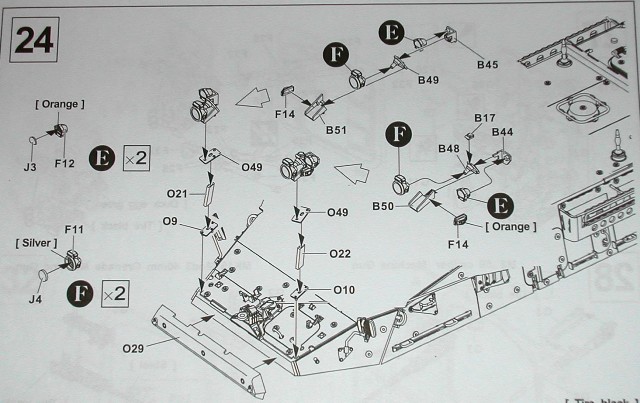

Step 24 is the construction and installation of the headlights (sub-assembly F)/drive marker lights(sub-assembly E) as well as installing the 'nose' of the vehicle part O29.

On this step, I did not install any of the clear parts. I will do that toward the end of finishing the kit after all of my final detail painting is completed. Part O29 was installed earlier in construction and is shown already in place in the step-by-step photos here.

My recommendation to you on this step is to install parts O9, O21 and O49 first. When you install those parts, let the glue cure for at least 24 hrs so that you have a solid assembly to work with when you install sub-assemblies E and F. I believe if you install sub-assemblies E and F to part O21/O49 prior to installing O9/O21/O49 on the hull, the off-set weight will be too heavy and you will have a hard time getting parts O21 and O22 to dry at the correct angle necessary.

Overall, I had a very difficult time with assembling the headlights and getting everything to assemble and dry at the correct angle.

The first thing I did was assemble parts B51 and B49.

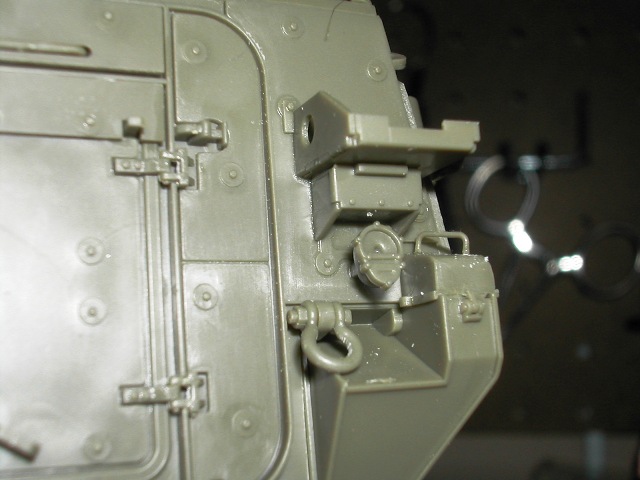

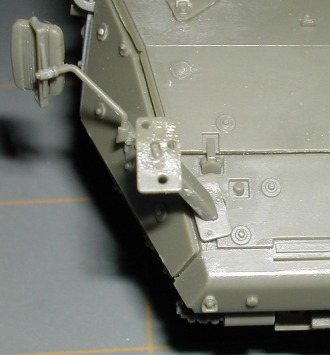

I then installed parts F11/F12 onto B49. This photo shows the very odd angle that parts F11/F12 need to sit at when assembled.

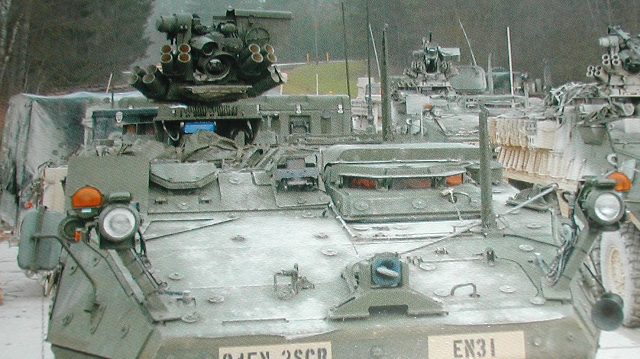

While the glue on the light assemblies cured, I installed O9, O21, O49 and O10, O22 and O49. Take note in the reference photos (again from Ralph Zwillings incredible book) of the angle that part O21 and O22 sit at.

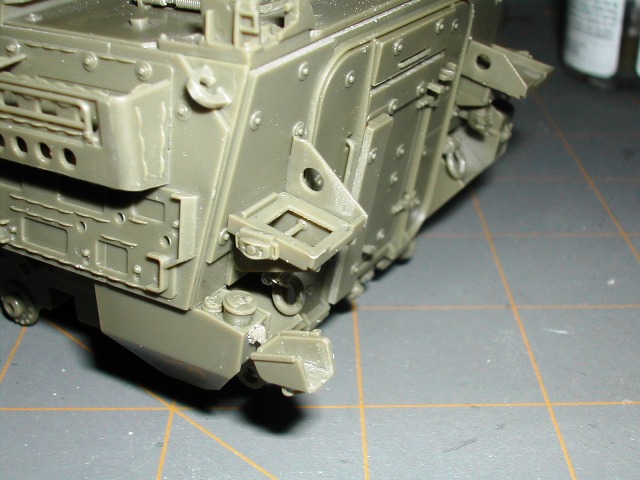

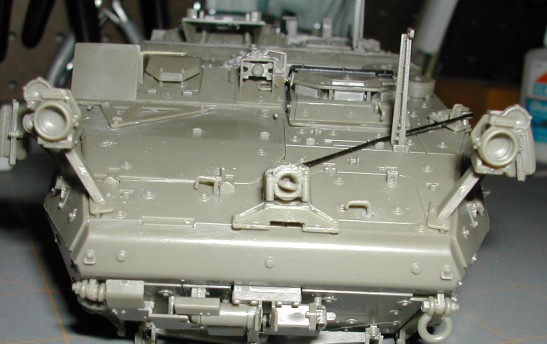

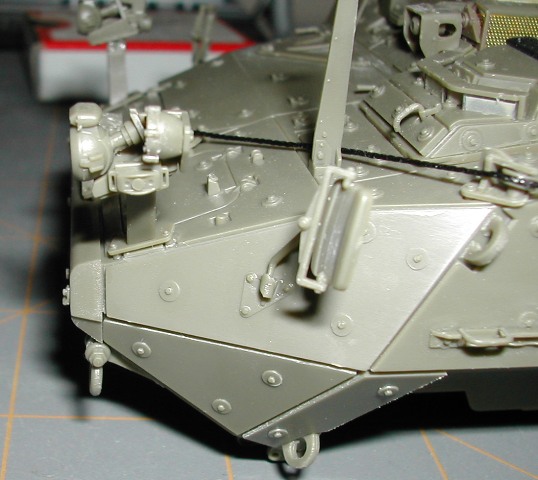

Here are a couple of shots of the installed O9, O21, O49 and O10, O22 and O49.

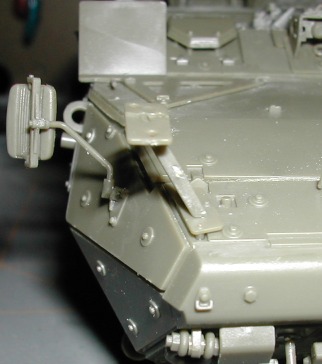

After 24 hours, I installed the headlight/drive light assemblies to parts O49. Here are a few more shots out of Ralphs book to reinforce the height and angles that these parts must sit at.

Here are a few final shots of the step 24 completed.

One point of interest is the appearance of kit part F14 as compared to how it looks on the real vehicle. AFV Club did a good job coming up with a 'compromise' part. I think the type of mounting bracket seen on the real vehicle could only be replicated in photo-etch.

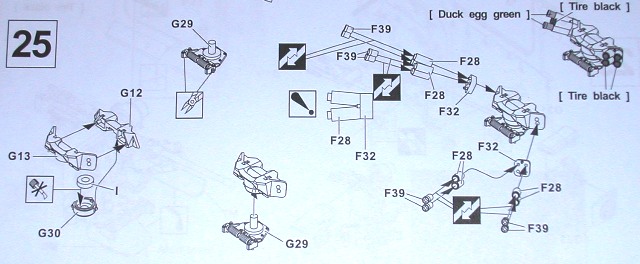

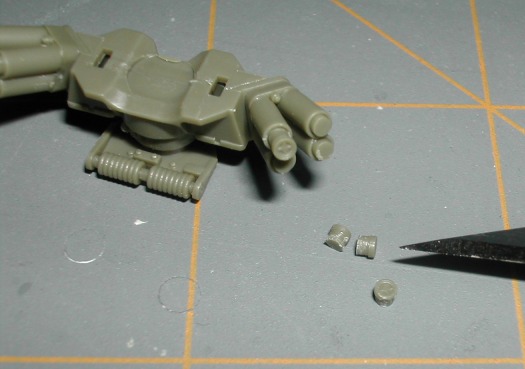

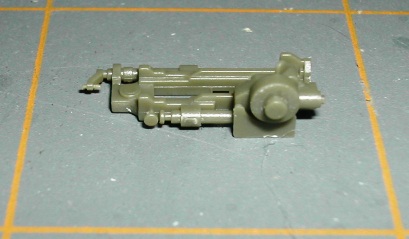

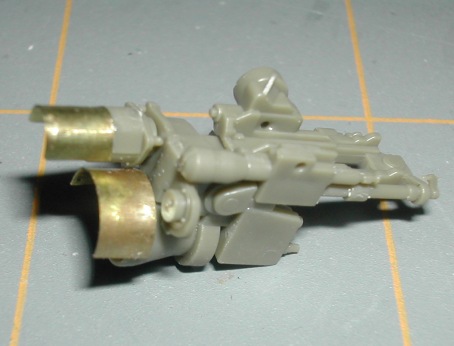

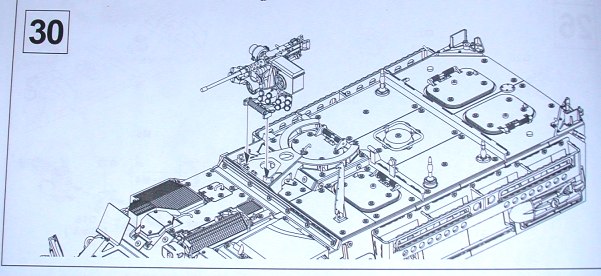

In step 25, I will begin construction of the RWS (Remote Weapon System). Stay tuned!