1⁄35All Bout Da Bones

12

Comments

ASSEMBLY

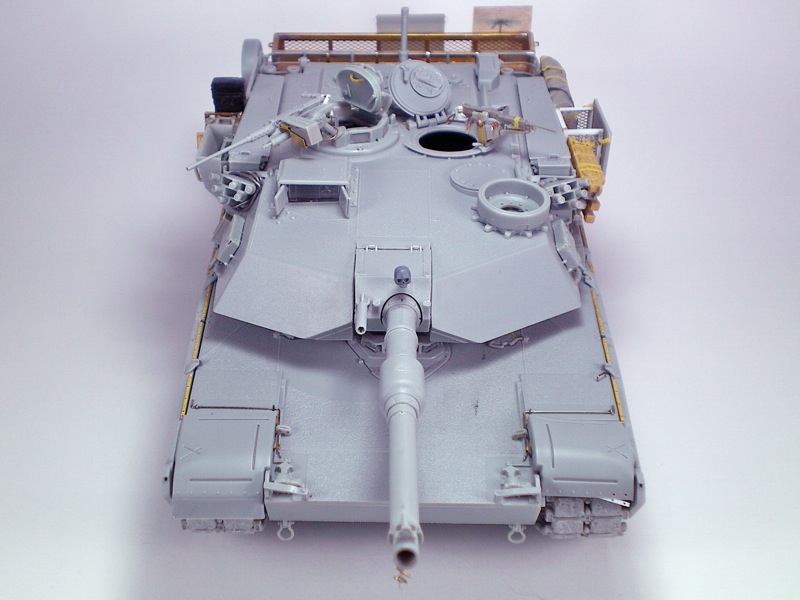

The basis for this build is Dragon’s M1A1 AIM (#3535), a real monster of a kit with over 700 parts! Conveniently, decals to represent “All Bout Da Bones” as well as photoetched parts for the extended turret bustle and jerry can rack were included with this kit. A few aftermarket products were also required to depict the tank during the time of the TR and I chose the Legend M1 Tank Stowage set (LF1163), AFV Club M1A1 AIM / M1A2 Abrams Anti-Reflection Coating Lens stickers (AC35017), DEF Models Modern Portable Coolers, and Live Resin’s M240B as well as their .50 caliber links and shells.The Dragon M1A1 kit is a fantastic kit with excellent detail but it turned out to be quite a handful during assembly as I was rather unfamiliar with some of the characteristics of modern armor. Additionally, it turned out that the lower hull of this particular kit was a bit warped right out of the box, requiring me to add some internal bracing in order to straighten it and prevent a “rocking horse” effect once the tracks and wheels were installed. The road wheel suspension arms are designed by Dragon to be articulated pretty much any way the builder desires, but I found that along with the warped hull, this further complicated my effort to get a nice level set-up. During assembly of the suspension, the arms had a tendency to move before I was able to get them all aligned and glued into place. In the end, however, I got everything pretty well lined up if not exactly perfect.

One of the main elements that the group was asked to depict when building the Abrams models was the high level of wear on both the road wheel rubber and the rubber track pads. These tanks saw heavy use and many traveled many miles on tarmac surfaces without adequate time for full maintenance. As a result, the rubber components were extremely worn by the time of the TR. In order to show this, I took to the wheels with a brand new #11 blade, adding gouges and nicks to the rubber portions of the wheels. The tracks required a slightly different approach. Using a soldering iron, first with a fine tip and later with an attached chisel blade (held in place by wrapping it with steel wire), I gouged and scraped the rubber pads to achieve a look similar to the reference photos. The heated point and chisel blade did a good job of replicating the worn, pocked and delaminated look of the pads, especially around the edges, and once this was done, a brisk sanding with a coarse sanding stick took care of any areas that looked “melted” rather than worn.

Other detail elements added for this build were the armored skirt ID plates replicated with .005 strip styrene, the iconic skull on the gun mantlet and the damaged left front fender. As befitting its name, All Bout Da Bones featured a Halloween skull decoration on its gun mantlet. One of the veteran crew members said that they even had it wired so that the eyes would light up! The crew had also tied a string of chicken bones onto the end of the main gun tube. For the skull I used a spare Warhammer skull from my gaming figure collection. To represent the chicken bones, I cut small pieces of brass rod and tied them together with very fine wire. The damaged front left fender was modeled by first thinning the part from the back side with a grinding tool and then heating it in boiling water to soften and bend it in order to match the shape seen in the reference photos. The “rubber” flap was removed from this fender and a drilled out strip of styrene was added to replicate the steel mounting bracket for the now missing rubber flap.

Part-way through the build, someone in the group discovered that several of the Abrams used in the assault had an unusual pair of brackets welded onto the upper right rear of the hull. These were determined to be residual brackets from older tanks that may have once used the hull-mounted Auxiliary Power Unit (APU) before the later turret-basket APU was developed. Close examination of the only photo I had of A32’s backside revealed that it was indeed one of these tanks, so scratch-building the two brackets was required. I penciled a rough shape onto two pieces of .80 styrene stacked and taped together, then carved out the shape. By stacking the two pieces together, I only had to cut the shape once and this would ensure that the pieces would be the exact same size. After checking the fit and size several times and adjusting as necessary, I drilled a bolt hole through the middle and separated the pieces before gluing them onto the hull. A slight modification to the right rear light shroud was also required both to mimic the actual shroud and to get the outer APU bracket mounted into the correct position.

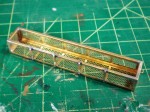

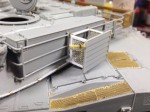

As mentioned earlier, tanks in this unit were issued a shop-fabricated turret bustle extension rack as well as two additional jerrycan racks that hung off the turret sponson boxes. The Dragon kit provides the bustle extension and one jerrycan rack as photoetched parts. For this particular tank, it was not clear if both jerrycan racks were in place at the time of the TR as none of the photos I had showed the left side of the turret clearly. I was eventually provided with a photo that did show the left side of the turret but no jerrycan rack was installed. However, this photo appeared to have been taken in Baghdad sometime after the TR and this was later confirmed by the tank’s driver. He was unable to recall if the second rack had been installed on the day of the TR so this gave me some flexibility to include it or not. After studying photos of several other tanks in the unit, I decided to go ahead and install the second rack but to place it behind a Combat Identification Panel (CIP) which was a fairly common practice. The rack was scratchbuilt using styrene angle strips and diamond mesh grill material meant for model car kits.

Additional details were added to the crew weapons including the wiring and solenoid mechanism for remote firing of the tank commander’s M48 Turret Machine Gun. This differs from a standard M2 .50 caliber machine gun in that it can be remotely fired and does not have the standard cocking handle on the right side of the gun. Instead, the gun is cocked using a “U” shaped handle attached to a cable which hangs just below the gun. I added these features using copper wire, brass rod bent to shape and bits of styrene stock in addition to PE chains for the weapon cradle mounting pins. For the loaders M240C I substituted a LiveResin M240B with the stock and trigger guard removed. The M240B included a heat shield around the barrels and also had a bipod that could be mounted in the stowed position. This allowed me to represent the a weapon with a partial “dismount kit” installed which was common on many of the Abrams M240s in the field. A wire charging handle and PE chains were added after mounting the weapon in the stock Dragon cradle.

Comments

Modern stuff is not my usual area of modelling interest, but I too doff my hat to you in recognition of a superbly completed model. True "museum quality" and great that it is going to be displayed there.

- Steve

NOV 24, 2014 - 08:22 PM

Dang that is one sweet build! Especially love the wear and tear and overall attention to detail, really outstanding sir!

NOV 24, 2014 - 09:49 PM

Great looking build and a very well article, congrats on your medals as well!

NOV 25, 2014 - 02:48 AM

This one is clearly a labour of love, all that detail work is paying off and the finish is amazing. A exellent piece of work,very acurate and precise to the real thing.

Congratulations, you did a great job. Are you an artist.

Greetings and respect,

Walter

NOV 25, 2014 - 12:27 PM

Hi Mario, Hi Don,

Don, you have provided a great article with useful reference pics, and definitely you made a great job !

I like very much the stowage arrangement and the weathering.

Thanks for posting !

DEC 04, 2014 - 12:26 PM

Outstanding build Sir...love it and the information you've provided will be very helpful to me.....thank you

FEB 16, 2015 - 08:17 PM

Copyright ©2021 by Don Haney. Images and/or videos also by copyright holder unless otherwise noted. The views and opinions expressed herein are solely the views and opinions of the authors and/or contributors to this Web site and do not necessarily represent the views and/or opinions of Armorama, KitMaker Network, or Silver Star Enterrpises. All rights reserved. Originally published on: 2014-11-25 01:46:10. Unique Reads: 16849