Battlewagon M4A3E8 ETO: Part 6-How About A Lift? In order to keep my sanity while assembling the tracks, I decided to do some additional work on the upper hull, notably the lifting rings.

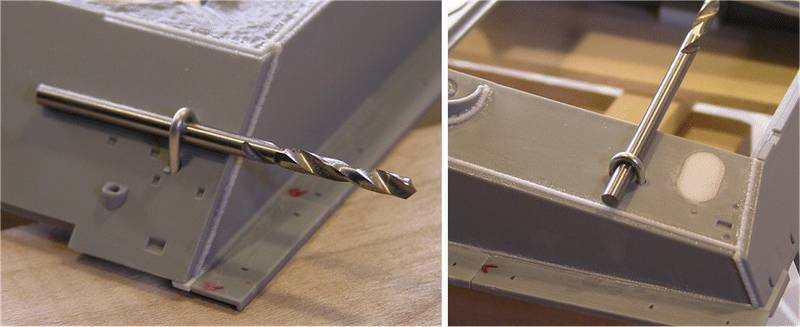

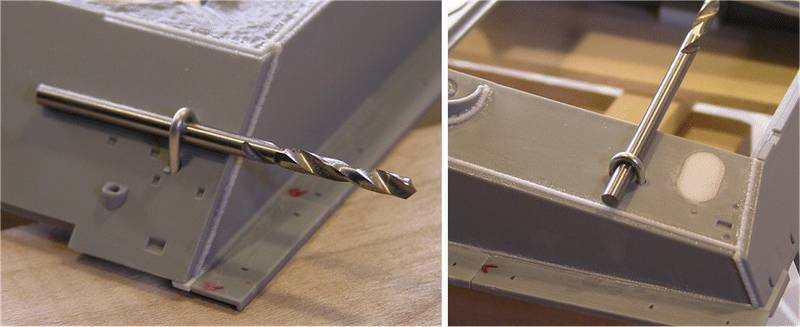

The lifting rings supplied in the kit are satisfactory but look a bit anemic. I decided to replace them with a suitable size wire. After a quick search around the work area, an acceptable product was located, 14gage lead-free silver solder. To determine the correct diameter of the bend for the rings, the original kit parts served as a guide. Select a round object that fits inside the ring to serve as a form, a drill bit works well. Next cut a length of wire/solder, ensure that the wire/solder is straight, and then bend it around the form as shown in the photo.

Using the gluing divots as a guide, drill the appropriate size holes through the plastic. Insert the newly made rings into the holes. Use the form to set the height of the rings as shown below and super glue into place from the inside of the hull.

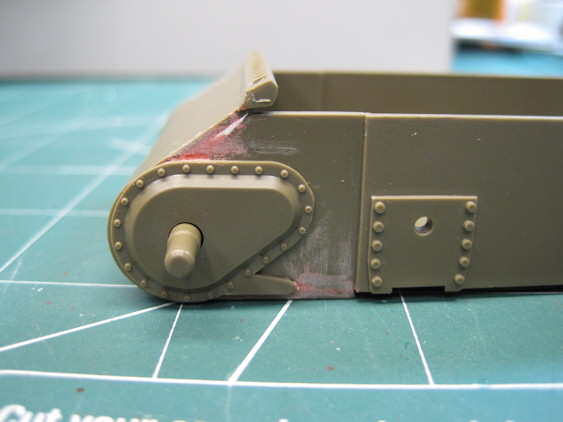

For the welds, epoxy putty can be used. Roll the putty into a thin thread and wrap around the base of the lifting ring. Using a suitable flat tipped object such as an old #11 hobby knife blade, the back side not the sharp side, texture the putty into a weld pattern.

I think welds turned out ok but maybe a bit over sized and a bit too course. An additional suggestion would be once the epoxy thread is in place, let it sit for a time and harden a bit before applying the weld texture. As usual, practice this a couple of times before doing this to your current build.

Below are the two products that were used to make the lifting rings.

I hope this helps out for this and future projects and if anyone has additional insights related to this technique please share.

That’s it for this time around. Excellent work by everyone thus far, keep to the updates coming!

What matters is that you've got your modeling juices flowing again. Keep it up!

What matters is that you've got your modeling juices flowing again. Keep it up!