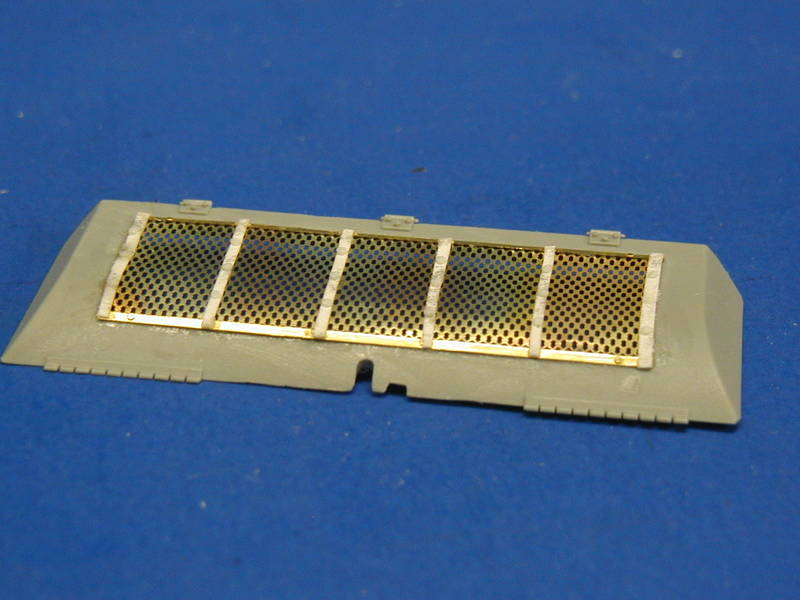

Working on the fan housing cover: I decided to try to use what was available in the PE fret to make the screen work. Seriously annoying that it does not, and DML T-34 kit 6479 also has the incorrect PE screen setup. I decided to use the screen as I did not want to wiat for mail-order to arrive (I can be impatient sometimes...)

I cut the screen itself to roughly the right size, and I then annealed it to make it pliable so that it woud not be too hard to impart the slight curve to the piece.

I cut up the framing and used the top and bottom pieces for the top and bottom. I then added thick paper as the cross bars and added sliced plastic rod for the bolts. In actuality these would be round head bolts, almost like rivets if not actually rivets. I would think that if someone came out with a PE screen and a paper cut frame with the rivet heads embeded or some such.

Anyhow...

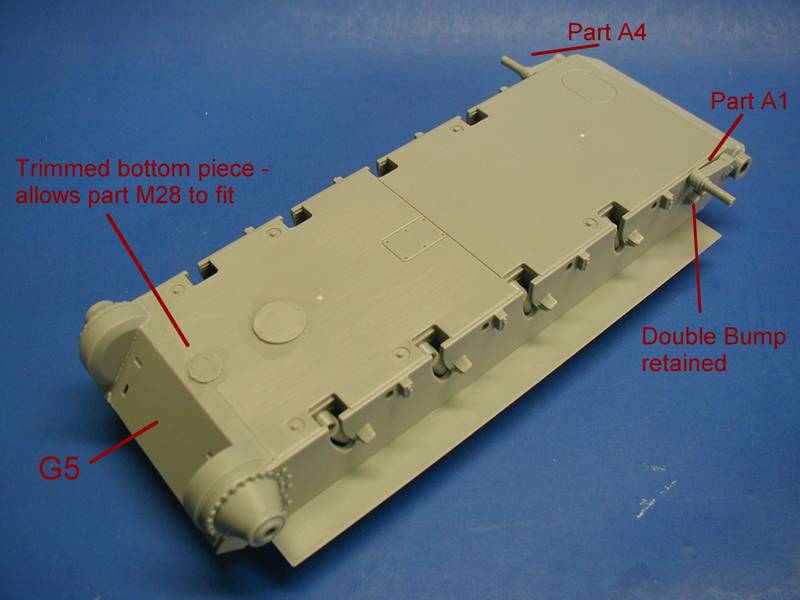

Hull with the added PE on the back. Yes, with the screen added to the cover and the louvres added underneath, it makes for a attractive display, at least enough to get me to rebuild the screen/framing. However, the details on the deck under the PE "sheet" need to be removed, something missing in DML's instructions.

all together...

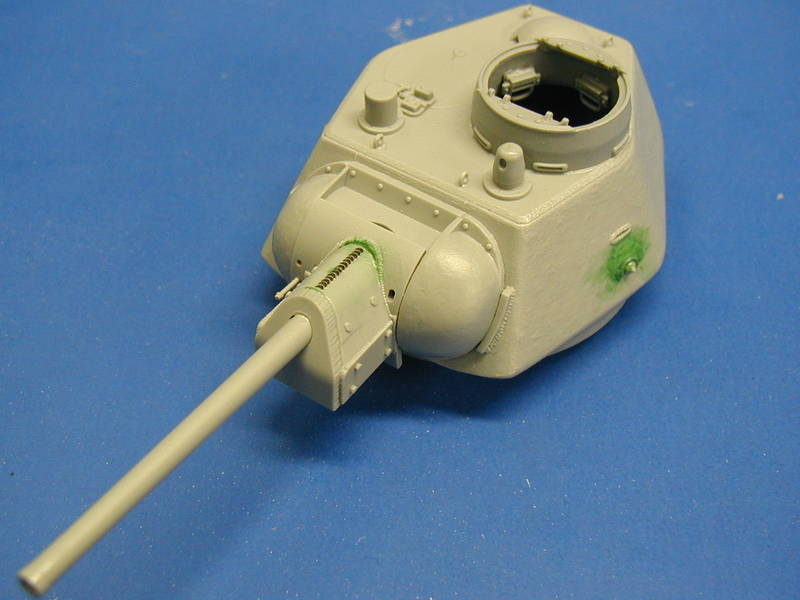

I wanted to make the pistol ports more appropriate as per Mark's commentary, so I used some putty to thicken and blend the pistol ports. Not sure how successfull yet, but ok so far...

Here it is, all together now...

Finally, the exhaust pipes...unless I made a mistake, the exhaust pipes should not have too much variation in them. DML offers 3 types of exhaust pipes in the kit, evolutionary examples of DML's molding and detail as time/attention has progressed. So I was dumbfounded when DML called out for the use fo the oldest and WORST of the thrre types...B3/B4...a two piece part. Part C16 is better, but you should actually use part N6, a nicely hollowed one piece part that would look quite nice. They are the same size/length and only differ in the weld bead and the number of parts.

Now, to be totally fair, I decided to pull out my T-34 m43 from Italeri (a Zvezda rebox) and compare. More on that later but, let me just say that after that short experience, if you can get the DML or AFV Club T-34's in the mid $30's range, it is far far better to do it. Well worth the price, even though the Italeri kit COULD be worked into a award winner. Pictures later....