Great building log! Very clean construction and I wish I knew how to solder PE like you do.

I plan to do one of the "Premium Edition" kits as a postwar variant, with wheels from the T-34/85 NVA and other details.

Cheers,

Christophe

Яusso-Soviэt Forum

Russian or Soviet vehicles/armor modeling forum.

Russian or Soviet vehicles/armor modeling forum.

Hosted by Darren Baker, Jacques Duquette

Build - Log Review of DML SU-100 Premium kit

C_JACQUEMONT

Joined: October 09, 2004

KitMaker: 2,433 posts

Armorama: 2,325 posts

Posted: Thursday, May 17, 2007 - 05:09 AM UTC

Jacques

Joined: March 04, 2003

KitMaker: 4,630 posts

Armorama: 4,498 posts

Posted: Friday, May 18, 2007 - 12:14 AM UTC

More work done:

First, I am doing a unsolicited review of the Maquette Engine/Transmission set, so look for that in the reviews section soon. Brief Conclusion: It is a good set, especially for the $3.36 + Postage I paid for it at Alanger USA They are also the only place I know of that is carrying them. The kit will give you a brief filler for the end of a T-34 and allow you to scratchbuild any more details you want, but it is not overly detailed or hyper-accurate. It is what it is,a cheap engine set. There are several aftermarket resin engines and tranny's, some with entire engine compartments, if you want to go that route. They appear to be far more detailed, but I cannot compare them since I do not have any on hand.

Here is a shot of the built transmission, one of it in place ont he kit hull (no I have not even cleaned it up) and one showing some of the ejection pin markes that need to be dealt with for proper fitting of the parts. The lower left shows the sinkholes in the exhaust's and the upper left shows two parts connected by a thick runner...be carefull, these are two seperate parts.

Next up is the engine/transmission built up as far as I will go before the first paint session. You can see the green putty in the exhaust.

*** SIDENOTE - Buying Squadron Green Putty more often that once every 8 years will lead to faster drying times of the putty. I can often be too cheap and use things far beyond their usefull lives...like my VERY old tube of SGP. Suffice it to say that with a new tube on hand, I don't mind puttying things any longer! Funny how that works...

I can often be too cheap and use things far beyond their usefull lives...like my VERY old tube of SGP. Suffice it to say that with a new tube on hand, I don't mind puttying things any longer! Funny how that works...  ***

***

Now to cover some loose ends.

What about that fancy, one piece, slide-molded barrel in the Premium kit? Well, as Terry at PMMS noted (you took notes, right? I told you there would be a test) the slide molded barrel is messed up at the reciever end...it tapers WAY too quickly. Well, can it be recovered? You decide...here is the metal barrel, the slide molded barrel, and the old three piece (barrel halves and end piece) barrel. Needless to say, it took a fair amount of putty, and the use of a drill press to help sand things round. I plan to use the metal barrel on kit 6359 and the three piece one on 6075. But now I have a spare 100mm barrel for somethig else...

Speaking of kit 6075, here it is sans fenders and with the upper and lower hulls connected and puttied. yes, while the design of the two hulls is very nice, it still requires putty to be seamless enough to look solid:

One area that is presenting problems is the front fender section. The kit was designed to have the front fenders in place to hide gaps. Without them, I am guessing blindly and just filling in as I can. I may modify these areas once I do specific research on them...more to follow.

Ok, back to kit 6359. I had to make sure that the engine/tranny would fit without major problems...and they do, no problems at all. But there is one catch...no interior firewall. So i made one up from plastic, and here is the basic layout:

And in place (Also notice the green putty needed to get the engine compartment looking proper...gotta fill those knockout points!):

And with the engine/tranny:

Finally, two shots with the upper hull on. It really looks good like that, I am not much of a add-interiors kinda builder, but seeing it like that kinda gives me a itch to get it done and maybe do more AFV's with some interior parts.

Now to get the PE done. (BTW I do not solder my PE , it is all done with super-glue.)

First, I am doing a unsolicited review of the Maquette Engine/Transmission set, so look for that in the reviews section soon. Brief Conclusion: It is a good set, especially for the $3.36 + Postage I paid for it at Alanger USA They are also the only place I know of that is carrying them. The kit will give you a brief filler for the end of a T-34 and allow you to scratchbuild any more details you want, but it is not overly detailed or hyper-accurate. It is what it is,a cheap engine set. There are several aftermarket resin engines and tranny's, some with entire engine compartments, if you want to go that route. They appear to be far more detailed, but I cannot compare them since I do not have any on hand.

Here is a shot of the built transmission, one of it in place ont he kit hull (no I have not even cleaned it up) and one showing some of the ejection pin markes that need to be dealt with for proper fitting of the parts. The lower left shows the sinkholes in the exhaust's and the upper left shows two parts connected by a thick runner...be carefull, these are two seperate parts.

Next up is the engine/transmission built up as far as I will go before the first paint session. You can see the green putty in the exhaust.

*** SIDENOTE - Buying Squadron Green Putty more often that once every 8 years will lead to faster drying times of the putty.

I can often be too cheap and use things far beyond their usefull lives...like my VERY old tube of SGP. Suffice it to say that with a new tube on hand, I don't mind puttying things any longer! Funny how that works...

I can often be too cheap and use things far beyond their usefull lives...like my VERY old tube of SGP. Suffice it to say that with a new tube on hand, I don't mind puttying things any longer! Funny how that works...  ***

***Now to cover some loose ends.

What about that fancy, one piece, slide-molded barrel in the Premium kit? Well, as Terry at PMMS noted (you took notes, right? I told you there would be a test) the slide molded barrel is messed up at the reciever end...it tapers WAY too quickly. Well, can it be recovered? You decide...here is the metal barrel, the slide molded barrel, and the old three piece (barrel halves and end piece) barrel. Needless to say, it took a fair amount of putty, and the use of a drill press to help sand things round. I plan to use the metal barrel on kit 6359 and the three piece one on 6075. But now I have a spare 100mm barrel for somethig else...

Speaking of kit 6075, here it is sans fenders and with the upper and lower hulls connected and puttied. yes, while the design of the two hulls is very nice, it still requires putty to be seamless enough to look solid:

One area that is presenting problems is the front fender section. The kit was designed to have the front fenders in place to hide gaps. Without them, I am guessing blindly and just filling in as I can. I may modify these areas once I do specific research on them...more to follow.

Ok, back to kit 6359. I had to make sure that the engine/tranny would fit without major problems...and they do, no problems at all. But there is one catch...no interior firewall. So i made one up from plastic, and here is the basic layout:

And in place (Also notice the green putty needed to get the engine compartment looking proper...gotta fill those knockout points!):

And with the engine/tranny:

Finally, two shots with the upper hull on. It really looks good like that, I am not much of a add-interiors kinda builder, but seeing it like that kinda gives me a itch to get it done and maybe do more AFV's with some interior parts.

Now to get the PE done. (BTW I do not solder my PE , it is all done with super-glue.)

Jacques

Joined: March 04, 2003

KitMaker: 4,630 posts

Armorama: 4,498 posts

Posted: Tuesday, May 22, 2007 - 08:24 PM UTC

Ok, what have I been up to?

First, kit 6075:

To make a fenderless SU-100 there are some front hull considerations, as noted earlier. Here are my results:

also, adding the "beak" to the front glacis will produce a noticeable gap on the lower hull joint where the weld line is. i loaded the seem with green putty BEFORE I glued on the piece, with the following result:

Finally, the joint of the small "fillet" behind the fighting compartment left a deep seam that looked poor, so I filled it with, you guessed it, green putty, and simulated the weld bead:

Now to kit 6359:

Overview with PE and putty work: the barrel/mantlet are not attached to the kit yet, they are just there for looks, as well as the two engine deck hatches and engine. I have added the fighting compartment side walls, the "coupola" , main gun mounting, and working onthe PE tool box and driver's hatch.

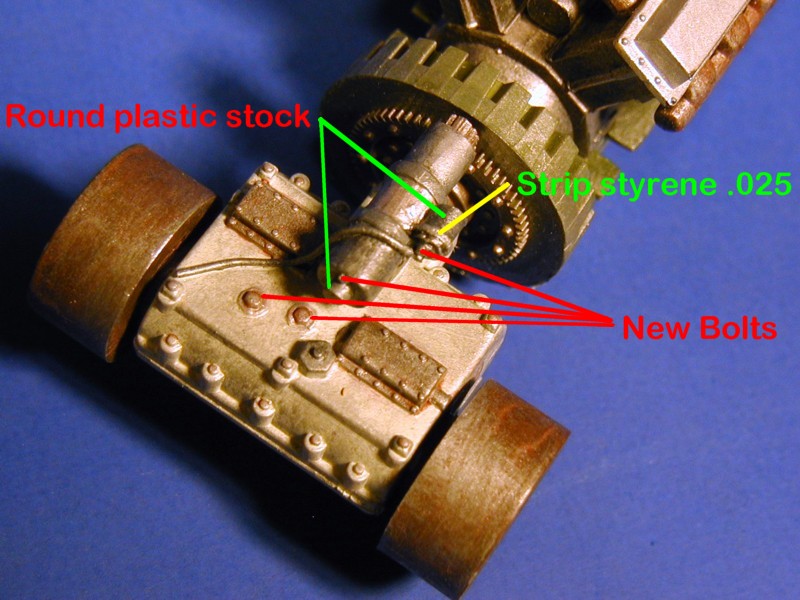

Engine compartment: I had to add one set of fuel tanks because even though they would MOSTLY not be seen, I did not want to leave them out. I did not feel the need to make them very accurate as they just needed to be the shape as that was about all would be seen, so I just glued some Evergreen tubing together, topped it off, and puttied.

Engine deck: I concenrated on getting the PE in this area in. Getting the PE top air intake plates in is a bit trickier than the side ones. I left the locating "tab" inside the trench and placed the PE piece on top, as per DML instructions (at least they do not tell you to remove the tab). Next time I think I would try to remove them. Also, make sure to carefully dryfit these pieces to make sure the angle is correct and you will not end up with any gaps.

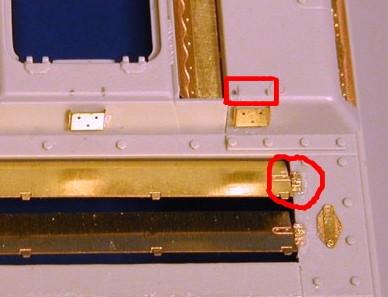

Dealing with the air louvers was interesting as well. DML had some bend lines etched into the small tabs on the end of the bracket (see red circle). There was no mention of them in the instructions. looking over the real deal, my best guess is that they were meant to be folded over above the bracket to allow a more 3-D effect as the end of the louver on the real thing is a steel rod going into a retaining bracket. Once I had done this, it looked pretty good.

Note also the red box. Make sure you use the engine deck cover to mark where the hinges are so that you can place the retaining "clips" in their proper place.

Speaking of the engine deck cover, I put on the mesh and frame. I am really impressed with DML's PE here. It is very soft and pliable and EXTREEM CARE needs to be taken with it so as not to bend it out of shape. It is more like soft copper in handeling than brass or Stainless steel. I did not have to anneal (heat) the metal before I put it on. however, lining everything up properly is a challenge as well...

Finally, seams and weld lines: As you may have noticed, i got busy with the putty. This kit is not necessarily in dire need of it, but since I had some work to do with putty, I did what I could. One thing I noticed about the DML kit is the two "fillets" on the back of the fighting compartment are better proportioned than on kit 6075 but they lack the very prominent weld lines of the real thing. So I added them.

I also had a bit of a gap between the front plate and the side plates.

If you look directly under the drivers opening, there is a green rectangle. This should be filled in before you add the PE pieces as the base of the PE piece will not fully cover it and it will look poor.

More soon.

First, kit 6075:

To make a fenderless SU-100 there are some front hull considerations, as noted earlier. Here are my results:

also, adding the "beak" to the front glacis will produce a noticeable gap on the lower hull joint where the weld line is. i loaded the seem with green putty BEFORE I glued on the piece, with the following result:

Finally, the joint of the small "fillet" behind the fighting compartment left a deep seam that looked poor, so I filled it with, you guessed it, green putty, and simulated the weld bead:

Now to kit 6359:

Overview with PE and putty work: the barrel/mantlet are not attached to the kit yet, they are just there for looks, as well as the two engine deck hatches and engine. I have added the fighting compartment side walls, the "coupola" , main gun mounting, and working onthe PE tool box and driver's hatch.

Engine compartment: I had to add one set of fuel tanks because even though they would MOSTLY not be seen, I did not want to leave them out. I did not feel the need to make them very accurate as they just needed to be the shape as that was about all would be seen, so I just glued some Evergreen tubing together, topped it off, and puttied.

Engine deck: I concenrated on getting the PE in this area in. Getting the PE top air intake plates in is a bit trickier than the side ones. I left the locating "tab" inside the trench and placed the PE piece on top, as per DML instructions (at least they do not tell you to remove the tab). Next time I think I would try to remove them. Also, make sure to carefully dryfit these pieces to make sure the angle is correct and you will not end up with any gaps.

Dealing with the air louvers was interesting as well. DML had some bend lines etched into the small tabs on the end of the bracket (see red circle). There was no mention of them in the instructions. looking over the real deal, my best guess is that they were meant to be folded over above the bracket to allow a more 3-D effect as the end of the louver on the real thing is a steel rod going into a retaining bracket. Once I had done this, it looked pretty good.

Note also the red box. Make sure you use the engine deck cover to mark where the hinges are so that you can place the retaining "clips" in their proper place.

Speaking of the engine deck cover, I put on the mesh and frame. I am really impressed with DML's PE here. It is very soft and pliable and EXTREEM CARE needs to be taken with it so as not to bend it out of shape. It is more like soft copper in handeling than brass or Stainless steel. I did not have to anneal (heat) the metal before I put it on. however, lining everything up properly is a challenge as well...

Finally, seams and weld lines: As you may have noticed, i got busy with the putty. This kit is not necessarily in dire need of it, but since I had some work to do with putty, I did what I could. One thing I noticed about the DML kit is the two "fillets" on the back of the fighting compartment are better proportioned than on kit 6075 but they lack the very prominent weld lines of the real thing. So I added them.

I also had a bit of a gap between the front plate and the side plates.

If you look directly under the drivers opening, there is a green rectangle. This should be filled in before you add the PE pieces as the base of the PE piece will not fully cover it and it will look poor.

More soon.

spongya

Joined: February 01, 2005

KitMaker: 2,365 posts

Armorama: 1,709 posts

Posted: Tuesday, May 22, 2007 - 10:34 PM UTC

Great thread!

I have a question about the welding and putty: how do you use the green putty so precisely? It dries so fast, I can only apply it to the surface, and later sand away the mass. I use the squadron putty -judging by the color, that's what you use too.

Do you dilute it with something? (Tried acetone, but it made it harden even faster, as the acetone evaporated quickly.)

I have a question about the welding and putty: how do you use the green putty so precisely? It dries so fast, I can only apply it to the surface, and later sand away the mass. I use the squadron putty -judging by the color, that's what you use too.

Do you dilute it with something? (Tried acetone, but it made it harden even faster, as the acetone evaporated quickly.)

Jacques

Joined: March 04, 2003

KitMaker: 4,630 posts

Armorama: 4,498 posts

Posted: Wednesday, May 23, 2007 - 09:31 AM UTC

I will be gone for the next three days, so no updates! (Sorry)

For putty, I use a fresh tube of squadron green putty now. But I did not have a lot of problems with my older tube other than it took longer to cure.

To thin it I use liquid cement from Testors. Nothing special about that, just what I have on hand. The glue thins it nicely.

However, I have a syringe and needle that I cut off so I can squeeze out a line of green putty. I use this for my weld beads...it is not especially easy, but it looks good as I can control the amount of putty.

I also use a blade from X-acto that has the cutting edge on a squared off front end to help apply and level things out.

I will post photo's of these tools after I get back. Be patient!

For putty, I use a fresh tube of squadron green putty now. But I did not have a lot of problems with my older tube other than it took longer to cure.

To thin it I use liquid cement from Testors. Nothing special about that, just what I have on hand. The glue thins it nicely.

However, I have a syringe and needle that I cut off so I can squeeze out a line of green putty. I use this for my weld beads...it is not especially easy, but it looks good as I can control the amount of putty.

I also use a blade from X-acto that has the cutting edge on a squared off front end to help apply and level things out.

I will post photo's of these tools after I get back. Be patient!

Jacques

Joined: March 04, 2003

KitMaker: 4,630 posts

Armorama: 4,498 posts

Posted: Monday, May 28, 2007 - 09:18 PM UTC

Here are the tools I use to make the putty welds:

The "needle" for the syringe has been cut down to about 1cm and is now flush. I may try it with a "proper" needle tp at a later date to se what effects that may have.

I have done some minor work on the drivers hatch. NOTE - if you plan to show the hatch open, you need to add the two PE handles. DML molded them on upside down, so the PE ones correct a problem. However, I removed the molded handles carefully and cut down the main part of the handle and glued it underneath the PE handle. The PE handle looks good, but lacks depth and substance that having a piece of styrene underneath adds. This is the main problem with PE and the instructions do not say to add anything.

It is not perfect, but it looks a lot better. Again, only if you keep the hatch open.

Finally, the all PE stowage box. As might be imagined, this is itty-bitty-part nightmare. All built up it looks good, but DOING it was a joy in messing with nearly microscopic parts. DML has done a good job in rendering these parts, but doing this is not for the faint of heart.

The end result:

Now, it has been suggested that maybe I am being a bit too anal about documenting all details of this build and that maybe I should "get on with it". I will see what I can do to expidite matters.

The "needle" for the syringe has been cut down to about 1cm and is now flush. I may try it with a "proper" needle tp at a later date to se what effects that may have.

I have done some minor work on the drivers hatch. NOTE - if you plan to show the hatch open, you need to add the two PE handles. DML molded them on upside down, so the PE ones correct a problem. However, I removed the molded handles carefully and cut down the main part of the handle and glued it underneath the PE handle. The PE handle looks good, but lacks depth and substance that having a piece of styrene underneath adds. This is the main problem with PE and the instructions do not say to add anything.

It is not perfect, but it looks a lot better. Again, only if you keep the hatch open.

Finally, the all PE stowage box. As might be imagined, this is itty-bitty-part nightmare. All built up it looks good, but DOING it was a joy in messing with nearly microscopic parts. DML has done a good job in rendering these parts, but doing this is not for the faint of heart.

The end result:

Now, it has been suggested that maybe I am being a bit too anal about documenting all details of this build and that maybe I should "get on with it". I will see what I can do to expidite matters.

zokissima

Joined: February 09, 2004

KitMaker: 259 posts

Armorama: 217 posts

Posted: Thursday, May 31, 2007 - 12:05 AM UTC

Wow, this thread is a gold-mine. From the included links, to the build pictures and explanations. Thanks a lot for taking the time to do it.

Also, if anyone is looking for the Maquette engine and tranny set, you can also get it from www.hobbyterra.com

I've ordered from them before, with no problems, albeit only once ,and it took a while for the order to come in.

Also, if anyone is looking for the Maquette engine and tranny set, you can also get it from www.hobbyterra.com

I've ordered from them before, with no problems, albeit only once ,and it took a while for the order to come in.

spongya

Joined: February 01, 2005

KitMaker: 2,365 posts

Armorama: 1,709 posts

Posted: Thursday, May 31, 2007 - 08:15 AM UTC

Hi,

Thank you for answering -I'll try to dilute it with cement...

Thank you for answering -I'll try to dilute it with cement...

Posted: Thursday, May 31, 2007 - 10:58 AM UTC

Quoted Text

Now, it has been suggested that maybe I am being a bit too anal about documenting all details of this build and that maybe I should "get on with it". I will see what I can do to expidite matters.

Jacques ..... you´re doing a smashing job .... and I must say the perfect amount of documenting .. to satisfy those from all levels. Its a pleasure seeing each step and reading the narrative as you go along.

Im particularily interested, as the back end is whats so cool with the T34, and Ive also the Maquette engine/tranny waiting. Keep it going.

Its a pity somebody feels they have to tell YOU how to, or whats needed, for YOUR blog.

Jacques

Joined: March 04, 2003

KitMaker: 4,630 posts

Armorama: 4,498 posts

Posted: Friday, June 01, 2007 - 04:35 AM UTC

Now now, no worries. Noone has offended or slighted me. Glad to see people rushing to my defense though...

I will keep going, in fact I am just finsihing up my work ont he engine compartment and the maquette engine setup and evaluation. I should have it done and posted today/tonight.

Glad this blog is a help, makes doing all the work worthwhile.

I will keep going, in fact I am just finsihing up my work ont he engine compartment and the maquette engine setup and evaluation. I should have it done and posted today/tonight.

Glad this blog is a help, makes doing all the work worthwhile.

wbill76

Joined: May 02, 2006

KitMaker: 5,425 posts

Armorama: 4,659 posts

Posted: Friday, June 01, 2007 - 07:00 AM UTC

Continuing to enjoy this one Jacques, keep up the good work on the blog!

spongya

Joined: February 01, 2005

KitMaker: 2,365 posts

Armorama: 1,709 posts

Posted: Friday, June 01, 2007 - 07:00 AM UTC

Hey, document every single step. Even how you pick your brushes up... Most of the "build articles" (even in books) show something like: step 1: I built the model step 2. I primed it step 3. whoa, the whole thing is ready. And I'm still trying to find a way to simulate realistic painted, weathered metal...

Jacques

Joined: March 04, 2003

KitMaker: 4,630 posts

Armorama: 4,498 posts

Posted: Friday, June 01, 2007 - 06:56 PM UTC

Ok, first off, I am doing this late, so if I mess this up, try not to laugh too hard!

I thought maybe a touch of background was due here: My college degree is in Biology but not as in hey-lets-take-a-walk-or-a-swim-and-see-neat-things type of Biology, I was into Molecular Biology and Immunology, stuff that requires you to do three things: Stay in a labratory for long periods, work under a microscope with REALLY TINY things, and keep REALLY good notes that are extreemly anal...er, detail oriented, especially in Chemistry labs. So I approach model building, and thus this B-log in the same fashion: If someone reading this cannot take the same kit and tools and get a similar result, then I screwed something up.

That said, the next installment.

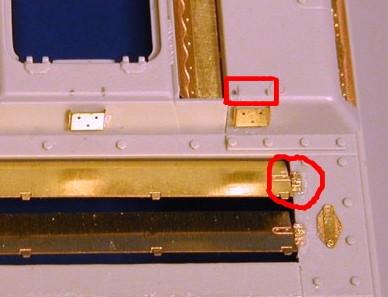

The Maquette engine/tranny built with added details and the base paint colors and initial drybrushing.

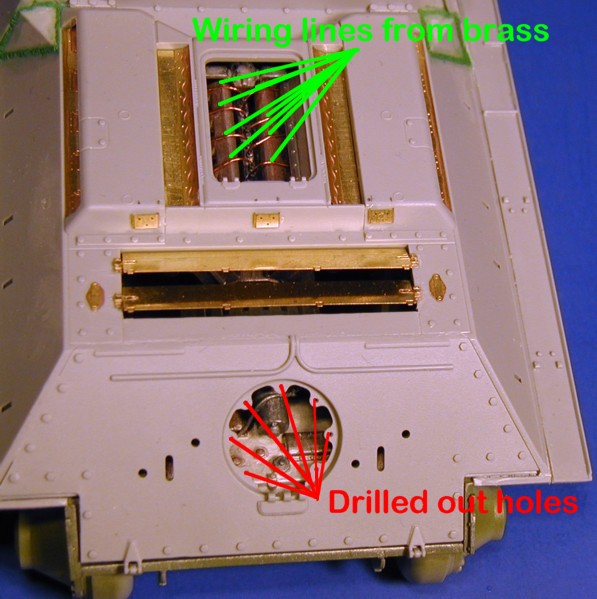

Engine closeup: All I have added is brass "wiring".

Some notes:

Painting was as follows:

Testors Model Master #4726 Dark Green: Engine Compartment, engine and tranny supports, cooling fan. Highlights with 50/50 mix of Dark Green and Testors Model Master #4812 US Army Marines Gulf AR.

Teestors Model Master #4768 Flat Black : Tranny and Engine, all parts.

Flat Aluminum (any kind should do, mine is OOP): Drybrushed HEAVY over all engine and tranny parts.

Camoflauge Grey: Tranny case, drybrushed with flat aluminum.

Various parts picked out with three metallic colors: Flat Aluminum, flat silver, and burnt aluminum. This is to give metal parts more variation. For example, I painted the engine heads (big rectangular blocks on each top of the engine) black, then drybrushed flat aluminum, then drybrushed burnt aluminum, then PAINTED flat silver. The engine is still the flat aluminum/burnt aluminum mix.

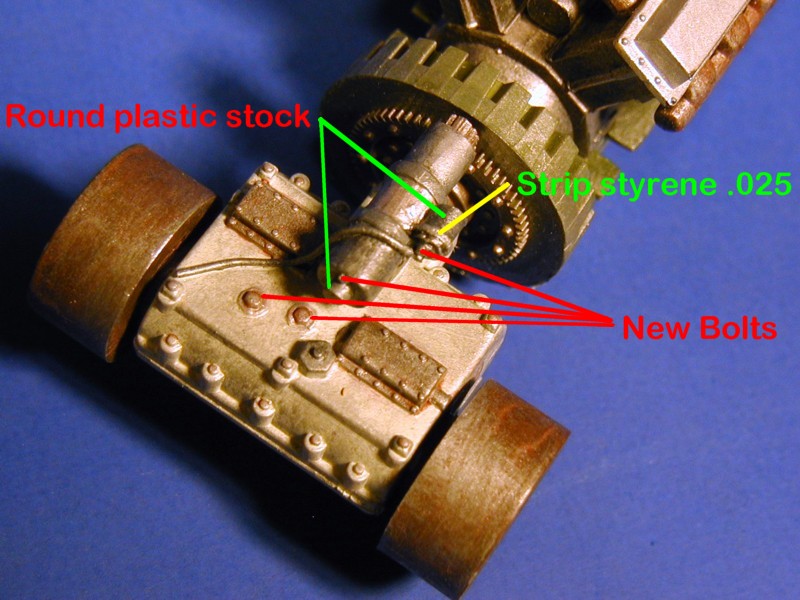

Since the tranny would be very viable, I added a couple of prominant bolts, a wire from the smaller motor? mounted above the suplied alternator (?), bolts and a axel end to this same alternator, and the smaller motor itself to the side of the Alternator. (Can you tell I am tired? ) See above pictures for a visual.

) See above pictures for a visual.

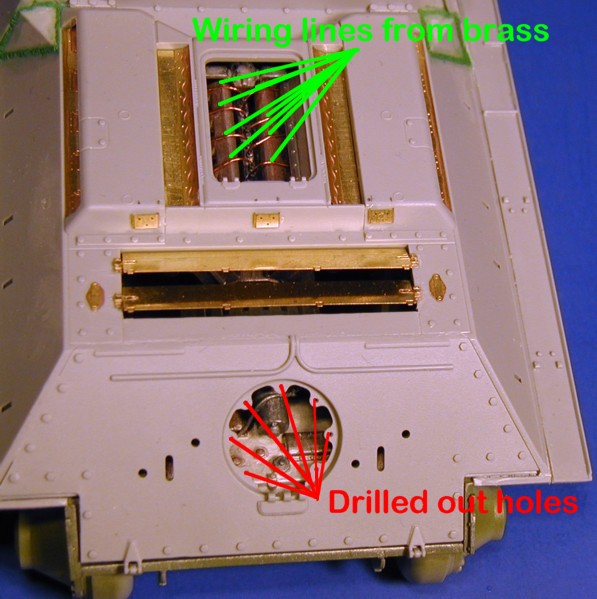

Finally, three looks at what you get:

All buttoned up

With the upper hull off:

and without the engine:

Yellow blocks are fuel tanks (Yes, some were painted yellow...or red, or just red-oxide primer). Stains are diluted flat black and rust acrylic paint, 70 water to 30 paint. "Chips" on firewall are just Testors MM Dark green applied with a small brush.

I'm off to bed, any ?'s please ask...

I thought maybe a touch of background was due here: My college degree is in Biology but not as in hey-lets-take-a-walk-or-a-swim-and-see-neat-things type of Biology, I was into Molecular Biology and Immunology, stuff that requires you to do three things: Stay in a labratory for long periods, work under a microscope with REALLY TINY things, and keep REALLY good notes that are extreemly anal...er, detail oriented, especially in Chemistry labs. So I approach model building, and thus this B-log in the same fashion: If someone reading this cannot take the same kit and tools and get a similar result, then I screwed something up.

That said, the next installment.

The Maquette engine/tranny built with added details and the base paint colors and initial drybrushing.

Engine closeup: All I have added is brass "wiring".

Some notes:

Painting was as follows:

Testors Model Master #4726 Dark Green: Engine Compartment, engine and tranny supports, cooling fan. Highlights with 50/50 mix of Dark Green and Testors Model Master #4812 US Army Marines Gulf AR.

Teestors Model Master #4768 Flat Black : Tranny and Engine, all parts.

Flat Aluminum (any kind should do, mine is OOP): Drybrushed HEAVY over all engine and tranny parts.

Camoflauge Grey: Tranny case, drybrushed with flat aluminum.

Various parts picked out with three metallic colors: Flat Aluminum, flat silver, and burnt aluminum. This is to give metal parts more variation. For example, I painted the engine heads (big rectangular blocks on each top of the engine) black, then drybrushed flat aluminum, then drybrushed burnt aluminum, then PAINTED flat silver. The engine is still the flat aluminum/burnt aluminum mix.

Since the tranny would be very viable, I added a couple of prominant bolts, a wire from the smaller motor? mounted above the suplied alternator (?), bolts and a axel end to this same alternator, and the smaller motor itself to the side of the Alternator. (Can you tell I am tired?

) See above pictures for a visual.

) See above pictures for a visual.Finally, three looks at what you get:

All buttoned up

With the upper hull off:

and without the engine:

Yellow blocks are fuel tanks (Yes, some were painted yellow...or red, or just red-oxide primer). Stains are diluted flat black and rust acrylic paint, 70 water to 30 paint. "Chips" on firewall are just Testors MM Dark green applied with a small brush.

I'm off to bed, any ?'s please ask...

Jurjen

Joined: September 21, 2003

KitMaker: 3,040 posts

Armorama: 1,016 posts

Posted: Sunday, June 03, 2007 - 11:14 PM UTC

Hi Jacques!

Well done mate! The engine looks superb this way. Can't wait to your next update.

Keep it up!

Jurjen

Well done mate! The engine looks superb this way. Can't wait to your next update.

Keep it up!

Jurjen

Jacques

Joined: March 04, 2003

KitMaker: 4,630 posts

Armorama: 4,498 posts

Posted: Wednesday, June 06, 2007 - 03:26 PM UTC

No, I'm not dead. Just too darned busy suddenly. I am doing a small update for now, I hope to add more soon, but I have yet another 2-day trip to deal with so...

I managed to paint the ignition wires (?) yellow. A hint, paint them camoflage gray first, THEN Model Master yellow and it will look a lot better.

I then put on my special mixture wash of Future floor polish diluted with water and windshield washer fluid (for the ammonia) and with a small amount of Burnt Umber and Burnt Sienna pigments. This gives a nice tonal wash that helps to blend colors and add sharp shadows.

I now need to add pastels and glue it in the compartment. Progress...progress...

I managed to paint the ignition wires (?) yellow. A hint, paint them camoflage gray first, THEN Model Master yellow and it will look a lot better.

I then put on my special mixture wash of Future floor polish diluted with water and windshield washer fluid (for the ammonia) and with a small amount of Burnt Umber and Burnt Sienna pigments. This gives a nice tonal wash that helps to blend colors and add sharp shadows.

I now need to add pastels and glue it in the compartment. Progress...progress...

spongya

Joined: February 01, 2005

KitMaker: 2,365 posts

Armorama: 1,709 posts

Posted: Wednesday, June 06, 2007 - 04:15 PM UTC

Hey, you're a fellow lunatic.  May I write a PM to you about Molec. Biology? Kind of having a professional crisis here. Thanks.

May I write a PM to you about Molec. Biology? Kind of having a professional crisis here. Thanks.

May I write a PM to you about Molec. Biology? Kind of having a professional crisis here. Thanks.

May I write a PM to you about Molec. Biology? Kind of having a professional crisis here. Thanks.

Jacques

Joined: March 04, 2003

KitMaker: 4,630 posts

Armorama: 4,498 posts

Posted: Sunday, June 10, 2007 - 03:16 PM UTC

No, still not dead, just recovering froma busy 10 days (more like 4 weeks). Anyhow, proper update with new info tomorrow, so keep waiting.

(Man, I prefer building kits to driving all over hell and forever, and wiring outlets, and taking kids to visit relatives...etc. Sigh. )

)

(Man, I prefer building kits to driving all over hell and forever, and wiring outlets, and taking kids to visit relatives...etc. Sigh.

)

)

Jacques

Joined: March 04, 2003

KitMaker: 4,630 posts

Armorama: 4,498 posts

Posted: Thursday, June 14, 2007 - 04:28 PM UTC

No pictures tonight.

I have decided to start painting kit #6075 to help me get a feel for the paint colors I want to use and to help give me a feel for the places I will have to take note of to make sure they are properly painted.

And so I trundled off to the trusty airbrush table. I am using Polly S Black Green as my initial coat of paint, rather than black as I find black can be too harsh for pre-shading. I am also using this to help me find any potential flaws in my construction...and I have indeed found two so far. So a little putty and glue to fix it up and add all the parts I had to spray under before I could glue them on (like the casement top double-domes) and then put on a second coat.

Exciting!

I use the second coat of paint as my true base color and then I will start adding the lighter "overcoats" to this. Once I get the base color on this kit, I plan to go on to kit #6359, which will be prepped by having the upper hull painted on the interior side, have in glued to the lower hull, and then masking off the interior areas so the exterior can be painted.

I have decided to start painting kit #6075 to help me get a feel for the paint colors I want to use and to help give me a feel for the places I will have to take note of to make sure they are properly painted.

And so I trundled off to the trusty airbrush table. I am using Polly S Black Green as my initial coat of paint, rather than black as I find black can be too harsh for pre-shading. I am also using this to help me find any potential flaws in my construction...and I have indeed found two so far. So a little putty and glue to fix it up and add all the parts I had to spray under before I could glue them on (like the casement top double-domes) and then put on a second coat.

Exciting!

I use the second coat of paint as my true base color and then I will start adding the lighter "overcoats" to this. Once I get the base color on this kit, I plan to go on to kit #6359, which will be prepped by having the upper hull painted on the interior side, have in glued to the lower hull, and then masking off the interior areas so the exterior can be painted.

Jacques

Joined: March 04, 2003

KitMaker: 4,630 posts

Armorama: 4,498 posts

Posted: Thursday, June 21, 2007 - 04:28 PM UTC

Ok, I apologize for this thread stalling out. Between family activities getting extreemly busy and new jobs (model commision work) popping up, I have been swamped. I am barely able to log on to make sure the forum is still around!

That in mind, I am going to try to finish up the build review of the #6359 kit and write that up before next Wednesday, and finish up the Marquette engine review as well. I will be gone until after the 4th of July after that, so getting the job doen early is better than doing it later.

I do plan to make all notes available here as I finish up the review, and also to keep notes as i do the painting and possible diorama. So bear with me, it has been crazy.

Oh, I have to beat Jurjen on his SA-13 build...sheesh is he working fast!

That in mind, I am going to try to finish up the build review of the #6359 kit and write that up before next Wednesday, and finish up the Marquette engine review as well. I will be gone until after the 4th of July after that, so getting the job doen early is better than doing it later.

I do plan to make all notes available here as I finish up the review, and also to keep notes as i do the painting and possible diorama. So bear with me, it has been crazy.

Oh, I have to beat Jurjen on his SA-13 build...sheesh is he working fast!

Jurjen

Joined: September 21, 2003

KitMaker: 3,040 posts

Armorama: 1,016 posts

Posted: Friday, June 22, 2007 - 01:35 AM UTC

Hi Jacques,

Busy :-> greatest enemy of modeling

Not to worry though, you will definately be faster then me!

Jurjen

Busy :-> greatest enemy of modeling

Not to worry though, you will definately be faster then me!

Jurjen

Jacques

Joined: March 04, 2003

KitMaker: 4,630 posts

Armorama: 4,498 posts

Posted: Wednesday, June 27, 2007 - 01:39 AM UTC

Quick note

First, I will be gone until the 3rd, so nothing after this.

Second. Work progresses. I am adding the various small bits I had been holding off on, and working with the tracks. I am not going to say a lot here as i will post pictures later. My main problem has been choosing between building or taking pictures and building won out.

As a teaser, I have some information on how to deal with the Dragon Majic tracks that may be of interest to all of you. Now you just have to wait!

It also looks like July will give me two good weeks to build kits, so I should finish up the SU-100 and be able to get my Maquette engine review finished up.

Off to enjoy vacation.

First, I will be gone until the 3rd, so nothing after this.

Second. Work progresses. I am adding the various small bits I had been holding off on, and working with the tracks. I am not going to say a lot here as i will post pictures later. My main problem has been choosing between building or taking pictures and building won out.

As a teaser, I have some information on how to deal with the Dragon Majic tracks that may be of interest to all of you. Now you just have to wait!

It also looks like July will give me two good weeks to build kits, so I should finish up the SU-100 and be able to get my Maquette engine review finished up.

Off to enjoy vacation.

sauceman

Joined: September 28, 2006

KitMaker: 2,672 posts

Armorama: 2,475 posts

Posted: Wednesday, June 27, 2007 - 05:02 AM UTC

Quoted Text

I managed to paint the ignition wires (?) yellow. A hint, paint them camoflage gray first, THEN Model Master yellow and it will look a lot better.

The wires are actually fuel lines, a little more UFI for ya!

cheers

Jacques

Joined: March 04, 2003

KitMaker: 4,630 posts

Armorama: 4,498 posts

Posted: Tuesday, July 17, 2007 - 05:36 AM UTC

Quoted Text

The wires are actually fuel lines, a little more UFI for ya!

cheers

DUH! (Smacks forehead) Oh man, I should have remembered that. Being it is a DIESEL engine, no spark plugs. Sigh. I guess I have to fire myself off of this build!

Ok, I am rehired. No more mistakes, or else the beatings will continue.

I am working on getting some new info up sometime this week, but no promises. See my personal note thread for more info.

Jacques

Joined: March 04, 2003

KitMaker: 4,630 posts

Armorama: 4,498 posts

Posted: Friday, August 10, 2007 - 02:55 PM UTC

Well, my airbrush crapped out on me when i went back into the spraybooth to work on the kits. No, really. Good news is that I got a Iwata HP-CS to replace it, just have to wait for the mail to bring it.

With that in mind I did my in-box and build reviews on the Maquette Engine set. Those of you who have read through this thread will not gleam any new info from them, but it is meant for those who have not dared this thread anyhow!

I also did some research and basic measurements on the SU-100 and here is what I found when compared to the kits:

The difference in the DML kit length measurements was the kit plastic barrel on #6075 and the metal barrel on #6359.

* Height was from bottom of tracks under roadwheel to top of commanders periscope.

** Clearance was from bottom of tracks under roadwheel to bottom of the lower hull.

Measurements were taken with a simple caliper, nothing fancy, and may have some error in them.

All measurements are within less than 2% error of what I found for the prototype. However, I cannot confirm that my "real deal" measurements are correct from my resources. So if anyone has something better to add, please do so.

Good to be back at it.

With that in mind I did my in-box and build reviews on the Maquette Engine set. Those of you who have read through this thread will not gleam any new info from them, but it is meant for those who have not dared this thread anyhow!

I also did some research and basic measurements on the SU-100 and here is what I found when compared to the kits:

- Measurement, Real Deal (###) and 1/35, DML 6075, DML 6359

- Length w/barrel, (9450mm) - 270mm, 265mm, 266mm

- Width, (3000mm) - 85.71mm, 85.7mm, 85.7mm

- Height*, (2245mm) - 64.14mm, 65.2mm, 65.2mm

- Clearance**, (400mm) - 11.43mm, 11.25mm, 11.25mm

The difference in the DML kit length measurements was the kit plastic barrel on #6075 and the metal barrel on #6359.

* Height was from bottom of tracks under roadwheel to top of commanders periscope.

** Clearance was from bottom of tracks under roadwheel to bottom of the lower hull.

Measurements were taken with a simple caliper, nothing fancy, and may have some error in them.

All measurements are within less than 2% error of what I found for the prototype. However, I cannot confirm that my "real deal" measurements are correct from my resources. So if anyone has something better to add, please do so.

Good to be back at it.

Jacques

Joined: March 04, 2003

KitMaker: 4,630 posts

Armorama: 4,498 posts

Posted: Wednesday, September 19, 2007 - 02:06 AM UTC

Bet you thought I was dead, or this thread at least. Well, not any longer. Look for updates to it starting tonight. Time to get the wee beasties done.

|