1⁄35Building Formations M5A1 Stuart

Getting out the Gate

Right from the start, I must caution you to study your Instruction Sheet carefully. The Formations Models part number codes are quite similar to AFV Club’s callouts. It is very easy to confuse one for the other if you get too excited to build up the conversion. Trust me…The Hull

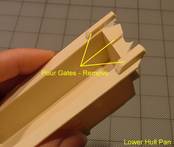

I began this assembly cleaning up the Lower Hull pan – in effort to mate it to the Upper Hull right off the bat and check for fit problems. Flush cutting the three pour gate points on the Lower Hull is a safe way to proceed and minimize risk of damaging the Sponson Floors or upper edge of the Engine Access Doors. Flush cutting means laying the razor saw blade against the flat surface of the Sponson Floors, slicing the pour gates away without cutting into the Sponson Floors. My thumb served as a stop for the razor saw blade to keep it from damaging the Sponson Floor. Use short strokes, as the spine of the saw can easily nick the resin Sponson part and create more clean up if you get too aggressive on a cutting stroke. When done, flip the Lower Hull pan upside down and cleanup on a sanding board if you’re going to place an interior into your kit.Openings for the Transmission Covers are flashed over in the Lower Hull Pan – but do not open these. Deciding to model a later production example of the M5A1, the separate Escape Hatch came into play. The Formations Models part is very thinly cast. Relatively easy to remove from the pour gate, this example came apart during cleanup. The two triangular resin strips that broke away during cleanup were replaced by lengths of Plastruct (Number 90841 .030 - .8mm) styrene triangular stock.

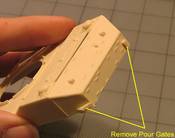

The Upper Hull has two pour gates to remove. These little nubs are deceptive and might provide more grief in the end if simply snipped away with a pair of cutters. It is very easy to damage the thin sides of the Hull casting in these areas. There is light flashing over the openings for the Hatches and Engine Grills – a sharp X-Acto Blade slices these away in short order. The Hatch openings will call for some minor application of filler putty after removing the flashing – to smooth out the final appearance of the opening. Naturally, if you’re going to model your M5A1 Stuart buttoned-up, all of this effort is for little return.

Formations Models provided two sets of their resin Engine Deck Screens in this conversion kit. This is a real bonus – though there were no problems separating them from the pour gates and sanding the thin flash off the back. Having another set put my mind at ease. I did attempt to remove the flash backing in effort to open up the Screens. This did not prove successful, as the casting is so thin, the screen itself began to disintegrate. Aftermarket photoetched screens are best for showing off any detail you decide to put behind them.

The Hull fits together positively – and there will be filling called for along the undersides of the Sponson Floors. These gaps are where weld beads locate on the real tank. I included a couple of photos that appear later on in this review. The Front Plate is attached to its pour gate in a way that flush cutting again becomes a preferred method of cleanup. The opening for the .30cal MG is flashed over, and simple to clean out. The Front Plate also carries subtle but scale torch-cutting effect on the upper edge. Clean up Part #D1 (Bolt Strip) as this piece is necessary to align the three others. On the real Stuart, there is a weld seam between the Bolt Strip and Front Plate – photographed later in this review.

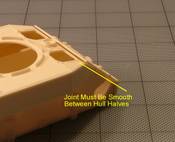

The Front Plate, Upper and Lower Hull pieces all must align together correctly to ensure your M5A1 Stuart miniature is shown in best light. Formations Models cautions the modeler in the Instruction Sheet on aligning these three pieces correctly. I pulled out the Bolt Strip as well to make fitting the Front Plate proper. Center the Bolt Strip in place on the forward lip of the Transmission Cover and super glue into position. When you fit the other three parts into place, you’ll only have a minor amount of adjustments and or filling to make. My review example would call for a bit of truing at the joint between the Bolt Strip and the Front Plate and the joint between the two addressed with a weld bead later in assembly. Before you despair at any minor fitting problems – consult Formations Models Instruction Sheet again and reread the instructions. The Upper and Lower Hull leading edges must form a straight and true line before you attach the Front Plate. Gentle sanding and smoothing the joint will solve your problems.