Campaigns

Where Armorama group builds can be discussed, organized, and updates posted.

Where Armorama group builds can be discussed, organized, and updates posted.

Hosted by Darren Baker, Richard S.

Panther Campaign

casualmodeler

Joined: February 04, 2009

KitMaker: 702 posts

Armorama: 665 posts

Posted: Saturday, November 26, 2011 - 10:30 AM UTC

Ok, if campaign ends on December 2012, then I may have time to finish a Panther model. Never built a one, just have to dig deep into my stash....

Posted: Saturday, November 26, 2011 - 11:13 AM UTC

Panthoholics,

Im enjoying the holidays here and I hope that many of you are too!

I build my kits from the inside out so I dont usually follow the instruction sheet build sequence and tend to bounce around a lot during the assembly. I go through the assembly instructions looking for where parts need to be added first so as not to have to go back and remove a part because another part needed to go there first. I usually wash the part sprue trees in warm soapy water follow by a blow dry before I start assembly but I find that the DML Dragon kits are mold release grease free so I skip this step and move on to the parts fitting before I start on the glue sniffing assembly parade.

Im a slow builder and as there are 14 months allocated for this campaign I can proceed with a step-by-step for this build and hope that at least someone will find some part of this crazy build process useful and inspirational.

According to my reference books for the Panther G there was a forward 25 mm panel followed by two 16 mm panels welded together forming the belly of the chassis near the start of production. This was also the case at the start of the Panther F production. A single 16 mm panel at the end of the Panther G production run later replaced the two-seperate 16 mm belly panels. Im just guessing here, as nothing is mentioned on any of my references, but this could have also been done for the Panther F had it gone into full series production to save on cost and to simplify production? Im going for the out-of-the-box lower hull (inset photograph) with the single 16 mm rear belly panel for an end of war vehicle.

This was also the same situation as above but for both the 16 mm chassis pannier panels on each side of the lower hull toward the end of the Panther G production run. I filled the separation between the pannier panels with super glue and applied a little accelerator with a micro brush to set up the super glue. The glue set up within a few minutes and I used a No. 16 curved edged X-Acto blade to slice off the glue as even with the surface of the plastic as I could get before sanding with both a course and medium grit foam filled sanding sticks. I then go over the finished area with a small piece of No. 0000 steel wool to blend the sanded area in with the rest of the surrounding area.

Each side of the kit supplied lower hull comes molded with the rear shock absorber mounting pinheads. The rear shock absorbers were dispensed with toward the end of the Panther G production run with only perhaps the Panther F prototype having them? Because the rear shock absorbers were not installed nor where the lower vertical side armor panels machined to accept for fitting of these parts I removed both the rear shock absorber pinheads on each side of the rear chassis. This is not mentioned on the kit instructions for building an early series production Panther F.

I also removed the kit molded half moon shaped inserts for the idler arms on each side of the lower hull as I will be using an aftermarket track link set and this will allow for free movement of the idler arms to adjust for track tensioning and sag.

All of the kit molded swing arm stop pegs on both sides of the lower hull were removed to allow me to adjust for a worn and weighted suspension. This is much better explained here on this link where Mike aka SdAufKla Roof, posted a reply detailing how he goes about getting the Panther suspension to sit and on the same page you will also find a link that Mike aka Kelley Land, posted that also covers this topic, both good reads with a lot of information on getting your kitty to sit. All of this is centered on the current Canfora Panther book, which is by the way an excellent read. If youre interested here is a link to a review about that Canfora Panther book.

With all of this rediscovered frenzy concerning the suspension attitude on the Panther I might just take my build a step further, before it begins to snowball as with most other fades (example - over chipping), and just go ahead and lower my Panther giving it that low and slow downtown Reseda ride with an eye-grabbing fiesta red primer paint job to top if off NOT!

Here Ive used the super glue to fill in the seams on both sides of the forward lower hull after installing the final drive housing armor guards. There are also three mold release pin marks on the edge of the armor guards that were also filled using the super glue. After sanding the super glue with the medium grit sanding stick it becomes almost completely transparent making it hard to see in the photograph. I like using super glue for filling sink marks and seam lines as it acts more like plastic and wont shrink when set. Just dont let it set up for more than a few hours or the glue will become harder than the plastic making sanding a chore.

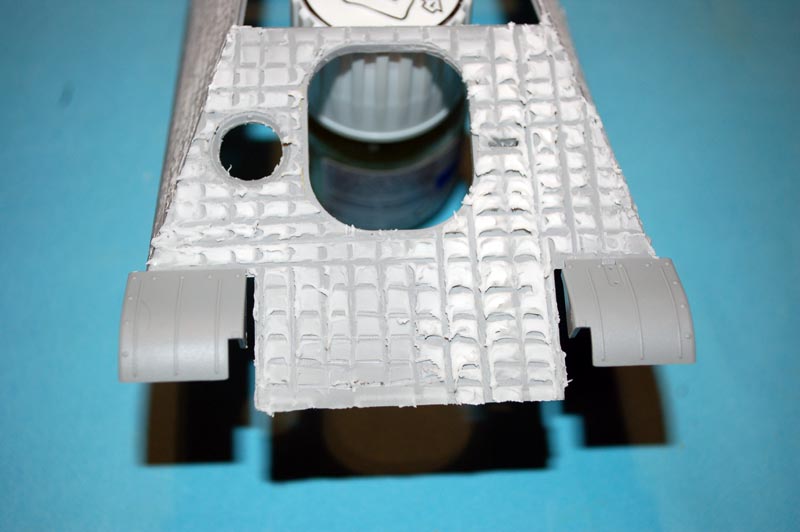

When I went to add the pannier panels to the lower hull I found that the forward part of the hull was slightly warped so I added two styrene tubes. The larger .250 (6.35 mm) diameter tube was used to even the width of the forward section of the hull with the rear and after the liquid cement had cured overnight I placed the second smaller .1875 (4.763 mm) diameter tube to adjust the very end of the hull extensions as both these sides were bowed further in.

Here you can see the kits molded flame cut lower hull armor side extensions. Toward the end of the war the Germans switched from machine cutting to flame cutting of parts to save on time and ease of production. Note the transparency of the super glue filler on the three release pin marks on the edge of the final drive armor guard.

I added the flame cut marks to the end of the lower portion of the side armor extensions where they mate up with the final drive housing armor guards as these where not molded on the kit.

I filled the gaps on both sides of the lower hull where the weld beads meet between the side extensions of the lower front armor bow plate using Squadrons white putty thinned with Testors liquid cement applied with a No. 2 paint brush. I thin the putty with the liquid cement until it becomes liquefied enough to easily have it flow from the brush into the gap after which I remove any excess with a clean brush dipped in the liquid cement.

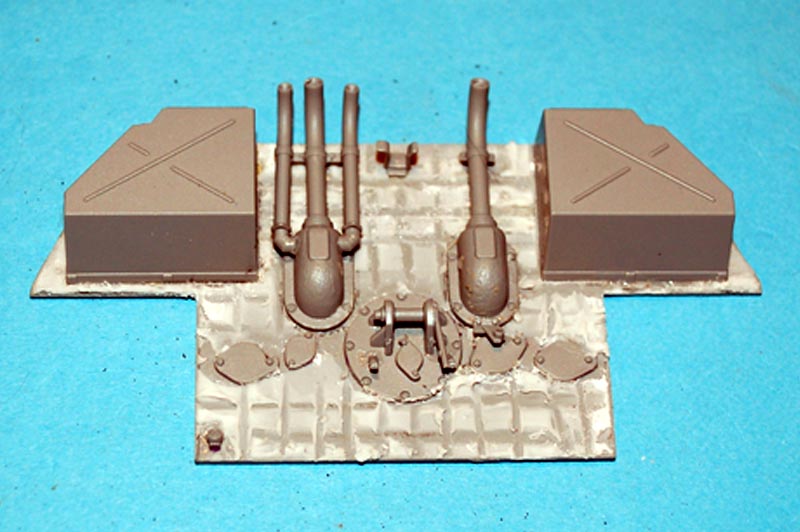

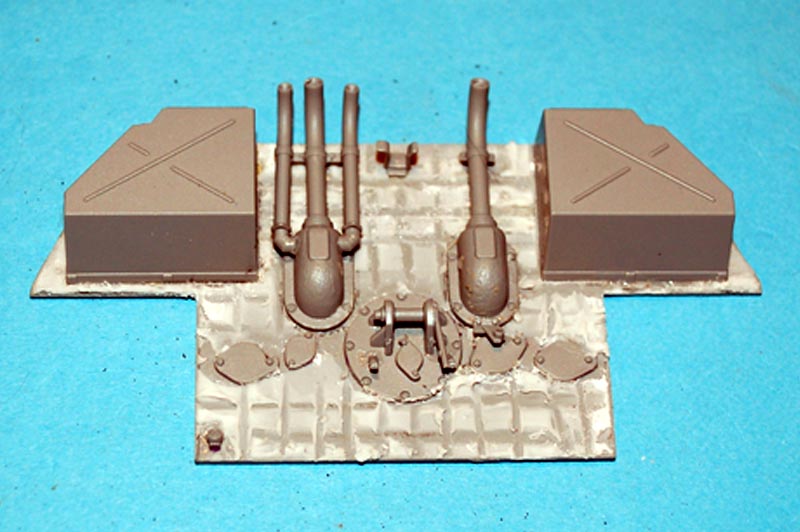

The kits rear horizontal armor plate before removal of the reflector and both storage bin-mounting brackets.

Here the rear armor plate has had the molded storage bin-mounting brackets and reflector removed along with the guide holes for the 20-ton jack mounting brackets plugged with stretched sprue. You can just faintly see where I drilled small shallow holes as guides for locating where the new photo-etched reflector and storage bin-mounting brackets are going to be fitted. I didnt drill the guide holes for the right side storage bin, as I will be changing it for an armor box for stowing the infrared sight equipment. For this I will need to add four separate mounting studs in that area.

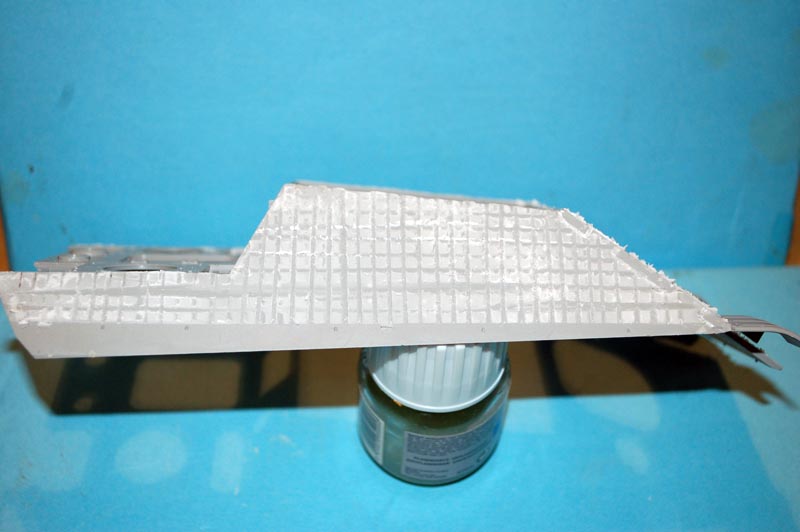

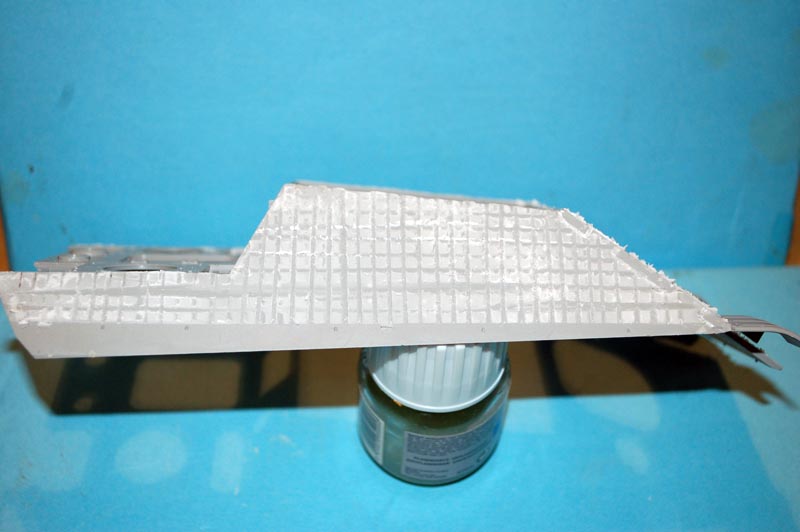

For whatever reason it may have been Dragon didn't include the flame cut grooves on the rear of the lower hull as this is quite present on some of my reference books. So using a small triangle file and extra course sanding stick I added the flame cut grooves to the ends of the rear extension sides. This was followed with a medium grit sanding stick to smooth the effect. A Scotch-Brite scouring pad was used to de-bur and slightly round out the edges.

A scribing tool was used to add relief to the engine access hatch as well as the armor cover for the starter penetration port, coolant heater, inertial starter, and track tension covers. A small hole was also drilled to the bottom of the armor guard for the electrical cable leading to the rear convoy taillight. I didnt do this for the bottom horizontal armor plate caps. Although it is hard to see in this photograph I applied Tamiyas extra thin liquid cement between the rear vertical armor plate and the bottom horizontal armor plate to soften the plastic and replicate a weld seam using a rounded edged micro metal tube.

The two locating holes on each pannier plate for the storage bin mounting brackets are now plugged with stretched sprue. The kit supplied storage bin brackets will be replaced with photo-etched pieces. Before I fill any of the holes with stretched sprue I add a shallow counter sink to the outside surface with a small sized drill bit to both allow room for the super glue and for the super glue to grab the sprue and assure a gapless free finish after sanding.

From the photographs on my references and Internet I noticed that the surface on the ends of the armor plates on the Panthers had gone from a smooth machine finish to a ruff and lumpy appearance on the later production batch of tanks produced toward the end of the war. The finish on some of the thicker armor plates are not consistent with flame cutting and I dont know how the Germans may have been cutting these thicker parts but I tried to replicate this on the top end of the rear vertical armor plate.

More coming soon.

@imatanker Jeff, My wife thinks that the tank looks like a person with a really small head and oversized butt! Jeff, in light of that comment, I think that you and I are both save with our translations.

@Itb073 Sal, you may not have all of the goodies for this build but it looks like youre having fun and youre almost complete with the assembly and paint. Youve done a good job of it so far . . . keep it coming!

Some builds have begun to roll in and things are just now beginning to happen here.

~ Eddy

Im enjoying the holidays here and I hope that many of you are too!

I build my kits from the inside out so I dont usually follow the instruction sheet build sequence and tend to bounce around a lot during the assembly. I go through the assembly instructions looking for where parts need to be added first so as not to have to go back and remove a part because another part needed to go there first. I usually wash the part sprue trees in warm soapy water follow by a blow dry before I start assembly but I find that the DML Dragon kits are mold release grease free so I skip this step and move on to the parts fitting before I start on the glue sniffing assembly parade.

Im a slow builder and as there are 14 months allocated for this campaign I can proceed with a step-by-step for this build and hope that at least someone will find some part of this crazy build process useful and inspirational.

According to my reference books for the Panther G there was a forward 25 mm panel followed by two 16 mm panels welded together forming the belly of the chassis near the start of production. This was also the case at the start of the Panther F production. A single 16 mm panel at the end of the Panther G production run later replaced the two-seperate 16 mm belly panels. Im just guessing here, as nothing is mentioned on any of my references, but this could have also been done for the Panther F had it gone into full series production to save on cost and to simplify production? Im going for the out-of-the-box lower hull (inset photograph) with the single 16 mm rear belly panel for an end of war vehicle.

This was also the same situation as above but for both the 16 mm chassis pannier panels on each side of the lower hull toward the end of the Panther G production run. I filled the separation between the pannier panels with super glue and applied a little accelerator with a micro brush to set up the super glue. The glue set up within a few minutes and I used a No. 16 curved edged X-Acto blade to slice off the glue as even with the surface of the plastic as I could get before sanding with both a course and medium grit foam filled sanding sticks. I then go over the finished area with a small piece of No. 0000 steel wool to blend the sanded area in with the rest of the surrounding area.

Each side of the kit supplied lower hull comes molded with the rear shock absorber mounting pinheads. The rear shock absorbers were dispensed with toward the end of the Panther G production run with only perhaps the Panther F prototype having them? Because the rear shock absorbers were not installed nor where the lower vertical side armor panels machined to accept for fitting of these parts I removed both the rear shock absorber pinheads on each side of the rear chassis. This is not mentioned on the kit instructions for building an early series production Panther F.

I also removed the kit molded half moon shaped inserts for the idler arms on each side of the lower hull as I will be using an aftermarket track link set and this will allow for free movement of the idler arms to adjust for track tensioning and sag.

All of the kit molded swing arm stop pegs on both sides of the lower hull were removed to allow me to adjust for a worn and weighted suspension. This is much better explained here on this link where Mike aka SdAufKla Roof, posted a reply detailing how he goes about getting the Panther suspension to sit and on the same page you will also find a link that Mike aka Kelley Land, posted that also covers this topic, both good reads with a lot of information on getting your kitty to sit. All of this is centered on the current Canfora Panther book, which is by the way an excellent read. If youre interested here is a link to a review about that Canfora Panther book.

With all of this rediscovered frenzy concerning the suspension attitude on the Panther I might just take my build a step further, before it begins to snowball as with most other fades (example - over chipping), and just go ahead and lower my Panther giving it that low and slow downtown Reseda ride with an eye-grabbing fiesta red primer paint job to top if off NOT!

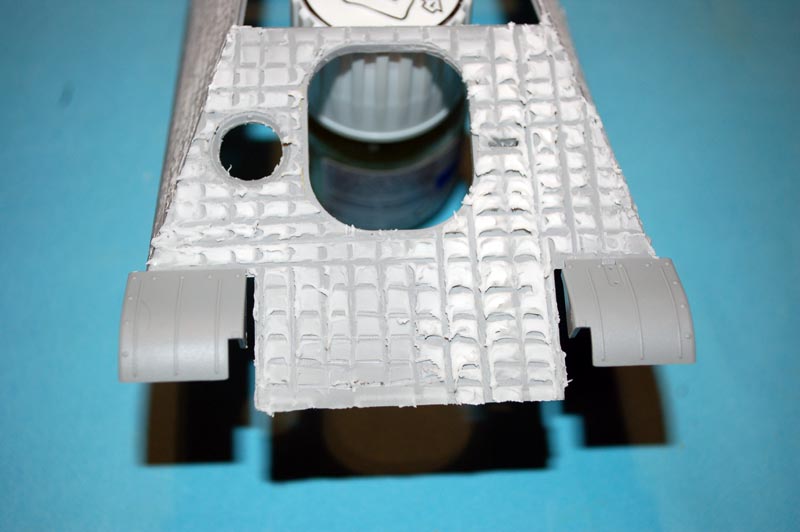

Here Ive used the super glue to fill in the seams on both sides of the forward lower hull after installing the final drive housing armor guards. There are also three mold release pin marks on the edge of the armor guards that were also filled using the super glue. After sanding the super glue with the medium grit sanding stick it becomes almost completely transparent making it hard to see in the photograph. I like using super glue for filling sink marks and seam lines as it acts more like plastic and wont shrink when set. Just dont let it set up for more than a few hours or the glue will become harder than the plastic making sanding a chore.

When I went to add the pannier panels to the lower hull I found that the forward part of the hull was slightly warped so I added two styrene tubes. The larger .250 (6.35 mm) diameter tube was used to even the width of the forward section of the hull with the rear and after the liquid cement had cured overnight I placed the second smaller .1875 (4.763 mm) diameter tube to adjust the very end of the hull extensions as both these sides were bowed further in.

Here you can see the kits molded flame cut lower hull armor side extensions. Toward the end of the war the Germans switched from machine cutting to flame cutting of parts to save on time and ease of production. Note the transparency of the super glue filler on the three release pin marks on the edge of the final drive armor guard.

I added the flame cut marks to the end of the lower portion of the side armor extensions where they mate up with the final drive housing armor guards as these where not molded on the kit.

I filled the gaps on both sides of the lower hull where the weld beads meet between the side extensions of the lower front armor bow plate using Squadrons white putty thinned with Testors liquid cement applied with a No. 2 paint brush. I thin the putty with the liquid cement until it becomes liquefied enough to easily have it flow from the brush into the gap after which I remove any excess with a clean brush dipped in the liquid cement.

The kits rear horizontal armor plate before removal of the reflector and both storage bin-mounting brackets.

Here the rear armor plate has had the molded storage bin-mounting brackets and reflector removed along with the guide holes for the 20-ton jack mounting brackets plugged with stretched sprue. You can just faintly see where I drilled small shallow holes as guides for locating where the new photo-etched reflector and storage bin-mounting brackets are going to be fitted. I didnt drill the guide holes for the right side storage bin, as I will be changing it for an armor box for stowing the infrared sight equipment. For this I will need to add four separate mounting studs in that area.

For whatever reason it may have been Dragon didn't include the flame cut grooves on the rear of the lower hull as this is quite present on some of my reference books. So using a small triangle file and extra course sanding stick I added the flame cut grooves to the ends of the rear extension sides. This was followed with a medium grit sanding stick to smooth the effect. A Scotch-Brite scouring pad was used to de-bur and slightly round out the edges.

A scribing tool was used to add relief to the engine access hatch as well as the armor cover for the starter penetration port, coolant heater, inertial starter, and track tension covers. A small hole was also drilled to the bottom of the armor guard for the electrical cable leading to the rear convoy taillight. I didnt do this for the bottom horizontal armor plate caps. Although it is hard to see in this photograph I applied Tamiyas extra thin liquid cement between the rear vertical armor plate and the bottom horizontal armor plate to soften the plastic and replicate a weld seam using a rounded edged micro metal tube.

The two locating holes on each pannier plate for the storage bin mounting brackets are now plugged with stretched sprue. The kit supplied storage bin brackets will be replaced with photo-etched pieces. Before I fill any of the holes with stretched sprue I add a shallow counter sink to the outside surface with a small sized drill bit to both allow room for the super glue and for the super glue to grab the sprue and assure a gapless free finish after sanding.

From the photographs on my references and Internet I noticed that the surface on the ends of the armor plates on the Panthers had gone from a smooth machine finish to a ruff and lumpy appearance on the later production batch of tanks produced toward the end of the war. The finish on some of the thicker armor plates are not consistent with flame cutting and I dont know how the Germans may have been cutting these thicker parts but I tried to replicate this on the top end of the rear vertical armor plate.

More coming soon.

@imatanker Jeff, My wife thinks that the tank looks like a person with a really small head and oversized butt! Jeff, in light of that comment, I think that you and I are both save with our translations.

@Itb073 Sal, you may not have all of the goodies for this build but it looks like youre having fun and youre almost complete with the assembly and paint. Youve done a good job of it so far . . . keep it coming!

Some builds have begun to roll in and things are just now beginning to happen here.

~ Eddy

PantherF

Joined: June 10, 2005

KitMaker: 6,188 posts

Armorama: 5,960 posts

Posted: Saturday, November 26, 2011 - 11:18 AM UTC

Tomorrow is officially "Panther Tank Build Day" for I have completed my honey do list and have the whole day to myself. In one corner of the workbench is the ever growing list of things I want to add to my 1/16 Panther G build, and in the opposite corner will be the start of my Panther Campaign build, which will go very fast since it's an OOB and not too many things to alter or scratch build ... other than the barrels which I plan to use brass tubing.

The earlier to bed the earlier the start!

Oh, and Braille ... your Panther build is going to be so detailed it may have the most pictures in the campaign!

~ Jeff

The earlier to bed the earlier the start!

Oh, and Braille ... your Panther build is going to be so detailed it may have the most pictures in the campaign!

~ Jeff

imatanker

Joined: February 11, 2011

KitMaker: 1,654 posts

Armorama: 1,565 posts

Posted: Sunday, November 27, 2011 - 12:30 AM UTC

Eddy,I,m building the same kit,but for another campaign.So I will be watching your build.I haven't even ordered my kit for this campaign yet  I need to finish "my" F first.It will be interesting to see if the hull on mine will be the same way.J.T.

I need to finish "my" F first.It will be interesting to see if the hull on mine will be the same way.J.T.

I need to finish "my" F first.It will be interesting to see if the hull on mine will be the same way.J.T.

I need to finish "my" F first.It will be interesting to see if the hull on mine will be the same way.J.T.

PantherF

Joined: June 10, 2005

KitMaker: 6,188 posts

Armorama: 5,960 posts

Posted: Sunday, November 27, 2011 - 03:56 AM UTC

Well, 2 hours in (no pics yet) and lots of things to fix. One, decided to go with the kits resin barrels because they are tapered. One was warped and hot water didn't do the trick so I reached for the hair dryer and then cooled it with cold running water. Also had to drill a pilot hole in each of the suppressors so the barrels would line up.

Went to check out the upper hull's turret hole (yep ... need to enlarge it) and found the hull really warped badly from being in the box for so long. Same treatment PLUS I have it now sitting with a rubber band holding it to the opposite direction of the warped bend.

Very, very few air bubbles and what little I did have I took care of with some thin CA ... which is what I used so far to assemble the barrels together and into the mantlet. Very little sanding with the kit and my impression with Accurate Armor is that they use quality material to pour with.

Gotta go make some lift rings now because I must have lost one of them and 2 resin and 1 metal ring won't look quite right.

~ Jeff

Went to check out the upper hull's turret hole (yep ... need to enlarge it) and found the hull really warped badly from being in the box for so long. Same treatment PLUS I have it now sitting with a rubber band holding it to the opposite direction of the warped bend.

Very, very few air bubbles and what little I did have I took care of with some thin CA ... which is what I used so far to assemble the barrels together and into the mantlet. Very little sanding with the kit and my impression with Accurate Armor is that they use quality material to pour with.

Gotta go make some lift rings now because I must have lost one of them and 2 resin and 1 metal ring won't look quite right.

~ Jeff

Posted: Monday, November 28, 2011 - 11:02 AM UTC

Eddie I would firstly like to thank you for doing in this campaign exactly what I envisaged, well done.

Now for my efforts thus far; I did remove and reapply the zimm on the rear plate and I include pictures of the upper hull zimm. One shows the zimm as it looks while I allow it to harden slightly and the other shows how it looks once I clean it up.

Now for my efforts thus far; I did remove and reapply the zimm on the rear plate and I include pictures of the upper hull zimm. One shows the zimm as it looks while I allow it to harden slightly and the other shows how it looks once I clean it up.

Tojo72

Joined: June 06, 2006

KitMaker: 4,691 posts

Armorama: 3,509 posts

Posted: Monday, November 28, 2011 - 12:33 PM UTC

I finished steps #7,8,+9 today involving the front and rear decks.The instructions want you to attach evey small part and tool and clamp to the upper hull BEFORE attaching the upper hull to the lower hull which is just asking for trouble in knocking off the little pieces while trying to attach upper to lower.So I glued the lower to upper as the 1st thing,after attaching the pieces that can't be acessed once the hull is closed,like the MG and some lens.Also you need to drill out the locating holes for the tool holders and fenders from the inside out because they are not real visable on the outside under the zimm.Next I will be attaching the fenders and tools,working on the turret,then finally the roadwheels.

Posted: Monday, November 28, 2011 - 02:26 PM UTC

Anthony I have a question; The rear buckled bin how are you going to hide the fact that it is solid?

Tojo72

Joined: June 06, 2006

KitMaker: 4,691 posts

Armorama: 3,509 posts

Posted: Monday, November 28, 2011 - 05:34 PM UTC

Quoted Text

Anthony I have a question; The rear buckled bin how are you going to hide the fact that it is solid?

It's not totally solid,it doesn't come to the top,too me I thought it was depicting something inside like a tarp or some rags.

Posted: Tuesday, November 29, 2011 - 02:00 AM UTC

That makes sense I was just interested in how you were going to cover up the solid area.

Posted: Thursday, December 01, 2011 - 12:29 PM UTC

Any one taking on the same Jagdpanther kit from DML as I should be aware that part N30 that attaches to the interior side bottom of the gun mantlet is about 2mm too wide and sanding is required to get a good joint. I will put up some pictures at a later date.

Panzercmdr

Joined: April 25, 2005

KitMaker: 110 posts

Armorama: 84 posts

Posted: Thursday, December 01, 2011 - 03:26 PM UTC

You guys can count me in! After a break from modeling for a while, I decided to get back into it when I saw the "Panther Campaign" and decided to build a second Panther this time a DML Sd.Kfz.171 Panther D and also to do this challenge with my dad:)

Posted: Thursday, December 01, 2011 - 03:44 PM UTC

Quoted Text

You guys can count me in! After a break from modeling for a while, I decided to get back into it when I saw the "Panther Campaign" and decided to build a second Panther this time a DML Sd.Kfz.171 Panther D and also to do this challenge with my dad:)

Welcome aboard and I hope you and your dad enjoy the campaign.

Serlone

Joined: February 23, 2011

KitMaker: 74 posts

Armorama: 68 posts

Posted: Thursday, December 01, 2011 - 05:50 PM UTC

hmmm... somehow managed to miss the requirement to take a picture after every step in the instructions

and the bad part about that is that i did quite a bit of building. But i'll do my best to atleast clarify what problems i encountered and what modifications i made during building.

The first part of the manual aint that much of a problem, making some wheels etc, making the backplate and adding stowageboxes and exausts. addin some details to the glacis plate etc etc so far not much problems and all pretty much straight forward.

but then you come to step 12. Here they tell you to attach the fenders to the upper hull

you could do this, but in my mind this would make your building a lot more complicated.

It's hard to see in the picture, but i dont have any better one atm, but there is a depression on the upperside of the fenders and a lip running allong the top outside of the lower hull, which you can see circled in red on the picture below

it's a lot easier, well i think it is , to attach the fenders to the lower hull and later attach the upper and lower. otherwise it might be dificult to manouver the top frontal armour in the correct place to line up with the lower frontal armor due to the lower hull lip, because wou will be restricted in your movement by the lip which is running pretty much the complete lenght of the lower hull tub and the spave you have to move around will be pretty limited.

, to attach the fenders to the lower hull and later attach the upper and lower. otherwise it might be dificult to manouver the top frontal armour in the correct place to line up with the lower frontal armor due to the lower hull lip, because wou will be restricted in your movement by the lip which is running pretty much the complete lenght of the lower hull tub and the spave you have to move around will be pretty limited.

hope this makes a bit of sense, otherwise i'll try to clarify it a bit further.

apart from this i didnt run into any trouble with the kit.

i did however have to make some slight modifications to it for the pe mesh screen, but this was limmited to removing some boltheads.

Getting the armorscale barrel and mantlet to fit was a slight bit more work

in step 20 they have you join pieces e23 and e24 to which the mantlet will attach in step 21. In the manual for the barrel they tell you to cut the front end of this piece as you can see below.

so i took out my trusty razorsaw, and started cutting dragon actually made this quite easy as they convienently put a slight ridge on the piece in the spot where you need to cut it. below i marked the spot to cut it in the picture with a red line, but when you have the piece in your hands its quite easy to detect in which spot you need to cut it.

apart from this i didnt make any modifications.

most major stuff is done atm and only some slight details and the schurzen need to be added. and i still need to build the track for one side.

below are some picture of how it is looking at the moment, sorry in advance for the crappy camera quality and lighting.

from now on i'll be sure to add a lot more updates, especially on the painting, as this will mostly be one big happy tour of discovery for me aswell

i had one picture form some earlier into the build.

and below this is how its looking at the moment.

edit:hmm the pics do look terrible i'll see if i can get some better ones soon.

and the bad part about that is that i did quite a bit of building. But i'll do my best to atleast clarify what problems i encountered and what modifications i made during building.

The first part of the manual aint that much of a problem, making some wheels etc, making the backplate and adding stowageboxes and exausts. addin some details to the glacis plate etc etc so far not much problems and all pretty much straight forward.

but then you come to step 12. Here they tell you to attach the fenders to the upper hull

you could do this, but in my mind this would make your building a lot more complicated.

It's hard to see in the picture, but i dont have any better one atm, but there is a depression on the upperside of the fenders and a lip running allong the top outside of the lower hull, which you can see circled in red on the picture below

it's a lot easier, well i think it is

, to attach the fenders to the lower hull and later attach the upper and lower. otherwise it might be dificult to manouver the top frontal armour in the correct place to line up with the lower frontal armor due to the lower hull lip, because wou will be restricted in your movement by the lip which is running pretty much the complete lenght of the lower hull tub and the spave you have to move around will be pretty limited.

, to attach the fenders to the lower hull and later attach the upper and lower. otherwise it might be dificult to manouver the top frontal armour in the correct place to line up with the lower frontal armor due to the lower hull lip, because wou will be restricted in your movement by the lip which is running pretty much the complete lenght of the lower hull tub and the spave you have to move around will be pretty limited.hope this makes a bit of sense, otherwise i'll try to clarify it a bit further.

apart from this i didnt run into any trouble with the kit.

i did however have to make some slight modifications to it for the pe mesh screen, but this was limmited to removing some boltheads.

Getting the armorscale barrel and mantlet to fit was a slight bit more work

in step 20 they have you join pieces e23 and e24 to which the mantlet will attach in step 21. In the manual for the barrel they tell you to cut the front end of this piece as you can see below.

so i took out my trusty razorsaw, and started cutting dragon actually made this quite easy as they convienently put a slight ridge on the piece in the spot where you need to cut it. below i marked the spot to cut it in the picture with a red line, but when you have the piece in your hands its quite easy to detect in which spot you need to cut it.

apart from this i didnt make any modifications.

most major stuff is done atm and only some slight details and the schurzen need to be added. and i still need to build the track for one side.

below are some picture of how it is looking at the moment, sorry in advance for the crappy camera quality and lighting.

from now on i'll be sure to add a lot more updates, especially on the painting, as this will mostly be one big happy tour of discovery for me aswell

i had one picture form some earlier into the build.

and below this is how its looking at the moment.

edit:hmm the pics do look terrible i'll see if i can get some better ones soon.

Posted: Thursday, December 01, 2011 - 06:22 PM UTC

The idea behind taking pictures after the various stages is so that someone checking the campaign now or in the future can see what problems are encountered and how to overcome them. Your build looks ok but it is difficult to tell due to the pictures and I look forward to some better ones.

Serlone

Joined: February 23, 2011

KitMaker: 74 posts

Armorama: 68 posts

Posted: Thursday, December 01, 2011 - 07:57 PM UTC

Yeah, the pics are pretty bad, i'll arange some other camera and try to get some decent pics during the weekend. I'll also try to find some pics to visualize the problem i had a bit more clearly.

Posted: Thursday, December 01, 2011 - 09:28 PM UTC

Quoted Text

Yeah, the pics are pretty bad, i'll arange some other camera and try to get some decent pics during the weekend. I'll also try to find some pics to visualize the problem i had a bit more clearly.

@Serlone Remco,

From your photographs could it be that you may just need to wipe the camera lens clean? Your photographs do not appear to be out of focus just a bit hazy and blurry.

~ Eddy

PantherF

Joined: June 10, 2005

KitMaker: 6,188 posts

Armorama: 5,960 posts

Posted: Thursday, December 01, 2011 - 10:27 PM UTC

Quoted Text

The idea behind taking pictures after the various stages is so that someone checking the campaign now or in the future can see what problems are encountered and how to overcome them. Your build looks ok but it is difficult to tell due to the pictures and I look forward to some better ones.

I too must admit that those requirements didn't occur to me until after I joined, thus delaying this build to some extent. I'm a streaky builder (when I get the time) and stopping to take pictures for every step will be daunting to say the least.

But, I should have read the fine print before I signed on the dotted line and will work hard to comply. It'll just be a slow, long haul ... something I'm not used to.

~ Jeff

Posted: Friday, December 02, 2011 - 03:27 AM UTC

Campaigners this is not a hard and fast rule about taking pictures at every stage, I just want this campaign to be as of much use as possible to someone reading it. It is my hope that with the number of paople taking part most of the currently available Panther chassis vehicles will be covered and the issues with the kits being solved in various ways answer the viewers questions.

This has the added benefit that some of the builds have the possibility to be turned into build features for the site.

This has the added benefit that some of the builds have the possibility to be turned into build features for the site.

PantherF

Joined: June 10, 2005

KitMaker: 6,188 posts

Armorama: 5,960 posts

Posted: Friday, December 02, 2011 - 12:41 PM UTC

Quoted Text

This has the added benefit that some of the builds have the possibility to be turned into build features for the site.

Now THAT should have been clear in the beginning.

But don't worry, I'm not going to bail. I have way too much planned for this build and still need to get 'them' out of the box anyway.

~ Jeff

Posted: Sunday, December 04, 2011 - 01:42 PM UTC

Panthoholics,

Im back with a small update.

I filled the guide holes using super glue for the bump stops with Bellevue washers (E14) over both the 7th left and 8th right swing arm stations. This view is over the 8th swing arm station on the right side of the lower hulls horizontal 40 mm armor plate. Apparently the rear bump stops, like the rear shock absorbers, had also been discarded by at least one of the manufactures. For whatever reason these bump stops were not installed is unknown to me, but they were dropped on some late production Ausf. G Panthers. It would stand to reason that by the time the Panther F had gone into full series production that perhaps these bump stops would no longer have been installed, so Ive chosen to delete these parts from my build.

While I was filling the guide holes for the bump stops, in the same general location, I also filled the bottom guide holes for the track pin return plates (A20) on both sides of the hull as I will be using the WWII productions cast resin replacements.

Now it was time to add a small amount of texture to the lower hulls 40 mm armor plates. Generally these plates were smooth with some areas exhibiting a light amount of porosity but as the limited supplies of alloy materials dwindled the German steelmakers found themselves having to use very low quality alloy armor. This presented very real problems that could not be properly addressed or eradicated during the war. The armor plates had gone to being ruff, porous and grainy and easily cracking with partial failing of weld joints under the impact of allied anti-tank guns. For the most part German tank armor quality remained quit high and it wasnt until the total collapse of the war in 1945 where the system really suffered and broke down.

With an old worn paintbrush I lightly stippled on Mr. Surfacer 500 to replicate the armor texture as seen late in the war on some of my reference books. I then knocked down the harshness of the Surfacer 500 with a light sanding using medium grit sanding stick and fine steel wool.

And a shot of the 40 mm horizontal rear armor plate.

I used the suspension components as outlined in the kit instructions suspension guideline for building a late production Panther F on the forward area of the lower hull. A Verlinden Productions cast resin bolt head was used for the final drive housings oil drain plug and I also added the screw head detail as per my references. I had damaged both circular stops on both the bump stops that sit above the 1st swing arm stations during removal from the sprue tree so using a punch and die set I replaced them with .010 (0.254 mm) thick sheet styrene. I also removed the molded on bump stops on the lower hull to match the replaced bump stops.

These are the WWII Productions dimensions given for placing the cast resin track pin return plates on the kit. These track pin return plates are included with the cast resin six-chevron track set. I used them because they come molded with a weld bead along the contact areas of the return plates and appear to be in scale thickness. The dimensions given for placing the cast resin track pin return plates fall exactly where the kit-supplied parts would be attached.

Because Im using an aftermarket track link set I will need to be able to adjust the idler wheel clocking for adjustment of the tracks sag. Im sure there may be better and easier ways of going about this business but this is how I went about it with the supplies that I have on hand.

I first cut a couple of 1 (25.4 mm) lengths of .156 (3.962 mm) diameter styrene solid rod using an X-Acto miter cutter. I found that this diameter styrene solid rod gave me the best match for the kits idler swing arm housing axle shafts. I found a brass tube in my parts stash that had the right inside diameter that would support the axles and it just happen to be 1 (25.4 mm) long. I then had to ream out the idler arms housing on the lower hull with a No.19 drill bit held in a pinvise to provide clearance for the styrene solid rods. After fiddling around with the parts to see how they could be placed on the lower hull to support the styrene solid rods I was able to match up a .156 (3.962 mm) I-Beam with a .020 thick piece of sheet styrene. I then cut these pieces to match the width of the brass tube.

Here Ive already cut off the larger housing axle arm shafts with my J&S razor saw and then placed the smaller idler wheel axle shafts inside of a styrene tube in order to keep them aligned at 90 to true them using the Miter Sander.

Using a long length of the same diameter styrene solid rod for the replacement axle housing shafts as a fixture for fitting the I-Beam, sheet styrene and brass tube against the inside of the lower hulls horizontal rear armor plate. I proceeded to cemented the I-Beam and sheet styrene together. After removing the parts from the lower hull I mixed a small amount of 5-minute epoxy on a sticky note sheet and applied the mixture between the I-Beam and brass tube and added a few extra beads of the mixture between the outside surfaces for added strength. After the mixture had set up I again used the same fixture rod to keep the assembly aligned and true and cemented the completed assembly against the inside of the lower hulls horizontal rear armor plate.

Here both 1 (25.4 mm) diameter styrene solid rod ends and the kits idler arm ends have been center drilled with a No. 61 .039 (0.990 mm) drill bit to press fit a .040 (1.016 mm) styrene solid rod thus making the cemented bond between the axle shaft and axle arm very strong.

I then drilled several holes in a 060 (1.524 mm) styrene sheet using a No.21 drill bit. I then removed the drilled holes from the styrene sheet using a punch and die set. I selected a punch that would provide a small enough diameter to remove the holes from the styrene sheet yet keep the diameter of the parts small enough from interfering with the lower hull and cracking from being press fit to each of the axle housing shafts. I then press fit the styrene donuts to the axle housing shafts and slide them against the inside hull while keeping the axle shafts against the outside axle housing. This would keep both idler axles snug against there respective lower hulls axle housing and from sliding away. I then cemented the press fit styrene donuts only to the idler axle shafts and not to the lower hulls inside walls in order to be able to rotate the axle arms for track adjustment. The axle housing shafts do not come in contact with each other within the brass tube and can be rotated independently of each other. I hope that the photographs explain this better than I can?

This is as far as I have gotten to date. Next comes the lowering of the chassis via the suspension swing arms as per the links I had provided earlier in my posting.

@PantherF Jeff, yes my build is rather photo intense and very time consuming. Im trying to keep the file sizes down for those viewers still on dial-up!

@imatanker Jeff, your welcome to follow along but I must worn you that I am a slow builder. Had the Panther F gone into full series production the lower hull may have incorporated many of the same components / modifications that I am depicting on my build. The easy answer is there is no easy answer the Panther F never had the chance to go into full series production the war ended that. Thank goodness! The Germans were building some incredible heavy-duty stuff in comparison to the death traps that the allies had.

@CMOT Darren, thanks for the cheers. It is really time consuming and slows down the build but I hope this will be of help to those interested so Im enjoying it and that is what matters most. You and Art aka MSGsummit have some interesting Zimmerit happening!

I may not have commented on some of the ongoing builds here, but Im watching and enjoying so keep them coming!

Thanks for stopping by and having a look, see you soon,

~ Eddy

Im back with a small update.

I filled the guide holes using super glue for the bump stops with Bellevue washers (E14) over both the 7th left and 8th right swing arm stations. This view is over the 8th swing arm station on the right side of the lower hulls horizontal 40 mm armor plate. Apparently the rear bump stops, like the rear shock absorbers, had also been discarded by at least one of the manufactures. For whatever reason these bump stops were not installed is unknown to me, but they were dropped on some late production Ausf. G Panthers. It would stand to reason that by the time the Panther F had gone into full series production that perhaps these bump stops would no longer have been installed, so Ive chosen to delete these parts from my build.

While I was filling the guide holes for the bump stops, in the same general location, I also filled the bottom guide holes for the track pin return plates (A20) on both sides of the hull as I will be using the WWII productions cast resin replacements.

Now it was time to add a small amount of texture to the lower hulls 40 mm armor plates. Generally these plates were smooth with some areas exhibiting a light amount of porosity but as the limited supplies of alloy materials dwindled the German steelmakers found themselves having to use very low quality alloy armor. This presented very real problems that could not be properly addressed or eradicated during the war. The armor plates had gone to being ruff, porous and grainy and easily cracking with partial failing of weld joints under the impact of allied anti-tank guns. For the most part German tank armor quality remained quit high and it wasnt until the total collapse of the war in 1945 where the system really suffered and broke down.

With an old worn paintbrush I lightly stippled on Mr. Surfacer 500 to replicate the armor texture as seen late in the war on some of my reference books. I then knocked down the harshness of the Surfacer 500 with a light sanding using medium grit sanding stick and fine steel wool.

And a shot of the 40 mm horizontal rear armor plate.

I used the suspension components as outlined in the kit instructions suspension guideline for building a late production Panther F on the forward area of the lower hull. A Verlinden Productions cast resin bolt head was used for the final drive housings oil drain plug and I also added the screw head detail as per my references. I had damaged both circular stops on both the bump stops that sit above the 1st swing arm stations during removal from the sprue tree so using a punch and die set I replaced them with .010 (0.254 mm) thick sheet styrene. I also removed the molded on bump stops on the lower hull to match the replaced bump stops.

These are the WWII Productions dimensions given for placing the cast resin track pin return plates on the kit. These track pin return plates are included with the cast resin six-chevron track set. I used them because they come molded with a weld bead along the contact areas of the return plates and appear to be in scale thickness. The dimensions given for placing the cast resin track pin return plates fall exactly where the kit-supplied parts would be attached.

Because Im using an aftermarket track link set I will need to be able to adjust the idler wheel clocking for adjustment of the tracks sag. Im sure there may be better and easier ways of going about this business but this is how I went about it with the supplies that I have on hand.

I first cut a couple of 1 (25.4 mm) lengths of .156 (3.962 mm) diameter styrene solid rod using an X-Acto miter cutter. I found that this diameter styrene solid rod gave me the best match for the kits idler swing arm housing axle shafts. I found a brass tube in my parts stash that had the right inside diameter that would support the axles and it just happen to be 1 (25.4 mm) long. I then had to ream out the idler arms housing on the lower hull with a No.19 drill bit held in a pinvise to provide clearance for the styrene solid rods. After fiddling around with the parts to see how they could be placed on the lower hull to support the styrene solid rods I was able to match up a .156 (3.962 mm) I-Beam with a .020 thick piece of sheet styrene. I then cut these pieces to match the width of the brass tube.

Here Ive already cut off the larger housing axle arm shafts with my J&S razor saw and then placed the smaller idler wheel axle shafts inside of a styrene tube in order to keep them aligned at 90 to true them using the Miter Sander.

Using a long length of the same diameter styrene solid rod for the replacement axle housing shafts as a fixture for fitting the I-Beam, sheet styrene and brass tube against the inside of the lower hulls horizontal rear armor plate. I proceeded to cemented the I-Beam and sheet styrene together. After removing the parts from the lower hull I mixed a small amount of 5-minute epoxy on a sticky note sheet and applied the mixture between the I-Beam and brass tube and added a few extra beads of the mixture between the outside surfaces for added strength. After the mixture had set up I again used the same fixture rod to keep the assembly aligned and true and cemented the completed assembly against the inside of the lower hulls horizontal rear armor plate.

Here both 1 (25.4 mm) diameter styrene solid rod ends and the kits idler arm ends have been center drilled with a No. 61 .039 (0.990 mm) drill bit to press fit a .040 (1.016 mm) styrene solid rod thus making the cemented bond between the axle shaft and axle arm very strong.

I then drilled several holes in a 060 (1.524 mm) styrene sheet using a No.21 drill bit. I then removed the drilled holes from the styrene sheet using a punch and die set. I selected a punch that would provide a small enough diameter to remove the holes from the styrene sheet yet keep the diameter of the parts small enough from interfering with the lower hull and cracking from being press fit to each of the axle housing shafts. I then press fit the styrene donuts to the axle housing shafts and slide them against the inside hull while keeping the axle shafts against the outside axle housing. This would keep both idler axles snug against there respective lower hulls axle housing and from sliding away. I then cemented the press fit styrene donuts only to the idler axle shafts and not to the lower hulls inside walls in order to be able to rotate the axle arms for track adjustment. The axle housing shafts do not come in contact with each other within the brass tube and can be rotated independently of each other. I hope that the photographs explain this better than I can?

This is as far as I have gotten to date. Next comes the lowering of the chassis via the suspension swing arms as per the links I had provided earlier in my posting.

@PantherF Jeff, yes my build is rather photo intense and very time consuming. Im trying to keep the file sizes down for those viewers still on dial-up!

@imatanker Jeff, your welcome to follow along but I must worn you that I am a slow builder. Had the Panther F gone into full series production the lower hull may have incorporated many of the same components / modifications that I am depicting on my build. The easy answer is there is no easy answer the Panther F never had the chance to go into full series production the war ended that. Thank goodness! The Germans were building some incredible heavy-duty stuff in comparison to the death traps that the allies had.

@CMOT Darren, thanks for the cheers. It is really time consuming and slows down the build but I hope this will be of help to those interested so Im enjoying it and that is what matters most. You and Art aka MSGsummit have some interesting Zimmerit happening!

I may not have commented on some of the ongoing builds here, but Im watching and enjoying so keep them coming!

Thanks for stopping by and having a look, see you soon,

~ Eddy

PantherF

Joined: June 10, 2005

KitMaker: 6,188 posts

Armorama: 5,960 posts

Posted: Sunday, December 04, 2011 - 03:59 PM UTC

"death traps that the allies had"

If you're referring to the thin armor the Allies had, if the war was in the USA then the Axis would have had to build armor thin as well. The native battleground allowed the Germans to build crawling fortress's in comparison to what the Allies could get across the ocean.

Besides, the Allies won with that approach of mass producing one design where the Axis lost so much precious time and resources trying to build that wonder weapon.

JMHO

(nice pictures btw)

~ Jeff

If you're referring to the thin armor the Allies had, if the war was in the USA then the Axis would have had to build armor thin as well. The native battleground allowed the Germans to build crawling fortress's in comparison to what the Allies could get across the ocean.

Besides, the Allies won with that approach of mass producing one design where the Axis lost so much precious time and resources trying to build that wonder weapon.

JMHO

(nice pictures btw)

~ Jeff

Tojo72

Joined: June 06, 2006

KitMaker: 4,691 posts

Armorama: 3,509 posts

Posted: Monday, December 05, 2011 - 03:29 AM UTC

These pics represent steps # 12-16 construction of the gun and turret.I skipped past the hull just to break things up a bit.Just some notes:There are no markings for the metal track hangers,I just used a link of track as a template to place the hooks.I may installed the pistol port backwards,so watch that.Any questions or tip,let me know.After this back to the tools and fenders on the hull.

Posted: Monday, December 05, 2011 - 04:33 AM UTC

Quoted Text

Quoted TextThis has the added benefit that some of the builds have the possibility to be turned into build features for the site.

Now THAT should have been clear in the beginning.

But don't worry, I'm not going to bail. I have way too much planned for this build and still need to get 'them' out of the box anyway.

~ Jeff

Jeff in the campaign sign in area I did include a part about build features, I am sorry if I was not clear enough. The main reason I wanted to take this approach to the campaign was in order that it could become a one stop problem guide for panther chassis vehicles released to date.

Posted: Monday, December 05, 2011 - 04:34 AM UTC

That looks a very nice clean start to your build Anthony.

|