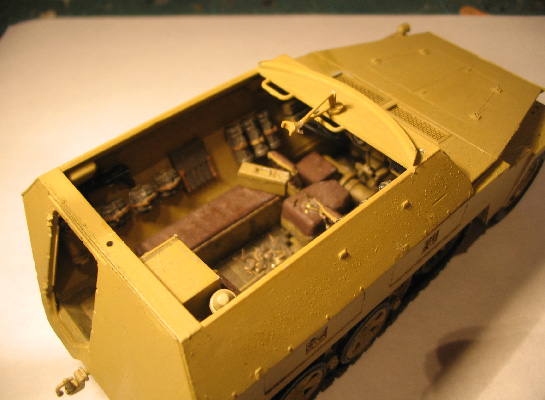

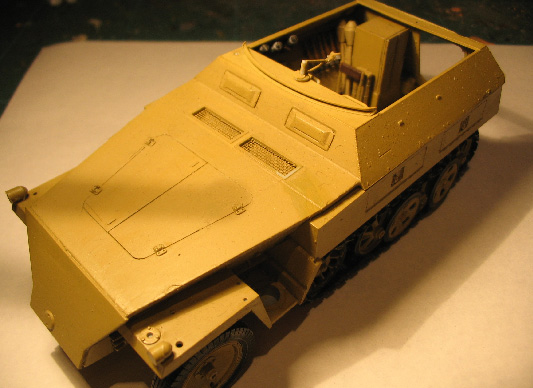

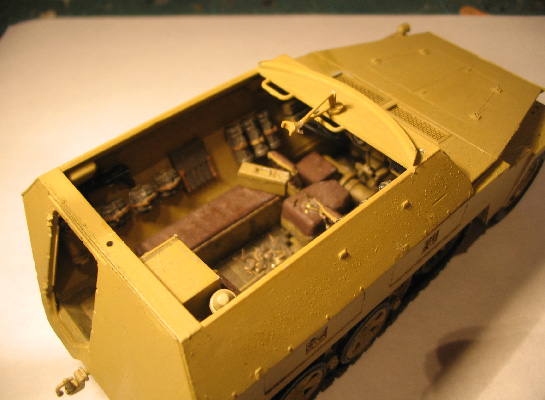

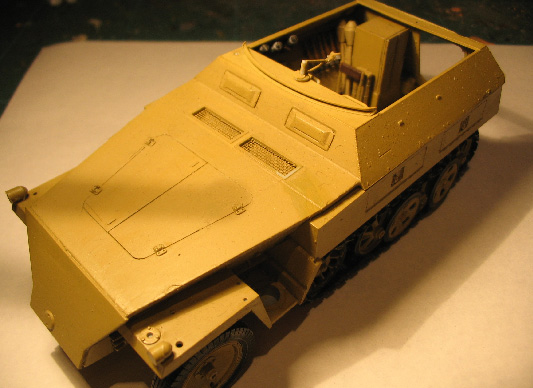

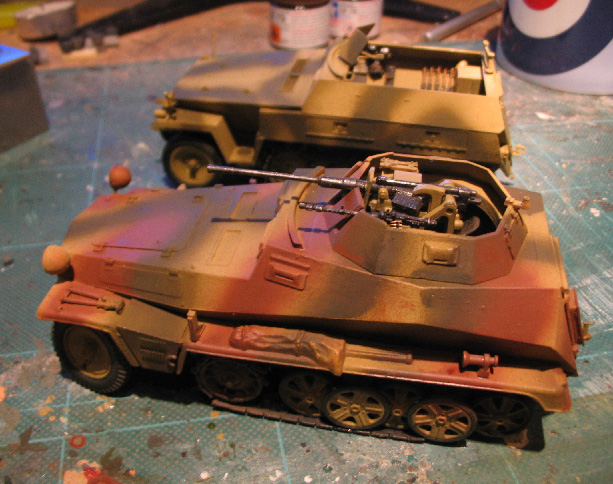

It's actually quite a nice kit but the instructions are crap. I'd never built a DML vehicle before this one and to say that the instructions are confusing and vague would be an understatement. Still onwards and upwards...

Not much accomplished this week. Installed the brass traveler bar at the rudder. Started to prep parts for the rigging. 8 blocks were supplied (3mm), so I started wrapping them with brass wire for loops, but lost 2 and never found them, broke 4 more wrapping the wire. Tried to make a couple but gave up on that. Ordered a couple packs of them from the LHS and got some smaller brass wire. I'll try annealing it before installation, if not, I have some small soft copper strands from wire clipping in the workshop scrap bucket, from 28 ga to 12 ga. Something's got to work. Also, the eyebolts supplied are actually small brass cotter pins. The eye portion is kinda tear-drop shaped which I didn't like the look of, so, I tried to close the eye and round it off by inserting a round plier tip in the eye and squeezing the shank to round out and "smallerize" the hole. Broke one leg off 4 of those, so picked up a pack of them as well. I think I'll wind up making my own eye bolts from an appropriately gauged brass wire.

The new blocks will be in on Tuesday.

EJ

Nice to see something out of the ordinary.

Nice to see something out of the ordinary.

|