I almost forgot about this build.

Coming along beautifully.

And you have more patience then most.

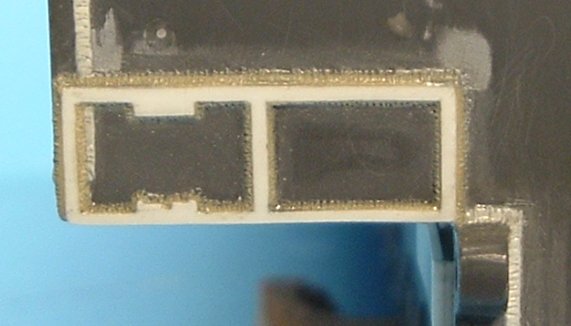

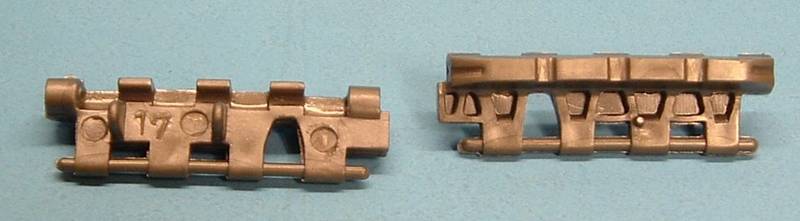

Not wanting to jump right back on the wingnuts, I looked around for something else to tackle. And oh boy, did I find a biiiggg problem. Is it me...or are the swing arms facing the wrong direction?

Matt :Quoted TextNot wanting to jump right back on the wingnuts, I looked around for something else to tackle. And oh boy, did I find a biiiggg problem. Is it me...or are the swing arms facing the wrong direction?

According to this picture, your swing arms are just fine.

Fido

, but I flipped the picture, and when viewed like this,

, but I flipped the picture, and when viewed like this,

Piotr :

I could still have it wrong, but I flipped the picture, and when viewed like this,

the swing arms still seem to face towards the rear just like Matt's model. BTW thanks for the warning, I will check out all my reference photos more closely next time.

Fido

I wanna see more LOL

I wanna see more LOL

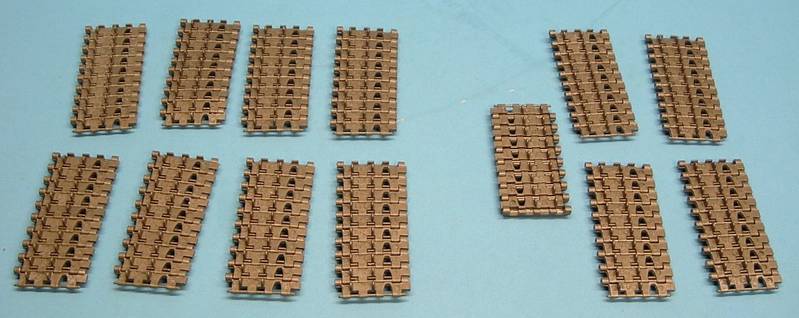

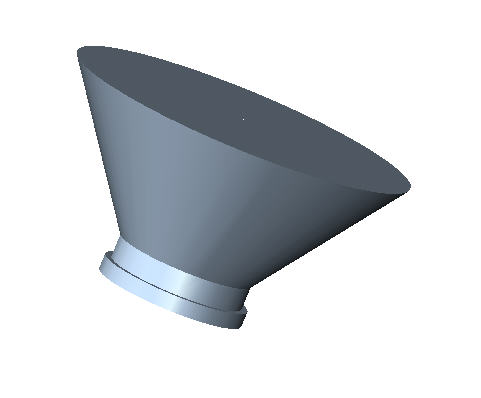

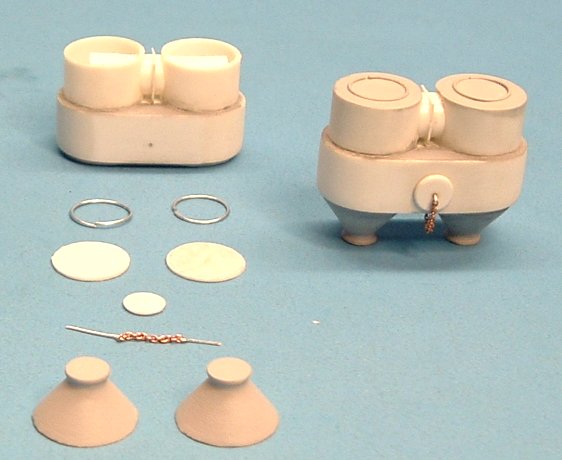

from dimensions I had provided. My friend Yiyan then used this awesome piece of technology/machinery to create the parts for me.

From what Yiyan told me, that rapid prototyper is one of the lower end models, they can get as expensive as a quarter million or more! Sounds like the lazer/resin is a couple notches above what we have here:) Have you ever had any parts made on it? If so, how did they come out?

From what Yiyan told me, that rapid prototyper is one of the lower end models, they can get as expensive as a quarter million or more! Sounds like the lazer/resin is a couple notches above what we have here:) Have you ever had any parts made on it? If so, how did they come out?

hehehe... Now then for the boat.. and being summer time.. I don't blame ya

hehehe... Now then for the boat.. and being summer time.. I don't blame ya

Hi James,

Funny that you should comment, I was just looking at your " One Week Stug IV". Have one of those built up on the shelf, no where near as nice as that though!

Apologies for the lack of updates recently, got burnt out with the Big Tig for a while. Been taking a short break from that project and moves on to something else for a while. Come Jan, I think I will have had sufficient time off to tackle it again. Hopefully Aber's set will be out by then to ease the pain! I do enjoy the challenge of scratchbuilding though, just not every single little detail lol

Thanks for your comment James!

Matt

P.S. btw what did you build OOB ??? hmmmmmm

but, hey.. you asked what I was building OOB!

but, hey.. you asked what I was building OOB!

|