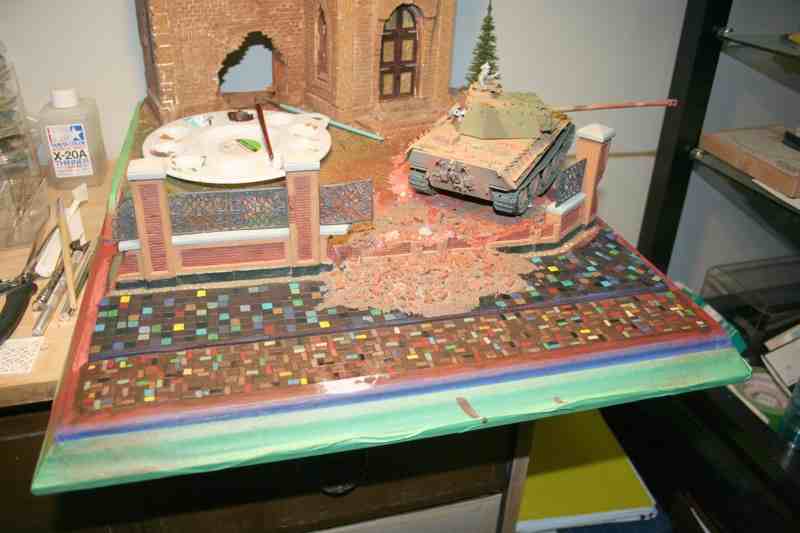

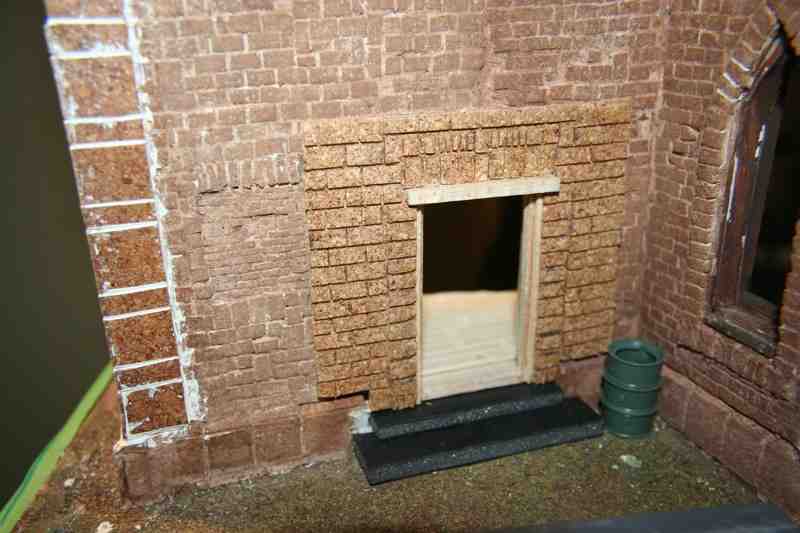

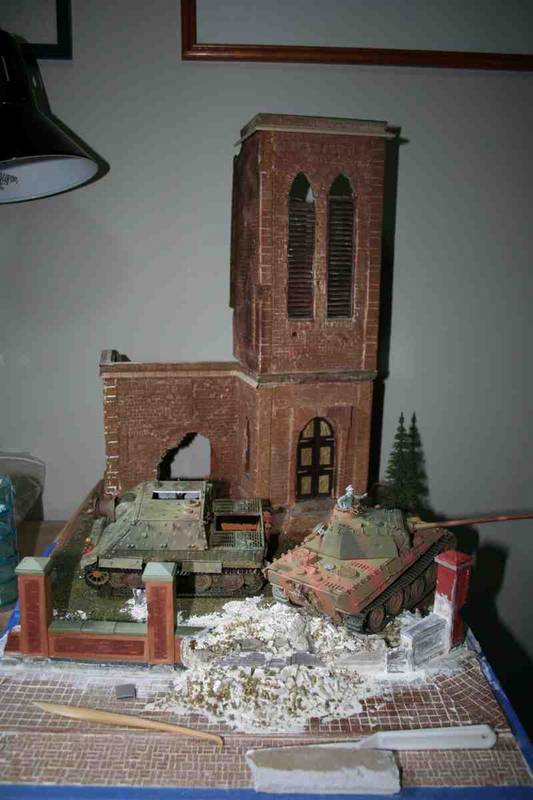

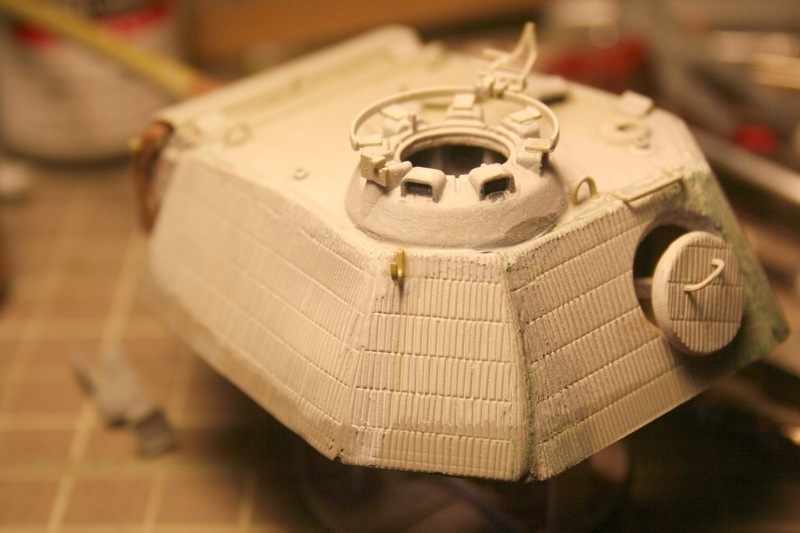

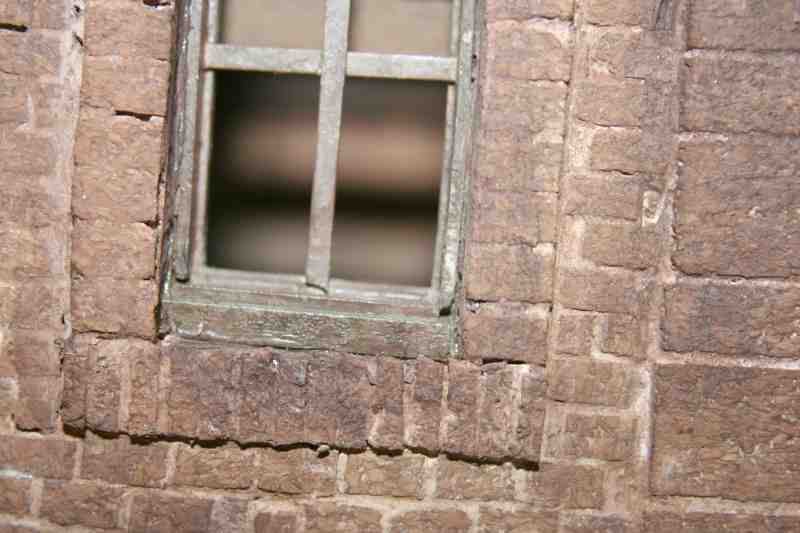

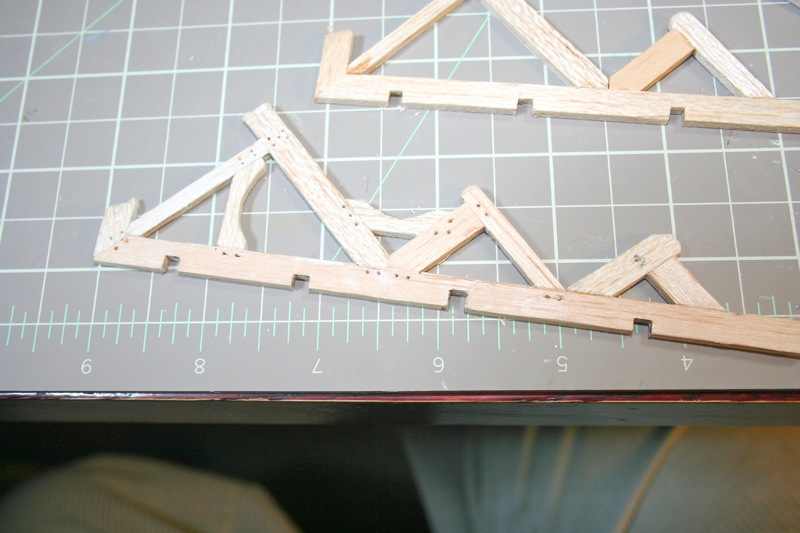

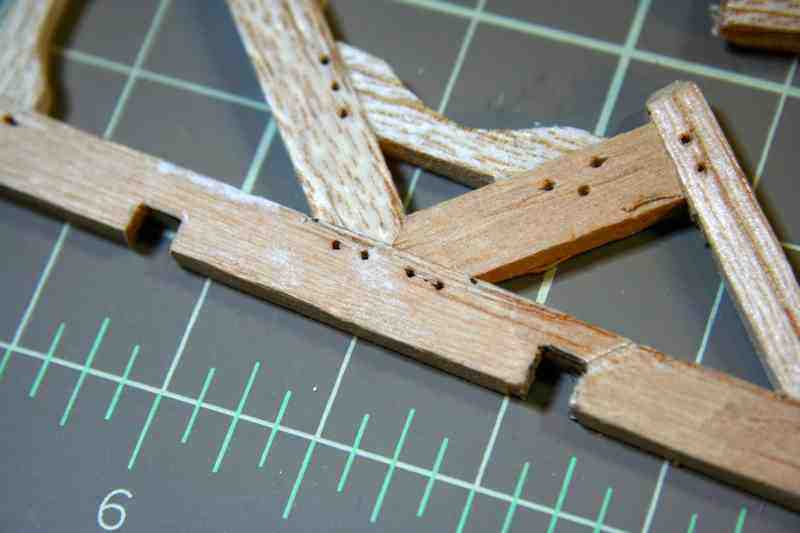

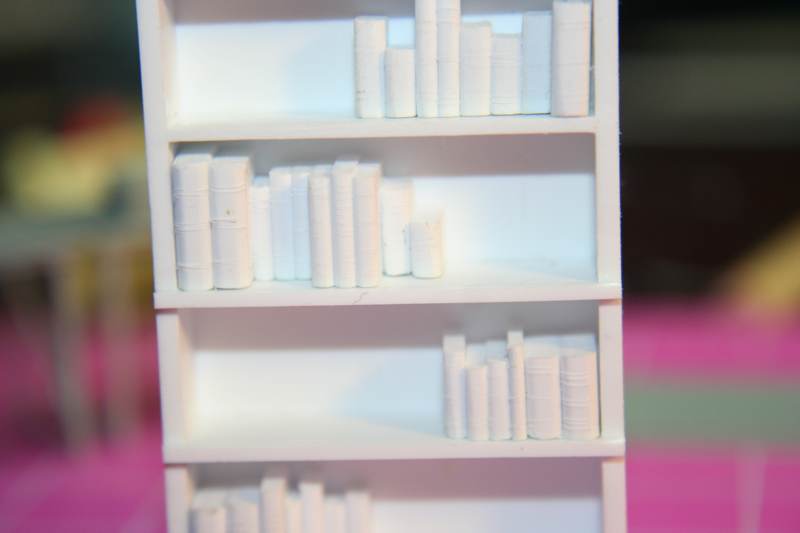

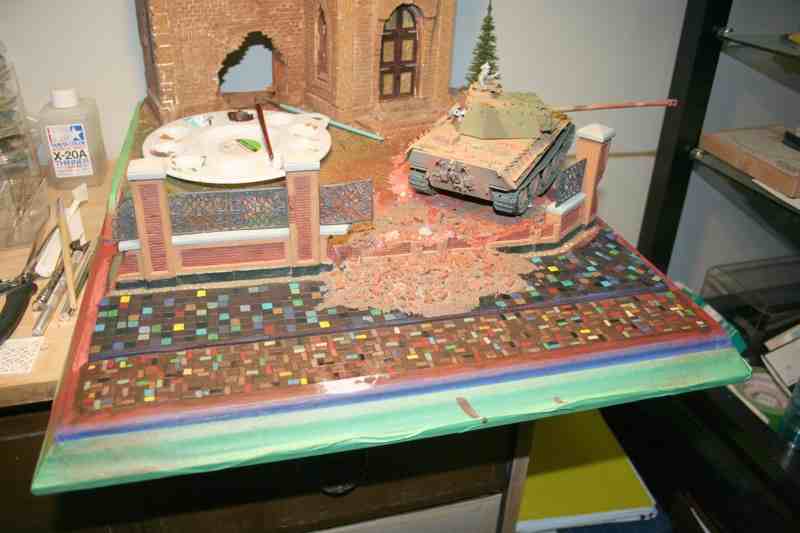

Here are some images of the actual church building in my diorama.

The basic construction is similar to many builds here on the site, and therefore I will only make a few comments about its make up which may explain more about my particular techniques used.

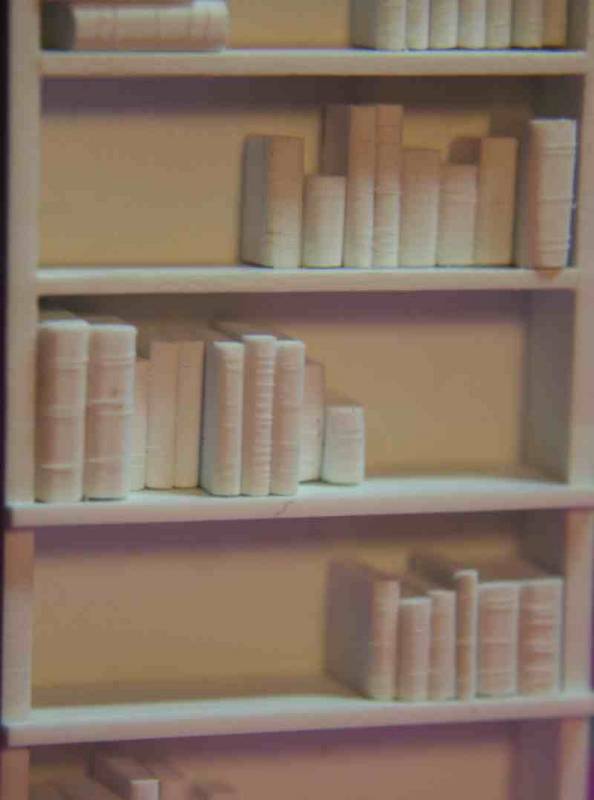

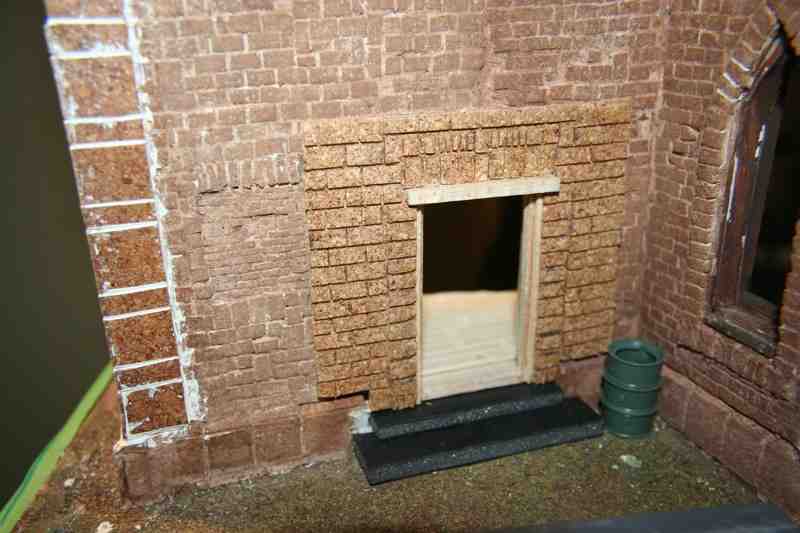

I started with a sheet of ¼ inch Foamcore board. This has been covered with cork, which has been covered with drywall Spackle, in this case a product found here in Alberta known as Dap Dry-dex Spackling. This is a fairly common compound here and is premixed in a reseal able container.

As it is drying like most of you fellow builders I wiped most of it off to leave just a faint mortar line.

The technique I have used to obtain the results you see here is slightly different then the accepted norm found in the posts of many diorama builders here on this site. My favorite Bible college professor used to tell us that a good preacher uses a simple guideline when preparing sermon illustrations and examples to include in their sermons. This guideline was: Steal, steal, and steal. Steal ideas, steal examples, steal patterns etc.

Now to be fair, he always said to steal but give credit where credit is due.

So when it came to my church building I looked at many examples in this forum and learned the basic principles of the illusion process in the scale representation of large-scale buildings.

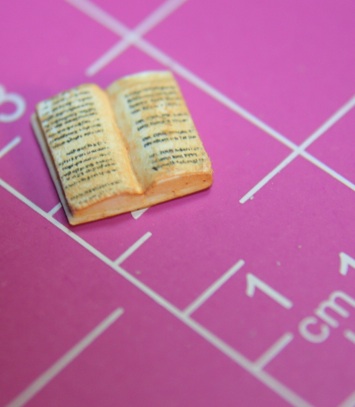

I have and continued to study the work of the master of Clervaux, Claude Joachim, Blochaus, my fellow Albertan Meaty_ hellhound and many others and decided that this is the medium I would use from now on in my dioramas.

Now I do have some real life contracting experience, framing, concrete pouring and such which have always helped me in building dioramas. Having been out of the loop for a while, I was immediately intrigued by this cork process.

Very realistic results, but it appeared to be extremely labor intensive and since I like to work smart & not hard, and being of higher than average intelligence I decided there must be a better, quicker and easier way to do it. Bear with me; I am not as arrogant as I may have just sounded.

So I began my quest for a better way.

Like all good stories this one began with a trip to my favorite hobby supply store, “ The Dollar Store”. There I found not just cork, but sheets of thin cork backed by an adhesive tape. That seemed to me to be the ideal answer to a problem that plagues many a man, and a few women in my condition.

That is slightly ADHD, and rather lazy!

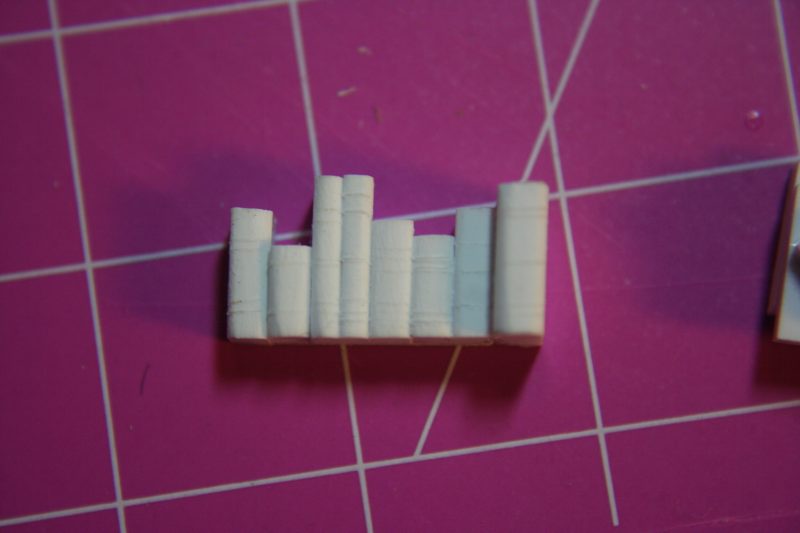

Instead of cutting up huge masses of thick bricks made out of expensive sheets of cork, only to cover them with drywall paste of some sort and thereby hide almost all of the thickness of the cork anyway, I decided to use this adhesive backed cork and cut it into long strips which would totally speed up the work and also cost way less!

Sounds simple doesn’t it?

In the words of Paul Harvey, here is the rest of the story.

My biggest problem wasn’t the thinness of the cork, or cutting it or anything to do with the process. No my problems came from a character flaw found in most of us adult males. I chose to dash headlong into a place where even angels fear to tread, with out taking the proper precautions.

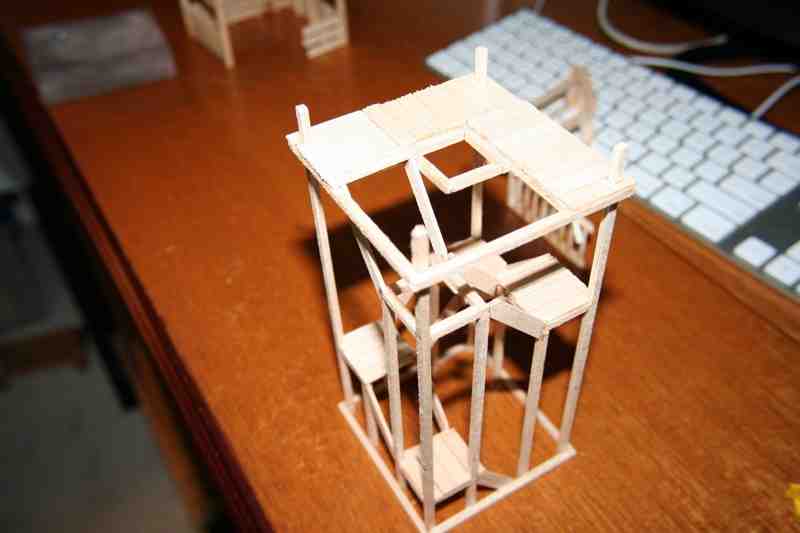

Simply I did not plan my work, and then work my plan. I soon found myself running footloose & fancy-free in the tiny world of cork construction with no blueprint for the church that was quickly taking shape and evolving almost faster then my semi-ADHD mind could dream up new things to try.

Abandoning everything I learned as a builder, and obviously not paying close attention to some of your build logs, I started peeling the backing of my great sheets of cork and covering my Foamcore church, without once taking a pencil to a sheet of graph paper or a ruler and sharpie marker to the foamcore board.

Well it didn’t take long for things to begin to unravel. Maybe I am not the only one to try to cut a doorway or an oddly shaped window out of a piece of ¼ inch foamcore without a solid frame or pattern to guide the edge of the knife?

Or to come to said window frame, after cutting it out only to find you neglected to measure the distance between it and the corner of the building or doorway and now you don’t have the proper spacing for the size of bricks you are using?

I am sure I am not alone here gentleman, but if I am then have a good laugh at my expense and I will continue.

So the basic building is not quite level and not quite square, which since I didn’t do my due diligence at the beginning has bit me in the butt at every stage of the build since. Let that be a lesson to you.

Let us just say I hope I have learned my lesson and the next project will begin with a much higher level of pre-planning and forethought.

The cork itself I think works quite well. I have found it relatively easy to use and because I cut it into lines and place it on the wall this way I can line it up quite well and most of the columns are straight to the naked eye. The problem of course, and one I did not plan well enough this time was of course getting the first course absolutely level. From there you merely have to do what I say and not as I do, & check, check and recheck as your building, wall or street takes shape.

The biggest issues honestly with doing things in this manner are these I think. One is that the building comes out thinner than if a thicker cork brick is used. At this scale it might not be a big thing. I don’t have much experience with old world buildings having never been to Europe, but many of the buildings I see here seem to be quite thick. However I do know from the research I have done that building with brick and especially stone, the building naturally become thicker then the traditional wood framed housing of the nature found here across the pond.

The second issue is that where by using separately cut bricks of thicker stock cork may be indeed time consuming and tedious, using the very cutters that aid in the process allow for exacting copies… every time. This ensures the proper spacing between bricks and that the mortar lines will be consistent both horizontally AND vertically. My method is a little harder to keep the brick size consistent so the vertical mortar lines don’t always line up as methodically as they should.

In the end I don’t know if my slant on the commonly used method of building saved me any time. It did for sure save me some money as the sheets were quite cheap, but at the end of the day I think I will give the traditional way a go on my next build.

Another thing I should mention is that after I had stuck the bricks onto the structure I would usually "paint" them with a watered down mixture of white carpenters glue, and sometimes for the really tiny bricks I would use CA as I found that especially on the edges of certain corners when i tried to spackle them some of the smaller pieces of cork did not have enough adhesive power to stay put. Another lesson learned...