this is my first post on Armorama (sorry for my basic English, but I studied French and Spanish in school and after... ;-)))

I am an Officer in the Italian Army and have just gone to the reserves after 37 years of active service.

So now that I'm retired, I started doing modeling seriously, that was a hobby that I never left.

For over 11 years, from 1979 to 1990, I commanded a company of tanks Leopard 1A2, and this beautiful tank has always remained in my heart (the first love is never forgotten!).

After thinking of building your own template for my tank, and after seeing some of my photos and others taken from the WEB, I thought to reconstruct an incident that happened to me many years ago when I was in training camp with my soldiers.

(This is an old picture of my tank. It is recognized that it is a tank for Commander platoon / company because it has the two antennas of the radio system RV4 213-V, consisting of a transceiver apparatus and an auxiliary receiver apparatus, while the other tanks of the platoon have only one transceiver apparatus RV3 13-V, and therefore only one antenna.

This photograph was taken during a training exercise at the Polygon Training of Cascina Pelato, near Biella (Vercelli).)

Basically, when I and my company finished the transfer of the column of 18 tanks from the barracks to the camp, in the engine of my tank - my own! - a sleeve of the cooling system broke and so my mechanic had to step over the entire engine to replace the broken piece.

I therefore decided to build a small diorama with models of Bergepanzer driven by my mechanic, which raises the engine of my tank to replace the broken piece, just like in the picture I found on the WEB.

(This is the picture I took from the Web and that it recalled me the incident that happened in 1986. From this picture I took the inspiration for realize my diorama.)

I therefore decided to build a small diorama with models of Bergepanzer, driven by my mechanic, which raises the engine of my tank to replace the broken piece, just like in the picture I found on the WEB.

Late last year I have therefore taken from my reserve of kit boxes, the kit of the Italeri Leopard 1A5 (catalog No. 6481) and I started to modify it to do again become a 1A2, since could not find the model of this version, this one produced by Italeri (catalog No. 374), that the factory realized a few years ago.

To properly play the scene, it was necessary to remove the top plate that covers the engine compartment or completely rebuild the interior ... my first serious scratch-built construction, which I started only after I have collected and cataloged all the images of the parts to build (about 2,000 images) through an in-depth research and by having the user's manual.

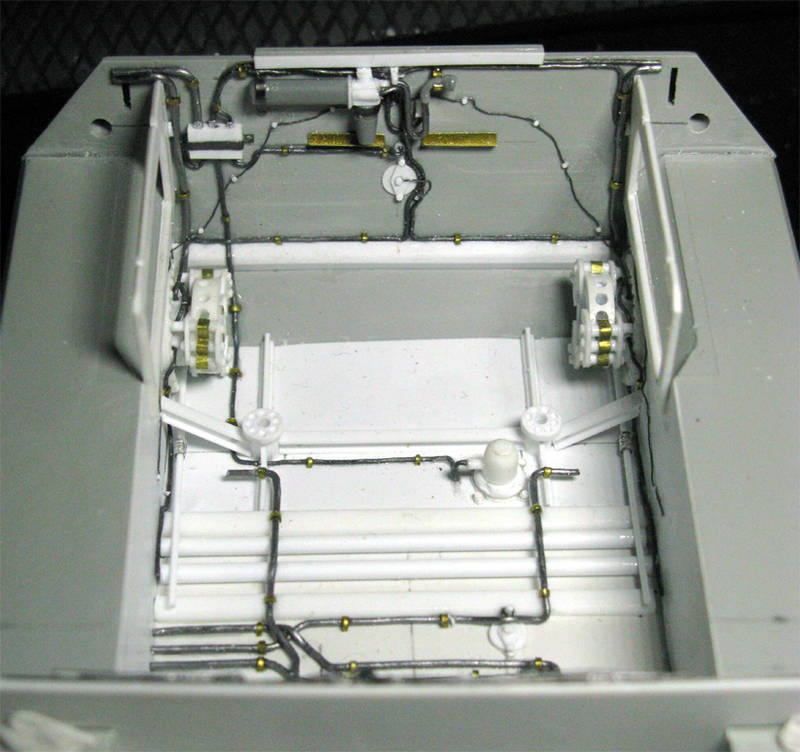

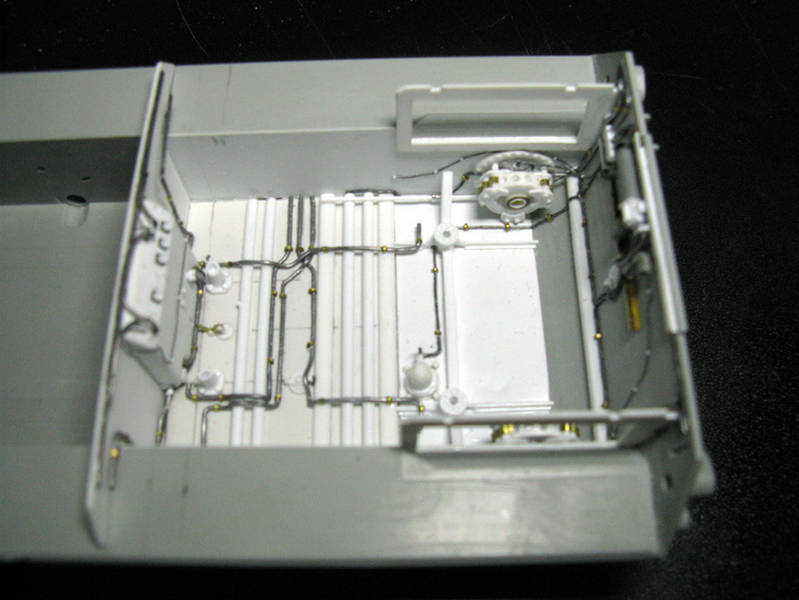

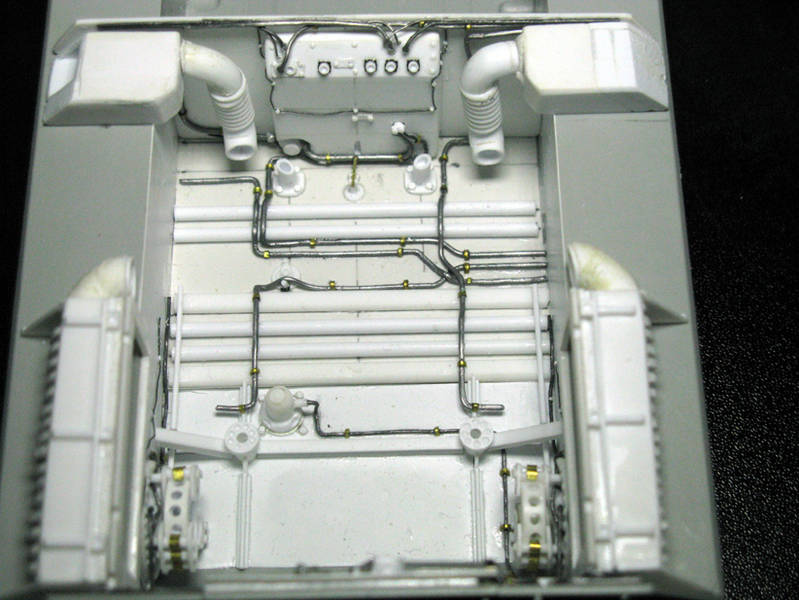

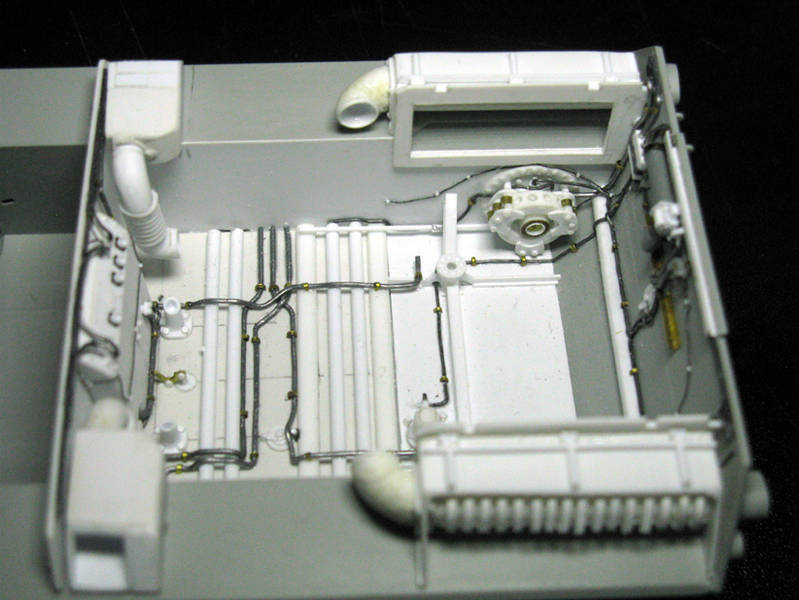

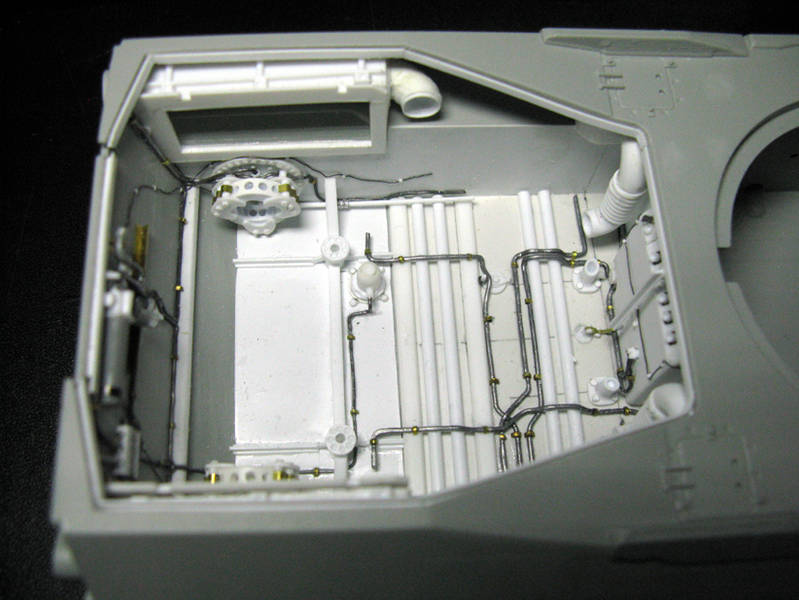

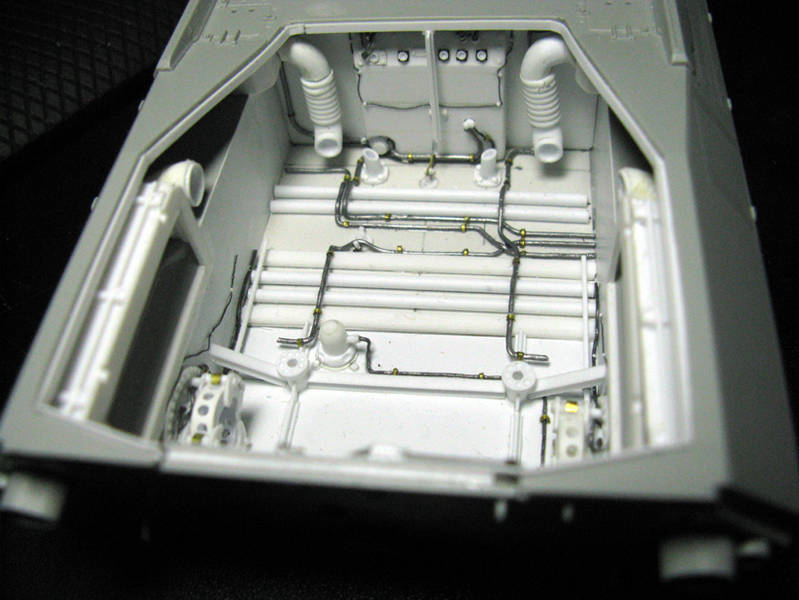

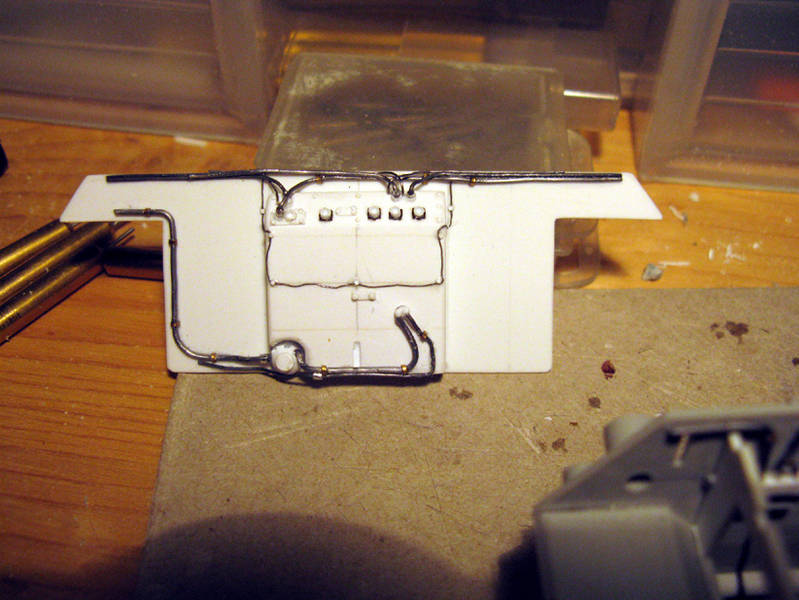

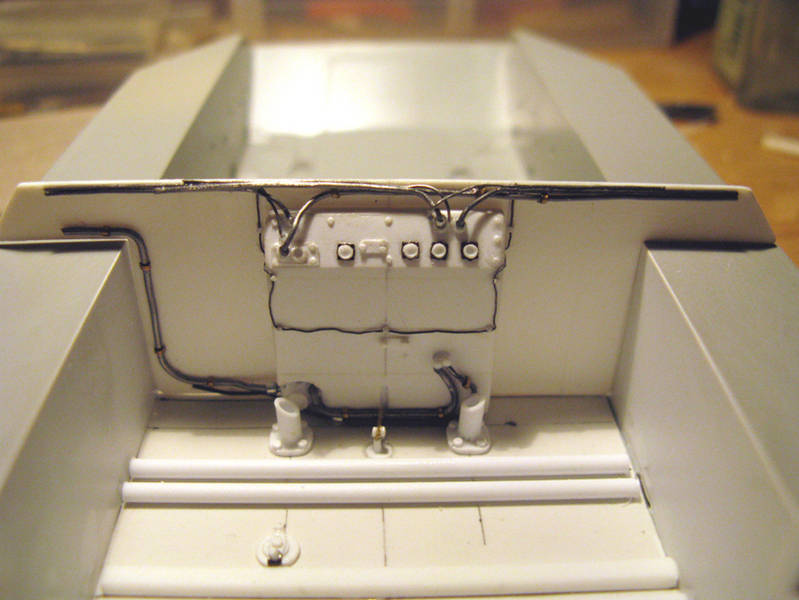

These are some pictures of my work.

As you proceed in the work, I'll post more pictures for your comments and suggestions.

I hope you will like my work.

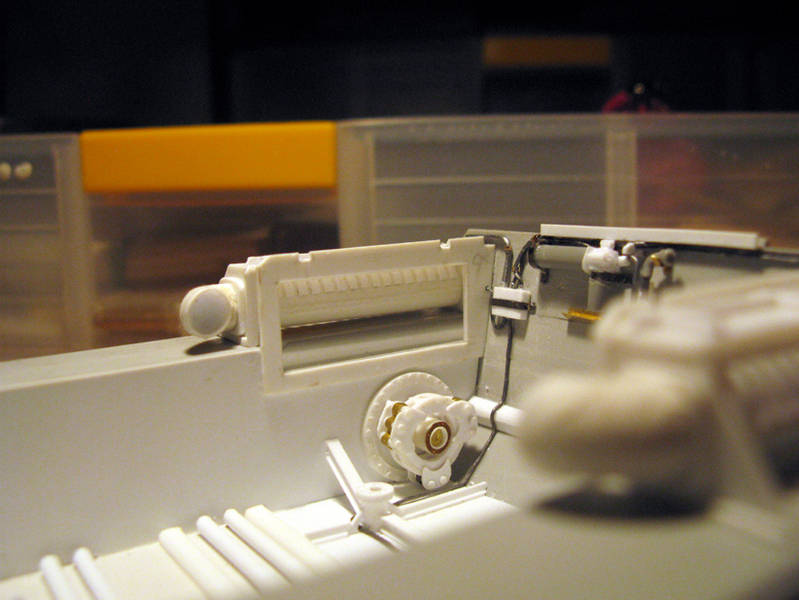

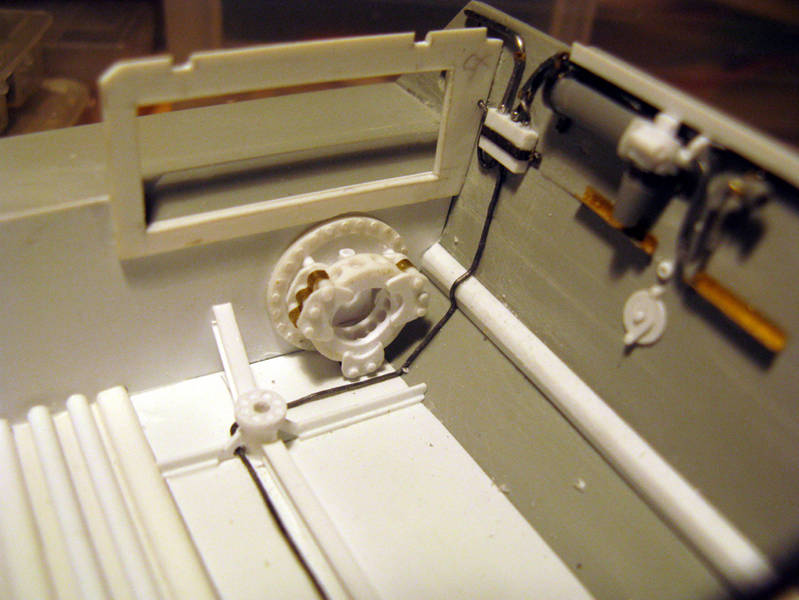

(Because the interior of the model is completely devoid of internal, I had to do a lot of tests to make correctly the dry spark bulkhead, which separates the engine compartment from the fighting compartment.

I then realized the box for relays and electrical contacts, based on the images at my disposal.)

(Meanwhile, also began to realize the inside of the engine compartment by mounting on its bottom, made with a thin sheet of plasticard, torsion bars, the supports of the engine, the drain valve and other details.

The thin wire, which is seen through the relay box, is the sensor of the fire protection system which surrounds the entire engine compartment and which controls the use, either automatically or by manual control, the fire system.)

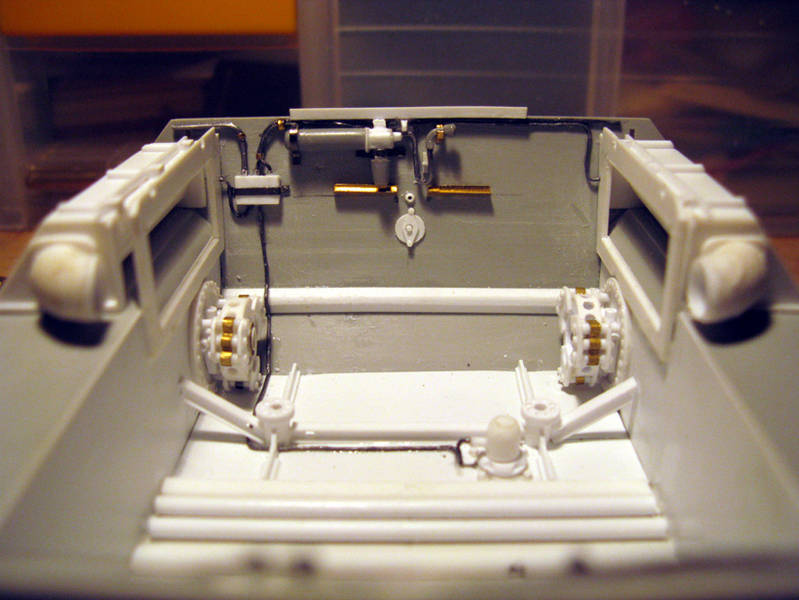

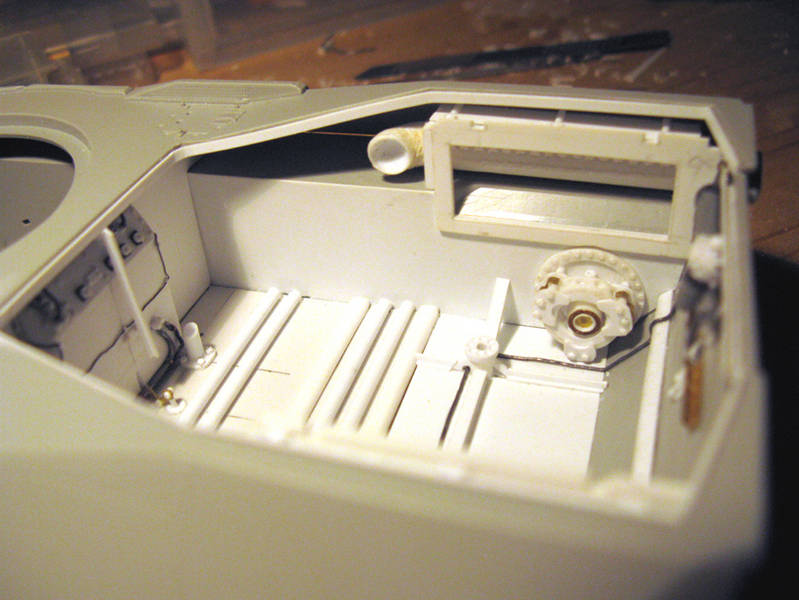

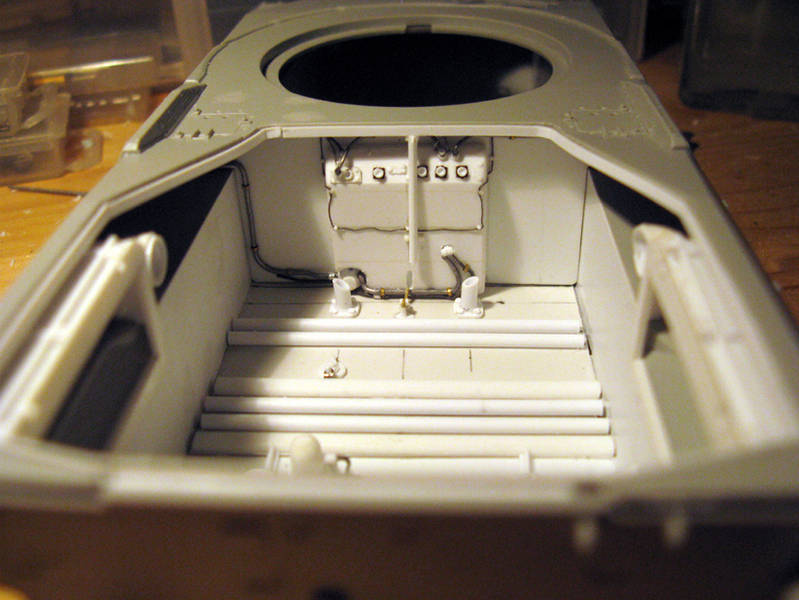

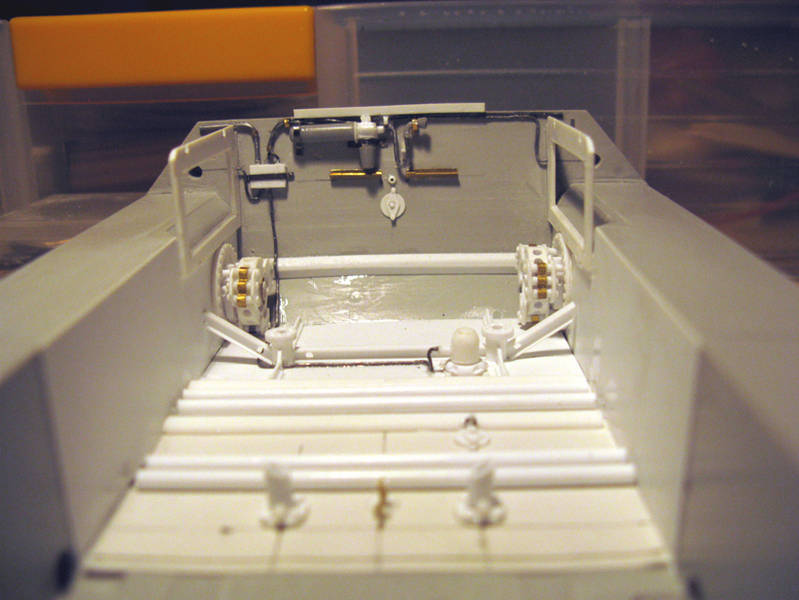

(I began to realize the frame bounding the compartments of the discharge and the final reduction groups with their controls and the brake calipers of the parking brakes.

I began to achieve even the rear supports of the engine, the bars of stiffening the hull bottom and the details that are fixed to the rear compartment bulkhead.)

(This image shows the rear compartment bulkhead on which I set to the left, the junction box for electrical controls, the pump for the brakes with his commands and pipes, inspection hatch at the center of the PTO of the engine.)

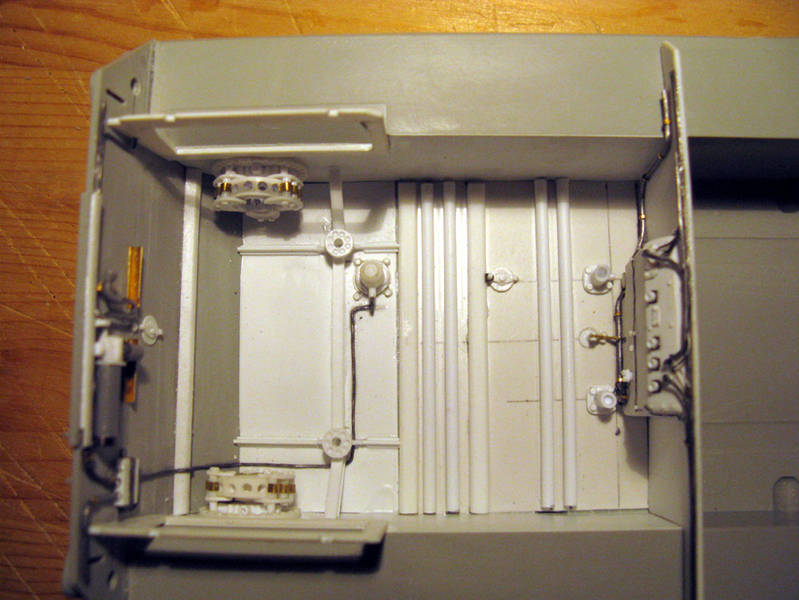

(Top view of the engine compartment, which allows to see the arrangement of all the details so far realized.)

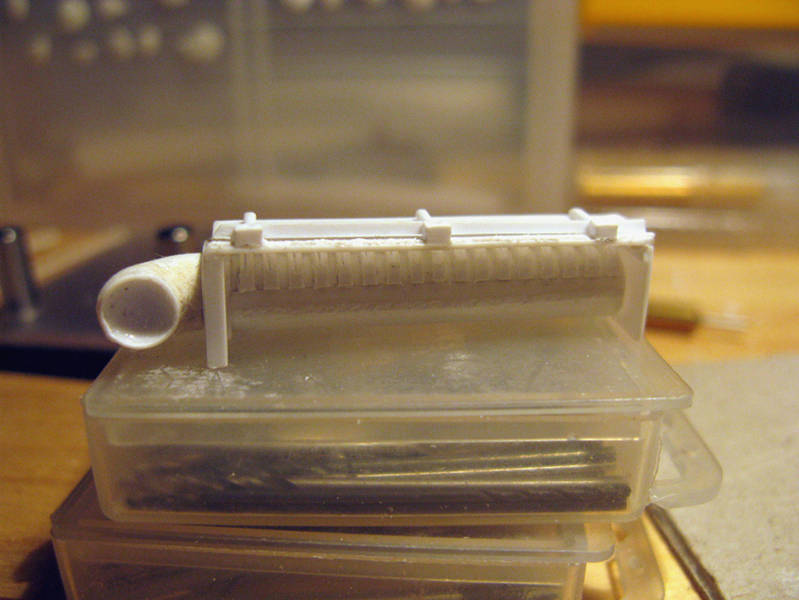

(This is the reproduction of the exhaust muffler, inserted into its compartment which separates it from the engine compartment and which prevents the fumes to enter into, and its collector which connects it to the engine.

To achieve these details, I took a round of plasticard and I dug it with a mini-drill to thin the board, on which I glued a thin section of plasticard to play the clutch to the engine exhaust collector.

I then coated the exhaust pipe with a piece of paper taken from a towel, to simulate the fireproof fabric.)

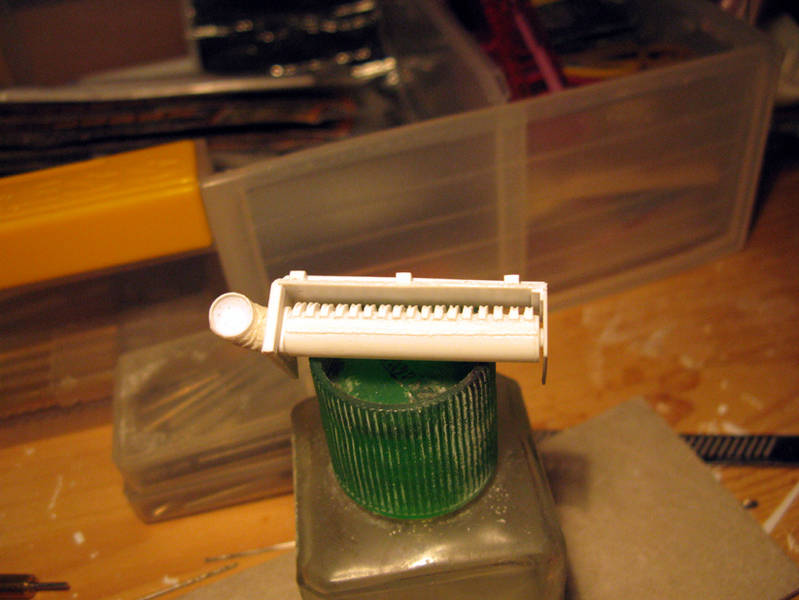

(I then realized the welding which joins the two parts of the muffler, pasting a thin strip of plasticard.

After, I've wet it with liquid glue Tamyia "Green Cap" and then I engraved with the blade of a knife.

I have also made the slots for the exit of the exhaust gases with thin strips of plasticard which I then etched with a circular blade mounted on the mini-drill.)