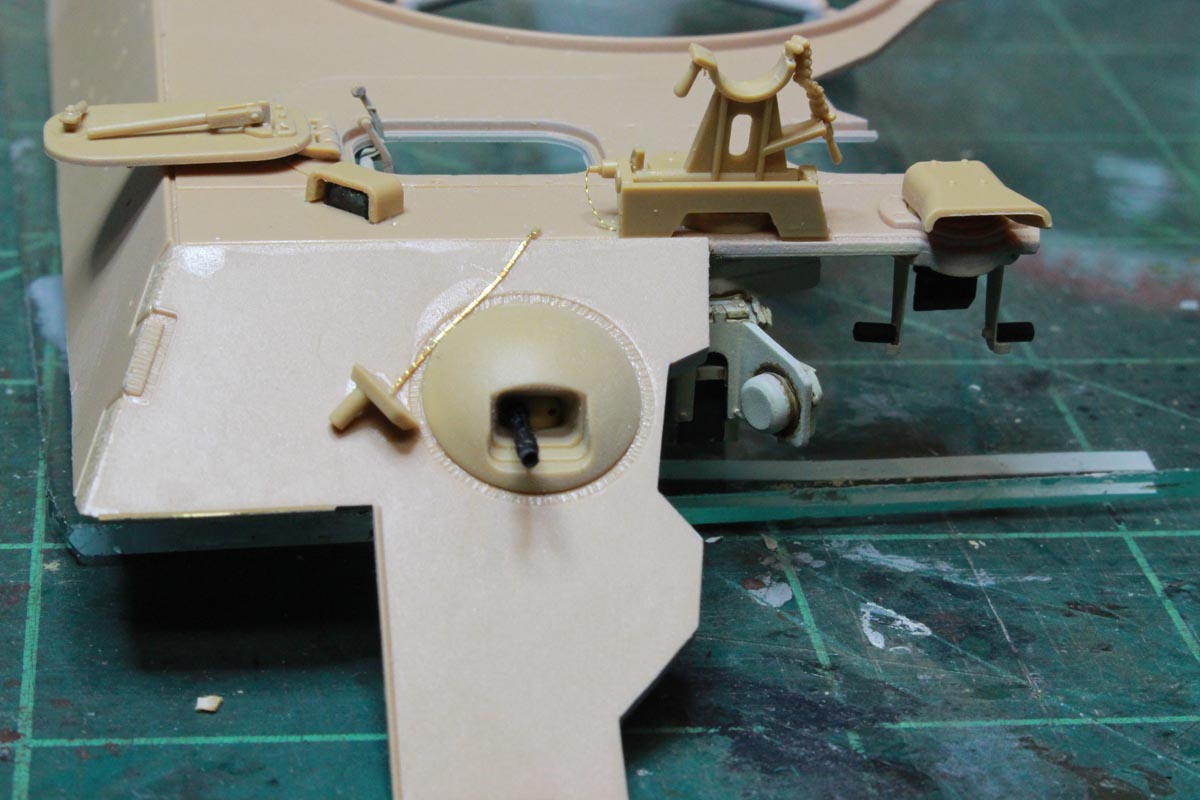

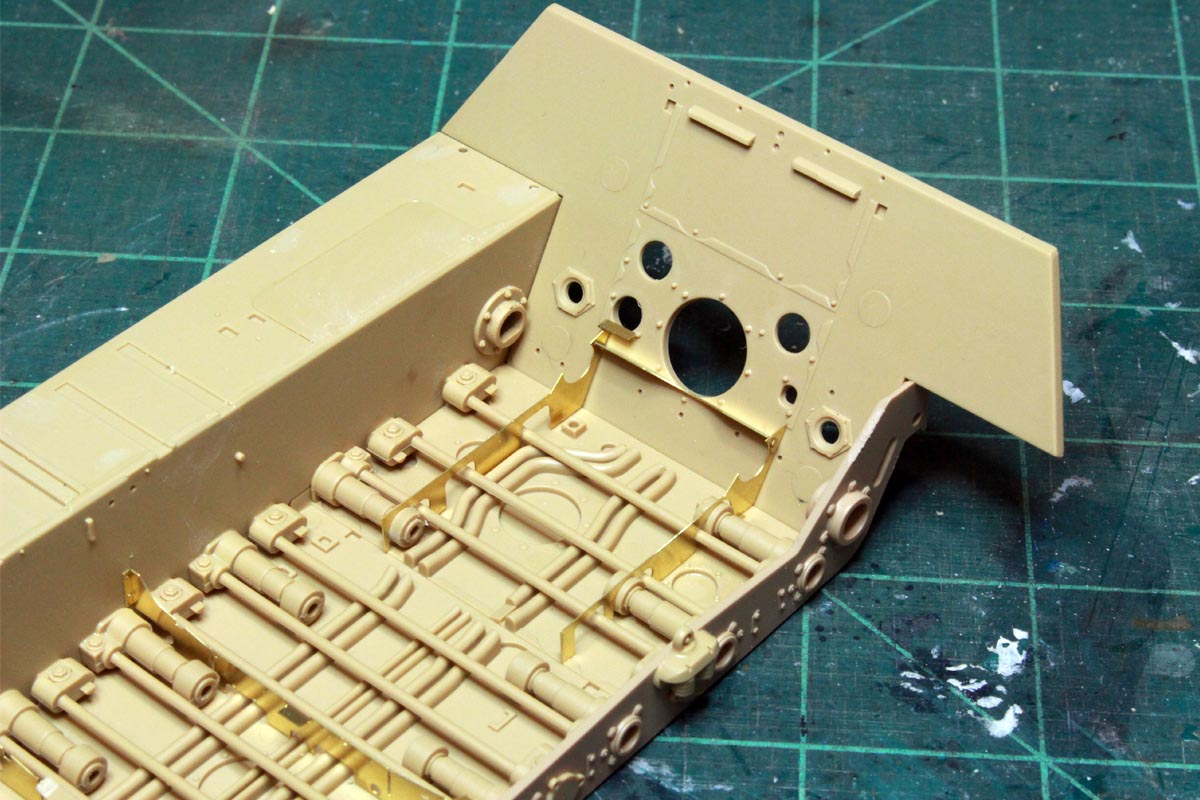

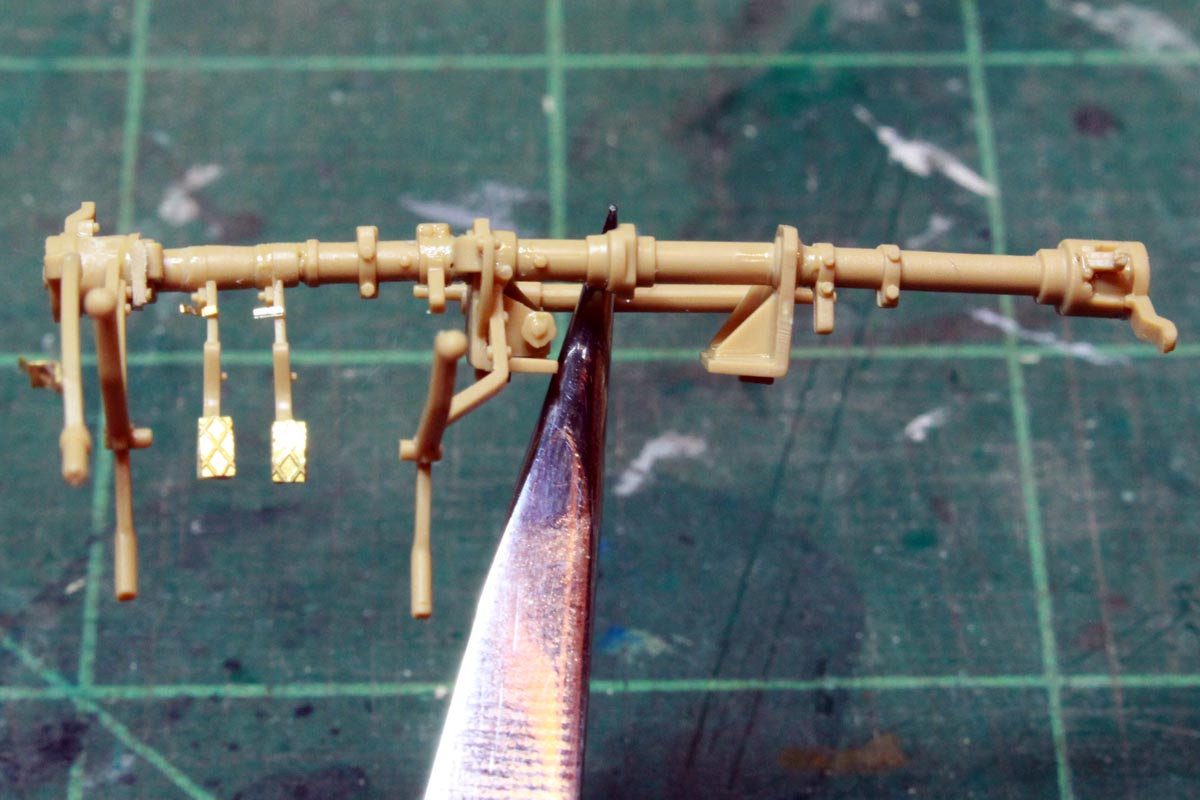

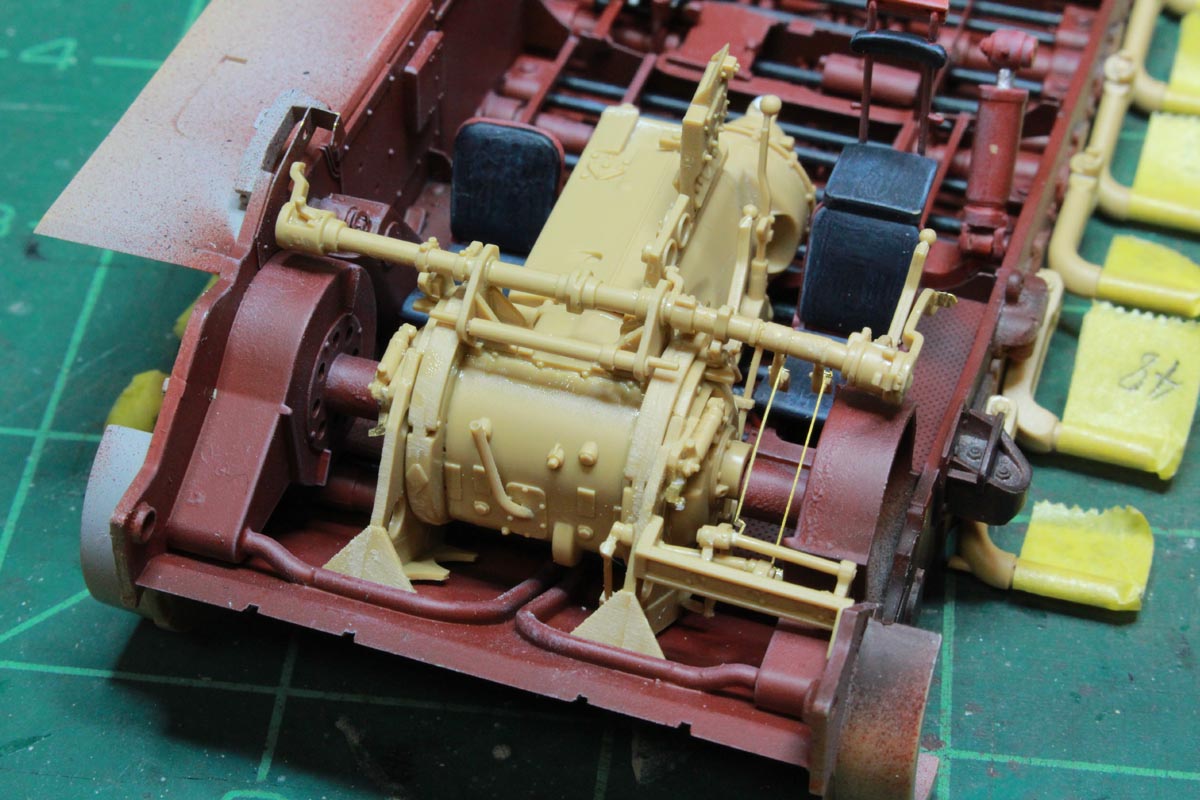

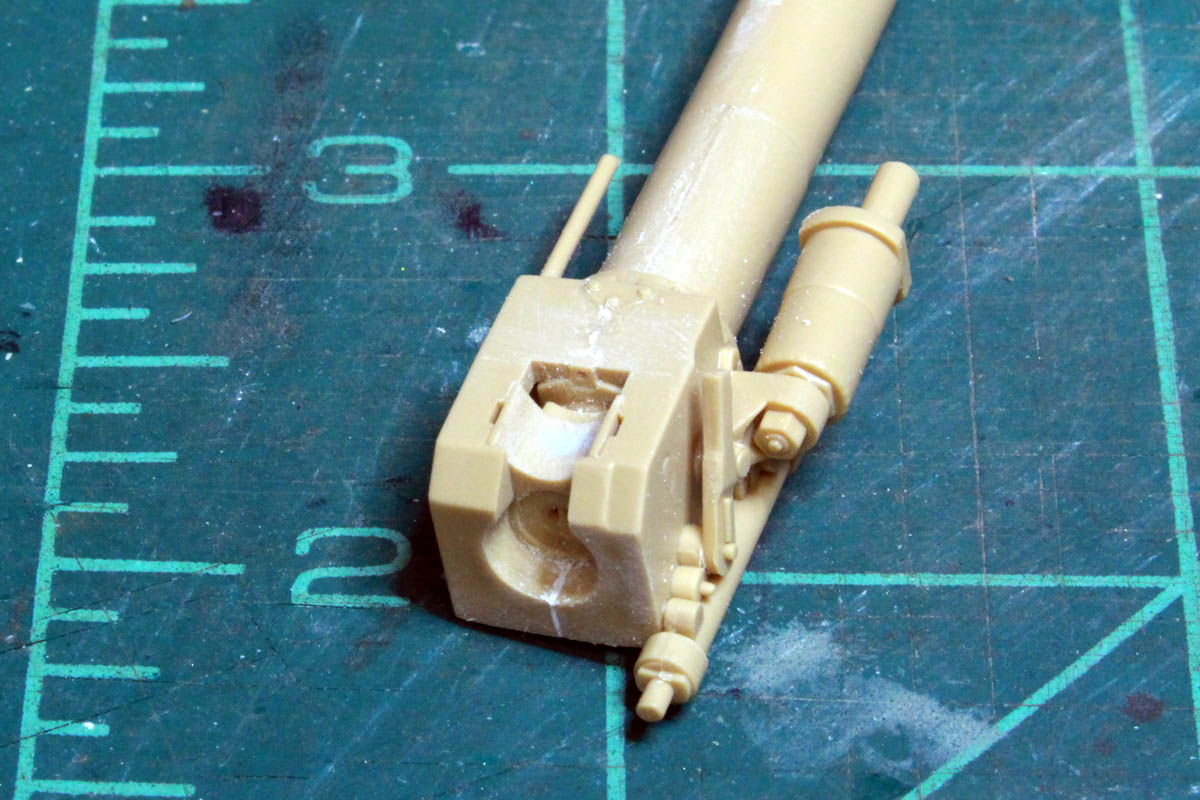

Next are the coax MG and gunners sight:

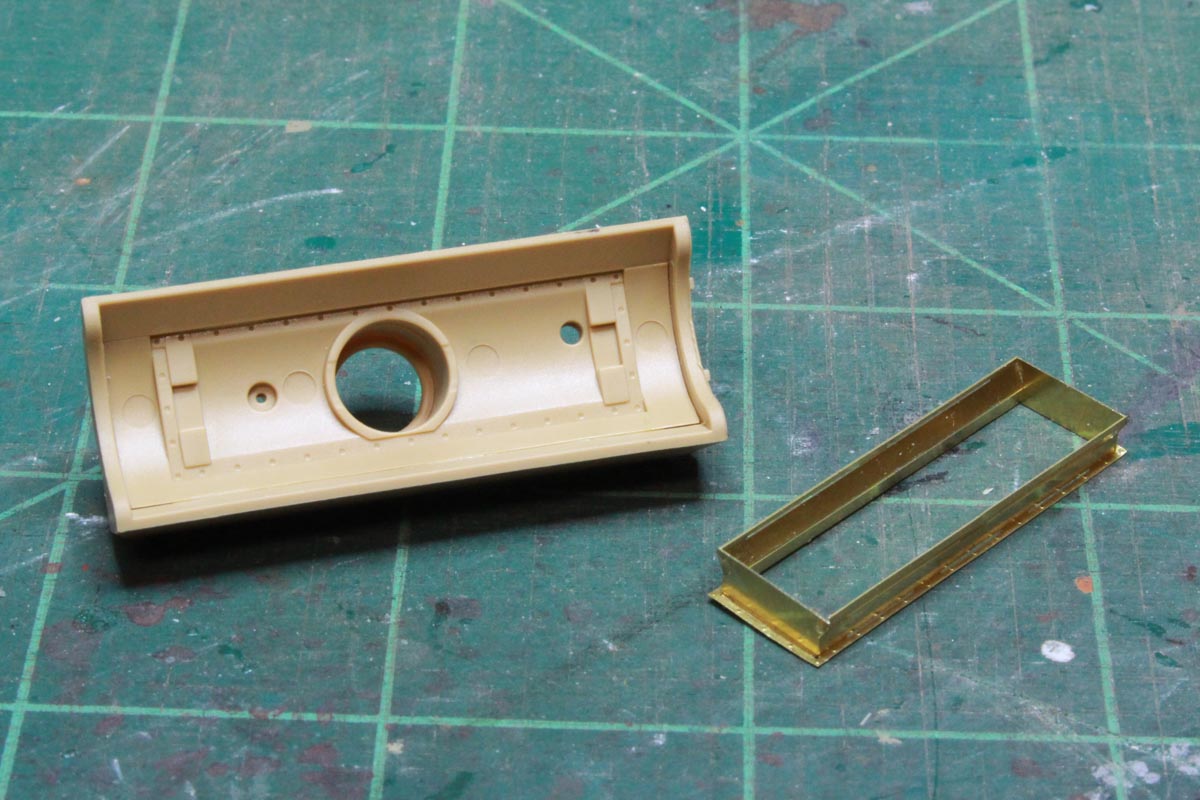

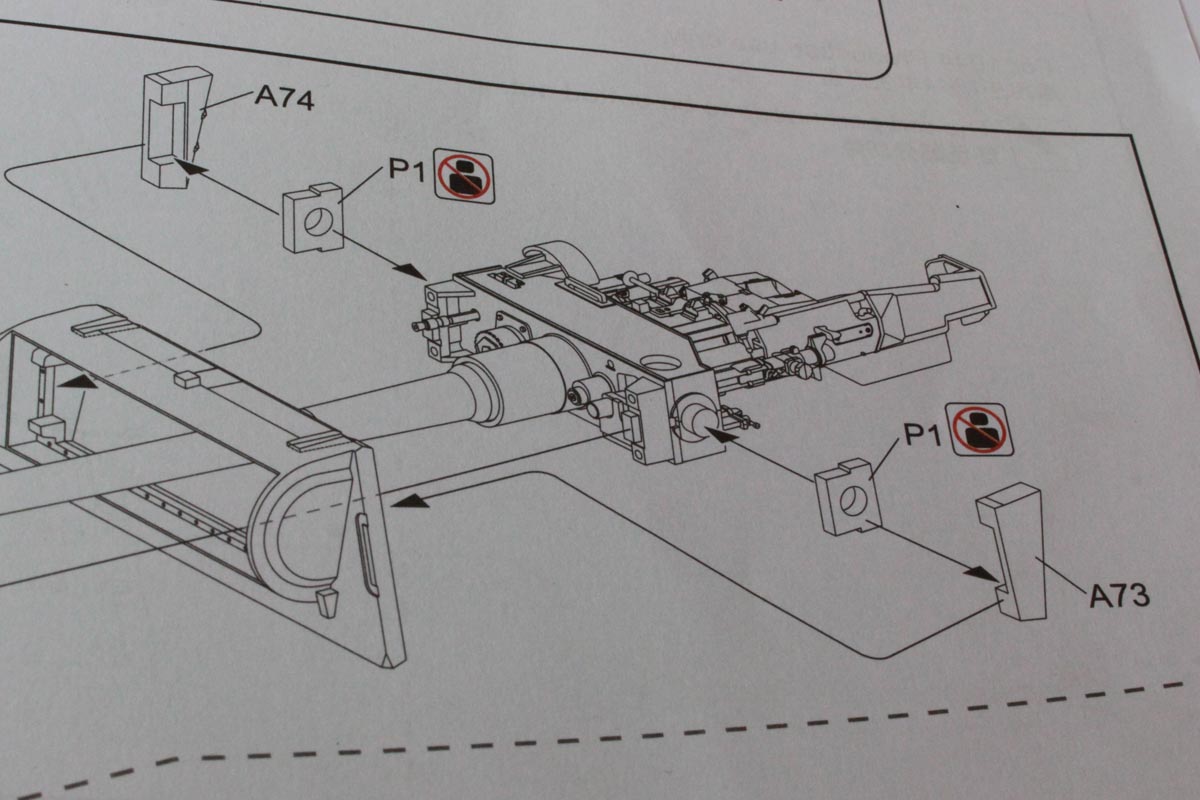

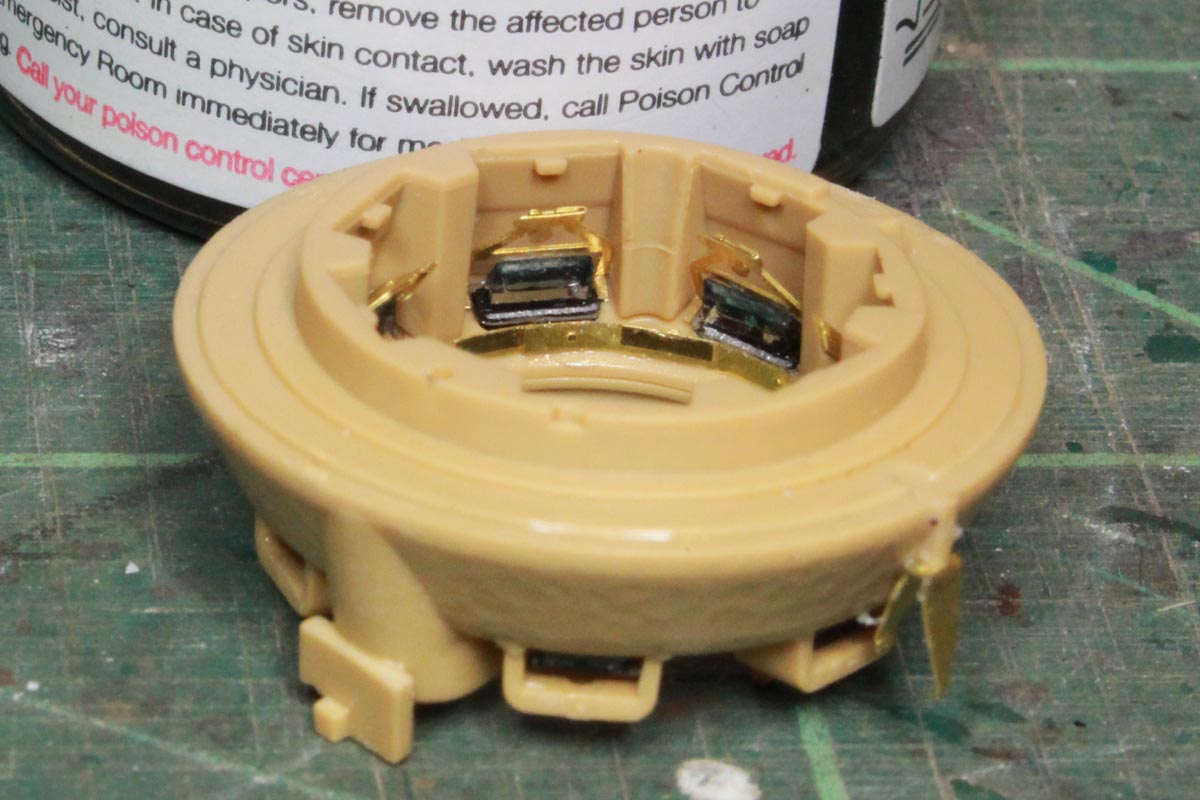

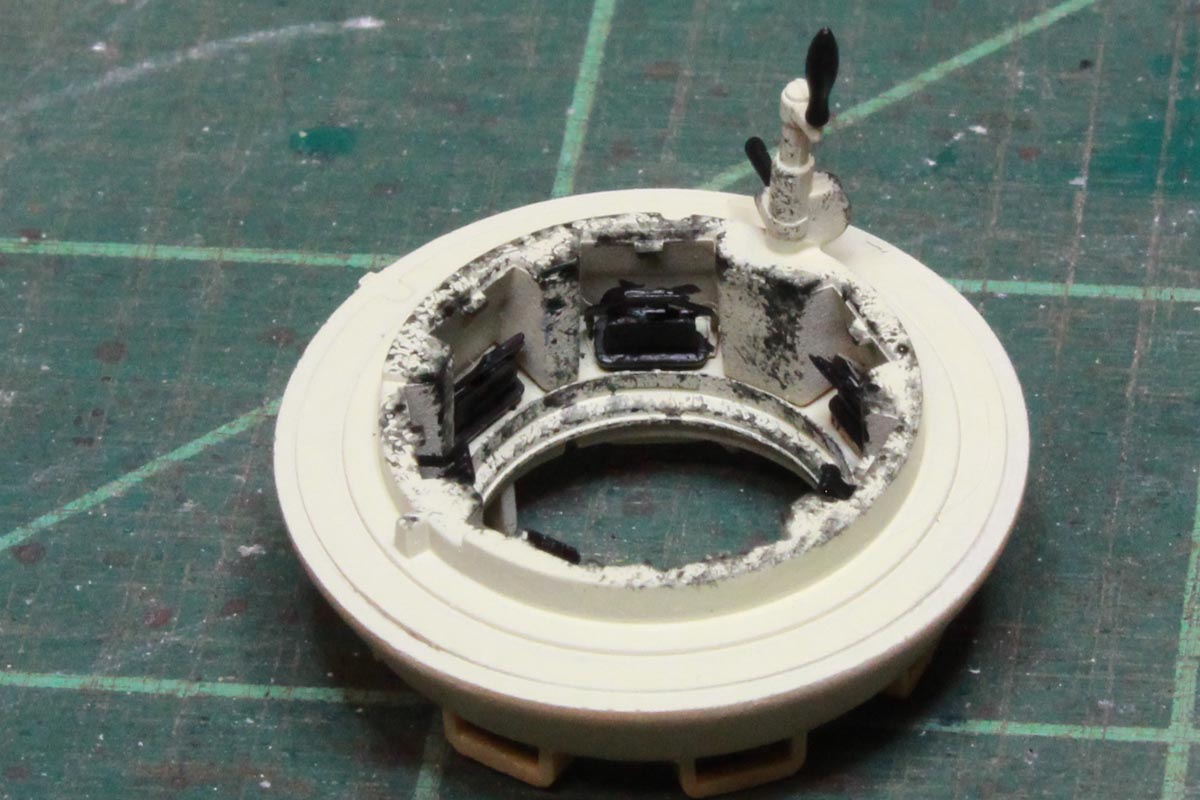

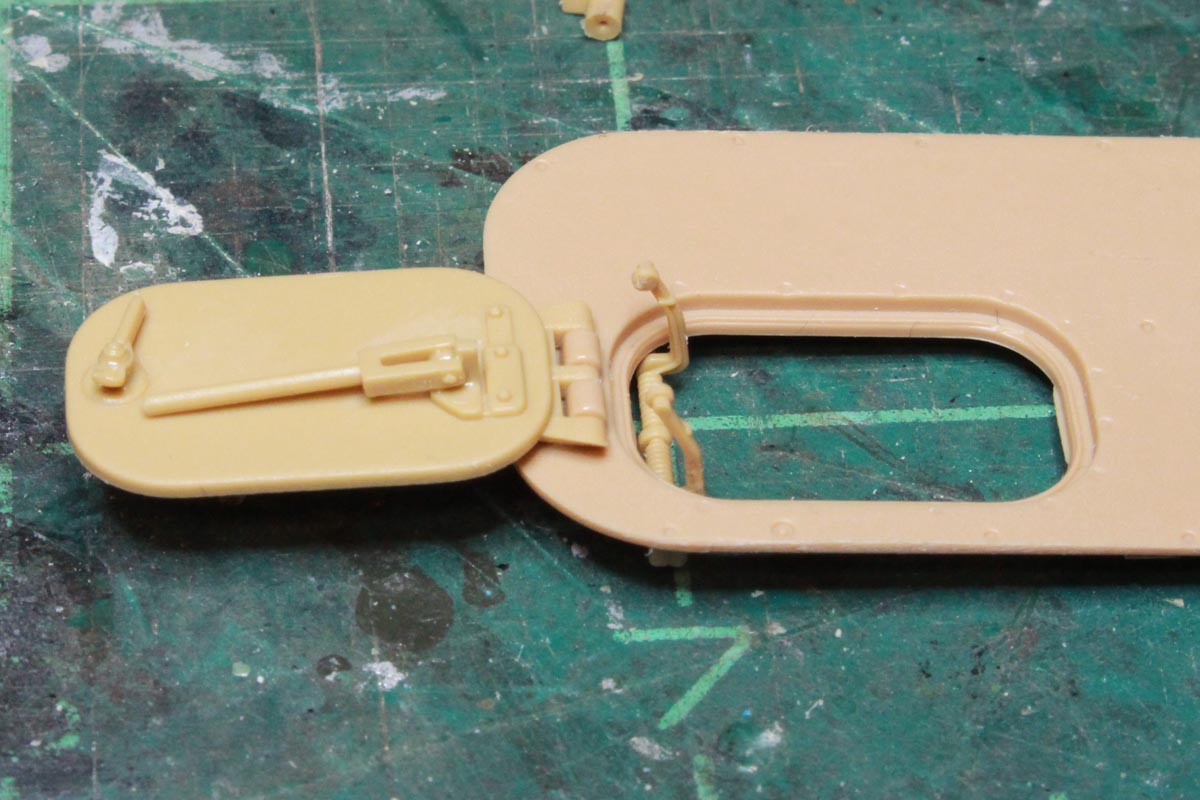

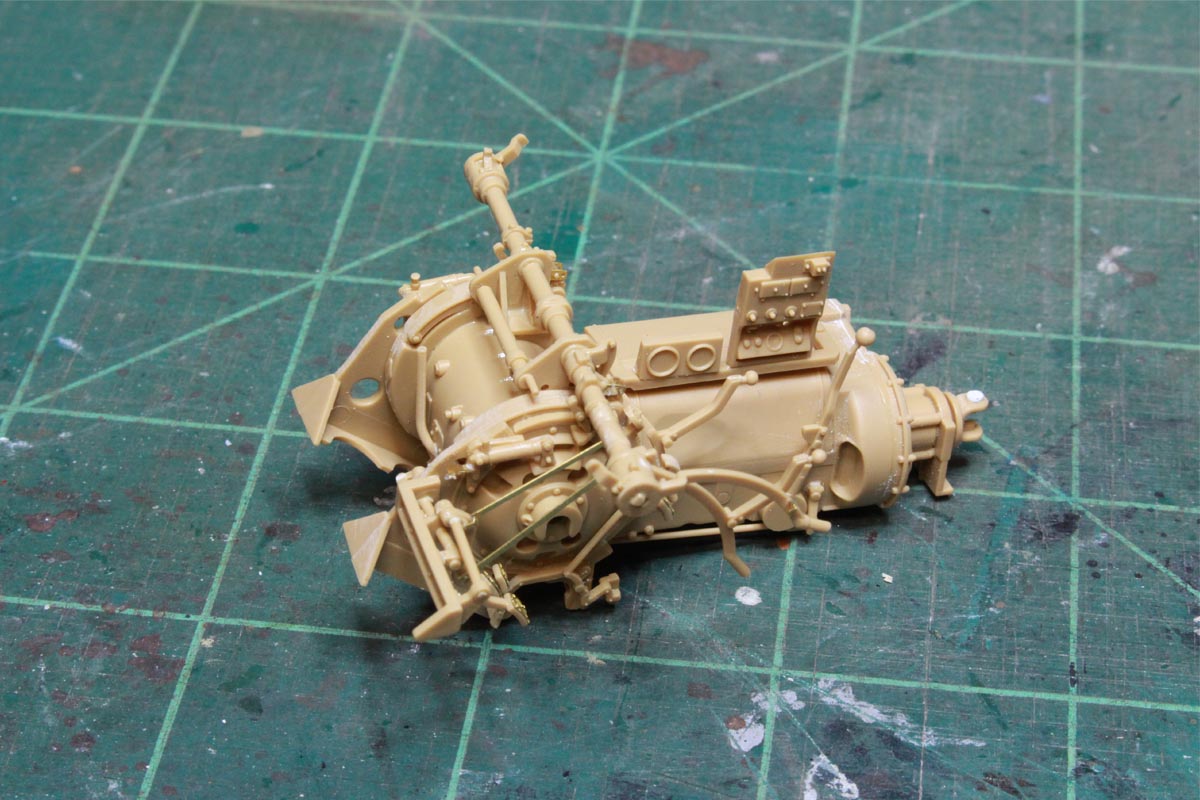

You can build the gun using the included spring and have a gun that will "recoil" but I chose not to use this and put in the blanking piece A35 instead. The gun can also be built with the travel lock locked or unlocked.