1⁄72

Monday, October 05, 2015 - 01:23 AM UTC

Mirage Hobby have turned their attention to braille scale World War 2 American Armour and have now announced a 1/72nd scale M3A1 Medium Tank.

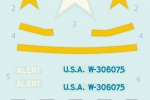

M3A1 (Medium) “Lee” early production series from subunit of Armored Force School & Replacement Center, Fort Knox, 1942

M3A1 (Medium) “Lee” early production series from photographic session in Aberdeen Proving Ground (Poligonie Aberdeen), 1942

Short history

M3A1 Medium Tank is one of the most extraordinary American tanks, as well as one of the most uncommon constructions in the history of the Tank as itself. For this tank was raised as the effect of the experiment aiming to explore the possibility of making homogenous cast element of the upper part of tank’s armor. Up to this time, which means Year 1941, tank hulls were cast of four (SOMUA S35) or two parts (Renault R35, Hotchkiss H35), and the tanks with such armor were made in France only. Application of tank hulls casting technology already has another reason: by minimal increased thickness according to plate armor hardened facially or by hammering “on the hot”, cast armor was not only quicker in production, but also significantly resistant for damages elicited by used then armor-piercing projectiles with penetrating cores made of tungsten-carbide (carbon “tooling” steel) alloy. Insofar such projectile with penetration of hardened armor not only pierced (penetrated) it, but also caused it’s cracking on big surface, as far as in case of cast armor of adequate thickness penetrating core or “bogged down” in it, or penetrated it not causing broader mechanical damages.

72803 - 1/72nd scale - M3A1 Medium Tank

M3A1 (Medium) “Lee” early production series from photographic session in Aberdeen Proving Ground (Poligonie Aberdeen), 1942

Short history

M3A1 Medium Tank is one of the most extraordinary American tanks, as well as one of the most uncommon constructions in the history of the Tank as itself. For this tank was raised as the effect of the experiment aiming to explore the possibility of making homogenous cast element of the upper part of tank’s armor. Up to this time, which means Year 1941, tank hulls were cast of four (SOMUA S35) or two parts (Renault R35, Hotchkiss H35), and the tanks with such armor were made in France only. Application of tank hulls casting technology already has another reason: by minimal increased thickness according to plate armor hardened facially or by hammering “on the hot”, cast armor was not only quicker in production, but also significantly resistant for damages elicited by used then armor-piercing projectiles with penetrating cores made of tungsten-carbide (carbon “tooling” steel) alloy. Insofar such projectile with penetration of hardened armor not only pierced (penetrated) it, but also caused it’s cracking on big surface, as far as in case of cast armor of adequate thickness penetrating core or “bogged down” in it, or penetrated it not causing broader mechanical damages.

72803 - 1/72nd scale - M3A1 Medium Tank

Click Star to Rate

2 readers have rated this story.

THIS STORY HAS BEEN READ 6,797 TIMES.

| Mirage Hobby Reviews | MORE |

| Copper Weld Lines by Ian Barraclough | of 1 ratings, 100% found this helpful | |

| Kubus Improvised Armoured Car by Paul Anstee | of 1 ratings, 100% found this helpful | |

| Samochòd Pancerny wz. 34-II by Stefan Halter | of 5 ratings, 100% found this helpful | |

| Vickers-Armstrong 6-ton Mk F/B by Tom Cromwell | of 3 ratings, 100% found this helpful | |

| M3 Stuart by | of 3 ratings, 100% found this helpful | |

| Pz.Kpfw. IV C, Normandia 1944 by | |

Comments