Finally the trout fishing season has started and I started it well. I am very happy for the catches I made with the fly-fishing (I practical the "catch and release") but the effort was very tough because I'm out of form.

So, now for a while I have to take me back from the fatigue of going to the mountain streams - soon I will be 57 years old and I make more effort to recover, unfortunately ... - and so in these days have dedicated myself to modeling.

In these days so I completed it some internal details of my Bergepanzer.

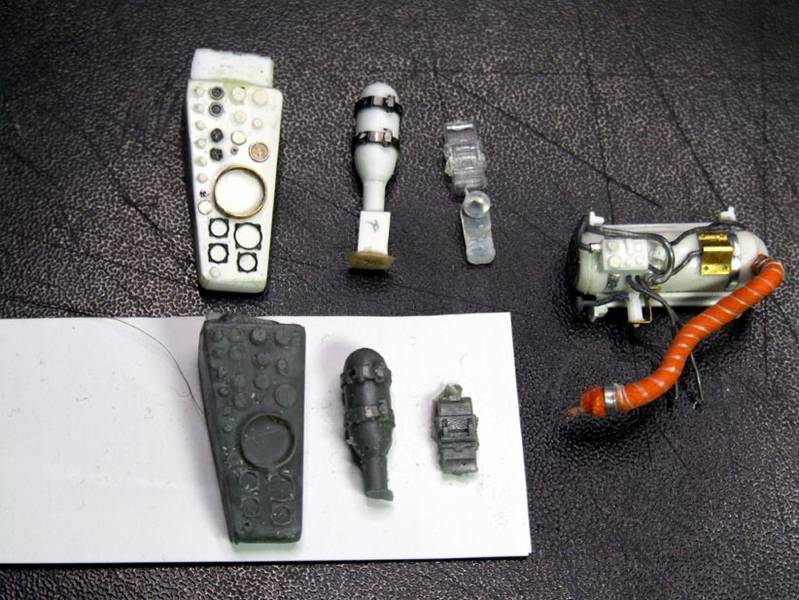

In particular, starting from the left and above, I constructed the bulkhead near the left hatch, the box of the inspection unit for the main winch cable, the box of the anti-NBC unit to air filtering, the rear storage basket, the sling to lift the engine and the mechanism of the hydraulic winch.

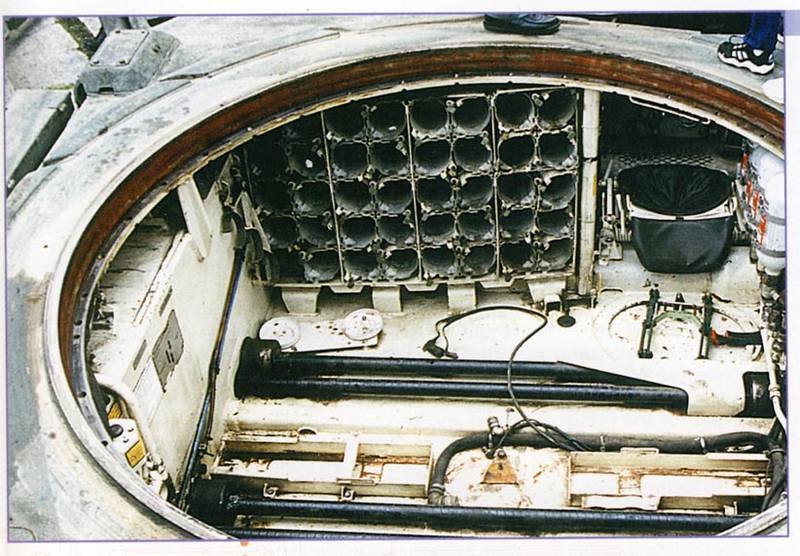

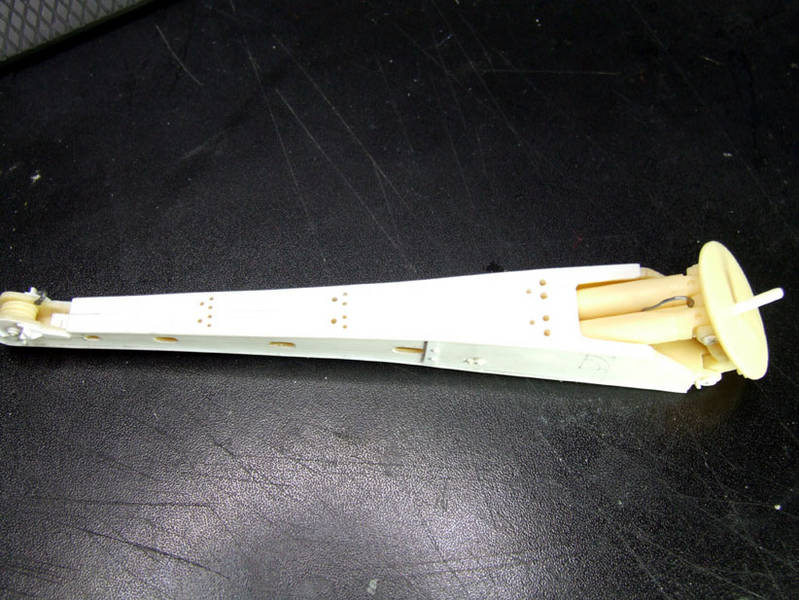

This is one of the photos that I used to build my model of the sling to lift the motor.

Unfortunately, I have no designs or patterns clearer of it, so I had to do a sketch and then I used this and other images to compare it the size and shape.

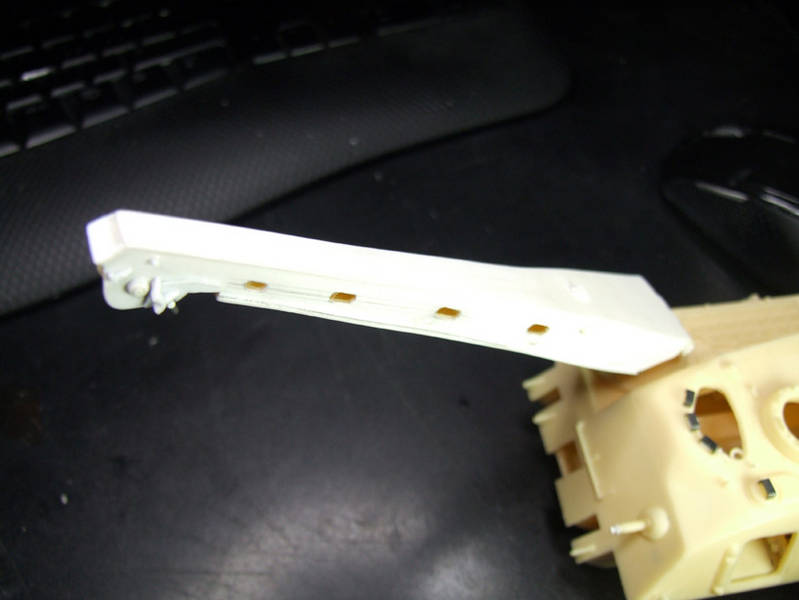

Eventually, after many attempts, I got a good result for me.

The sling is entirely scratch built with profiles and strips of Plasticard and Evergreen.

Bolts and pins were made with a punch & die, exagonal and cylindric.

Instead of using the traditional methods, the welds were made using a cyanoacrylic glue very liquid on which I poured a little of artificial snow crystals in micro-spheres of Kallamity.

I have also improved the sheave of the winch lifting, remaking any parts and pivots original damaged and completing it with some few bolts missing.

To reproduce some parts, I used some photoetched scraps, modified accordingly.

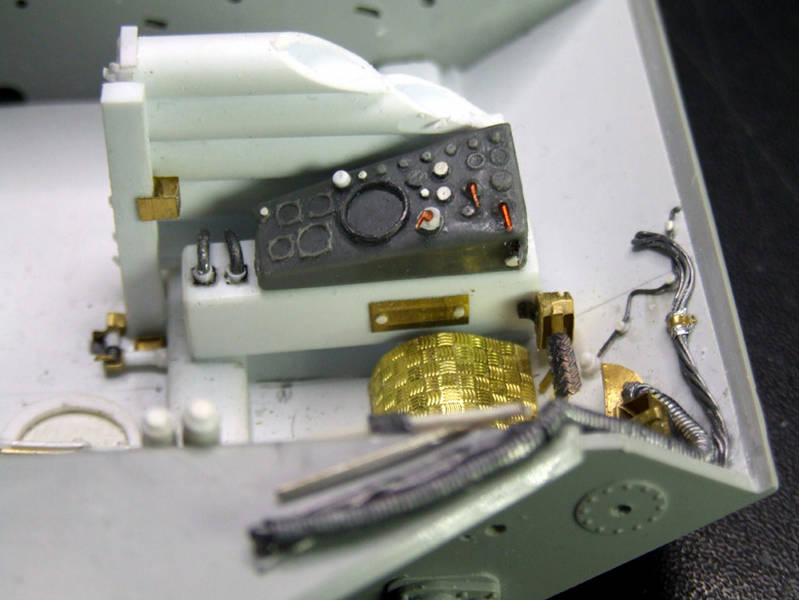

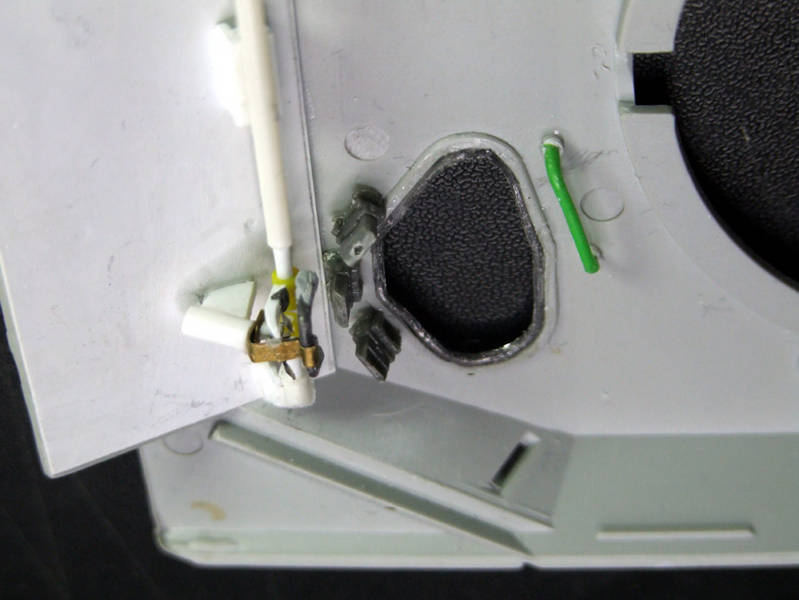

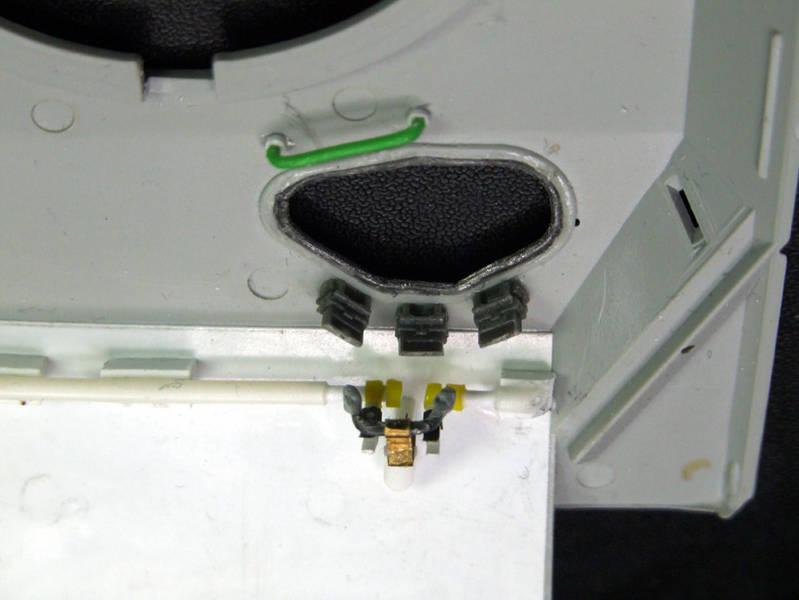

This is the photo of the inner box of the ventilation anti-NBC system (it's the big box on top, tilted forward because it's welded to the rear wall of the tank's armor).

You may notice the two large twin pumps for air and the relay box.

The perspective distorts the part in the picture, but I have carefully measured its size and shape, referring to those of the real part of the system outside the shell.

I etched the central hatch with an engraver and a template, while the cables and tubes are made as usual with the lead's wire.

The piece will be completed at the end with some cloth bags that contained tools (these have yet to get them ...).

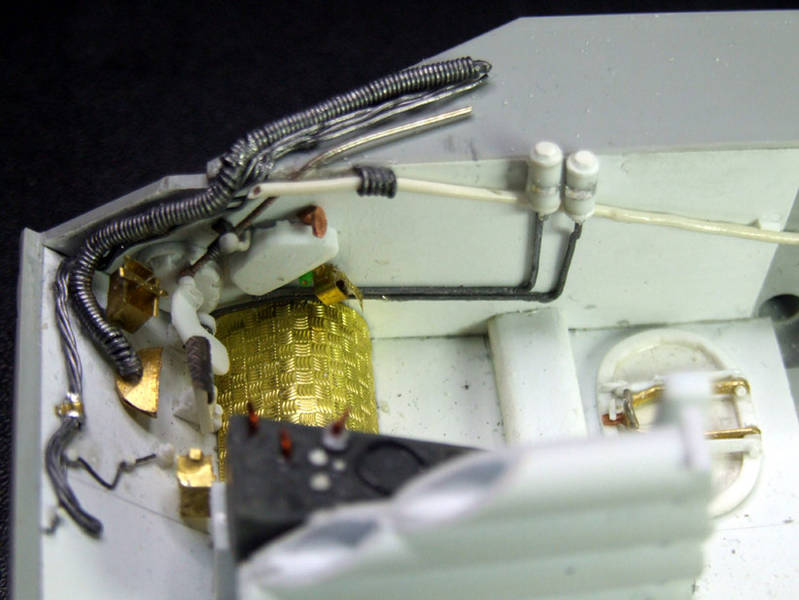

This is a picture of the winch mechanism that you can see, partially, through of the left hatch of the bulkhead of the tank... unfortunately...

This is the design of the overall...

... this is the scheme of the mechanism.

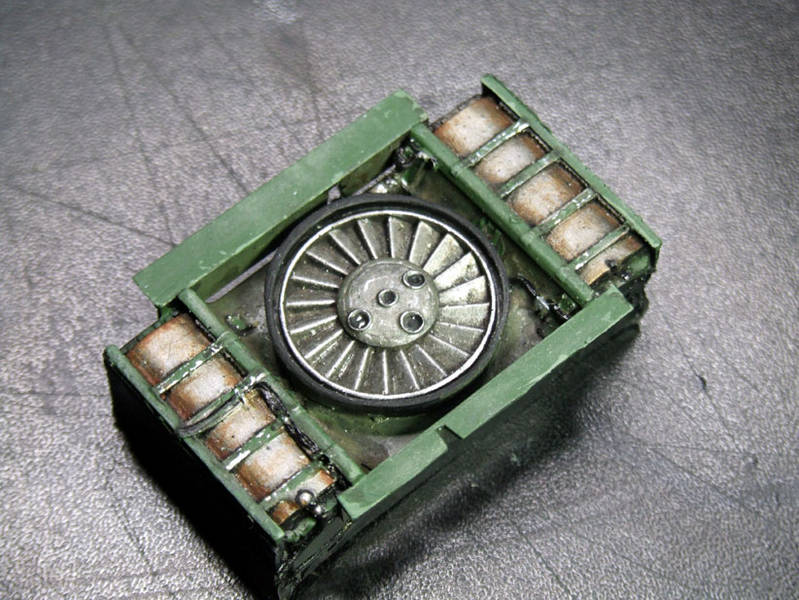

... and here is the corresponding piece that I realized with the usual materials.

In addition to homemade parts, I also used some resin pieces taken from my bank of scrap pieces (a roller, that I excavated, for the wheel of the cable's reel, and a wheel's hub for the hydraulic engine).

I built the conic gear with a disc of resin to which I gave the conical shape with a little file, and then I engraved it with the blade of a small saw mounted on a mini-drill.

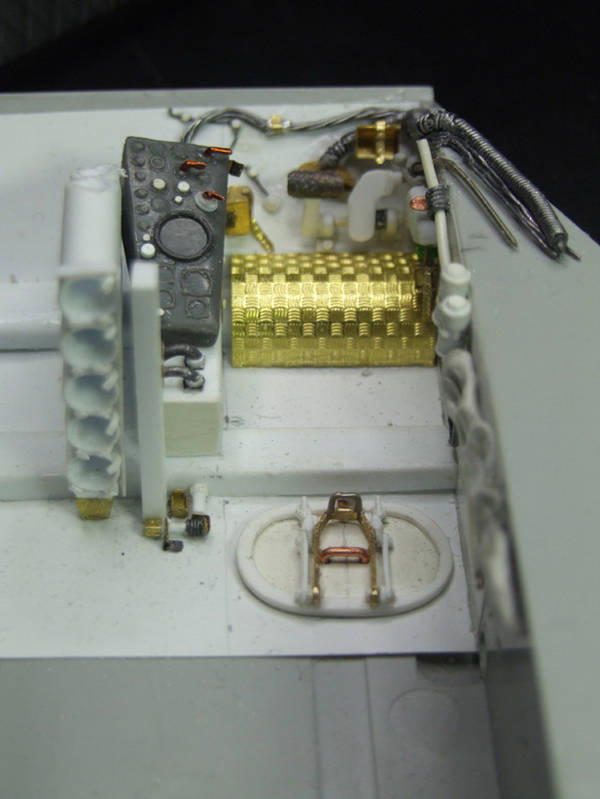

This is the photo of what you can see through the hatch that I'm going to leave open ... (there is really a lot of pieces to do... damn it!)

In the background, behind the orange corrugated pipe of the heating system, you can see the box of the inspection system of the cables of the main winch.

The piece that I obtained, using the usual profiles and some photo-etched pieces properly adapted.

In fact, there are some differences from reality but I hope that, from afar, you don't they note too much ...

This is the photo of the rear storage basket.

A piece pretty easy to fix or redo.

In fact, the original piece was incorrect because the walls were crooked, the tube was damaged and the wire mesh bottom was unrealistic, so I have corrected its flaws.

I straightened the walls of the workpiece by heating them, I replaced all the tube with a copper wire of suitable diameter and I cut away the underlying net and I replaced it with a net cropped and shaped from an photoetched piece.

Later, I'll finish it with the hinges, the two straps, the locking hook to the armor and the two small boxes that are seen on its surface.

But now it's time that I resume the work on my Leopard, otherwise I'll be back too.

At the next time ...

Cheers - Gianfranco

The first of Tamiya's R/C tanks I built waaaayyyy back in 1970 or so was the Leo I. I still have the screen-covered engine deck somewhere