The quality of Shapeways prints seems to be a big problem. Does anyone know of a similar 3D printing service which could be employed to print Peter's designs?

Mario

Hosted by Darren Baker

3D printed kits SPM. Modern/futuristic armor.

Maki

Joined: February 13, 2002

KitMaker: 5,579 posts

Armorama: 2,988 posts

Posted: Thursday, December 03, 2015 - 10:50 PM UTC

matt

Joined: February 28, 2002

KitMaker: 5,957 posts

Armorama: 2,956 posts

Posted: Thursday, December 03, 2015 - 10:52 PM UTC

Believe me guys, I wish we could control the quality of the prints.

I've had a few issues as well with the stuff I'm doing as well. Some day the more detailed printers will be more affordable for the masses!!!

IIRC the printer that does the FUD and FXD is north of $500,000... A bit out of the hobby budget!

I'd be interested in an alternate place as well.

I've had a few issues as well with the stuff I'm doing as well. Some day the more detailed printers will be more affordable for the masses!!!

IIRC the printer that does the FUD and FXD is north of $500,000... A bit out of the hobby budget!

I'd be interested in an alternate place as well.

young_sven

Joined: May 14, 2010

KitMaker: 749 posts

Armorama: 743 posts

Posted: Friday, December 04, 2015 - 12:29 AM UTC

Quoted Text

The quality of Shapeways prints seems to be a big problem. Does anyone know of a similar 3D printing service which could be employed to print Peter's designs?

Mario

Hi Mario,

Click2detail is another option, I purchased some parts from them for another project.

However, I think that the high level of detail we all expect might still be somewhat beyond the capabilities of the equipment (I have seen what extremely high-end 3D printers can do, and that grainy surface always seems to be there, more or less), and for now its up to the modeller to clean up the surfaces as best he/she can. Not easy on parts with a lot of intricate detail.

Maki

Joined: February 13, 2002

KitMaker: 5,579 posts

Armorama: 2,988 posts

Posted: Friday, December 04, 2015 - 01:25 AM UTC

Quoted Text

However, I think that the high level of detail we all expect might still be somewhat beyond the capabilities of the equipment (I have seen what extremely high-end 3D printers can do, and that grainy surface always seems to be there, more or less), and for now its up to the modeller to clean up the surfaces as best he/she can. Not easy on parts with a lot of intricate detail.

I've seen images of Reedoak figures and those look way better than anything Shapeways is able to produce. The surface seems almost devoid of printing lines... will have to see the figures in the flesh to offer better comments though.

Mario

samofptr

Joined: April 27, 2015

KitMaker: 130 posts

Armorama: 130 posts

Posted: Friday, December 04, 2015 - 01:55 AM UTC

Sven, I am sorry that the Shapeways print quality was disappoint you. Could you show photos of models? As I understand it, your order is realized by the Shapeways NL Eindhoven the Netherlands. There are a lot of claims to SW NL, much more then SW NY. I recommend to write a claim for quality of printing. Typically, the SW replaces a product or makes refund the money. The address for claims: [email protected]

The Shapeways declare a description of the materials: "With 29 micron layers, Frosted Ultra Detail offers very high detail and is ideal for miniatures and figurines which will be finished and painted. With 16 micron layers, Frosted Extreme Detail offers the highest detail of any of the materials we offer and can be used for the most detailed miniatures, and models like molds and mold masters where very smooth surface finish is critical."

If the item does not match to the description, this means that the goods are of poor quality and must be replaced.

I have a lot of unpublished models for printing, and a lot of projects in development. But I'm in no hurry to publish these projects because of poor print quality of the Shapeways. Unfortunately, at this moment the SW only one who provides a service of author's shop, printing and selling of orders to customers. If I find an alternative option for the production of my 3D models, I'll say "Goodbye" to SW

There is another option. Under pressure of large number of claims from buyers, the Shapeways will have to provide good quality of printing. If customers are dissatisfied with the quality of the product and want to replace the product or return the money, it causes financial losses for the Shapeways. If such claims are many, there are two ways - termination of service or improving the quality of products. Do not hesitate to state a claim if the quality of the goods does not match the description on the SW website. The address for complaints [email protected] . Also good idea do such a claim on the Shapeways page on Facebook.

I have repeatedly offered to SW to buy a different printer. Such as EnvisionTEC or similar. The thickness of the print layer 0,025-0,03mm. This printer makes a very good surface smoothness. This will provide a high-quality surface of models and printing in gray plastic material. They have equipment worth millions of dollars, really the printer cost in $20-30 thousand is expensive purchase?

They answered like this: "...The ET printers are on our radar and we appreciate your input on this. ... we had a wonderful conversation about it."

I think if a lot of customers will be sent a letters to SW with a wish to provide print service on EnvisionTEC printer or the similar (gray plastic, thickness of the print layer 0,025-0,03mm), it will strongly affect the decision of the Shapeways.

The Shapeways declare a description of the materials: "With 29 micron layers, Frosted Ultra Detail offers very high detail and is ideal for miniatures and figurines which will be finished and painted. With 16 micron layers, Frosted Extreme Detail offers the highest detail of any of the materials we offer and can be used for the most detailed miniatures, and models like molds and mold masters where very smooth surface finish is critical."

If the item does not match to the description, this means that the goods are of poor quality and must be replaced.

I have a lot of unpublished models for printing, and a lot of projects in development. But I'm in no hurry to publish these projects because of poor print quality of the Shapeways. Unfortunately, at this moment the SW only one who provides a service of author's shop, printing and selling of orders to customers. If I find an alternative option for the production of my 3D models, I'll say "Goodbye" to SW

There is another option. Under pressure of large number of claims from buyers, the Shapeways will have to provide good quality of printing. If customers are dissatisfied with the quality of the product and want to replace the product or return the money, it causes financial losses for the Shapeways. If such claims are many, there are two ways - termination of service or improving the quality of products. Do not hesitate to state a claim if the quality of the goods does not match the description on the SW website. The address for complaints [email protected] . Also good idea do such a claim on the Shapeways page on Facebook.

I have repeatedly offered to SW to buy a different printer. Such as EnvisionTEC or similar. The thickness of the print layer 0,025-0,03mm. This printer makes a very good surface smoothness. This will provide a high-quality surface of models and printing in gray plastic material. They have equipment worth millions of dollars, really the printer cost in $20-30 thousand is expensive purchase?

They answered like this: "...The ET printers are on our radar and we appreciate your input on this. ... we had a wonderful conversation about it."

I think if a lot of customers will be sent a letters to SW with a wish to provide print service on EnvisionTEC printer or the similar (gray plastic, thickness of the print layer 0,025-0,03mm), it will strongly affect the decision of the Shapeways.

young_sven

Joined: May 14, 2010

KitMaker: 749 posts

Armorama: 743 posts

Posted: Friday, December 04, 2015 - 02:41 AM UTC

Hi Peter,

Many thanks for your response to my post. I will be happy to send you pics of the parts I received, I will take some this weekend.

It is a great shame that the quality of the printing does not do your incredible work the justice it deserves.

Thanks also for the advise, I will contact SW and see what they can do to fix this.

Thanks again!

Sven

Many thanks for your response to my post. I will be happy to send you pics of the parts I received, I will take some this weekend.

It is a great shame that the quality of the printing does not do your incredible work the justice it deserves.

Thanks also for the advise, I will contact SW and see what they can do to fix this.

Thanks again!

Sven

Posted: Friday, December 04, 2015 - 04:23 PM UTC

Hello.

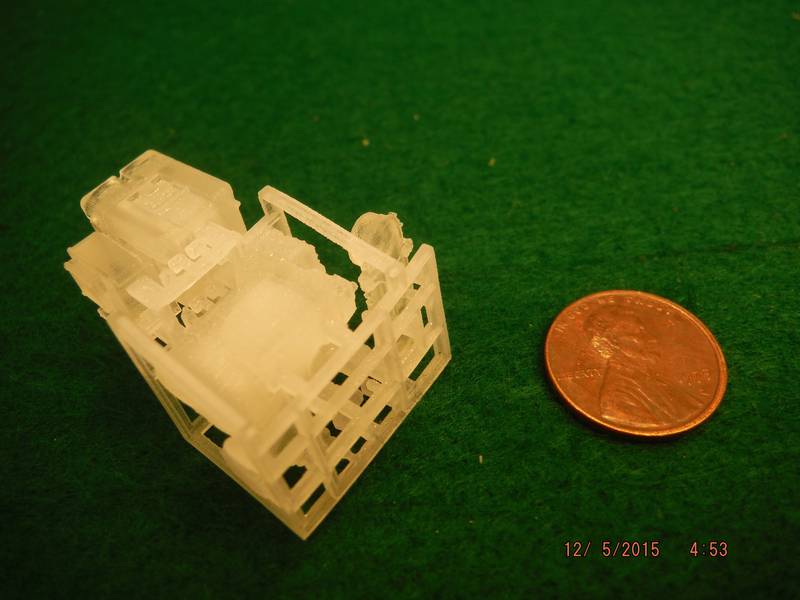

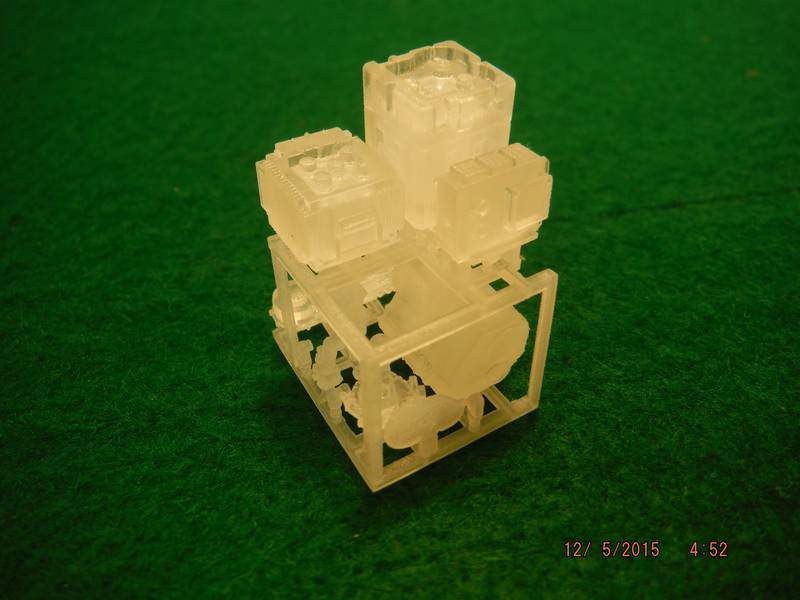

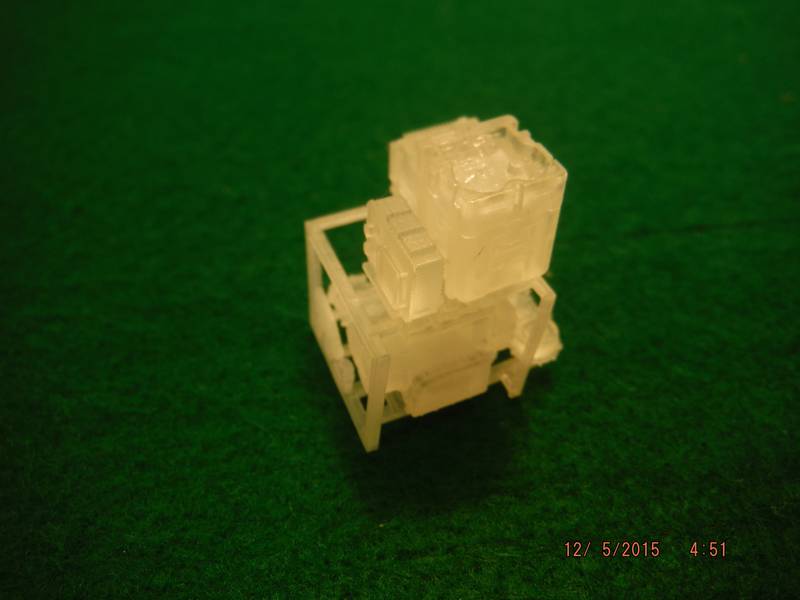

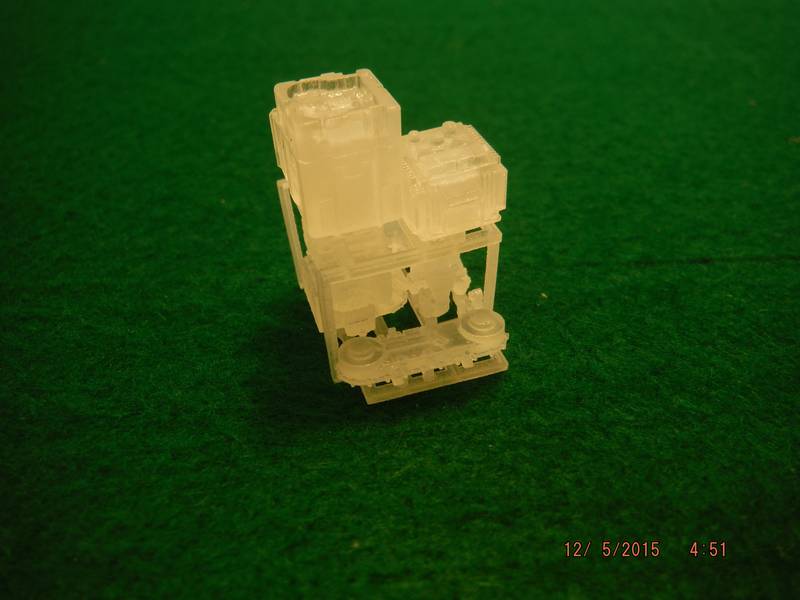

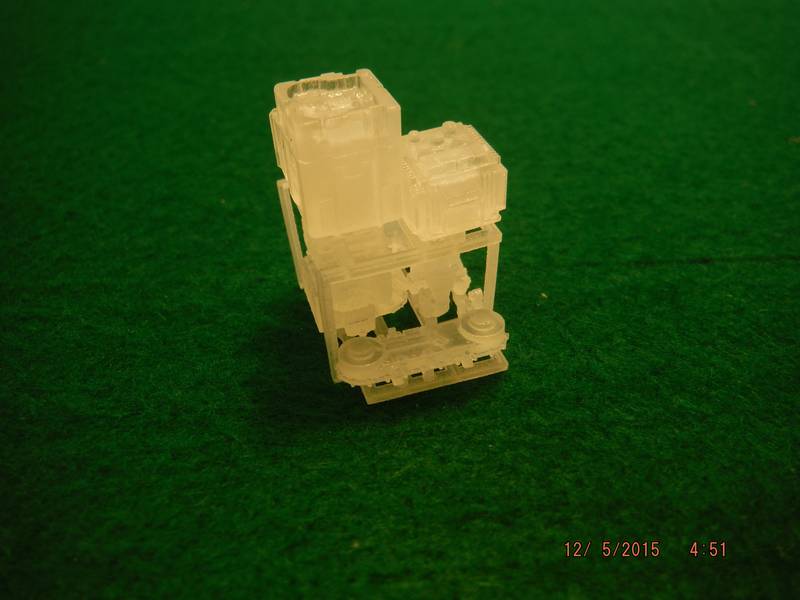

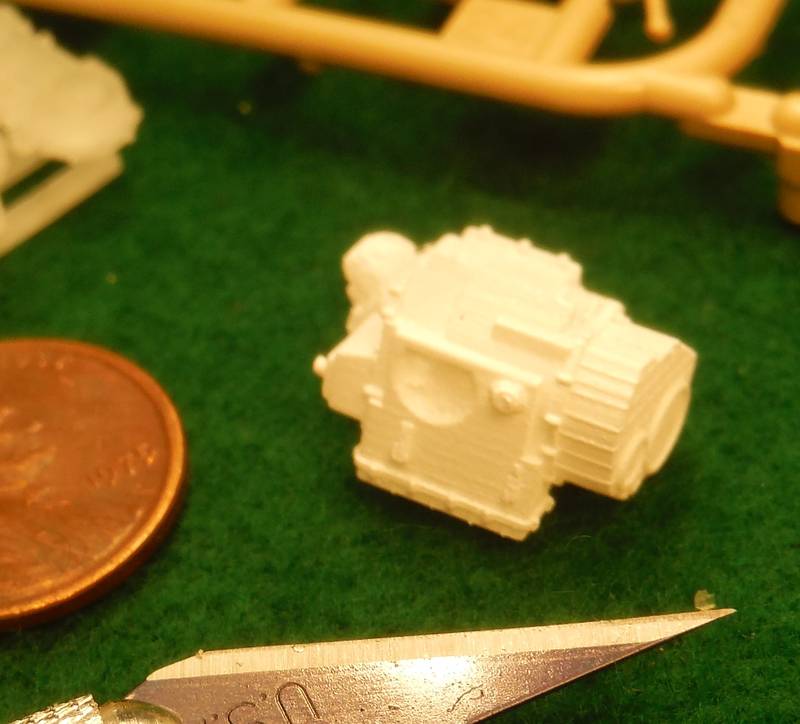

Just wanted to add another data point. I agree Norbert's equipment does seems to provide better 3D printing quality than SW's. Still, IMHO a bird in the hand is worth two in the bush. These photos are intended mostly to say thank you to Peter for his excellent work and effort on the TOW ITAS parts. Please see the photos of his recent offering printed in the best available from Shapeways USA. I have had this TOW ITAS for a week and finally tried to get some photos. Thank you Peter.

Raw form out of the box...

Just wanted to add another data point. I agree Norbert's equipment does seems to provide better 3D printing quality than SW's. Still, IMHO a bird in the hand is worth two in the bush. These photos are intended mostly to say thank you to Peter for his excellent work and effort on the TOW ITAS parts. Please see the photos of his recent offering printed in the best available from Shapeways USA. I have had this TOW ITAS for a week and finally tried to get some photos. Thank you Peter.

Raw form out of the box...

Posted: Friday, December 04, 2015 - 04:27 PM UTC

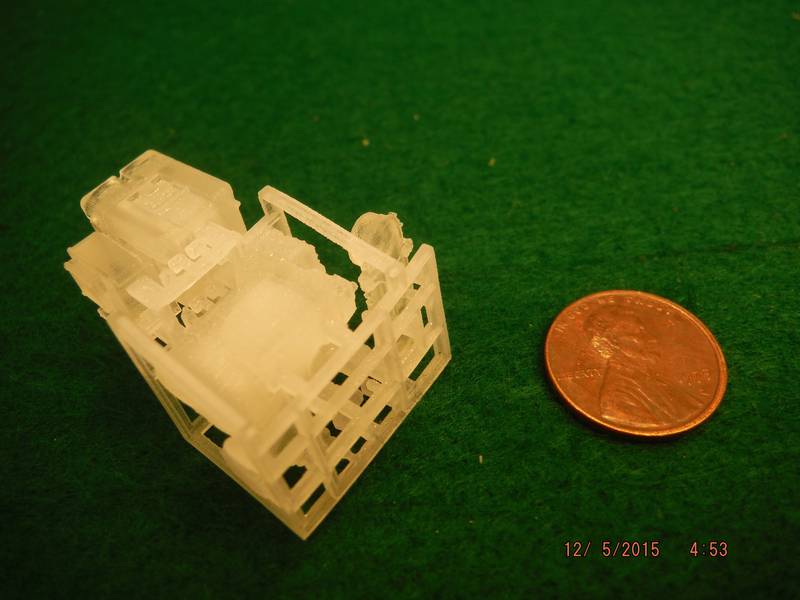

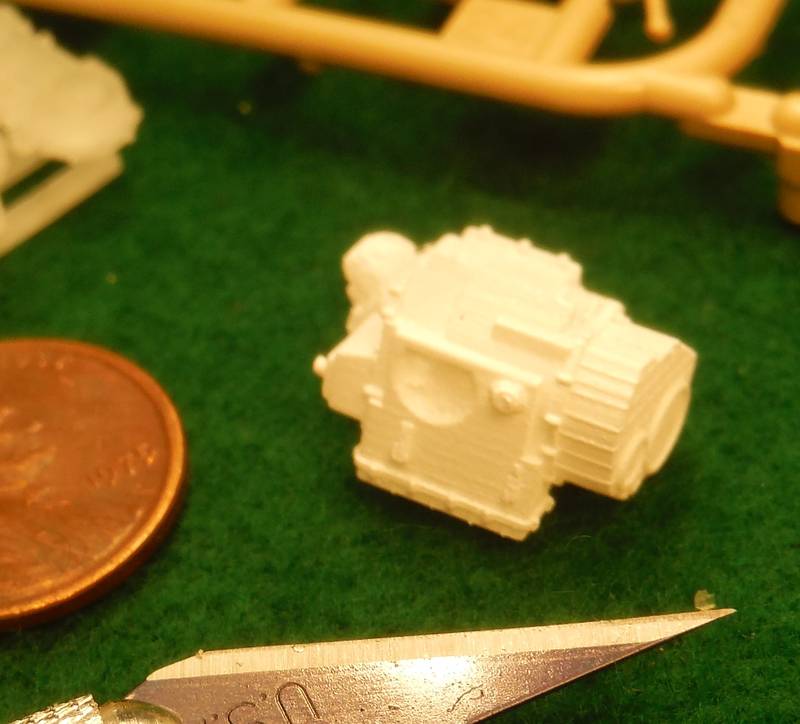

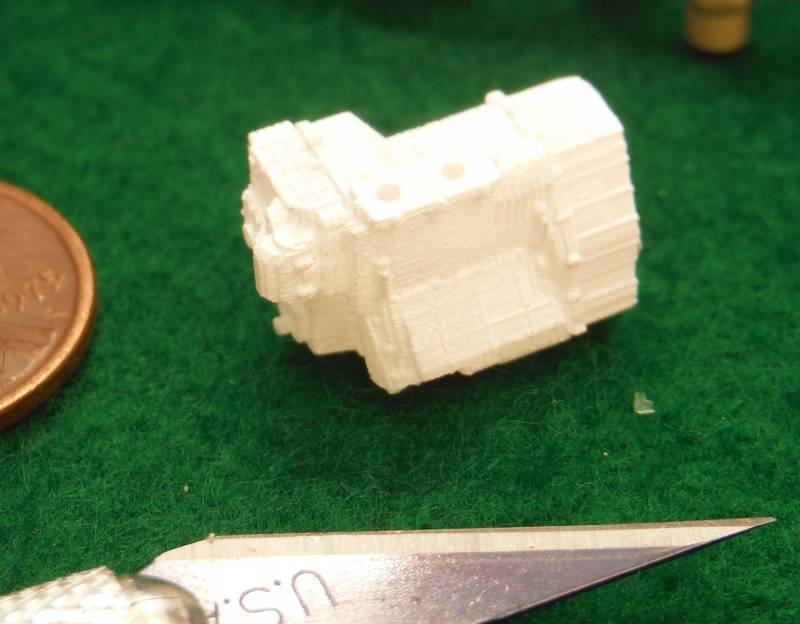

The TOW ITAS separates as here...

Posted: Friday, December 04, 2015 - 04:32 PM UTC

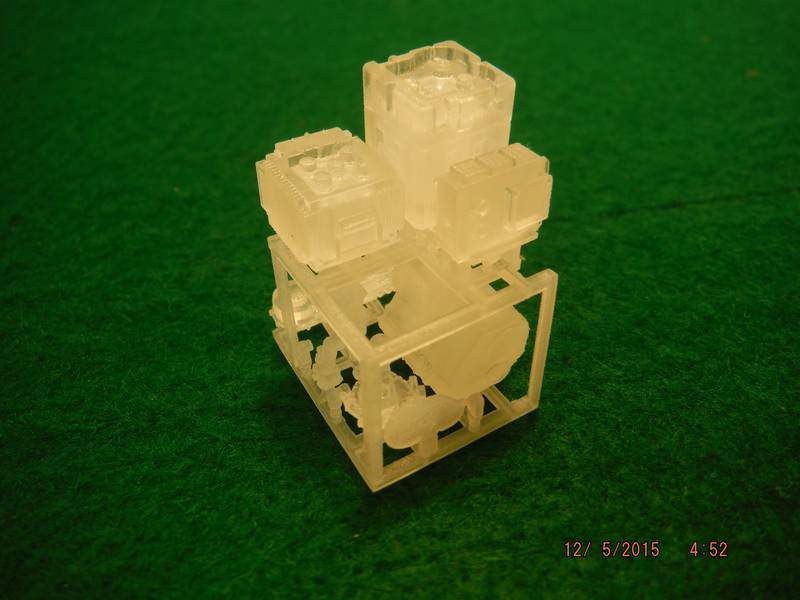

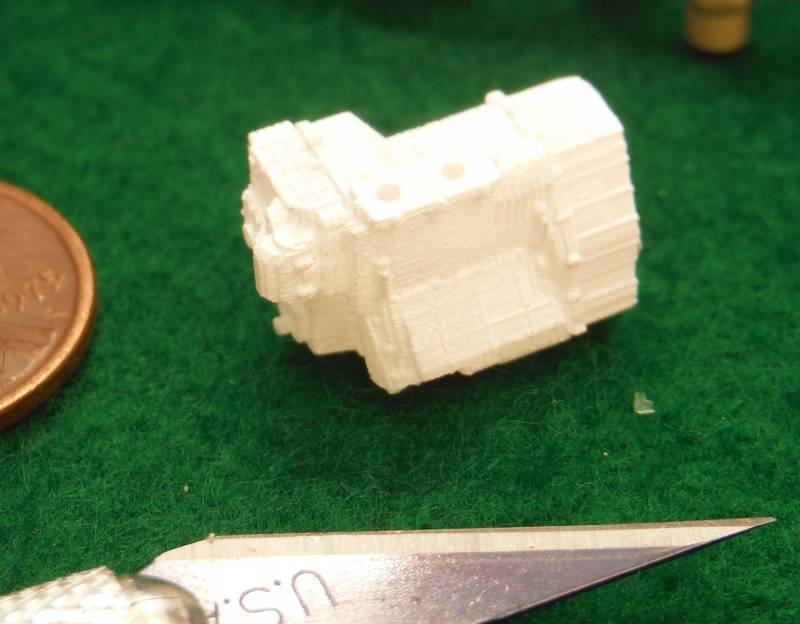

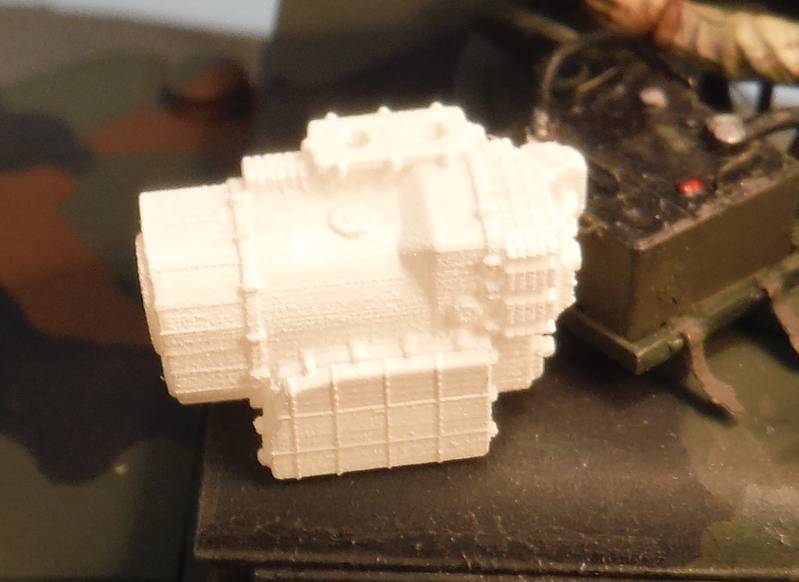

These show Peter's TOW ITAS parts compared with the TAMIYA M1046 TOW Humvee kit parts...

Posted: Friday, December 04, 2015 - 04:57 PM UTC

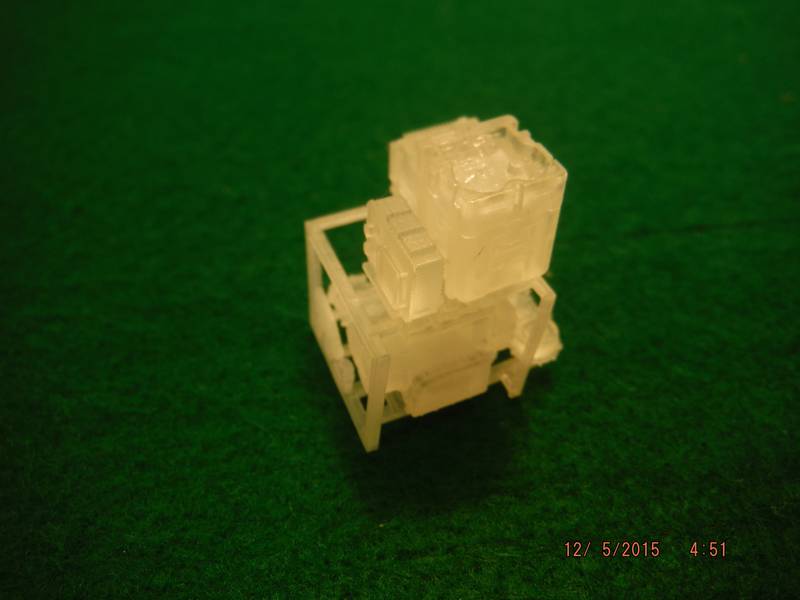

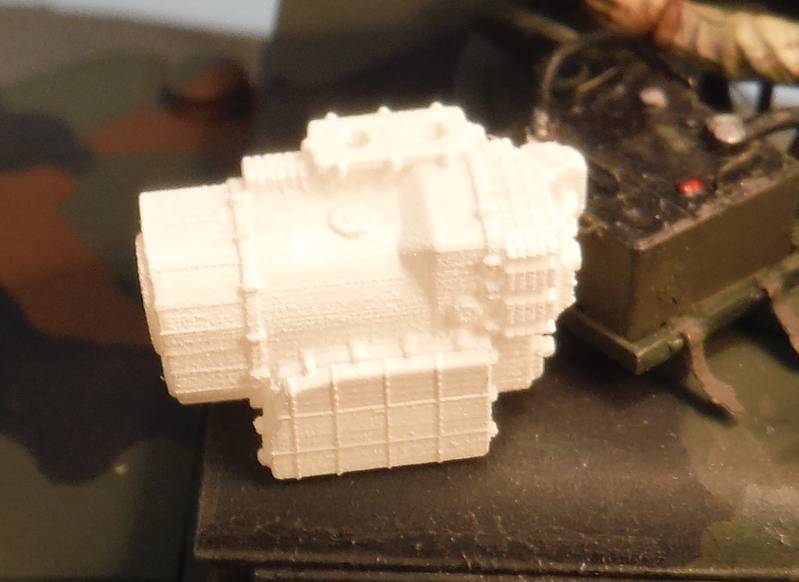

These photos show Peter's ITAS TOW sight after a wash, alcohol rinse, and a light spray from the Tamiya Fine Surface Primer rattle can only. No other sanding or prep was done in order to show the surface quality from Shapeways with their best printing option offered.

To model this!

Hope this helps show the parts. Thank you again Peter for your great efforts!

To model this!

Hope this helps show the parts. Thank you again Peter for your great efforts!

young_sven

Joined: May 14, 2010

KitMaker: 749 posts

Armorama: 743 posts

Posted: Friday, December 04, 2015 - 06:24 PM UTC

Hi Gillespie,

I hope my post is not interpreted as a criticism towards Peters work, he does indeed deserve a big thank you for his superb work. My post was just a reflection of disappointment about the print quality on my parts, despite me ordering at "highest print quality".

However, even though your parts look far better than the ones I received, you can still see the roughness on the surface in your pics. This is not easily removed on for example an instrument cluster on a dashboard, or in other areas of fine detail.

I will try to rub them down with steel wool so I don't destroy any detail, but I am sceptical this will help. Hopefully I will be proved wrong.

A bird in the hand is indeed better, but not if it is unusable.

I hope my post is not interpreted as a criticism towards Peters work, he does indeed deserve a big thank you for his superb work. My post was just a reflection of disappointment about the print quality on my parts, despite me ordering at "highest print quality".

However, even though your parts look far better than the ones I received, you can still see the roughness on the surface in your pics. This is not easily removed on for example an instrument cluster on a dashboard, or in other areas of fine detail.

I will try to rub them down with steel wool so I don't destroy any detail, but I am sceptical this will help. Hopefully I will be proved wrong.

A bird in the hand is indeed better, but not if it is unusable.

Posted: Friday, December 04, 2015 - 08:27 PM UTC

Hi Sven. Yes understood and I agree that even this sight stepping will need work. Yes the surface issues are not due to Peter's work, only created by the existing Shapeways process. I am please interested to learn how the steel wool would work? My glass fiber pen does not seem to remove this material very quickly as it is hard (and brittle) compared to typical injection molding plastic or resin. Looking forward to any photos you could share. All the best! - Stuart

pstansell

Joined: November 10, 2005

KitMaker: 167 posts

Armorama: 163 posts

Posted: Monday, December 07, 2015 - 01:35 AM UTC

These are 1/35th scale slotted .30 caliber barrels designed by my pal Fish and printed by http://www.click2detail.com/

The material is very smooth, almost like glass. The very minor striations seen are on the inside of the part.

They were printed on the Objet30Pro 3D printer with either the VeroClear material, or the Viper SLA with SL Clear resin. I will check and confirm.

Pat

MMiR

The material is very smooth, almost like glass. The very minor striations seen are on the inside of the part.

They were printed on the Objet30Pro 3D printer with either the VeroClear material, or the Viper SLA with SL Clear resin. I will check and confirm.

Pat

MMiR

HDSC2D

Joined: March 12, 2013

KitMaker: 170 posts

Armorama: 141 posts

Posted: Monday, December 07, 2015 - 02:03 AM UTC

Quoted Text

These are 1/35th scale slotted .30 caliber barrels designed by my pal Fish and printed by http://www.click2detail.com/

The material is very smooth, almost like glass. The very minor striations seen are on the inside of the part.

They were printed on the Objet30Pro 3D printer with either the VeroClear material, or the Viper SLA with SL Clear resin. I will check and confirm.

Pat

MMiR

Actually Pat I used Fine Line Prototyping for that project. They are a little pricy for most hobbyist since they mainly deal in industrial applications but the price per unit goes down the more you order. Click2detail.com is the other option for 3D printing and their company is geared towards the hobbyist. They have pretty good surface detail but like all 3D printing you can get some surface roughness where the print has to "staircase" on angled surfaces. A very light wet sand with 600 grit emery paper takes care of most surface irregularities or a Nik Stick will work in hard to get areas. Mr. Gunze or Tamiya primer is recommended as well.

Hisham

Joined: July 23, 2004

KitMaker: 6,856 posts

Armorama: 6,363 posts

Posted: Monday, December 07, 2015 - 02:29 AM UTC

Just noticed this thread and I remembered the figure I got from Norbert.. when you look at it in real life you can't see any of these striations.. this pic is enlarged a lot.

Hussein Elkaissy, who is a member here, has a 3D printer and I remember he said he uses some liquid to smooth out the surface.. I'm wondering if such a liquid can be used with this kind of material also.

Anyway, I think in the case of this figure.. a coat of primer, and then the paint over it will cover up these striations.

Hisham

Hussein Elkaissy, who is a member here, has a 3D printer and I remember he said he uses some liquid to smooth out the surface.. I'm wondering if such a liquid can be used with this kind of material also.

Anyway, I think in the case of this figure.. a coat of primer, and then the paint over it will cover up these striations.

Hisham

HDSC2D

Joined: March 12, 2013

KitMaker: 170 posts

Armorama: 141 posts

Posted: Monday, December 07, 2015 - 03:36 AM UTC

That is true. In the clear materal you get a "layered cake" effect which makes it look worse than it actually is.

samofptr

Joined: April 27, 2015

KitMaker: 130 posts

Armorama: 130 posts

Posted: Monday, December 07, 2015 - 11:03 PM UTC

Stuart, Sven, thank you friends for your kind words about my 3D projects! Unfortunately, the quality of the printing of Shapeways is really very low. It's a disappointment to spend the time to make good 3D set and not to find opportunities to print a high-quality model. It's a disappointment to order a set and get a "blank for self-treatment" from Shapeways.

But I saw this ad on the click2detail.com:

Upload & sell your products in the c2d shop

Currently accepting design partners for beta testing

It seems that the Shapeways will soon cease to be a monopoly for service of author's shops. And quality of click2detail.com at a high level, as far as I know. I think closely to study this opportunity for 3D printing.

Michael (HDSC2D), perhaps you have a relationship to the click2detail.com?

But I saw this ad on the click2detail.com:

Upload & sell your products in the c2d shop

Currently accepting design partners for beta testing

It seems that the Shapeways will soon cease to be a monopoly for service of author's shops. And quality of click2detail.com at a high level, as far as I know. I think closely to study this opportunity for 3D printing.

Michael (HDSC2D), perhaps you have a relationship to the click2detail.com?

Ultra_aussie

Joined: May 20, 2014

KitMaker: 197 posts

Armorama: 145 posts

Posted: Sunday, December 13, 2015 - 05:44 PM UTC

Quoted Text

Just noticed this thread and I remembered the figure I got from Norbert.. when you look at it in real life you can't see any of these striations.. this pic is enlarged a lot.

Hussein Elkaissy, who is a member here, has a 3D printer and I remember he said he uses some liquid to smooth out the surface.. I'm wondering if such a liquid can be used with this kind of material also.

Anyway, I think in the case of this figure.. a coat of primer, and then the paint over it will cover up these striations.

Hisham

Reedoak uses a Envisiontec Perfactory 4 printer for their printing. Not sure which specific "4" though.

Ultra_aussie

Joined: May 20, 2014

KitMaker: 197 posts

Armorama: 145 posts

Posted: Sunday, December 13, 2015 - 05:45 PM UTC

Quoted Text

That is true. In the clear materal you get a "layered cake" effect which makes it look worse than it actually is.

I think it is more the printer that shapeways use is the cause of the wood grain..

samofptr

Joined: April 27, 2015

KitMaker: 130 posts

Armorama: 130 posts

Posted: Sunday, December 20, 2015 - 06:45 PM UTC

Does anyone know what with the Click2detail?

I tried to register for upload account. I filled out the form and received a confirmation link, but when go to the link I see the message: ERR_TOO_MANY_REDIRECTS.

In the two last week I sent few letters to the C2D, but no receive any answers.

Maybe they have paused business?

I tried to register for upload account. I filled out the form and received a confirmation link, but when go to the link I see the message: ERR_TOO_MANY_REDIRECTS.

In the two last week I sent few letters to the C2D, but no receive any answers.

Maybe they have paused business?

samofptr

Joined: April 27, 2015

KitMaker: 130 posts

Armorama: 130 posts

Posted: Sunday, January 17, 2016 - 11:47 PM UTC

Published Built Review of 1/16 scale figure of Assault Trooper with M240L Machine Gun and MICO Pack Ammo Can:

https://armorama.kitmaker.net/review/11915

Thank you very much Mario

https://armorama.kitmaker.net/review/11915

Thank you very much Mario

knewton

Joined: June 19, 2013

KitMaker: 1,217 posts

Armorama: 1,092 posts

Posted: Monday, January 18, 2016 - 12:55 AM UTC

Quoted Text

Published Built Review of 1/16 scale figure of Assault Trooper with M240L Machine Gun and MICO Pack Ammo Can:

https://armorama.kitmaker.net/review/11915

Thank you very much Mario

hello Peter,

yes, it's a great figure, and I'm working on my in multi-cam... there are photos somewhere here.

Please do another figure, ANY!

thank you,

kylie

Posted: Monday, January 18, 2016 - 12:57 AM UTC

Well, after some thought I am going to order an assortment of the HMMWV related parts.

norbertJ

Joined: May 29, 2008

KitMaker: 219 posts

Armorama: 166 posts

Posted: Monday, January 18, 2016 - 12:50 PM UTC

Hi Peter

You can do a test by me (Reedoak) as I do also printing service.

Machine is not made for large surfaces, but much more for tiny details as it is originaly dedicated to jewelry and luxury watches parts. I originaly printed by Shapeways but was not happy with the frosted look, and also by the fact that cement did not hold firm on it (I printed there my 1/35 Mi-6 helicopter)

Norbert

You can do a test by me (Reedoak) as I do also printing service.

Machine is not made for large surfaces, but much more for tiny details as it is originaly dedicated to jewelry and luxury watches parts. I originaly printed by Shapeways but was not happy with the frosted look, and also by the fact that cement did not hold firm on it (I printed there my 1/35 Mi-6 helicopter)

Norbert

Posted: Monday, January 18, 2016 - 05:47 PM UTC

Quoted Text

Hi Peter

You can do a test by me (Reedoak) as I do also printing service.

Machine is not made for large surfaces, but much more for tiny details as it is originaly dedicated to jewelry and luxury watches parts. I originaly printed by Shapeways but was not happy with the frosted look, and also by the fact that cement did not hold firm on it (I printed there my 1/35 Mi-6 helicopter)

Norbert

Now these are correct folks to be talking! I am excited thinking about future possibilites. Much success!

|